-

Posts

3,084 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Jaager

-

-

1. You do not make it easy when not identifying the class and year of Echo.

2. If you are at all serious about 18th C. RN vessels and aim at authenticity you should own a copy of Yedlinsky.

18 gun sloop of war:

Floor timber : Every other floor timber to be bolted through the main keel - bolt dia. = 1"

Keelson : To be square = 12" x 12"

exclusive of what is let down between the floors which may be = 7/8"

Scarphs in length = 4' 6"

The keelson bolts should be driven through and carefully clenched on the underside of the main keel dia. = 1"

Excepting where the rabbet for the plank is taken out in the middle. There, they come through and clench on the underside of the keel that is coaked to the main keel.

-

Working from a fixed inventory, I am not surprised that Donna may have depleted Model Machines inventory. You may wish to try email and see what is left that you want by contacting Donna.

Malco seems to offer single blade purchase on these pages:

Martindale may be a possibility -they seem to want to talk first- but you will need a 1" to 1/2" arbor adapter bushing. Even way back when it was Jarmac and Dremel as 4" table saw and ordering was snail mail and checks - their blades were 1" arbor.

I did a Google search and found Temu.com and found low cost - no bets on the quality - 4" but their arbors are 20mm - I got that adapter bushing for the Diablo so I can do a trial - the prices are low enough to be worth the gamble. $16.00 for four different blades to sample.

The HSS blades with lots of teeth, thin kerf, have small gullets and no set to the teeth. Not a good tool for resawing stock of significant thickness. The carbides have "ouch" kerf thickness.

- Ryland Craze, mtaylor and Canute

-

3

3

-

Marquardt shows 6 long guns - 4 x 6lb 2x9lb 1x 6lb boat carronade on a turning base - forecastle. 1x 4lb Howitzer

The 6 long guns were trussed and on the main deck. No sign of a location for the Howitzer - it may have been stored below until required for use in what stood for the main launch.

The long guns were clutter and mostly in the way. Once England was out of site, I would consider parking them in the hold were I having FitzRoy's job. Running them out would be pointless. Any locals who might physically object to the English trespassers would probably find the carronade to be a sufficient discouragement.

The U.S.Ex.Ex. used a gun to measure distance when mapping. The home ship would fire a gun, someone on a launch would use a stopwatch to measure the difference between the flash and the sound. The carronade would be perfect if Beagle used this method.

- Roger Pellett, Keith Black and mtaylor

-

3

3

-

On 5/6/2024 at 8:31 AM, Martes said:

Blender and similar tools (Maya, 3DMax, etc) are suited creating computer game models and 3D printing, and, while everything they produces may look very pretty, it would never be exact, because down under it is still a polygonal extrapolation consisting of vertices connected with triangular faces.

A NURBS modeler is better for precise and predefined curves. For animation in a vertex based program - a NURBS model that is then converted to polys can be way too "heavy" to allow render times within a human's lifespan. Is there a free NURBS based program?

-

Sails are not attached to yard arms. They are attached to yards. The arms are the sections at the end of the larger yards with a step down diameter.

Yardarms have popular notice because naval vessels attached the hangman's rope there for executions. A body hanging from a line at the yardarm would be over water, not the deck. The poo and **** would not foul the deck.

Running rigging from higher yards and sails in front a lower yard would impede that yard's ability to swing and pinch the sail.

It would no matter on a museum ship that is essentially a statue. It would require some special occasion for such a ship to even have enough manpower to set and furl even one sail - it seems to me.

- Chuck Seiler, allanyed, Keith Black and 2 others

-

5

5

-

Go back to the Byrnes site. Click on the Tablesaw in the "Our Products" dropdown.

The saw itself is no longer available - but the blades and screws are.

If you do not have an arbor adapter for blades with a 1" arbor - get at least one.

If you get an adapter 0.787" (20mm) a Diablo 4-3/8" x 36 Tooth Finish Saw Blade - D0436X - carbide ( kerf is 0.05" though) will fit. Peachtree has it for $15.00

Harbor Freight has : WARRIOR 4 in., 24T Mini Table Circular Saw Blade 1/2" arbor is on clearance for $3.00 which probably means that it will not be available for much longer.

- Ryland Craze, modelships, mtaylor and 4 others

-

7

7

-

David Macgregor drew a set of plans for Thermopylae I believe. His plans went to an outfit that really ain't much of an ally.

Something is available: https://ssgreatbritain.printstoreonline.com/ship-plans/

here is a link here to chase: https://modelshipworld.com/topic/24168-merchant-sailing-ships-serie-david-macgregor/

and another: https://www.ssgreatbritain.org/wp-content/uploads/2021/05/david-macgregor-ship-plans-collection-july-2013.pdf

This said, collect plans, collect books. I think that collecting kits only serves the kit manufacturers. The old pre-fire Mantua kits look to be really awful to me. I think three of their most popular subjects are the same hull in different clothes: Bounty, Endeavor, Beagle. For their kits in general: All of it seems to have been just the minimum required.

A clipper is a major project. A composite hull post 1860 clipper even more of a challenge. Large hulls at a small scale is requiring miniaturist skills. Unless it is a widow recently stuck with "toys" that she resented having funds spent on when obtained, I suspect that "deals" for old kits are gilded bricks. Someone trying to recover some of the money spent on really poor decisions about illusions, dreams, and mirages.

Here is an idea: Keep a diary of subjects as they grab your interest. Have the links and references there. Buy no kits until your board is clear. When you get to the 'buy another kit' stage, you will be surprised at the number of diverse trails, strange ideas, and dry holes there are in the diary.

- mtaylor, modeller_masa, Canute and 2 others

-

5

5

-

Two of the reasons for preserving an obsolete ship:

sentimentality - a cultural symbol - purposes that both Constitution and Victory serve quite well

true historical exhibit - as direct evidence and data for what the ship actually was in the instant of time it purports to represent.

If the Ship of Theseus - had been repaired by using the same source material (species of tree, etc.), with the identical shape, and attached using the method that is identical to the original - even if none of the actual molecules are those of the ship as launched - it would be just as valid as if it had been teleported. The information would be identical and equally valid.

Both Victory and Constitution are failures by this standard. Constitution underwent "improvement" and "modernization" probably about every 20 years while on active serve and after it was saved from the breakers, been manipulated and adjusted to the preconceptions of whatever committee was in charge when repairs of the effects of time, oxygen, microbes, electromagnetic radiation, was required. Victory has seen its share of the same. Both are chimeric rather than being a frozen instant of time.

Would that we had now, and in the past, a more elaborate and minutia obsessed version of HAAMS for every vessel of some importance.

- Chuck Seiler, Canute, mtaylor and 1 other

-

4

4

-

5 hours ago, MBerg said:

is a loose representation of a "Swift 1805 Virginia Pilot Boat".

I think this was taken from Steele 1805 plates. A pilot schooner was probably about at the limit for long term deep water sail.

Since it is from Steele, his table of scantlings should serve.

Western wooden sailing vessels did not have bulkheads - except perhaps some fishermen with a live catch hold. They had deck beams.

The outer ends rested on clamps - thick inside planks.

The small vessel I have selected from Steele is the 10 guns Brigantine - small two masts

clamps # 2 3.5" thick at upper edge 2.5" thick bottom edge the pair are 13" wide ( 6.5" + 6.5" or 7" + 6" - like that)

Deck plank 3"

Beams round up 6" sided 9.5" moulded 7" # 16

Use the location of the hatches and masts to give a starting point for the spacing. I do not have data for how wide the space between the beams at each mast is, but it was fairly close with room for changing the angle of the mast.

The hatch just are. The other beams are probably at regular intervals. A deck house would be a hatch.

The beams are a series of arched timbers 9.5" wide, 7" thick - each has a different length- Because the peak of the arch for each is 6" in the middle, the curve is different for each one.

-

Richard @Richard Braithwaite,

When I billoted my Holly, the near stream of water being pushed out of the cut end by the bandsaw blade told me that Holly has water tubes that communicate readily.

Your paint MAY have saved the interior from the Blue Mold, but I would not bet any money that I could not afford to lose on that being the situation. But, even so, that would not decrease the value of the wood for model ship building. The structural integrity of the Holly is not affected by that particular mold as far as I can see. The color change is more in tune with ship building wood than is the snow white Holly that has become so expensive. Robbins egg blue would be weird, but Holly readily takes up alcohol based aniline dyes, so that is easily fixed.

- mtaylor, Scottish Guy and bruce d

-

3

3

-

To add to your possible options:

First, I have been following this since the early 1970's and subscribing to all of the English language "journals" as well as about every book as it came out. The only instance of having a deck plank butt on the same beam with every other strake has come from OcCre. I have no idea where they came up it something both hideous and dangerous engineering. Having ax handle diameter trunnels - standing out like carbide lamp beacons - at and only at each butt - is graphitti.

Wood swells across the fibers. They are not muscles. they do not get longer. If the end to end butt is tight when the deck is laid, a wide caulk filled seam is not needed. The end to end butts would be difficult to see.

On actual ships that were well built, the deck trunnels were supposed to be as invisible as possible. If it is to be modeler's convention show off deck trunnels, there is a rigid pattern to be followed - and the contrast should still be subtile.

Polaris is more boat than ship. I do not see when it was supposed to have been built - or where - but in early to mid 19th c US, 40 foot long 10 inch wide planks were specified for corvettes - much larger. A single plank per strake - without a cross scratch - would pass muster. If you are laying it on a subdeck before it joins the stanchions/top timbers and outside planking a single is easy. Trimming off the overhang at each end is easy. If the deck is laid on beams. with waterways in place, the complex ends are more difficult to fit. Jogging, nibbing, or curved starting outside in. Getting a winning role of the dice at both ends is difficult. Here two pieces may be easier. A simple 90 degree join in the middle is easier to pull off.

Higher cost and not so good a choice for end cutting.

Choppers - crush fibers - even as a knife blade - they do not cut.

HF Drill Master 2 inch - motorized - needs a lot of work on the work surface- kinda dangerous - throws what it cuts off - is clearance so is probably soon to be extinct - MicroLux is probably the same unit. Prozzon wants your next born for something 10 times more expensive and maybe 25% better made.

Quick and dirty:

Use a saw - a razor saw - mass market work fine - Zona , Exacto,

I prefer a cut on the pull stroke. This requires either a Japanese mini saw - expensive - or a razor saw with a blade that can be separated from its backing and reversed.

a miter box - depends - with a saw with teeth that have set, the slot has to be wider - so some play.

Protractor:

Draw a line and cut by eye, then:

Get a 3/4" thick square of wood 12"x12" is enough - plywood is OK, an off cut from an Oak stair tread wonderful. Overhang the end of the plank. Sanding blocks - 80 grit to remove a lot. 220 grit to finish. If you can find sand paper with a simple paper or cloth backing - not the non-skid stuff - a coat of rubber cement on the block and on the paper - wait 15 min - press together - endless supply.

I found a $13 Porter Cable replacement miter gauge that might fit the board. A stick of wood with a center pivot, a distance out spike or screw, and a protractor with movable arms may be all you need to get accuracy for any angle.

-

Although Beagle was at the verge of explosive shells - which made their own splinters, it was of the kinetic ball era. Additional sources of wood splinters on deck - not all that wise.

The boats in the waist tended to be nested. They were wood. They probably required having their hull planking kept wet enough that they did not desiccate enough to open their seams.

That is not a good storage environment for loose parts and equipment. If Beagle's task was like that of the later U.S. Ex. Ex., the primary function of the larger boats was for mapping. The smaller ones were probably better at getting onto and off of a beach - water, food, getting investigators on to unknown shores.

- allanyed, mtaylor, Scottish Guy and 2 others

-

5

5

-

Beech would be an appropriate wood for a 1:60 keel. But not a lot of help as something readily available as a economical domestic species in the Philippines.

The tropics in South America have several desirable species, so the climate does not preclude the possibility of a domestic at reasonable cost per BF.

From just reading the Wood-Database only Hard Milkwood comes up as a possible. It may take making friends with an old crotchety independent hardwood sawmiller to get a lead and source for domestic lumber with appropriate characteristics and get it in lumber form. With a chainsaw, a kiln, and a bandsaw, no tree would be safe - theoretically.

-

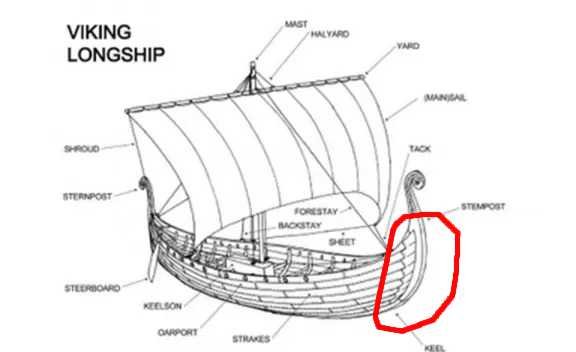

What I mean by tunnel vision in this situation is to focus on building Roar Ege as close to the way that Billing as designed it. I think that any time and effort spent on trying to augment or add realism would be better spent on a later project. A time tested, perhaps THE time tested, path into scratch building is to augment a kit with more sophisticated elements. I think that this particular kit has too much that is too far from real. It would be like starting in a deep hole.

In preparation for composing what is real (or at least my admitted limited knowledge of what is real in Viking practice), I scanned all of the Viking kit build logs. Which are authentic looking?

At least as far as the hull and the planking - which is pretty much my area of focus.

Realistic seems to be Marine Models Dragon class solid carved, Dusek Gokstad, Dusek Knarr, Artesania Latina long boat. The sheer of all is sort of flat. Anything but realistic Billing Oseberg, Roar Ege, and Amati Drakkar.

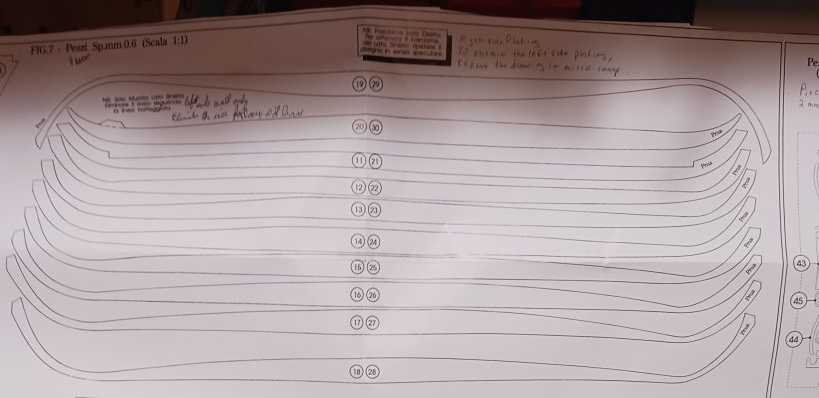

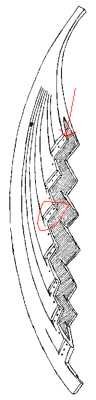

I thought that the impossible planking of Amati:

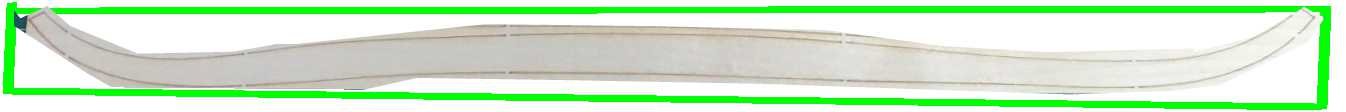

and Roar Ege, which is a bit less cartoon - and pointing out that the planking was freed from Oak trunks/balks using a maul and wedges - I don't see how an individual smith could fabricate a saw. For your kit, the green box is the plank that this plank would have to be spilled from:

That these extreme - probably for show - stem and stern were large carved timbers - not actual planks:

And these two links are from logs here:

https://modelshipworld.com/topic/29710-skuldelev-wreck-3-viking-knarr-by-antyronnen-billing-boats-120/ post 4 pic 4

That the planks had lands in the carved piece:

Then I realized that the kits with these extreme curves on their planking were never intended to be realistic. It is a cynical method to avoid having to deal with providing the proper stemson and sternson. At least for Roar Ege, I think that the planks are far too wide. The extreme twist that includes countervailing directions for the kit planking at each end is something that I see as being a frustrating combat for a builder.

Being totally outside my Universe, I am not qualified to rule on which short cuts are acceptable in a kit.

Oh, about one of my POB terminology complaints - on most POB ships, the central spine fills the midline of the whole hull. Usually it reaches up to the lowest deck being included in the model. For Roar Ege, that part may only be as much as the actual keel. In this situation naming it "keel" would be correct. The possible horrible part would be if it is plywood, with end grain showing where it should not be.

😉 This is meant to be fun. Even if we were part of a university naval architecture department/museum and hair splitting stroum und drang - actual models are no longer in favor. Those decisions seem to be in the control of individuals who have the equivalent of a life long continuous release LSD depot somewhere in their body.

- Keith Black, Glen McGuire, mtaylor and 2 others

-

4

4

-

1

1

-

On 5/3/2024 at 4:41 PM, Scottish Guy said:

Part 11 (first plank to the spine)

About 1000 years later, and on carvel planking, this plank is the garboard plank.

OK, I just checked Leather (CLINKER BOATBUILDING, John Leather, IMP, 1973) and Simmons (LAPSTRAKE BOATBUILDING , Walter Simmons, IMP, 1978)

and they both name it the garboard.

If it is any consolation, here is a quote from Simmons: "The garboard that I am considering at the moment is a plank with considerable fore and aft twist, and it requires more work to fit properly than any other plank on the boat. To make it fit to the rabbet as well as to fixed lining marks can stir up ulcers."

Michael, are you considering a scratch build of a viking boat? If so, I have some factors about the planking that different from what Billing and Amati burden a builder with.

So far, this kit seems to be fulfilling its primary purpose, your introduction into all this, and a beginning indication for what you need to learn. You should probably use tunnel vision and view this kit as a unique world unto itself.

- Glen McGuire, GrandpaPhil, Scottish Guy and 1 other

-

3

3

-

1

1

-

The Wood-Database does not have much specific for your part of the world. I would try to find a local hardwood sawmill and see if they have a local wood that is fine texture, no pores large enough to see, straight grain. Something that looks like Oak or Elm that has been scaled down 50 times. If you use actual Oak, the grain, pores, and texture will be 50-100 times too large.

There is no tree species with grain that small. It could not transport water thru tubes that small. There are however species that are a whole lot closer to scale than is any nutwood.

Basswood and Linden have excellent grain characteristics, but their surface is soooo fuzzy.

-

No way would I pay that much for a machine like that. I would question its ability to move enough air to do the job.

For in the house - at the bench - I use a Kenmore Blue Magic small canister vac. It uses a collection bag - which is a pain, but otherwise does the job.

The handle at the end of the hose has the ON-OFF - which is a slide power control.

I attached the handle to the end of a desk lamp arm (less the bulb part) using cable ties.

There are desk lamps and THERE ARE DESK LAMPS - I prefer serious articulation, a desk clamp with some mass, and arms that will stay in position -no weak wingnuts.

There are desk lamps and THERE ARE DESK LAMPS - I prefer serious articulation, a desk clamp with some mass, and arms that will stay in position -no weak wingnuts.

The handle has some weight to it.

It took some serious jury rigging to get a hose to fit the opening in the handle and also fit the dust collection port on my Byrnes disc sander.

I use the tablesaw and thickness sander in my garage. They are not about finesse. The disc sander is.

An additional advantage is that it can be used to clear stair treads of dust.

-

The 3rd edition that I have has two foldout sheets - not all that large. They are not what I would call plans, never mind "working plans".

The missing plans are no loss. The book itself was bush league in its time.

The S.I. sells 1/4" scale copies of the plans in Chapelle's books. There is a fair selection of 1850's clipper ships.

The site with downloads of the plans from Wm Webb's Folio has lines and mast/sail plans for Black Hawk - Challenge - Comet - Flying Dutchman - Gazelle - Swordfish - Young America

The clippers were about as large as a wooden sailing vessel could be. This puts them in an unfortunate situation. A model with a scale large enough to include detail is also one that will take over the room that it is in. A model whose size is one that you can live with will require miniaturist skills. See the work of @rwiederrich in the scratch section for a view of what is involved.

-

Pine is good. I use a lot of it.

There is another wood that is worth a look. Goodreau Sawmill & Woodworking has Yellow Poplar that costs about the same as their White Pine.

If your focus was a couple hundred years earlier - they also have Hard Maple, Black Cherry, Beech.

They also have the usual nutwood species whose grain and open pores do not scale.

I would place a bet that you will come to regret having a large solid wood carved hull. The rules that Dana Wegner developed for USN museum acquisitions - rules that specify a hollow hull, are probably the result of lessons paid for from disasters reflected by solid hulls.

- JKC27, mtaylor and Scottish Guy

-

3

3

-

1 hour ago, Gregory said:

What do they look like?

I agree. Going back to the baseline and defining any problem is key to getting things done correctly.

There is no standard process. What, if any, color adjustment depends on the starting material.

There are lots of How To articles covering block making. An easy method for mass production and minimal individual block manipulation is a goal for many.

One possible beginning:

If you have plastic blocks from a kit - then perhaps using a series of coats of a dilute enamel paint that is the desired wood shade?

String the blocks on wire and dip them over and over? Light touch as far as pigment density per coat? On small blocks - I see brush application being frustrating. Using an aerosol application on a sphere - a lot of manipulation of the target - awkward manipulation.

-

46 minutes ago, Frank Burroughs said:

Alcoholic walnut stain for all the blocks. Is solvent based the same as alcoholic base?

The first generation acrylic paints had icky surface texture - like chalk- the paintings that I saw - I did not care for the look. But the molecules are hydrophilic. They play nice with water. Alcohol and acrylic molecules may not play nice together - or - a shade that is a mixture of pigments may have some molecules having a different affinity and the color come out different.

The lack of precision in the use of terminology leads to confusion and misunderstanding.

A dye has a solvent. It is a true solution. individual molecules evenly dispersed in the solvent. No settling, no change in content over time. Where the solvent goes, the dye molecules also go.

A stain has a vehicle. The pigment particles - a clump of pigment molecules - are temporarily suspended in the liquid carrier. They settle out if left alone. They stay on the surface of wood.

The dyes that I am familiar with are hydrophilic - they dissolve in water or alcohol - I think alcohol is preferable for scale work. Surface fibers of wood do not swell with alcohol, they do with wood.

Some old style stains are organic solvent based. Think of them as semi transparent paints that are wood colored. Some stains must also contain dyes if they are featured as being "penetrating".

I suspect that an acrylic stain - if such exist - will use water as a carrier - an awful prospect to imagine as far as ending with a smooth surface.

I wonder if the fanatics who ban VOC products use water in their engines?

Dyes are for high quality wood. As with a fabric dye, the internal substance of the wood becomes the new color. The grain is unaffected. Other than the color, the surface is unaffected. PVA still bonds it.

Stains are for wood with unremarkable grain. The pigment sits on the surface. I think a stain will either need a clear overcoat (a varnish - in the original meaning of that word - before there was commercial anything doing that) or will also contain a polymerizing clear component (varnish stain) or a plastic (polyurethane).

-

Phil, @GrandpaPhil

AAMM is the source for another (two actually) Polar ship -but South Pole - L'Astrolabe (and her sister La Zelee).

The S.I. has plans for the four USN Polar explorers at the South Polar region at the same time - Vincennes, Porpose II, Peacocok II

- the Flying Fish -ex. Independance pilot schooner that is the S.I. plan is also available for free- the John McKeon from the Wm H. Webb folio. - to actually match Flying Fish the breadth needs to be increased 20' 7" to 22' 6', the depth 7' 6" to 8' 8" , the length 70' to 85' 6" Increasing the Body plan by 110% is all that the breadth and depth require. Increasing the length by a fixed percent is not without some unwanted distortion. Just increasing the breadth alone and making the 54 spaces 8" instead of 6" lengthens the hull without distorting the stem and stern.

Beagle also took a shot at the region I believe. For this, I think starting with ZAZ5137 and following Marquardt's demonstration of the alterations.....

- GrandpaPhil, Canute, Scottish Guy and 2 others

-

3

3

-

2

2

-

This ship is a subject of a AAMM monograph.

The plans are 3 sheets and the scale is 1/75.

If the OcCre plans are not as complete as they could be, this is a ready source for details.

As with the other AAMM Age of Sail subjects, the plans are designed for a carved hull build.

The lines are more than enough for a POB build. There are enough points for a standard plotting of frames for POF - but no buttock lines.

To my eye, the frigate itself is an excellent example of the last of the pure sail warships. When efficiency was the primary guiding factor of the design.

Here is the description from the AAMM shop:

"La Belle-Poule

first rank frigate (1834 - 1861)The Belle-Poule is one of the last large sail frigates and a masterwork of the shipyards because of its speed, power and handling ease.

With very pure lines and little camber, its battery painted white accentuated further the horizontality of its hull. Launched in 1834 she was involved in a number of military actions. But her fame is essentially due to the fact that, under the command of the Prince of Joinville, King Louis Philippe’s son, she was sent to St.Helen’s island to recover Napoleon’s body for burial in its final resting place in the Invalides. It was at that time that the white line of its gun ports was painted black and so it is for the Museum model.

This model, albeit complicated, can be built by non professional, but patient and skilful model boat builders. It is a rather large model, very decorative, especially if one paints in white the gun ports line, as for all the ships of that period in France.

Specifications :Displacement : 1 500 tonneaux.

Lenght : 54 m.

Beam : 15 m.

Armament :Battery :Two 80 pound howitzers

Twenty eight 30 pound gunsDeck :Twenty six 30 pound caron guns

Four 30 pound howitzers on deckFighting tops :Eight swivel guns

Model building : Advanced skills and time required

Scale of drawing : 1/75th,

Three plans, four photographs, one notice (french)."- mtaylor, SighingDutchman, JeffT and 3 others

-

6

6

-

2 hours ago, kurtvd19 said:

I don't often mention Harbor Freight but for some stuff they are pretty good.

I have found that the HF 4" ratcheting bar clamp - the one with the large wingnut - is the only one that I have tried that really works.

The HF model with a small wingnut, the MM variety, the Widget Supply model, the expensive Irwin 4'' - none of these will apply any appreciable pressure.

Plus, the trigger tends to break.

- Scottish Guy, mtaylor and Canute

-

2

2

-

1

1

bolting frames onto keel

in Building, Framing, Planking and plating a ships hull and deck

Posted

From the above, I would bolt the keelson to every timber. With a bolt already in every other timber a pattern that avoids having the keelson bolts and existing timber bolts on different tracks is needed. A "Z" with the hole 4" in from the edge of the keelson and since the floors are sided 11" ( 11/3= 3 2/3") about 3.5" in from the edge of the floor. The next timber would be a mirror. The floor bolts having the same pattern - staggered by one timber - but since it not visible, the floor to keel bolts can be skipped.