-

Posts

3,141 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Good work on the edge bending. It looks like the planks are laying flat on the bulkheads. are you foregoing tapering the planks at the bow for a reason? It’s not so important with the first layer, but will make a big difference with the 2nd layer..

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

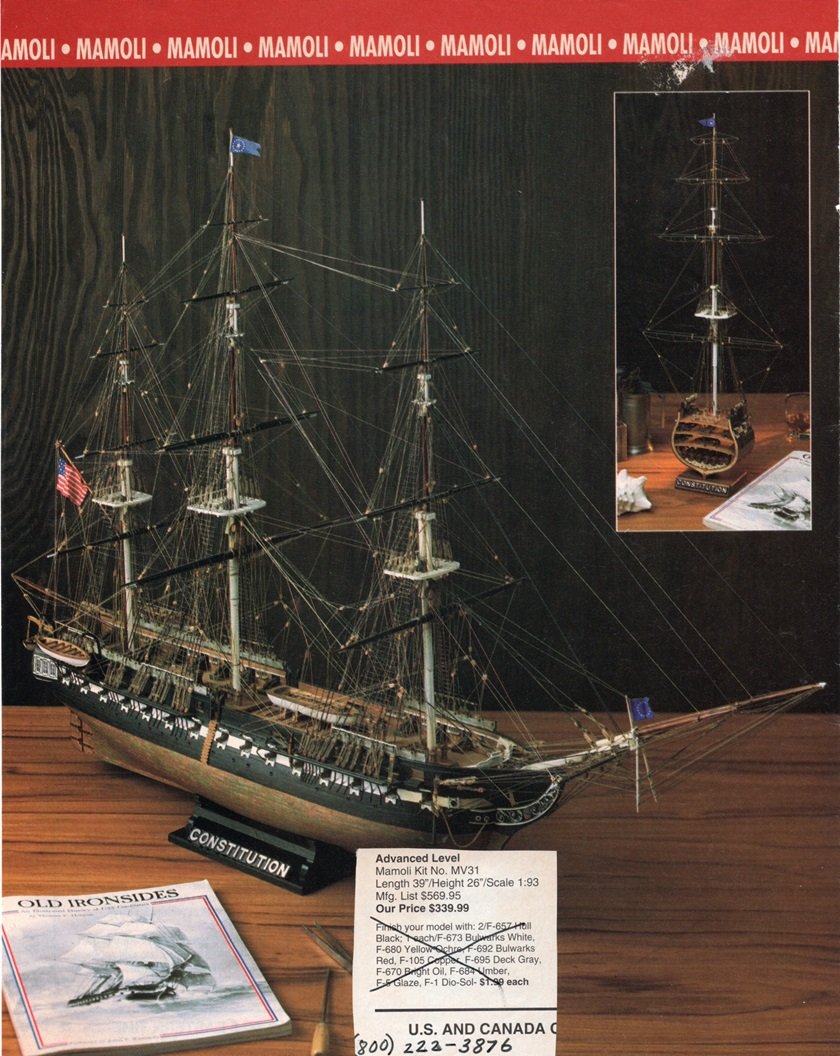

The Mamoli kit had little competition when it was released. Mamoli had a lot of the best kits available at the time . Check some of the drawings for a date. I would like to remember, because I had that kit back in the early 90's, but sold it because life got in the way. I believe the drawings are very good, but the kit itself may have it's detractors these days because kit quality in some areas has come a long way with laser cut parts and such. My recollection is that the Mamoli kits really have everything you need in the box to build it to match the drawings. That has been my experience with a few other Mamoli kits I have built. If I were going to go outside the box, I would consider a different coppering scheme than the little green wood chips they provide, other than that, I would be happy to build it as is. I look forward to following your progress.

-

Unfortunately, that color chart on the box is as good as it gets. There is such a wide variation in wood color, a third party chart will not be any better. If you are trying to identify the wood within the box, the amounts provided my be your best help to match it to the box chart. In this case the lighter wood should definitely be the maple.

-

A lot of builders put a layer of painters tape on stem etc.. It can save a lot of grief..

- 87 replies

-

- Lady Nelson

- Amati

-

(and 1 more)

Tagged with:

-

What’s great about MSW is we have a lot of logs and experienced builders here to help you with these ‘flawed’ kits.

-

Use of “other power tools”

Gregory replied to kgstakes's topic in Modeling tools and Workshop Equipment

I felt that LightBurn doubled the value of my old 40w C02.. I now have a 40w diode, and I can't imagine not having LightBurn.. -

Use of “other power tools”

Gregory replied to kgstakes's topic in Modeling tools and Workshop Equipment

Here are the particulars. Cricut It should work with any operating system that supports BlueTooth or USB. It's not so much the OS as it is connectivity support. I believe the interface is web based. I don't have one, but my wife uses Brother Scan n' Cut which is a similar machine.. -

Use of “other power tools”

Gregory replied to kgstakes's topic in Modeling tools and Workshop Equipment

I'm pretty sure Cricut works with Apple and Windows. It may even have a Phone app. It will have BluTooth/WiFi capability and a USB connection. -

Interestingly, the rigged model of Hawke is not showing any bowlines on the square sail (?). I, personally, would be reluctant to model them in the absence of sails. However, I certainly wouldn't fault you for including them. I think your best guess would be as good as any.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Just looked at my copy, ( Fore and Aft Craft ) and bowlines are not shown. Were you looking at the photos in front of AOTS? One photo shows bowlines going out to the end of the bowsprit, but of course, we can't see where they lead. My best guess would be the pin rack in front of the windlass.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Re the bowlines, I can see what Petersson says later, if you don’t get an answer before then.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

As if we haven't seen/heard enough options here is a drawing DrPr posted from an unnamed source, but appears to be one of the AOTS books. The attaching of the breeching rope appears to be an eye splice with a cow hitch(?) While we are at it, the mystery eyebolt we have discussed in other threads ( dotted line #10 ) says it was for training tackle., which would have been the outhaul repurposed. An option that I believe was presented.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.