rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

Was looking at different cutters and I am wondering if anyone can tell me what metal would be the hardest, most durable, and least likely to be nicked? I have seen stainless, carbon, high carbon etc. Richard

-

Thanks to all, For me, the descriptions on line at Riogrande are not helping me understand which cutter would work (my lack of knowledge). Once I get past the weekend I will try to call to see what they suggest. Richard

-

I am looking for a small wire cutter capable of cutting hard wire from .040 down to .0135. Currently I am cutting metal pins (medical quality) and the Irwin brand cutters are not cutting cleanly, also the wire is leaving indentations in the edge of the cutter blade. Thanks, Richard

-

I have been testing drill bits from separate manufacturers. I have ordered cheap Chinese on E-bay and not so cheap at McMaster-Carr. As a result of this thread, I ordered a set from drill bit city this morning. Driving this research is my attempt at creating finer nailing patterns on copper hull plates. This is also the reason I am testing different chucks. No sense having a great bit with poor quality chuck. I use both a Dremel workstation for simple, hand held drilling and my micro mill its x-y table for drilling out complex hole patterns such as on the copper plating. I suspect I will need different chucks for each machine I use. I tried two of the Dremel chucks that I already have, both on the Workstation and on the Micro Mill by inserting it into the mini mill chuck but am not happy with the result. Richard

-

Does anyone know of high quality chucks for the #70 - #80 range of bits? All the ones I have used have had wobble in the bits. I wish I could find a brand that will hold the bits straight and true. Richard

-

Are those electric plank benders worth it?

rtropp replied to Spaceman Spiff's topic in Modeling tools and Workshop Equipment

I think there are mixed feelings. Some use them and like them, others not so much. When necessary, I use a plank bender that cuts a small notch on the inside of the plank to promote a clean bend. it looks like pliers but has a triangular ridge, but does not have a very a sharp edge. Of course you have to be careful not cut the plank into pieces. It is a very gentle pressure that creates and indentation in the wood. I only use it when wet bending does not get what I need or if I need small corrections to an existing bend. For wet bending, I tend not to use heat if I can avoid it. I build a bending jig that matches the curve I am looking for. With clamps, I slowly bend the plank to fit the shape then let it dry. It worked well for the bends and did a good job on the cap rail of the stern transom which is a right angle bend. We all have preferences for tools and methods that work for us. My philosophy is to try it and if it doesn't fit my style, sell it on E-bay. Richard -

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Little machine shop has a similar item but of a different build. It looks like it is made to fit into the jaws of a chuck. Also, there are some on Amazon, one is inexpensive but does not have the chuck. Richard -

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

The part screws onto the external threads of the spindle. Nice thing about sherline is their extensive library of instructions. This part can be found at: http://www.sherline.com/1012inst.pdf I'll know for show if it fits the MM micro mill once I get it next week. I'll take some pictures and provide the results here. Richard -

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

I just ordered one from Sherline. with shipping it was just over $100. Perhaps it will help drilling these darned copper jigs. Richard -

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

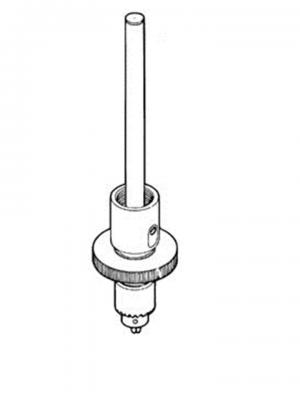

As far as I know the sherline mills do not have the drill feature. They sell a part that goes into the head that has a spring set up. You use your fingers to lower the drill bit while it is turning. It is Part number 1012. On the positive side, it is supposed to provide more control, less bit breaking then a hand wheel for small bits. I am using gauges between 70 and 80 so we will see how well it works. That said, for most drilling it would still be easier to have the hand wheel. I am not sure of the tradeoffs for that kind of set up. I am checking into it with some sites that sell them but was hoping to hear from someone's personal experience. Richard -

That is a great idea. Simple and inexpensive. Plus they appear to have a complete range of movement, raise and lower, tilt as well as being on wheels to move around. I checked Amazon and they seem to run in the $50 range. Not too bad. I might try one out when I get to the rigging stage. Richard

-

Help with Mill handwheel and dial too tight

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

David, thanks for the tip Mark, ditto. Also, not sure I will have the micromark for too much longer. I visited the Sherline factory on trip to California recently and noticed a marked difference in the handling of the mill. The Sherline is very smooth and responsive. Also, can't beat the support team. Their museum was an eye opener and they did demos where the demonstrator was willing to not show me some of the things that I wanted to do on both the mill and Lathe. Very helpful. Since I have been using the mill more frequently I am considering selling the MM to upgrade. The one sticking point is that I am not sure if I wouldn't be better off with a combination drill/mill such as the ones that I see at Little Machine Shop. Turning the crank (or dial) when drilling is tedious after a while. I will be testing our the recommendations for fixing the scale dial on my MM mill when I am next in my shop. It's just that would rather get the copper stamping jig done sometime this decade Richard -

Hi all, I have been using my fairly new mini mill and have run into a problem. The ring with the scale is so tight that it is very difficult to reset to zero without turning the hand wheel at the same time. This, of course, moves the head from its "0" position which screws up the settings. This problem occurs on both the Y and Z scales. The X scale works well, easily resetting to zero without any stiffness. It is a Micro Mill mini mill, the one that is MT1 compatible. I am not sure if there isn't an easy or recommended way to fix this before I start muddling around with it. Thanks, Richard

-

Metal vs. wood files - how to tell the difference

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

This has been a great education. Thank You all for your posts. I think I finally understand the difference... and how to use and care for them. I appreciate everyone's responses and will continue to look in as anything new is added. Richard -

Metal vs. wood files - how to tell the difference

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Ok, I am going to paraphrase what I am hearing to see if I truly understand. Rasps, with their longer, coarser teeth are for wood only. Files with finer grain (flat grain) can be used for any material. If used with metal, use a Lubricant. (I think I would separate the tools keeping two sets so that I did not chance ruining wood.) These multi use files would include most files with single row of teeth, crossed rows, bastard, etc. They could be used for wood or metal. HSS is ok for wood but should use tungsten carbide for metal work. Please let me know if I understand correctly. Also, what about diamond impregnated files? Richard -

Augie, I really enjoy following along with your build. In Chapelle's book, History of the American Sailing Navy. He writes about the confederacy and includes the Admiralty draughts made after it's capture. This is included as part of his discussion of the early continental navy. He writes "the confederacy was an ornate ship, profusely carved. She was very handsome....she had one oddity in a large vessel of this period: her keel was slightly rockered forward. The Confederacy was described at the time of her capture as being a very fast ship and well built" Anyway, I ran across this and thought you might be interested. Richard

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Help with a Byrne's Saw - end of cut problem

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

guys, I really appreciate all your thoughts. I have made a list of the ideas and will begin by pushing the end of the fence away from the blade about .005. This seems to be considered the first thing to try and will also be the quickest. If that doesn't help I will keep going down the list to see what helps. I'll let you all know the results as I get a chance to test them. Thanks to all. Richard -

Hi, I have been using my Byrnes saw to cut strips, mostly 1/14, 1/16, 3/32. The strips are coming out spot on to measurement. Never having used a table saw of any type before, this was pretty surprising. Its really nice to be able to rip strips as I need them. No worry about running out, especially nice with all the rework I do. Anyway, I was ripping a few different strips from Basswood. One example of the sheet was a 1/4 by 4" by 24" from which I cut an 11/32" wide strip. For almost all the strips, when I get about 4-6" from the end of the 24", The blade starts to catch, burn the wood a little and the wood struggles to get through the cut. I make sure the wood is firmly held flat at the blade towards the feed side. I have added a prop behind the saw that prevents the ends from sagging, at it helped a little, but I still get the wood catching in the blade. I would appreciate any suggestions. Richard

-

Coppering the 1:64 Syren

rtropp replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Hi Bob, believe me I considered that, but this is my first kit and a learning experience so I am trying to push myself. Thomas Gahm left a note in my build log suggesting the use of needles from diabetes testing and increasing the number of pins. His boat really looks great so I am considering it. I guess I really am a glutton for punishment Richard -

Renshape for scratch builders

rtropp replied to rshousha's topic in Modeling tools and Workshop Equipment

I am interested in finding out more about Renshape. Do you have a link to a description or demonstration? Richard- 11 replies

-

- scratch building

- parts

- (and 8 more)

-

Coppering the 1:64 Syren

rtropp replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Augie, I have a pounce wheel and plan to compare its results to that of a the jig described in the Syren instructions. I think the one I have does not run small enough, but I will try it anyway and see how it looks compared to using the nails on the jig. Tadeusz, Great Pictures, Thanks. Lucky for me the kit supplies the copper in an adhesive roll. It just looked like the nails supplied would be too large for the 1:64 scale. I went back and checked my copy of Goodwin's book for sizes (great suggestion, had it sitting on the shelf.) Chuck, I measure the existing nails in the kit at 1/32" or 0.03125". Using Tadeusz's suggestion, I checked my copy of Goodwin's Construction and fitting of English Man of War and at their largest suggested nail size was about 1 1/2" long and 1/4" wide (for a 74 gun). (Taduesz, I did not see 1 1/4" width, just 1/4" width in the write up and 5/32" width in the drawing on page 225.) So, using the largest size discussed I tried to calculate the actual myself. I posted them below to see if my calculations were correct... (hey, I was an arts major in school... cut me some slack ) Actual nail width of 1/4" is .25" decimal At 1:64 this reduces to .00390625" width for model size. So unless I messed up the math or am wrong about the actual size of the nail, this is one tiny part and is not going to happen. So my question becomes, how small a nail is appropriate? I guess I can file down the nail heads but am not really sure how small I should go before it becomes wire and loses its rigidity and its ability to make an impression. What size nail width would you all recommend? Also, Can anyone suggest an online source for nails smaller than 1/32" diameter? (by the way, its really great to be able to run this by other more experienced builders to check on new skills I am acquiring.) Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.