-

Posts

153 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by CaptnBirdseye

-

-

Nice Christmas present! What laser cutter did you get?

-

I liked the look of this on Chuck's website too, so will be very interested to see what you make of her. Every confidence in you tho

- mtaylor, FrankWouts, Blue Ensign and 1 other

-

3

3

-

1

1

-

Beautiful design, Chuck, absolutely love the lines and build so far. Do you mind me asking: how skilled do you need to be to attempt a build like this?

- Ryland Craze and mtaylor

-

2

2

-

Have to say Rick, what a glorious first build! Very impressive stuff you have going on here. Your background has obviously stood you in good stead. Makes me very envoius

-

-

This just looks to get better and better! Think Chris has a winner on his hands here 😍

- Dave_E, mtaylor, thibaultron and 4 others

-

7

7

-

Thanks to you all for your replies. Not sure if it’s the ‘easiest’ method, but Chuck’s method would seem the way to go (if I can get the hang of it 😬).

I had wondered if anyone would recommend cutting the pin heads off and recessing them, then fill when sanding with the dust.

Question: can Chucks method be used on bluff bows and steeply raked stern of Victory?

-

Sorry if this has been asked before, but i couldn't find the answer. I have 1:84 Deagostini Victory build, which is almost at the planking stage. Looking forward a little, because this kit is only single planked, what is the best way to acheive a look without seeing the pin holes in the planking? I haven't fully decided on the 'naked' or 'painted' look, but if i go for the former the pinholes will obviously show.

Thanks in advance

Gray

-

Hi J

My advise would be one of the builds from Vanguard, maybe one of the fishing boats like Lady Elenor would be a good primer. The thing you have to bear in mind is that the subject matter has to be of interest to YOU, otherwise you will just lose interest in it. The main benefit of Vanguard is that Chris (owner and designer of Vanguard) is a member of this forum!

The only other piece of advice is start small and take your time. Oh, and enjoy - It's a hobby after all

- JDillon, mtaylor and Ryland Craze

-

3

3

-

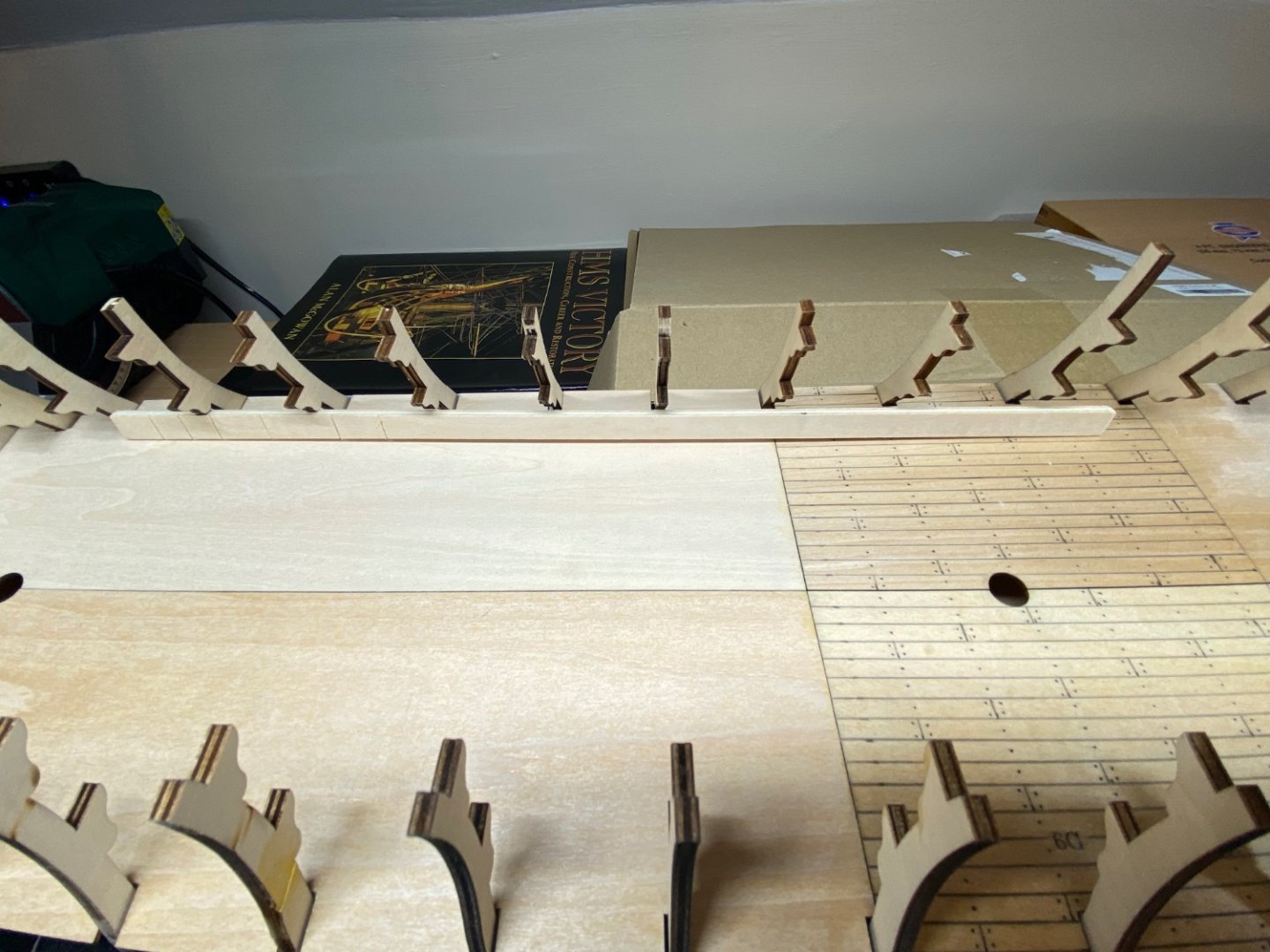

Thank you everyone for your replies and advice. I have been able to get hold of an old Issue 18 (the ones that originally came with a magazine) and the beams in there are wood, not plywood!

This looks to be the way to go, as mentioned above by Mark.

- thibaultron, Canute, mtaylor and 1 other

-

4

4

-

- thibaultron, mtaylor and Canute

-

3

3

-

Hi Jaager,

Unfortunately, not knowing enough about hardwoods and their different properties, i wouldn't know which to use

They would be painted black anyway, but is there a type that is quite pliable (forgive the pun) anyway?

- mtaylor, Canute and thibaultron

-

3

3

-

One of the current kits I am building is the HMS Victory partwork by De Agostini. In Pack 2, Stages 18 and 19 we are issues with 4 plywood strips: 2 of 4mm x 10mm x 300 mm and 2 of 5mm x 15mm x 330mm.

The istructions say that to allow for the curvature of the deck and placement of the ribs, these beams need to be sanded back and then shallow cut. Unfortuately for me one of these shallow cuts went to far and the plywood became too weak to hold shape. Having contacted Modelspace for a replacement, they have told me that there isn't stock in the country to replace, and replacements would have to come from Italy!

Now i don't know if any of you have had any dealings with DA in Italy, but lets put it like this.... my hopes aren't very high of getting these replacements any time soon

So what i'm thinking is why not try to make my own replacements. My question is: what type of staock would be best to make the replacements?

- Canute, thibaultron and mtaylor

-

2

2

-

1

1

-

😲Interesting build! Can't wait to see how this one turns out 👍

-

impressive stuff Robert 👍I really do like your build

-

-

2 hours ago, James H said:

Sort of. The bench pics Chris sends me are usually of 2 or 3 test fits, sometimes with different sequences. I spend a lot of time going through many hundreds of photos and working out what I think is the best order of doing things, especially as the parts I've been sent often differ to the ones in the photos. Those differences are little things like the inner bulwarks changing from 3 parts per side to 4 parts, and other more constructional changes.

Sequence changes and suggested modifications to parts are then looked at, and you then see the results here.

What a brilliant insight into the build process and your colaboration with Chris. Guess it's not as easy as we all thought lol

-

4 hours ago, chris watton said:

I cannot wait to see Jim's model in its full livery!

I think a few of us will echo that sentiment 😄

- chris watton, mtaylor, thibaultron and 3 others

-

6

6

-

-

Fantastic build. Can’t wait to see what you do with the Sphinx 👍

-

At the moment it seems to default to 'Pay in 3'. Wonder if it goes by purchase price then? Bring it on then 👍👍👍

- thibaultron, Dave_E, mtaylor and 2 others

-

5

5

-

Chris, with the Indy costing around the suggested £1k mark, is there any way you can afford to sell it on PayPal’s ‘Buy in 4’? Just that that would make a massive difference for us who are ‘financially challenged’ lol. Really, really, really want this one 🤗 and can’t wait for its release 🤞

- Canute, mtaylor and thibaultron

-

3

3

-

Chris, the wife's going to kill me when i show her this 😄 I have to say she really does have beautiful lines. Just hope i can clear the decks for when she's launched .

-

Medway Longboat 1742 by Blue Ensign - FINISHED - Syren Ship Model Company - ½” scale

in Medway Long Boat - 1742 - Public group project.

Posted

Great start, but then would expect nothing less! Could i ask - the tip for centering the keel section, was that your idea or mentioned in the instructions? Either way a great idea 👍