-

Posts

2,332 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

My 'Future Projects' Folder, what I would very much like to do for main kits before I die. (not included are smaller subjects) - all 64th Amazon (32 - 1770's) Amphion (32 - Hoste's command) Phoebe (36 - 1790's) Arethusa (38 - 1780's) Imperieuse (38 - Ex Spanish Medea, Cochrane's command after Speedy) Bonne Citoyenne (20 - Influential captured French large flush deck corvette) Royal Oak (70 - 1740's) Centurion (60 - Anson's) Bellona (74) Spartiate (very large 74 captured at the Nile) Foudroyantt (80) Royal George (100 - 1750's) Calendonia (120 - 1800's - if only to see the look on my wife's face when building up the hull on the dining room table...) Restoration warship (1670-1690) Constitution (US) If I live to do even half of that list, I shall be somewhat happy.

-

I thought I had better post on this thread, Trial Cutter is now available and in stock: HM Trial Cutter – 1790 – VANGUARD MODELS There will be a couple of days delay in shipping, due to both being very busy (just finishing a couple of large distributor orders) and packing the kits. There will be one more kit release this year (making 4 new releases for 2023), and then a much longer break for the 16th kit, Bristol, which will be released next year, all being well.

-

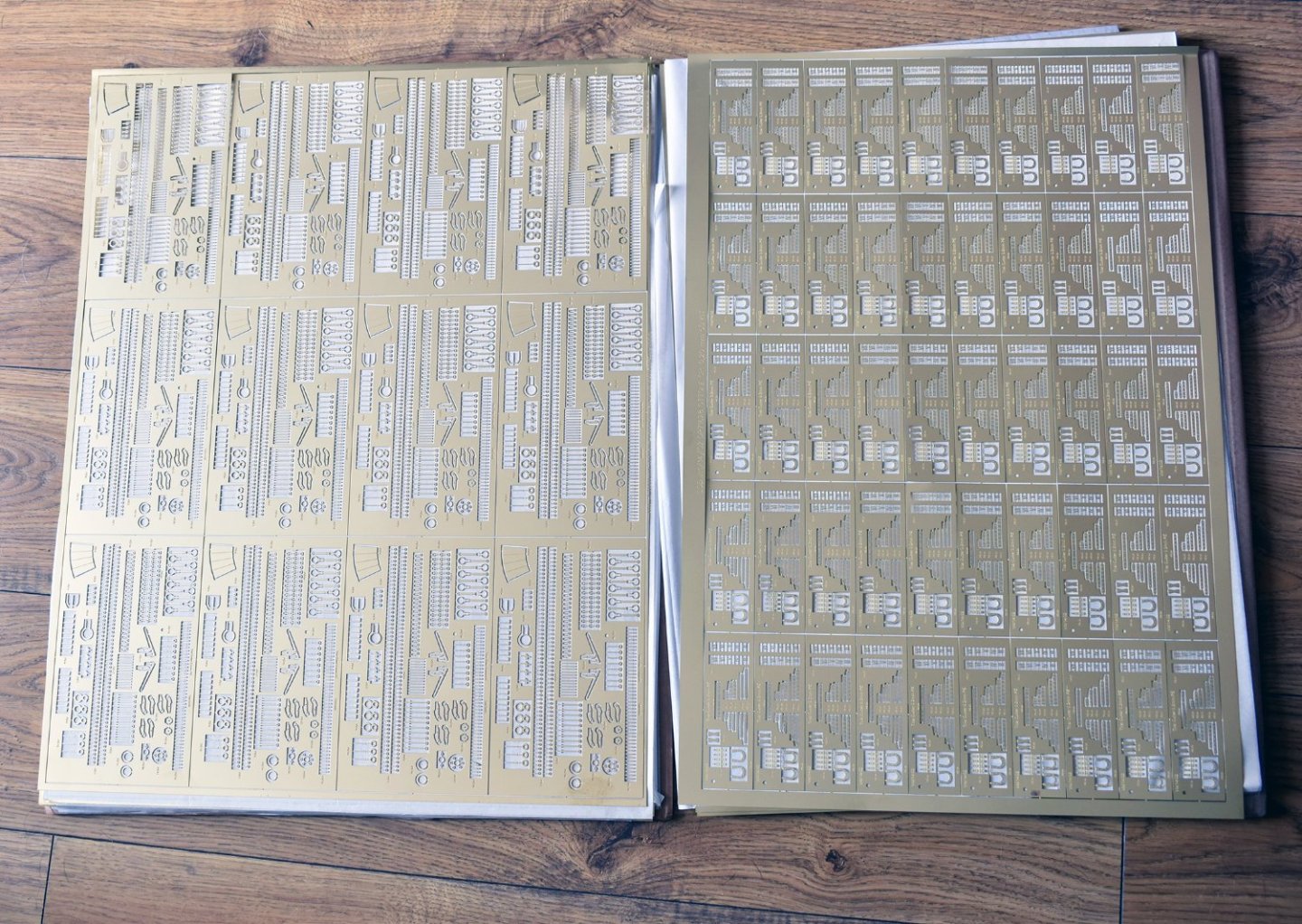

I now have the final piece of the Trial puzzle, which is now complete! The production PE just arrived, so I can now finally add this kit to stock.

- 57 replies

-

- Trial

- Vanguard Models

-

(and 1 more)

Tagged with:

-

It is called a Wash Cant, and added so that the water didn't hit the underside of the cheeks too much. An optional fitting, but it seems that it was quite standard with commissioned vessels, and I am stone cold sure Indy would have been fitted with them, given her stations/hunting grounds.

- 233 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Your Speedy is brilliant, very well done! I love it!

- 10 replies

-

- Speedy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Update: I thought I would not be getting my photo etched sheets for this until September, as I was convinced the Italians would not have them ready before they shut down for almost 2 months. However, yesterday, I received news that my production Trial PE sheets are ready to pick up! I have just booked the parcel pick up, so will have the photo etch sheets next week, and the Trial Cutter will be available - finally!

- 57 replies

-

- Trial

- Vanguard Models

-

(and 1 more)

Tagged with:

-

It will have the exact same masts and rig as a 64-gun ship of that period. The only difference being the lower masts are cut a deck shorter to take into account the height difference. Originally, they gave Indy the mast and yard plan of a 50-gun ship, but that proved almost disastrous, so was changed back to a 64 set up very soon after initial commissioning.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

They might be..... No plans to re design Flirt, as I am happy with the kit. The only reason I felt I had to do Speedy is because the kit had changed a lot since 2019, so a complete re doing of the PE sheets was absolutely necessary. At the same time, I removed all 'legacy' parts and updated a load of others. It now has laser cut pear grating, ladders and a binnacle as standard, rather than optional extras - plus of course the new laser cut and engraved outer and inner bulwarks, plus wale and spirketting. I believe both Alert and Flirt are a perfect balance between more 'old school' and newer kits. You do not have to copper Speedy, and can paint her exactly as Flirt if you so wish.

-

I always end up smearing on a little diluted wood filler in the frames, had quite a few for the Victory!

- 587 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I do not think I have planked a hull yet that hasn't had that clinker effect somewhere....

- 106 replies

-

- Grecian

- baltimore clipper

-

(and 4 more)

Tagged with:

-

Hi BE. I can state quite categorically that my plates do not originate from Amati. My plates were designed for Speedy originally, back in 2019 and they had completely new tools made for the photo etch process (I actually used a picture of a copper plate from the full size Victory, sized to 64th and then copied the nail patterns from that). The patterns are completely different, but are obviously the same size per plate. The plates I designed for Amati were originally for the 64th Cutty Sark, and then another set were produced in 72nd for the Vanguard kit. This was in 2007. So, although I did design the Amati and VM plates, they are not the same. In fact, I decided not to design my new plates the same exact pattern in case some thought I was copying my designs from 2007.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

As they are very close to the shrouds, it may be better to leave them off altogether.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

There is not kit supplied equivilent. I did have a few laser etched decks when first released as an optional extra, but these were on custom sized wood and very expensive, and very costly in the end due to most of the sheets being unsuitable for purpose. I do however buy large quanties of 1x150x1000mm limewood, which I use for all engraved decks now, so I thought I would again offer the Indy pre made decks, albeiit in more separate parts than before due to width limitations.

-

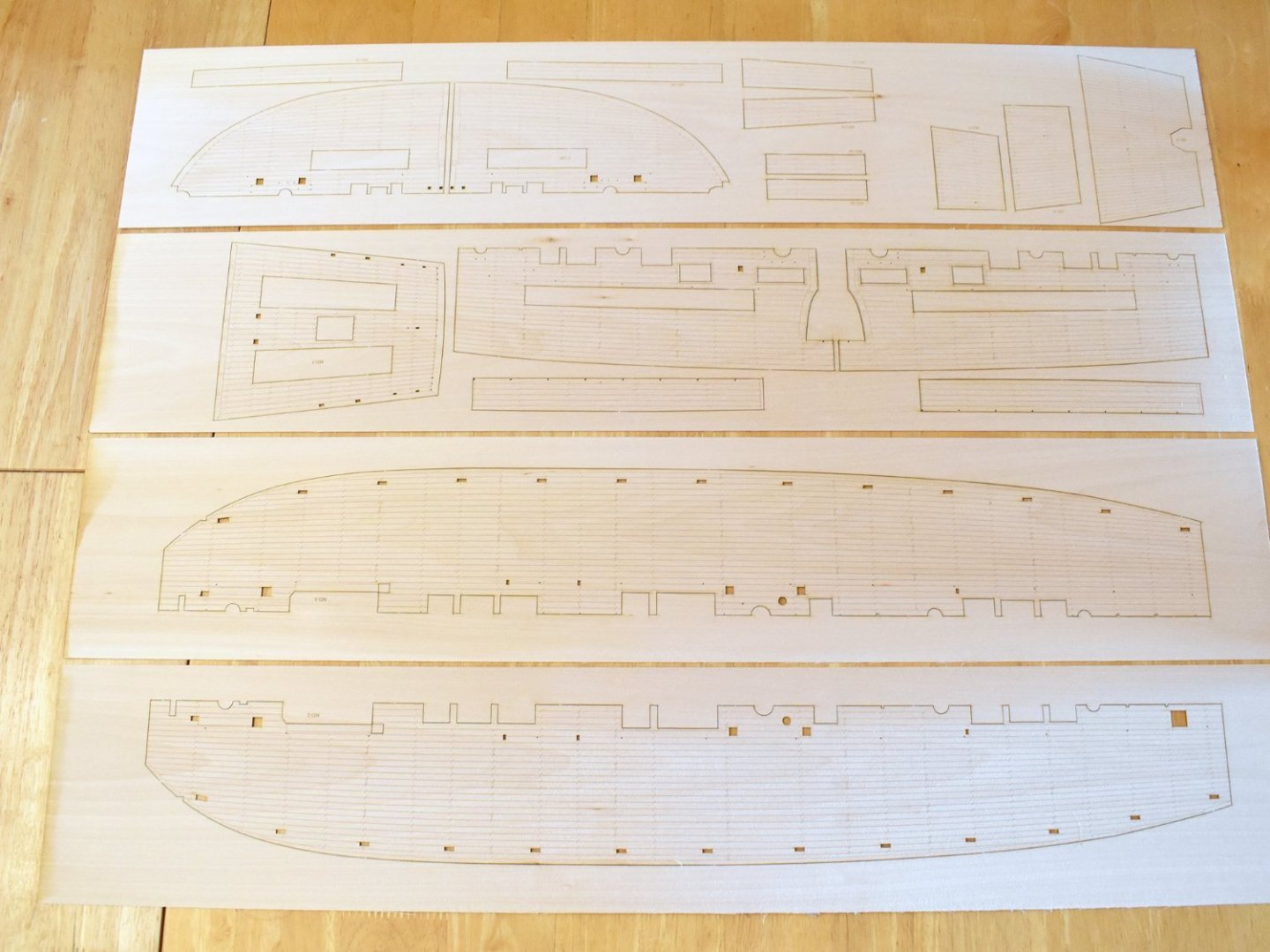

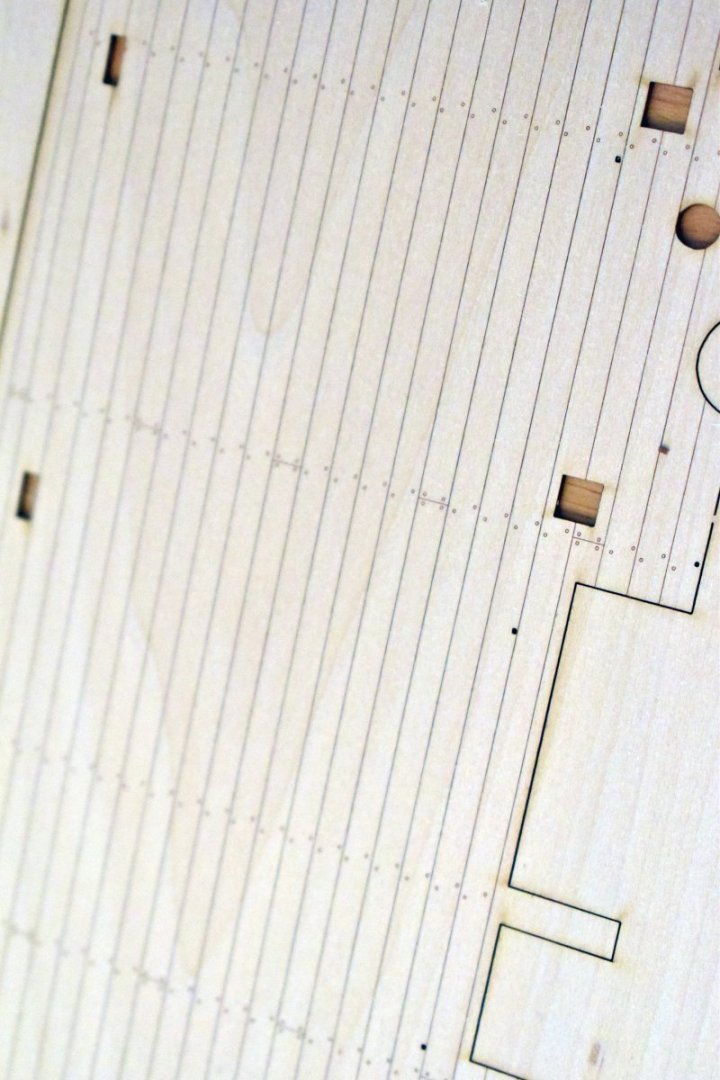

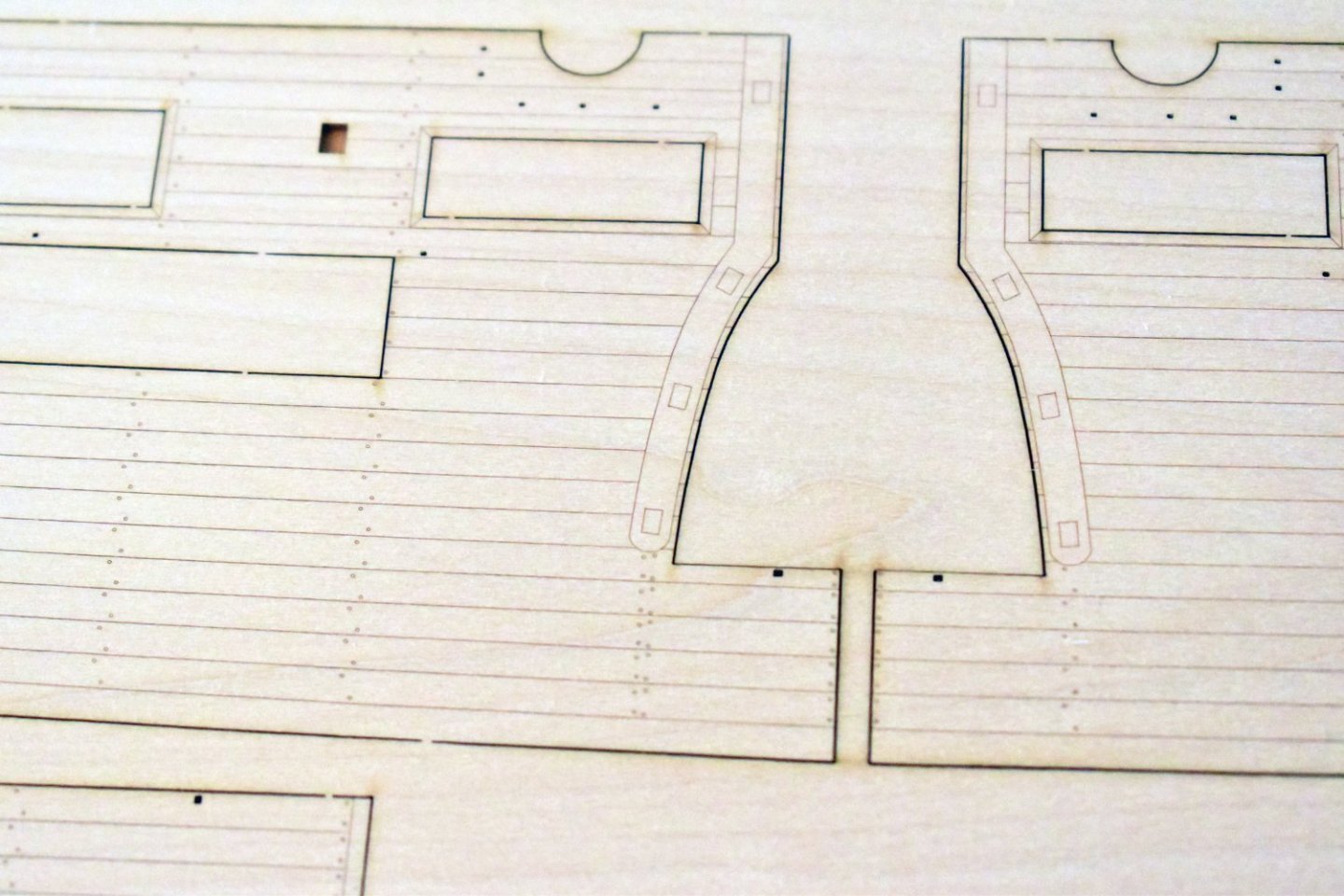

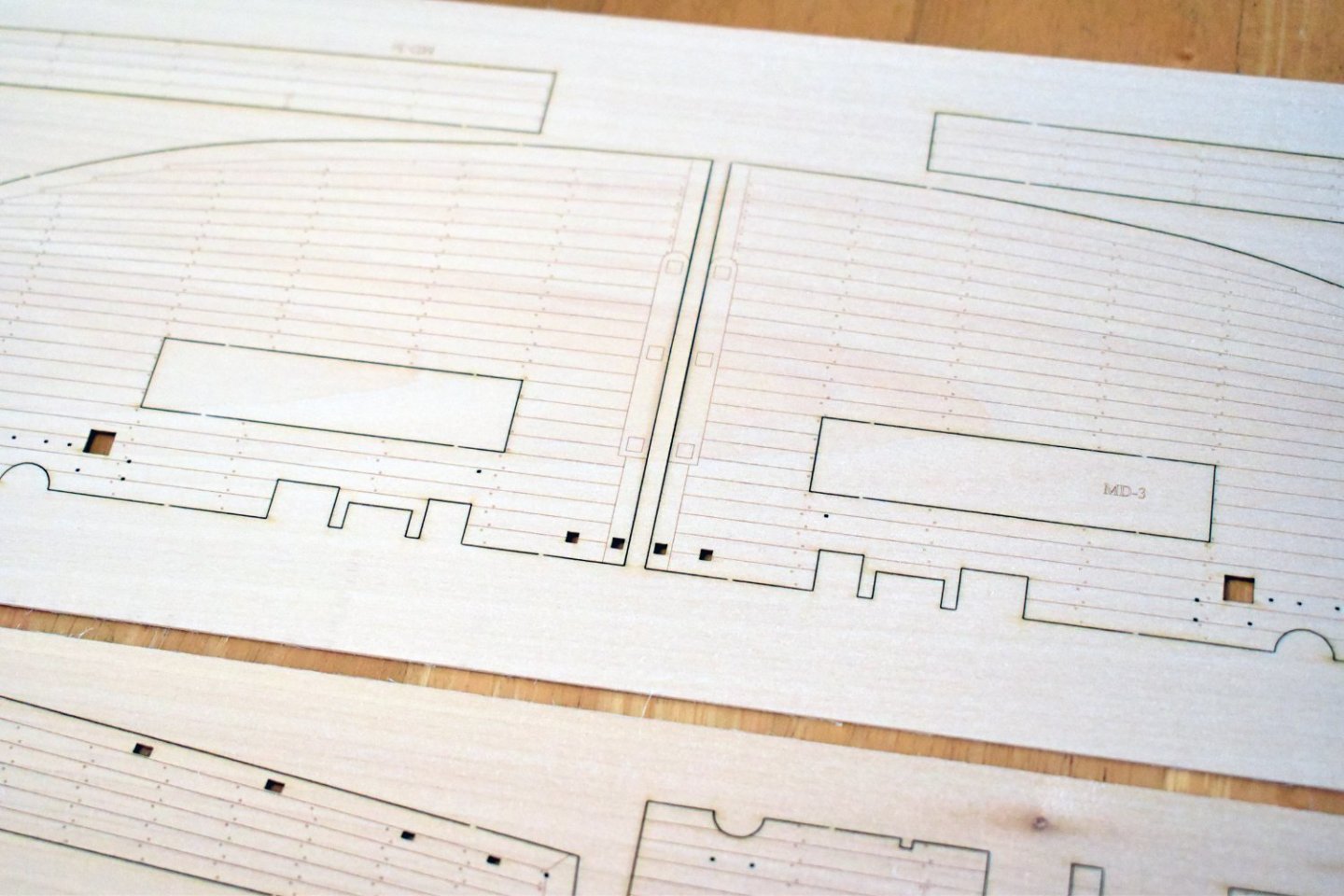

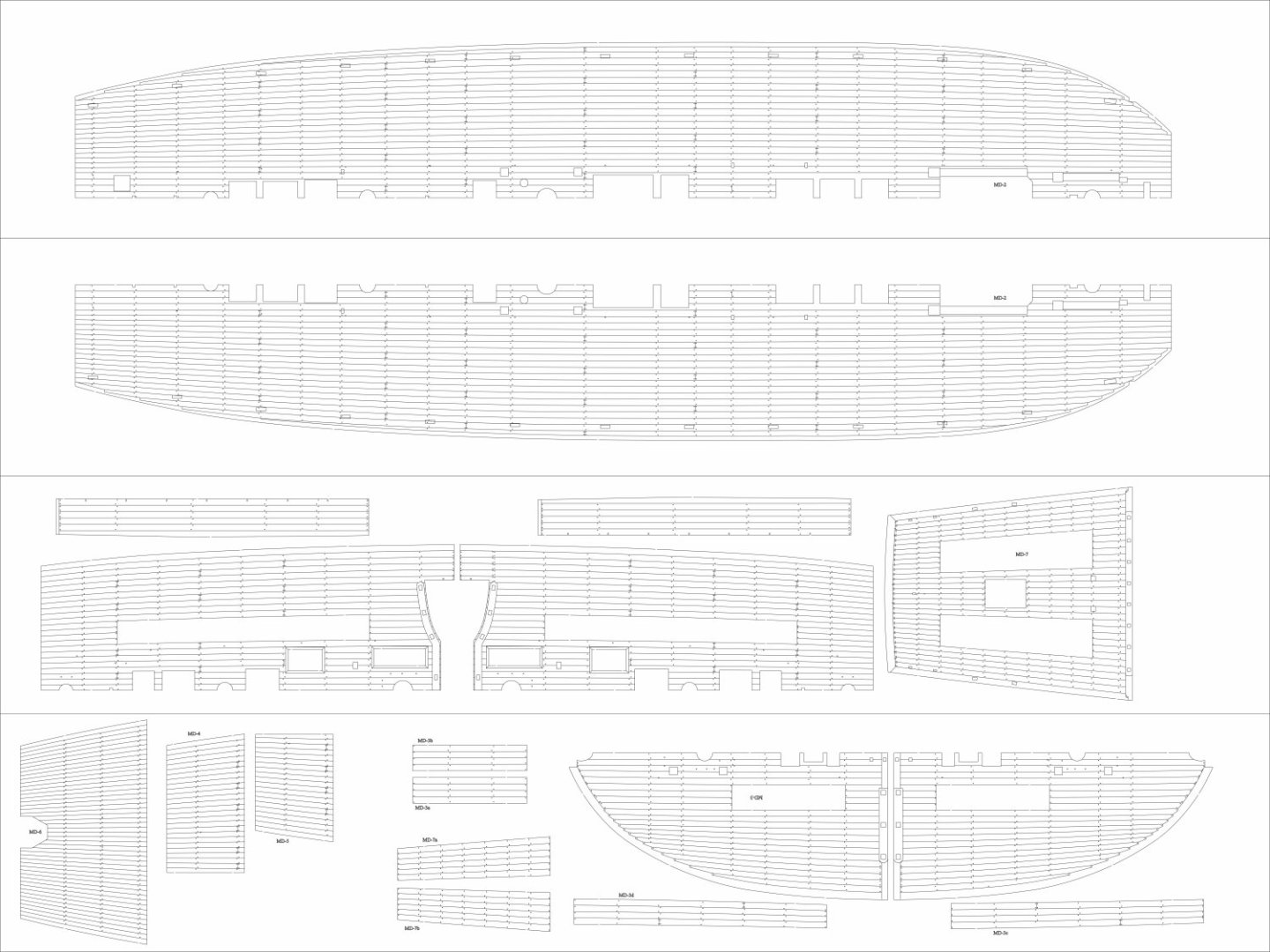

For those that may be interested, I have produced a new file for the Indy laser engraved limewood deck set. It will be on 4 separate 1x150x800mm limewood sheets, as seen on the drawing. The decks have had to be split down the centre, due to width restrictions. I should have three sets ready for early next week, and have a new batch of limewood arriving in September, so can do more if there is a call for them. Speedy printed stuff arrived today, so that's all ready and in stock. (Even has a little binnacle now...) But still waiting for my damn Trial Cutter PE......

-

I did think about doing the main wale, but in the end, decided against for a couple of reasons. The first is the length of pear required, well over 800mm. The second is that it is very wide, and one piece laser cut part would have been a nightmare to glue down flat in all areas. I did think about having separate planks laser cut, but I know for some this would be a disaster, as everything would need to align perfectly around the bends, with wide gaps appearing because of the curvature of the hull - meaning these edges would need very careful bevelling in order for the gap to be very tight, and all the time hoping you haven't bevelled the upper edge away. (I did actually try this method with Sphinx when developing that kit) That was my thought process, so in the end, decided with the tried and trusted planking strips, which I know all could acheive with little issue. So, it is not because I didn't want to, it's just that the standard method made more sense for such a large model.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

OK, the updated Speedy is now live: HMS Speedy – Version 2023 – VANGUARD MODELS These will be ready to ship early next week, as I have the printed stuff arriving at the end of this week. The old manual is still avaialbel to download and the updated manual is now also available to download. The ladders and gratings option have been deleted, as these are all included with the 2023 version. Regarding Trial Cutter, it is very frustrating for me, as I am still waiting for a delivery date for the phot etched sheets. These are all I am waiting for, with everything else ready to go.

-

I have actually designed quite a few kits in the range that are aimed primarily at the complete beginner. They cost a little more because there are more pre cut parts, and in more suitable materials.

- 16 replies

-

- Lady Nelson

- Victory Models

-

(and 1 more)

Tagged with:

-

That is a shame, the perils of eBay purchases!

- 16 replies

-

- Lady Nelson

- Victory Models

-

(and 1 more)

Tagged with:

-

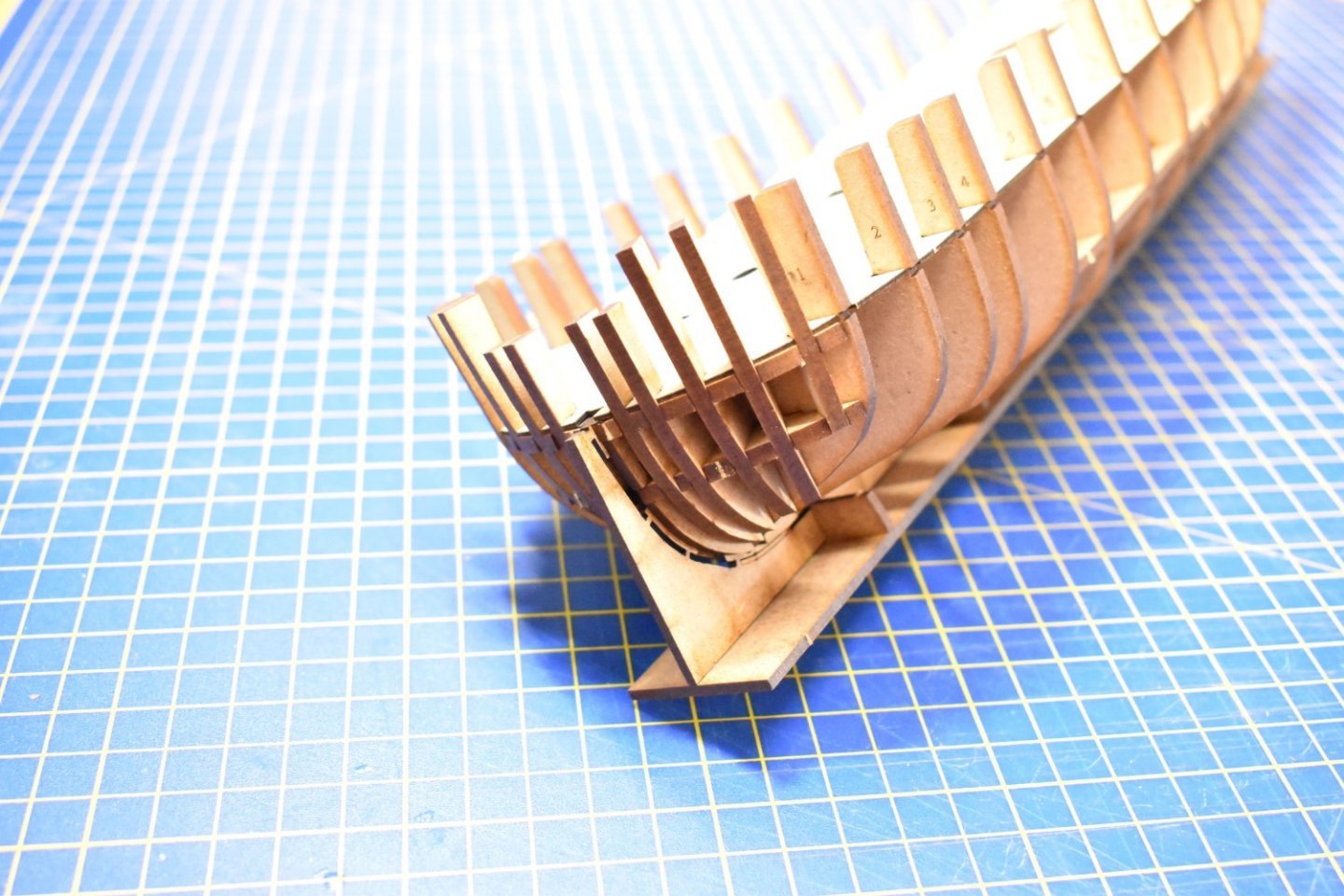

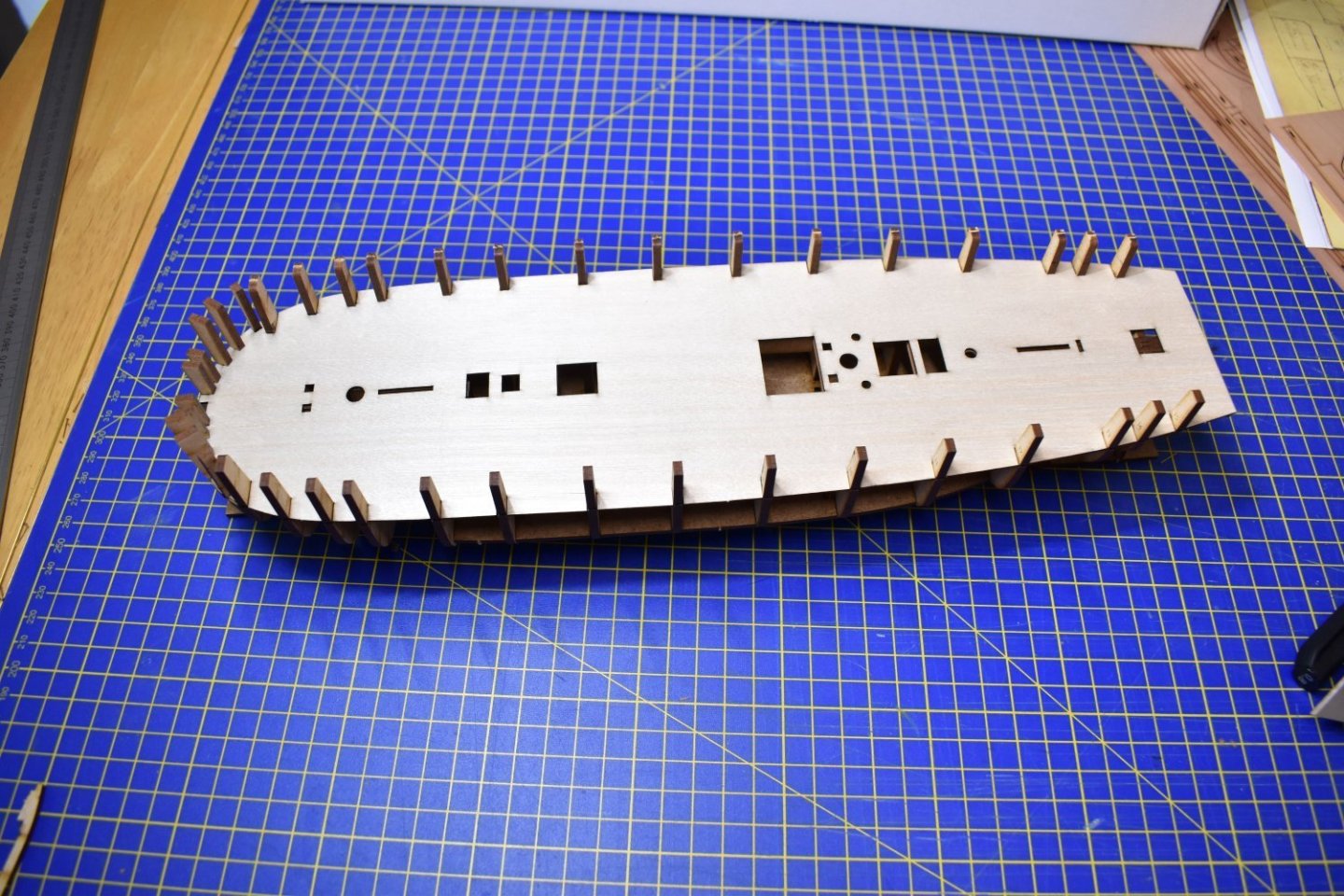

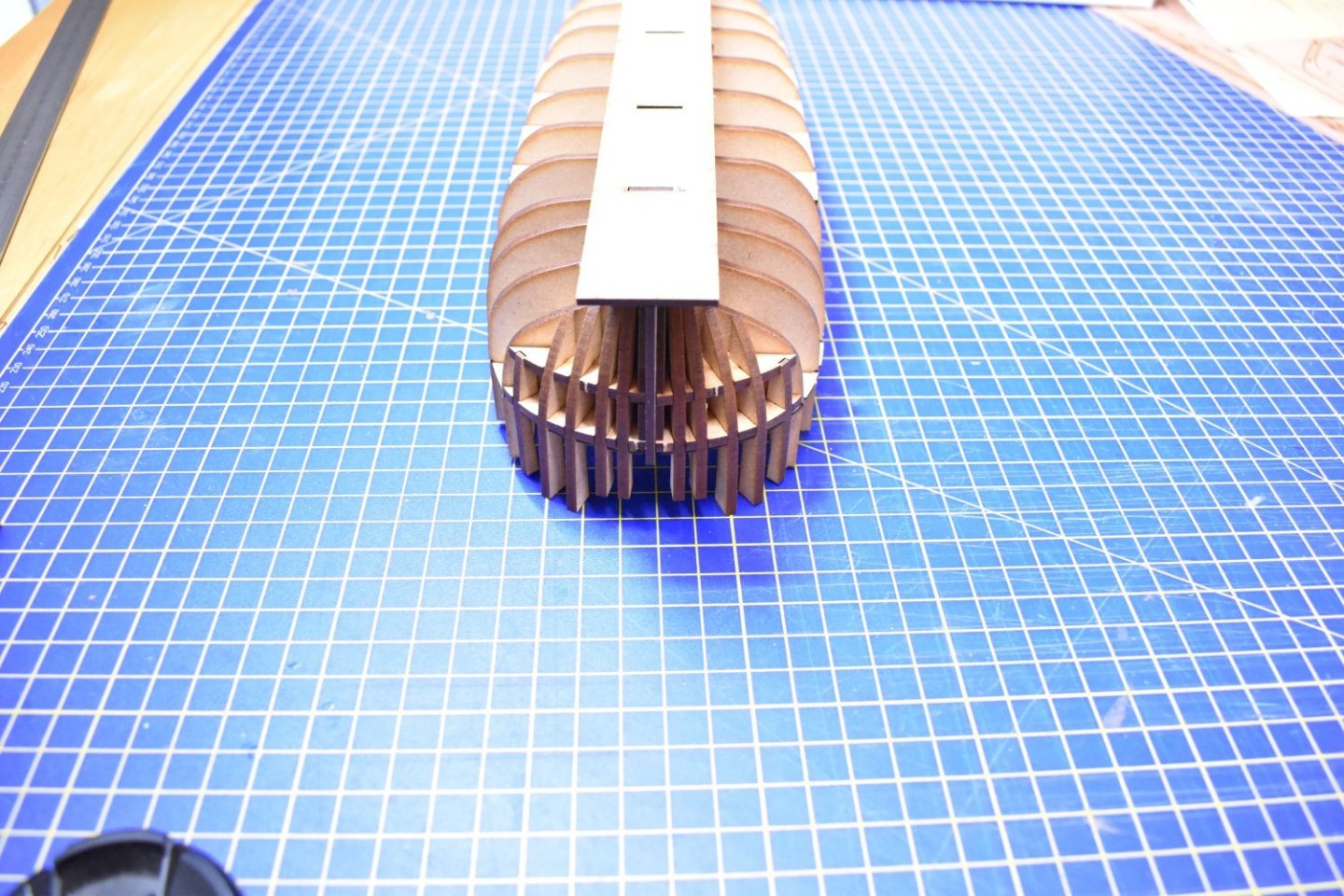

OK, I have just finished what I need to regarding building up the new Speedy hull. These pics will show what has changed. The old Speedy required planking all the way to the top of the bulwarks, also the inner bulwarks. The new version is completely pre cut from the main wale up, with spirketting added for the inner bulwarks, plus engraved planking and treenail detail for all surfaces. All channels, inner bulwark belaying racks and cleats now slot and glue into place, in pre cut slots, saving the need for pinning and gluing. Please bear in mind that the model shown has no real finishing, no varnish etc. It was used just to add new pictures to the revised manual. I will now spend the rest of the week updating the manual, ready to send to printers, and next week, start cutting the new sheets, so I hope to have this re released in around 2 weeks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.