rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

The Byrnes Saw "inside and around"

rtropp replied to nobotch's topic in Modeling tools and Workshop Equipment

Mark, I guess I was wondering if the MM feather board would fit the Byrnes slots and fence. I cannot find their measurements at the MM site. The slots on the Byrnes are 1/2" wide and 1/8" deep. Jim sells an extended fence so I suspect could adapt it as you have... but will check with him to see if feasible. I was considering adding a slitter but not sure how to attach it to the zero clearance insert which is metal. A metal insert would make sense but not sure if know enough to fabricate and attach correctly :-) Richard -

Pete, Thanks for the link. I must have missed it when I searched. As a result of reading it, I am also considering using masking tape to line out the plates. I'm not sure I did a great job up to now on the port side... think I will try it when I do the starboard side. Clearway, a coating of lacquer or wipe on poly might help. I will experiment with both on a separate piece. wq3296, great thought about minor dings and scratches being real world patina. By the way, do you have a build for your Ajax? Thanks to all, Richard

-

Thanks for the responses. Hornet, I should have said that I am using copper tape with one side pre glued. It is very thin, fragile so I am could do as suggested. Since your reply I have looked around on line and see that there are companies that sell actual copper plates, some come with nail impressions. I may try some of these to see how they compare. Pete, except for the bowsprit I pretty much did the same. But the tape is so thin and damages so easily that I am pretty sure I will do some damage. I have read about some folks who put a protective finish on the plating but cannot find the references. I appreciate your ideas. Richard

-

Hi, I am copper plating the Syren. I am looking for various options/experiences others have tried in protecting the finish before continuing with the build. I know that as I continue work there is a good chance that it will be damaged. I can foresee both fingerprints as well as scratches and dents. Thanks Richard

-

Mark, I agree. I bought similar sticky back pads. They are a lot less expensive, last longer and seem to work better. I put some of the money saved into an extra set of tips so I can keep two grades ready. Richard

-

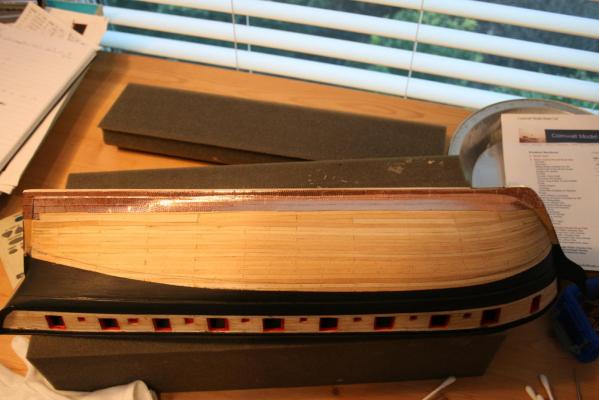

Hi all, Its been the summer from hell but I am finally able to get back to my Syren. I thought I would begin with a photo of its current state which is a few rows into the coppering. It was not just a question of figuring out the stamp, but also learning how to use the tools. I will post my coppering saga in another post when I have more time. I was not thrilled with how the deck came out. Not all of the tree nails lined up as well as the should. I was at the point that I was seriously considering scrapping it and starting over. But, I realized that I still do not know what mistakes I have yet to make. So, I decided to continue on with this. I figured some of the deck furniture / cannons would cover up some of the mistakes and it should end up ok. Richard

-

Toni, did that impact the top of the sill (overall height)also, making the top of the gun port too high or only the bottom sill, making the gun port too small? Richard

- 1,449 replies

-

Hi Cabrillo, do you have a build log or any pictures? Richard

-

a question for Sherline mill owners

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Thanks all...appreciate the comments Richard -

Hi all, I have been considering a Sherline mill. I see that the motor is mounted on the right side (as you face it). I am concerned that, being right handed, the motor would get in the way of using the height adjustment. I would appreciate any thoughts. Thanks Richard.

-

The Hobby Lobby near me has a large selection of basswood strips and reasonably priced. I did not have much luck at the Michaels in my area. Richard

- 259 replies

-

- Gunboat

- Philadelphia

-

(and 1 more)

Tagged with:

-

I also have been looking at metal lathes. I am a rank beginner and it would be my first metal lathe. My hesitation about buying a used one from ebay is not knowing if any of the parts are damaged or set incorrectly. I have read some of the problems faced by others who bought used ones and ran into problems. Especially for those not experienced enough to spot problems. Also, I have found that companies like Sherline or Little Machine Shop have extensive support which has been very helpful as I start out. Richard

-

Hi all, I find myself using my micro mill for drilling as much as for milling. I make heavy use of the x-y table, especially where hole measurement is critical, such as making the coppering jig for the Syren. . The problem I am facing is that I dislike have to turn a wheel vs. having a drill type lever or crank. I will be upgrading my mill (it has other limitations) and am not sure which type to get. The combined mill/drill looks like it has all the advantages but I am not sure if there is a downside to the construction or use of a combined tool versus using a dedicated mill and just putting up with the hand wheel. The two that I am looking at are the Sherline (for the standard Mill) and the Little Machine Shop (for the Mill/Drill). Any thoughts would be appreciated. Richard

-

Does the thickness sander work with individual strips or do you need to size them as sheets and then cut to strips? Richard

-

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Well, I had to return the sensitive drill head to Sherline. It looked like a great accessory but did not fit the MicroMark mini mill. The drill head has a brass shaft that goes up into the mill head and it did not fit into the MM. It went a small distance than was blocked. So, I continue to use the hand wheel and am about to try out the suggestions for fixing the inner wheels. I had a suggestion from Drill Bit City to use a higher speed to help preserve the drill bits, so I moved the belts to the lower (faster) settings as shown in one of the very few instructions on the "manual". I suspect that when I go back to milling, I will have to move the belt to the lower speed setting. Meanwhile, I continue to consider the combined drill/mill but I am not sure if there are any downsides to the drill/mill combination. Using the included x-y table is the primary reason but also a combined function would work better in the limited space I have for the workshop. Any suggestions would be appreciated. Richard -

I received the Xuron 2193. It works very well. Once I developed a feel for the amount to allow for its center cut I was in business. I also found there is not fly off when cutting, it just drops into the container. Thanks to all. Richard

-

Mick, congratulations, its a great gift. My wife bought me one for my birthday. The HobbyMill has a tab with a great write up about how he uses the saw, including the blade sizes and how he applies them. www.hobbymillusa.com/byrnes-saw-operation.php There are also a few threads that provide advice here on MSW. I believe they are in the tools and/or wood sections. Richard

-

The 1/8 shank bits from drill bit city have resolved my problem with wobble. Great tip thanks. Richard

-

thanks David, I have ordered the Xuron 2193 you recommended. I hadn't thought of using a cutoff wheel but that sounds like it would be more difficult and somewhat messy. When a cut piece flies off, it is really difficult to find. That should do the trick. Richard

-

I am creating jigs for making nail impressions in copper hull plating. I am using the needles from diabetes lancets. They are a perfect size and stiff / hard enough to be worked (cut, ground, etc.) without losing shape or strength. They need to be cut down to size to use. When cutting them, the edges on the cutters I have are too soft and end up with nicks. It looked like cutters made for piano wire might be too large for the very thin needles. The wire is about #77 thickness in drill bits and I may be trying out thinner lancets that require #80 drills for the holes. I noticed on the first cut that the Xuron cutters I had were being damaged so I stopped using them. The ad for the Irwin cutters described them as " induction hardened cutting edge of nickel chromium steel." Sounded pretty tough but ended up not really good enough. Not knowing that much about cutter strength, I did not know what descriptors signified cutters with cutting edges that were hard enough to take on the needles I was cutting.. I have other Xuron cutters and am pleased with them so, unless I get other thoughts, I think I will try out the suggestion for the Xuron 2193 to see how they work. Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.