-

Posts

2,347 -

Joined

-

Last visited

About chris watton

- Currently Viewing Forums Index

- Birthday 11/21/1966

Contact Methods

-

Website URL

www.vanguardmodels.co.uk/

Profile Information

-

Gender

Male

-

Location

Forest of Dean, Gloucester, UK

-

Interests

Ships and cars.

Recent Profile Visitors

-

Craigie65 reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

Craigie65 reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

TJM reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

TJM reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

Ryland Craze reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

Ryland Craze reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

bhanley reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

bhanley reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

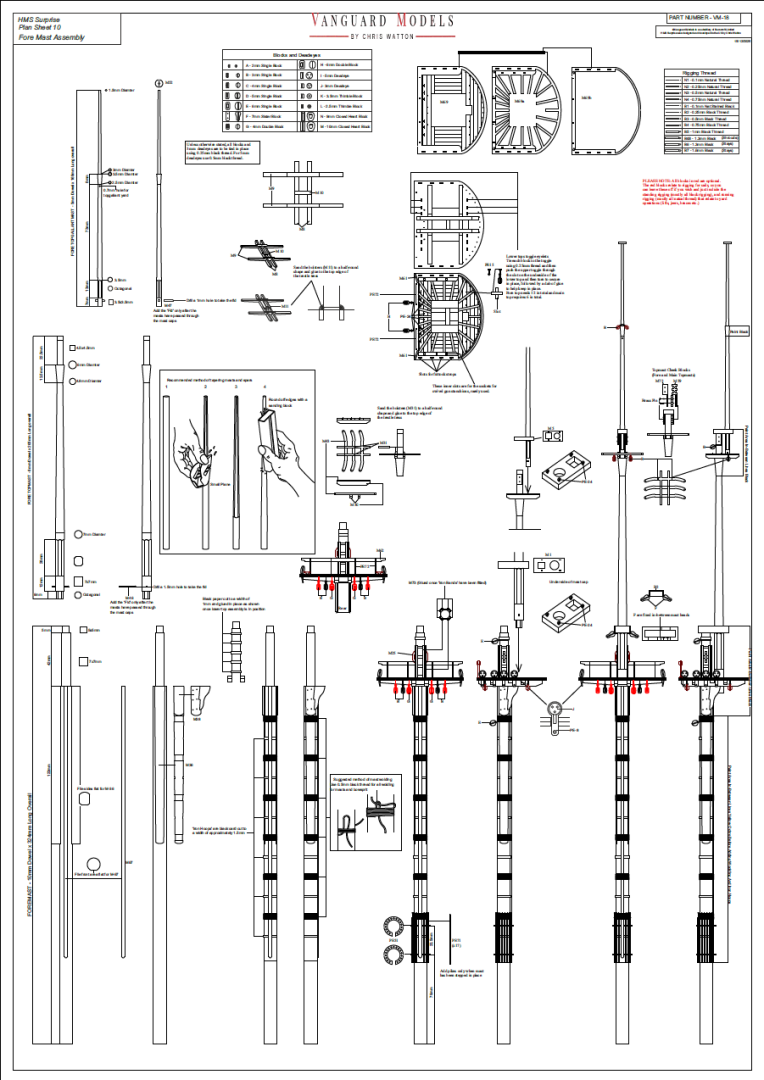

There are no less than 10 A1 size plan sets dedicated to the masting and rig for Surprise, giving you all the dowel sizes, lengths, block positions etc, with the rigging plans broken down into 8 separate stages, so as not to overwhelm the modeller. So, they may not figure as much as the main hull in the manual, but they do in the plan sets, with half of the entire plan set dedicated to masts and rig - and less sheets for the hull, as this is featured much more in the actual manual. Plus, because the vast majority of parts are already marked where they go on the hull or decks, full size plans for the hull are not so important (but I still add them anyway - although not essential to). ETA - here is the A1 plan sheet for just the foremast assembly, with no less that eight views of the lower mast, and 4 views each for the Topmast and Topgallant, all in 64th scale:

-

Amazingly, only 2 items are from Ikea, the book shelf (which is great, holds so many books)!, and the smaller white slim locker. The cupboard unit is from Amazon: HOCSOK Kitchen Pantry Cupboard, 180 cm Tall Storage Cabinet with Countertop, 4-door Larder Cupboard with 2 Drawers, Kitchen Storage Units, White : Amazon.co.uk: Home & Kitchen And the rest was a huge order from BugDug, spent a few weeks putting it all together - I have many cuts and bruises.....

-

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

chris watton reacted to a post in a topic:

Chris Watton and Vanguard Models news and updates Volume 2

-

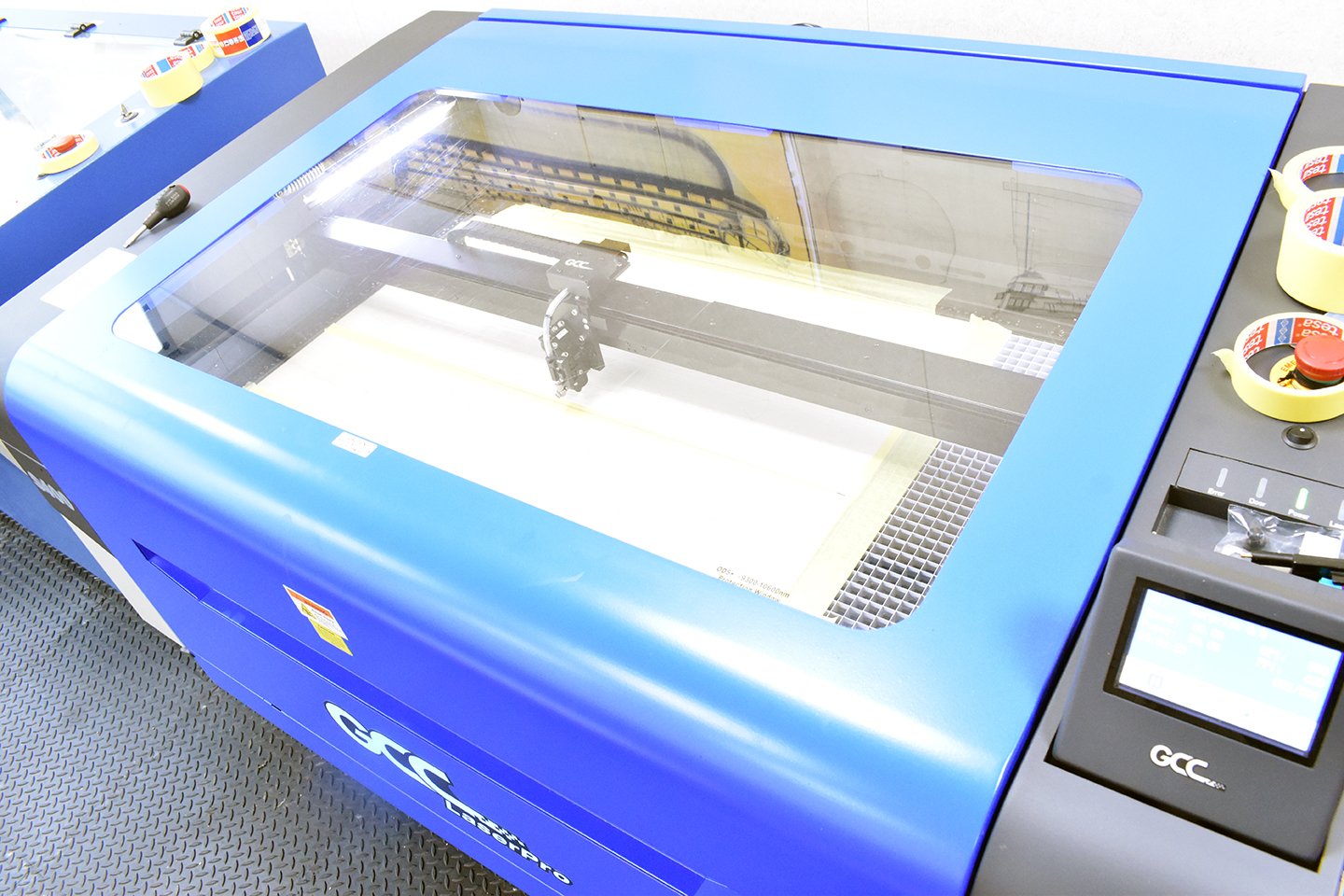

Cheers! My wife has now taken over where the laser machines were in the converted garage at home, so she can pack kits in there. But I think the main aim is to get something larger again and have everything in one place. But for now, we have a little breathing room, and I can run both lasers in concert. That isn't a kitchen table, it will eventually house 3-d printer stuff, with the larger table for the Formlabs 4L, which will be quite an investment, second only to the lasers, so may wait until Surprise is released before getting that.

-

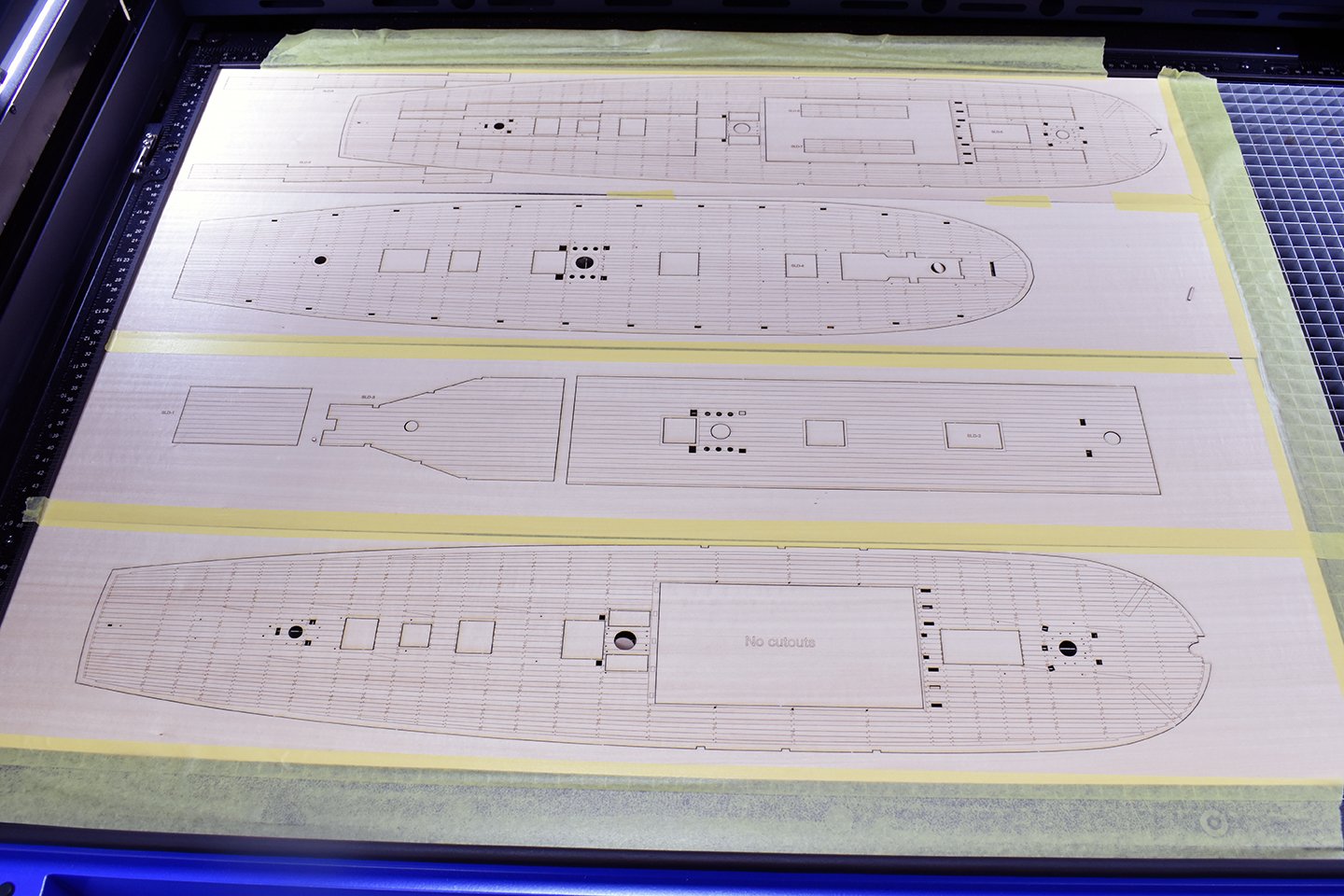

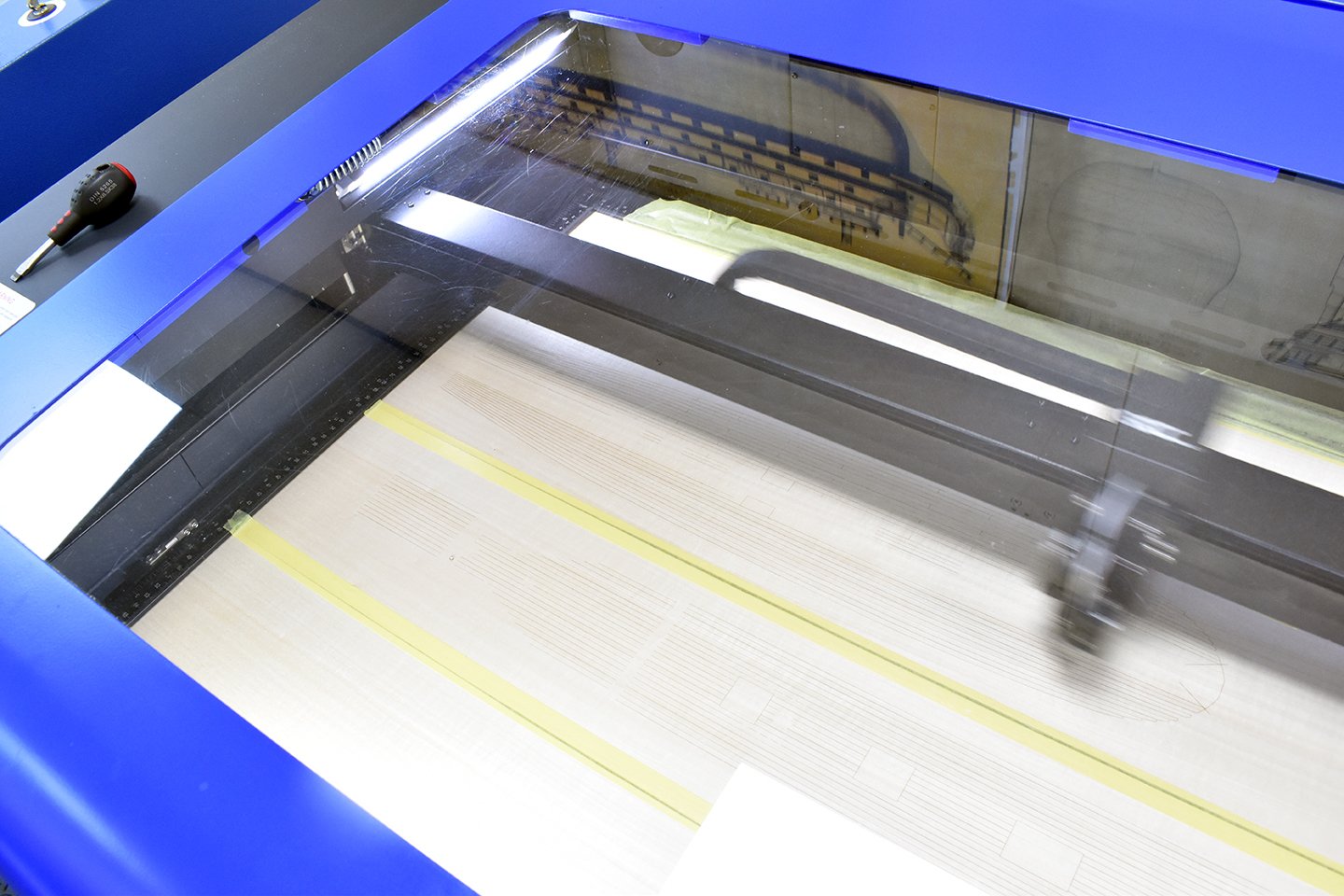

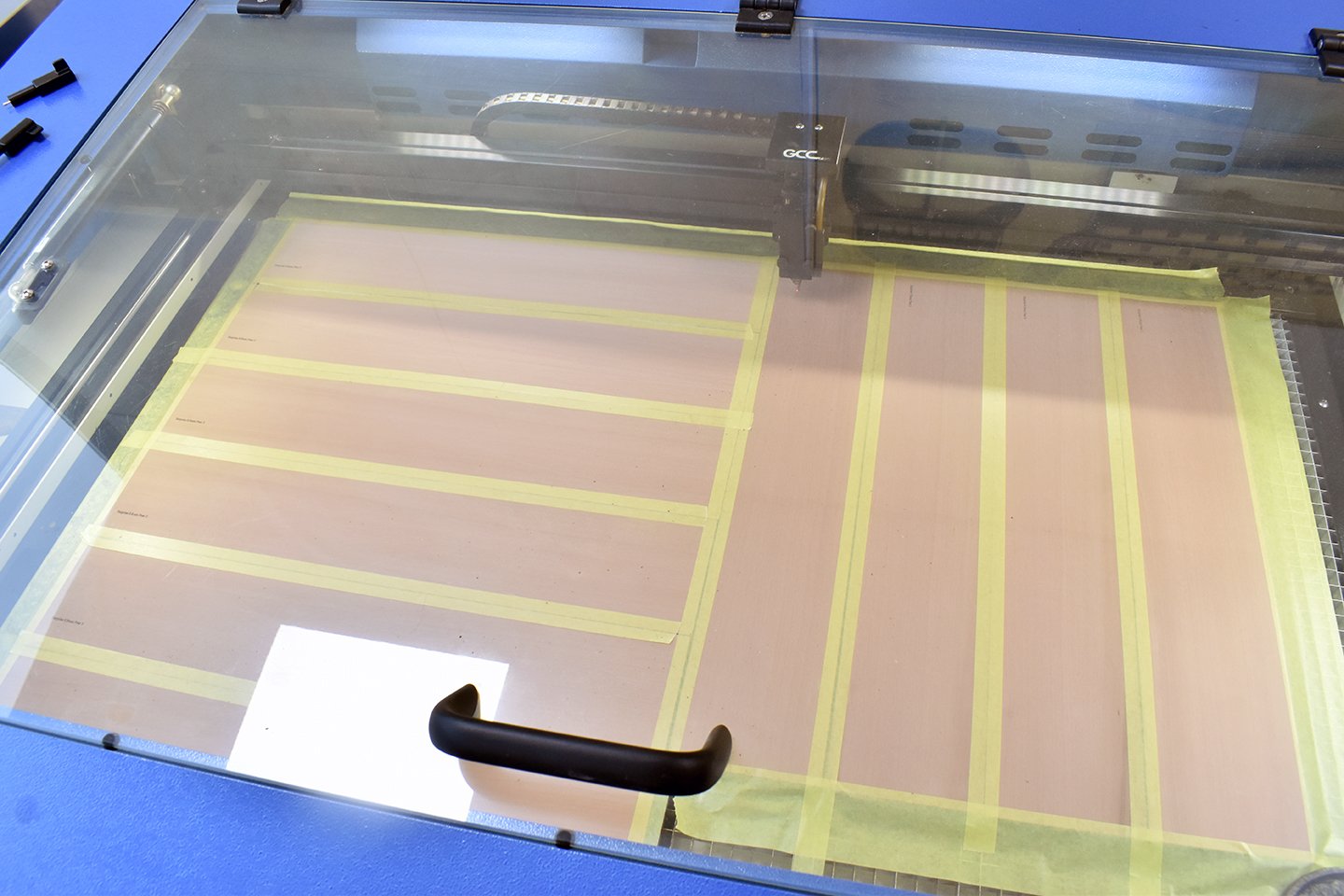

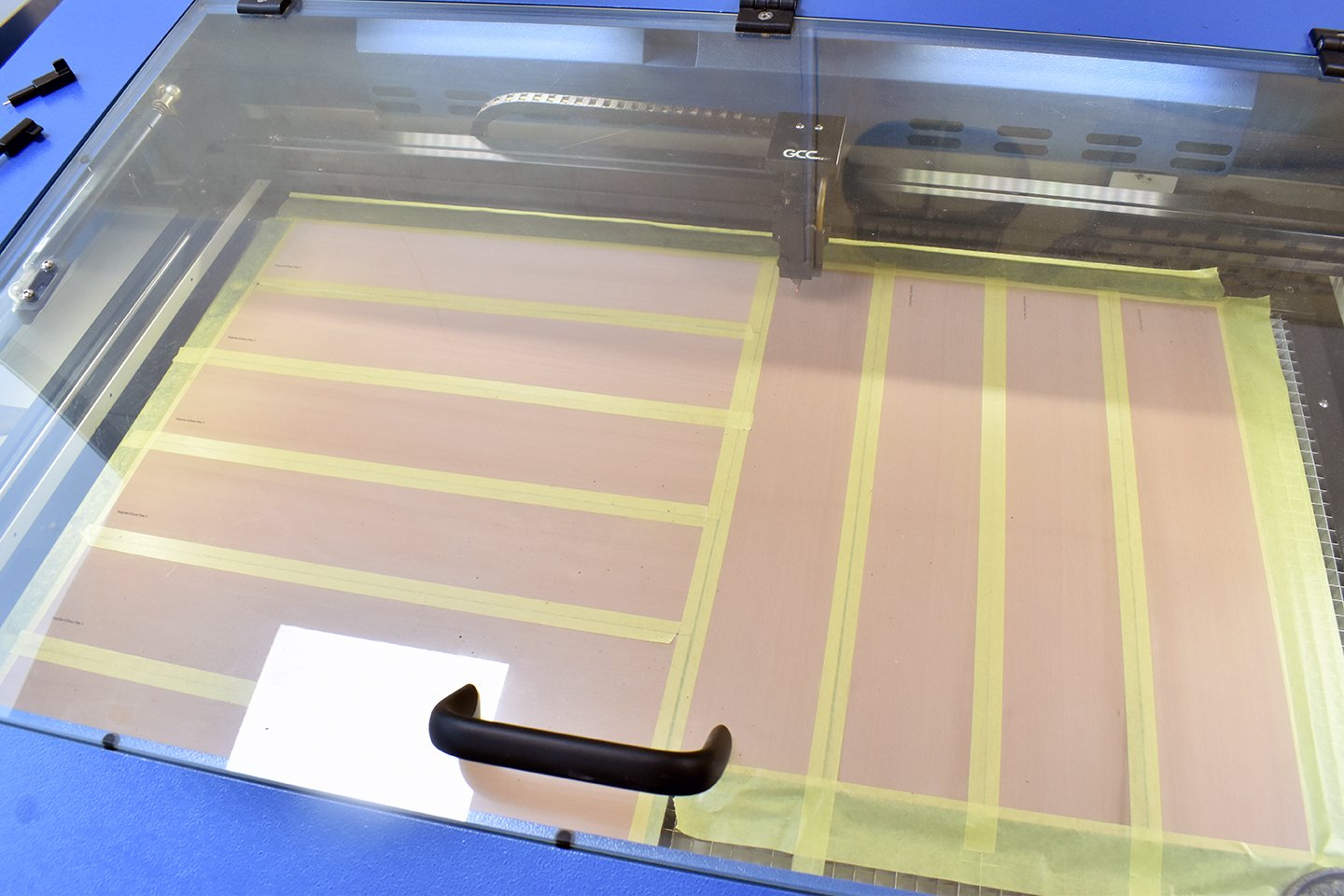

And here is that Surprise deck set complete! For a few, I am also cutting an upper deck with no openings, (the deck seen at the bottom) so just like a standard deck, in case anyone asks for it and they don't want to show the gun deck. For one set, this takes just over an hour and 16 minutes - and this is just for one kit..

-

I have just taken some more pics of the unit, as it is starting to look a little better with most of the rubbish from packaging removed. All I am really waiting for now is a sh*t load of more materials (MDF, pear etc.) and a large new 3-d printer. Laser machines are up and running though, which is the main thing... Both machines currenlty working on Surprise production.

-

Rigging is never as bad as you first think. Most of the lines go to and through blocks that you have already attached to the various masts and yard, kind of like a 'rigging by numbers' - plus, as most rigging was standardised, if you have rigged one ship, it will probably be little different to another even larger ship, with the only major increases in rig being perhaps the mast shroud count, which means more ratlines to tie. For Surprise, I have highlighted some sections of the rigging in red, which do not need to be done, but can if you want to fully rig her. So you will have a choice of how far you want to go (this is when the printers decide to mess up and print all my plans in black and white....)

-

chris watton reacted to a post in a topic:

HMS Harpy 1796 by dunnock - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Harpy 1796 by dunnock - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

chris watton reacted to a post in a topic:

HMS Surprise 1796 (prototype) by James H - Vanguard Models - 1:64

-

chris watton reacted to a post in a topic:

Duchess of Kingston 1798 by Glenn-UK - Vanguard Models - 1:64 - Commission Build

chris watton reacted to a post in a topic:

Duchess of Kingston 1798 by Glenn-UK - Vanguard Models - 1:64 - Commission Build

-

chris watton reacted to a post in a topic:

Duchess of Kingston 1798 by Glenn-UK - Vanguard Models - 1:64 - Commission Build

chris watton reacted to a post in a topic:

Duchess of Kingston 1798 by Glenn-UK - Vanguard Models - 1:64 - Commission Build

-

Mat L started following chris watton

-

I have now watched them so many times, that I realised that every British 2-decker is actually the 50 gun Leopard.. Great set of videos, though.

-

OK, I am now moved into the new unit. Laser machines were installed Friday, and both are running right now! Still a lot of work to do and loads of other stuff to set up (plus bringing all materials for the shelves), but laser production at least has started again. (Am waiting for Biffa Bins to send us new bins so that we can get rid of that mountain of packaging...)

-

I always add rigging hooks to the PE, even when they don't seem to be used, always handy....

- 50 replies

-

- Sherbourne

- vanguard models

-

(and 1 more)

Tagged with:

-

You would need to ask Amati, as they own the designs, as I was paid by them for the developements.

-

Thank you I cannot do anything about the Victory. I have contemplated designing a third, but it is a very long development, and not sure my heart would be in it for the 2-3 years it would take. But I always get emails asking if I will do a Victory, so always torn on the issue.. I think Royal George would perhaps make a welcome alternative for a British 3-decker. I have even contemplated HMS Temeraire (1798), but I know full well that once done, and when painted in her Trafalgar colours, people will think it's Victory (as it was virtually identical in size and layout), and when realising it isn't Victory, they will moan asking why I didn't do that one instead! I wish it wasn't this way, but sadly, seems true judging by the amount of emails I get asking if I have a Victory...always been the same. Cheers I know something like Royal George will never 'Fly off the Shelves' because of cost (estimated £2-3k), but it is one I have always wanted to do - and I no longer have no one pulling the purse strings telling me I cannot! I will look at the US sloops of war at some point, but I already have around 5-6 years of developments booked up! A 3 decker with perhaps all deck detail and deck beams is a 3 year project - If it was designed like I did a couple of decades or so ago, with an empty hull and 80% dummy barrels, perhaps a year tops - but where's the fun in that... Now, I just worry that I will not live long enough to develop all the subjects I want.....

-

Sails on a British Cruizer Class Brig

chris watton replied to DennisL's topic in - Build logs for subjects built 1801 - 1850

I would imagine yes, royals were used on such vessels at that period. They usually aren't shown because they were classed as 'Flying', meaning no lifts, just hoisted up when needed. (as far as I know, at least) Also, yes to flying jibbs/jibbooms, which were introduced in the late 1790's - so between 1806 and 1811, they would very likely have been used.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.