-

Posts

8,149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by allanyed

-

3D Printing Cannons in Resin

allanyed replied to thibaultron's topic in 3D-Printing and Laser-Cutting.

Hi Lieste Can you share where these instructions can be found? Are they based on contemporary sources? I may be the only one not understanding what you are implying, but if you can you please post drawings of each (as Ron has done for all of us) to show what you mean, it would be appreciated. Many thanks Allan -

Even after curing, exposure to sunshine and other UV light sources may cause the resin to weaken over time. To prevent this, you can seal the cannon and stop the resin from further reacting with UV light photons by using paint or any other type of UV blocker. I have used a matte clear with no problems. Allan

-

HI George Whatever you can fair and will support the planking is a good way to go, be it fillers or more bulkheads. If this was a warship with many gun ports I would go with drawing and making double the number bulkheads, maybe more, depending on the spacing of the ports, but as this is not the case filler blocks seem like a great alternative. Allan

-

Just a thought based on experience...... I hope 14 bulkheads are enough to allow a smooth run of planking. With an overall length of 172 feet, the bulkheads at 1:72 will be about 2 inches apart so you will have huge gaps between each bulkhead. If you decide to go with more (28?) bulkheads the body plan with the station lines will be a great guide to drafting the additional pieces. Allan

-

Hi Tim, A bit late now, but for the future, the forward edge of the completed rudder was not flat. If it was flat, the rudder could no be turned very much, if at all. There is a bearding piece on the forward edge of the rudder that was made of elm and had angles of 30 degrees from about 1650 to 1720. It was changed to 45 degree angles about 1720 to allow a wider turning arc when the rudder was hard over. There was a bearding piece on the after edge of the stern post with similar angles. (Peter Goodwin, The Construction and Fitting of the English Man of War, pp 129-30 ISBN 0-87021-016-5) He also has a chart showing the dimensions. Also, the rudder tapered, it was not the same thickness at the bottom as at the head. The taper of the rudder matches that of the stern post which can be found on the contemporary plans of Speedy 1828 at RMG Collections site. It appears to taper from about 10 inches thick at the head down to about 6 to 7 inches at the keel. Allan

-

If you are trying to simulate tarred standing rigging lines, it was dark brown, not black. You can buy Stockholm tar today, but I have no idea if it is like the Stockholm tar used in the age of sail. I do wonder if anyone has tried it on model standing rigging instead of dyes. Allan

-

Not really a chore at all. I make up a couple dozen rings at a time by winding the appropriate diameter copper wire around a drill bit that yields the right diameter ring then cut them with a small wire cutter into individual rings. The eye bolts are even easier. My go-to for the bolts is a round nose plier for bending the eye into a u-bend/circle. I just added 20 rings and bolts to 10 cover boards for the main hatch and it took about an hour total to make, install, and LoS the rings and eye bolts. Give it a try, I THINK you will find it pretty easy. Allan

- 152 replies

-

- Flirt

- Vanguard Models

-

(and 1 more)

Tagged with:

-

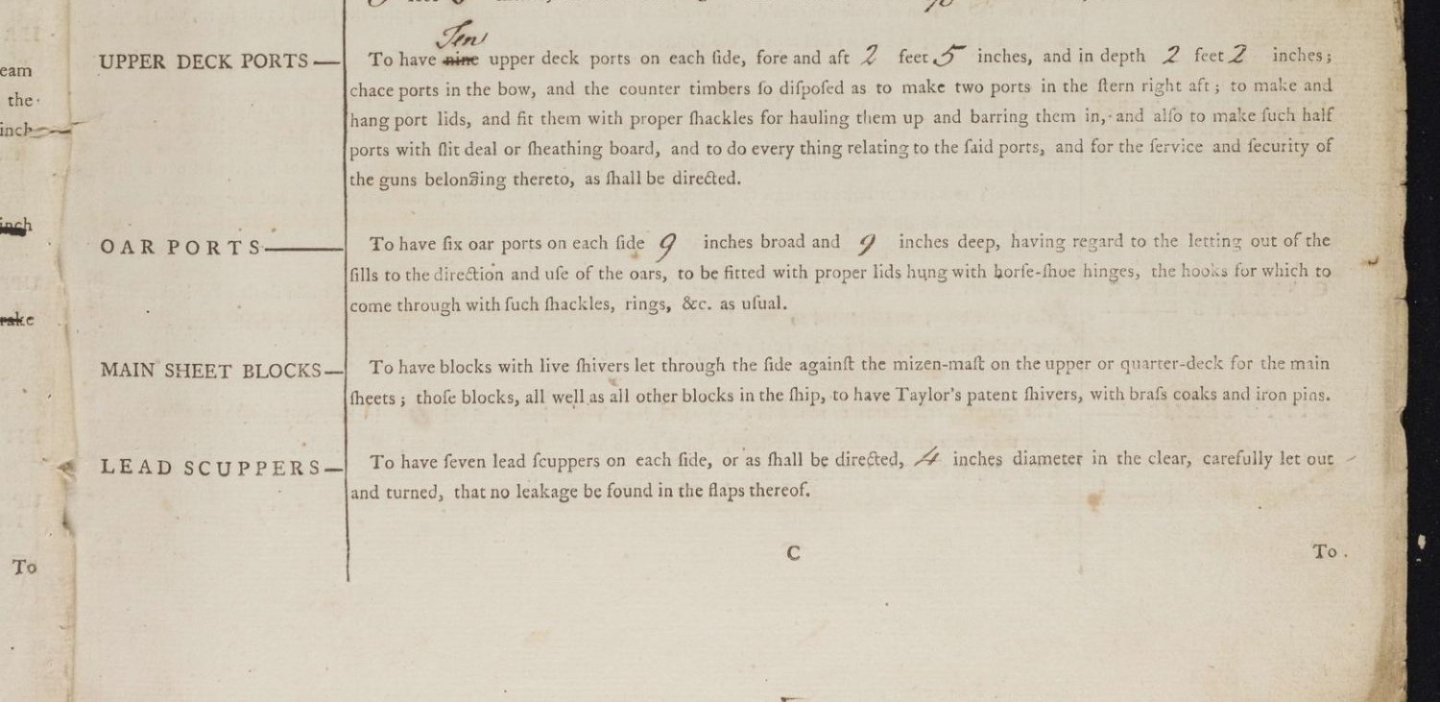

Hi Gregory, Regarding English ships, the only dimensions for the sweep ports that I can find are in Goodwin's The Construction and Fitting of the English Man of War, (ISBN 0-87021-016-5,) page 191. In his drawing the sweep port lid was 10 inches vertically by 12" horizontally and about 3" thick (the thickness of the planking?) The horseshoe strap was 1.25" wide by 0.5" thick. He also has a dimensioned drawing of a ventilation scuttle, the use of which started about 1778. These were fitted in every other gunport lid on the lower decks until 1789 when they were incorporated into every gun port lid on the lower decks. One of those things not often seen on models. Allan

-

I agree with the above regarding brass. The old Blackin It was the best, but BC works very well for me on brass. I prefer to make most metal parts with copper so I can blacken them in situ instantaneously and avoid having to handle them to get them set in place once blackened. Ed Tosti goes into the use of LoS in his build logs for those interested. Allan

-

They sometimes had horseshoe shaped hinge plates and opened sideways versus vertically. The first photo below is of a contemporary model of a fifth rate of 1689 at Preble Hall. It is hard to tell but the second is a contemporary model of a 24 gun of 1745 from RMG and appears to have straight hinge plates, but they do open horizontally as well. Allan

-

I have gone to copper wire for rings and eyebolts so there is no painting necessary. I drill the hole in the wood a tad undersized so bolt fits tight, then once the ring and bolt are in place, I touch a little watered down liver of sulfur. They will instantly turn black and will not stain the wood. Allan

- 152 replies

-

- Flirt

- Vanguard Models

-

(and 1 more)

Tagged with:

-

The main thing is to enjoy your time with whatever model you go with. Allan

-

I agree with you as this appears to be the way the ports were typically lined, no stop on the bottom of the upper sill. A lot of modern models have the linings on all four sides but then again they are often flush with the planking outboard which makes no sense as then they would not accommodate the port lid within the port opening. Allan

-

Based on contemporary models this is what appears to have been the common method. I have only seen one that may have a stop on the bottom of the upper sill that forms the top of the gun ports, in this case on the lower gun deck. This may be original or may have been a modern repair, not sure. Regardless they were only about 1 1/2" thick (0.6mm at 1:64) for a vessel the size of Sphinx (20) 1775 Allan

-

Welcome to MSW. Advice,,,,, lots of good advice here at MSW, but I think a common piece from many members is that it is better to start with high quality kits that will teach you good practices on the details, including the three vessel series designed by David Antscherl at Model Shipways which is becoming a classic for beginners. I truly wish these were around when I started back in the day. https://modelexpo-online.com/Model-Shipways-Shipwright-3-Kit-Combo-Series_p_5465.html Allan

-

Found the following that you may find interesting. https://catalogs.marinersmuseum.org/object/CL408 There are a lot of contemporary based drawings from 15'6" to nearly 20' that popped up with a quick search if you are looking for more info on Lunenburg two man dories like those used on Bluenose. Allan

-

The photo of the model of the Halifax brings up a question. Was the white stuff applied on the rudder pintles and braces (gudgeons) as well? Looking at photos of models at RMG the ones I found all have the white stuff on the hardware as well as the rudder and hull. One example..... https://www.rmg.co.uk/collections/objects/rmgc-object-66437 shown below. Allan

-

Second that comment. There are myriad discussions here at MSW on different hard woods that should help if you do not have a specific species in mind. Allan

-

Welcome Kevin! Looking forward to your future builds, subs or otherwise.😀 Allan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.