-

Posts

2,350 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

The kits are made up in batches, which my wife does, using a picking list drawn up by me. I can accommodate the odd change, but what I cannot do is offer an 'A La Carte' choice for each kit, as they have been developed from the start to be full kits. So, something like Indy (or even Sphinx) would become an absolute nightmare to produce if they were not all the same, there are just so many parts.

-

The problem is that the parts for masts are also on the PE and laser cut sheets, which also contain hull parts. I have said this before, omission of dowel, blocks and rigging thread would not have much of an impact on the overall kit cost, as around 98% of the costs go into the hull - plus you would still need 7, 5 and 3mm deadeyes for the chainplates. However, for those who do not want dowel, thread and blocks, you can contact me and I will see what I can do - but it will not make much difference to the cost.

-

I will need to wait until Jim has finished the hull. I will then release. I am hoping to implement pre orders in December and the actual release being in January. By December, I will have all remaining parts I ordered here with me and all laser cut sheets done (I started this before Summer!). I already have the PE sets here, and all castings are done and packed. I should have a pear block and deadeye option available too, by the time of pre order. For those that may ask, yes, the Indy will contain all parts for masts and rig, there are 9 x 980x680mm plan sheets for masts, yards and rig; and all dowel, rigging thread, blocks and laser cut parts are included, as usual.

-

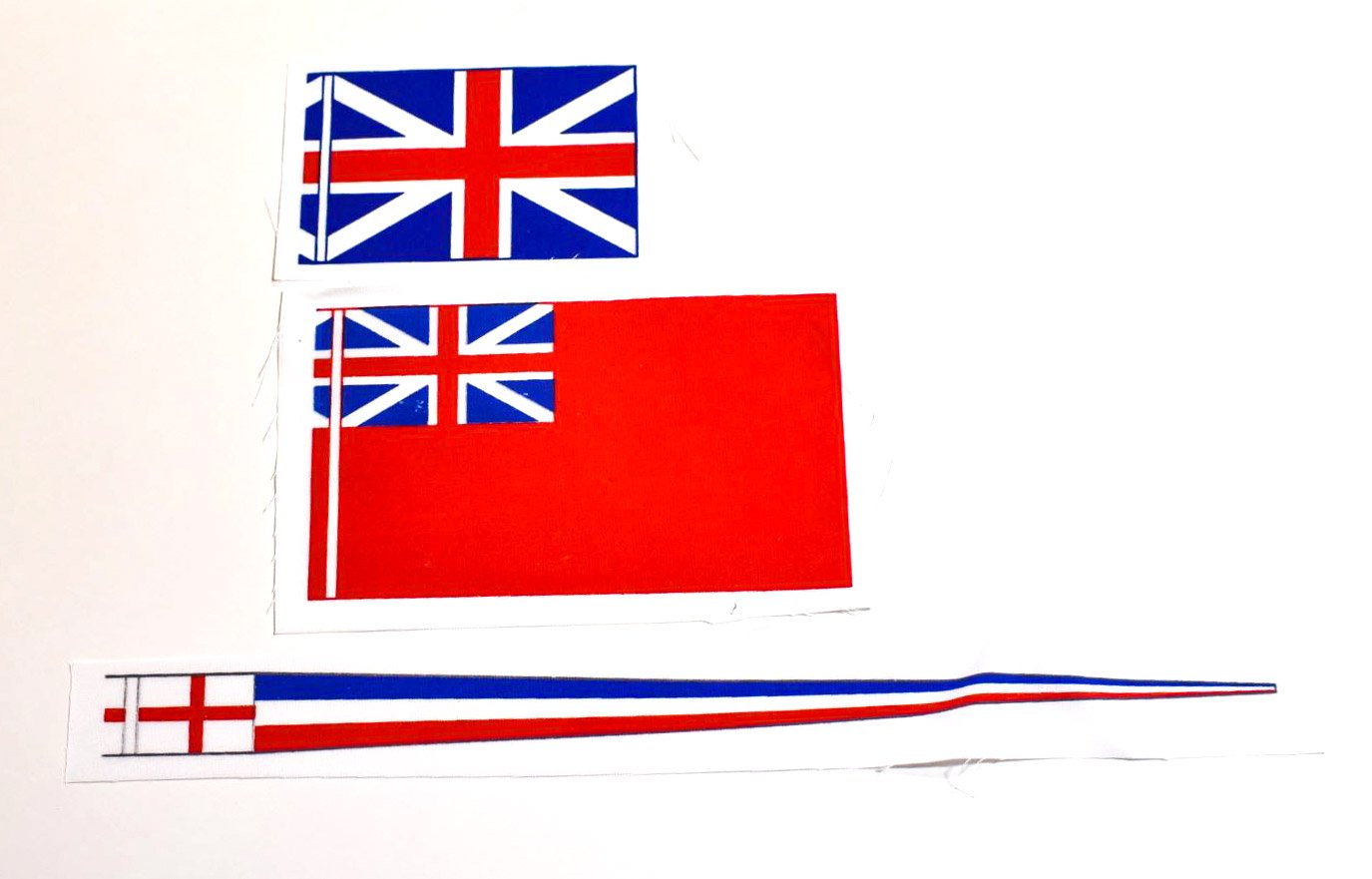

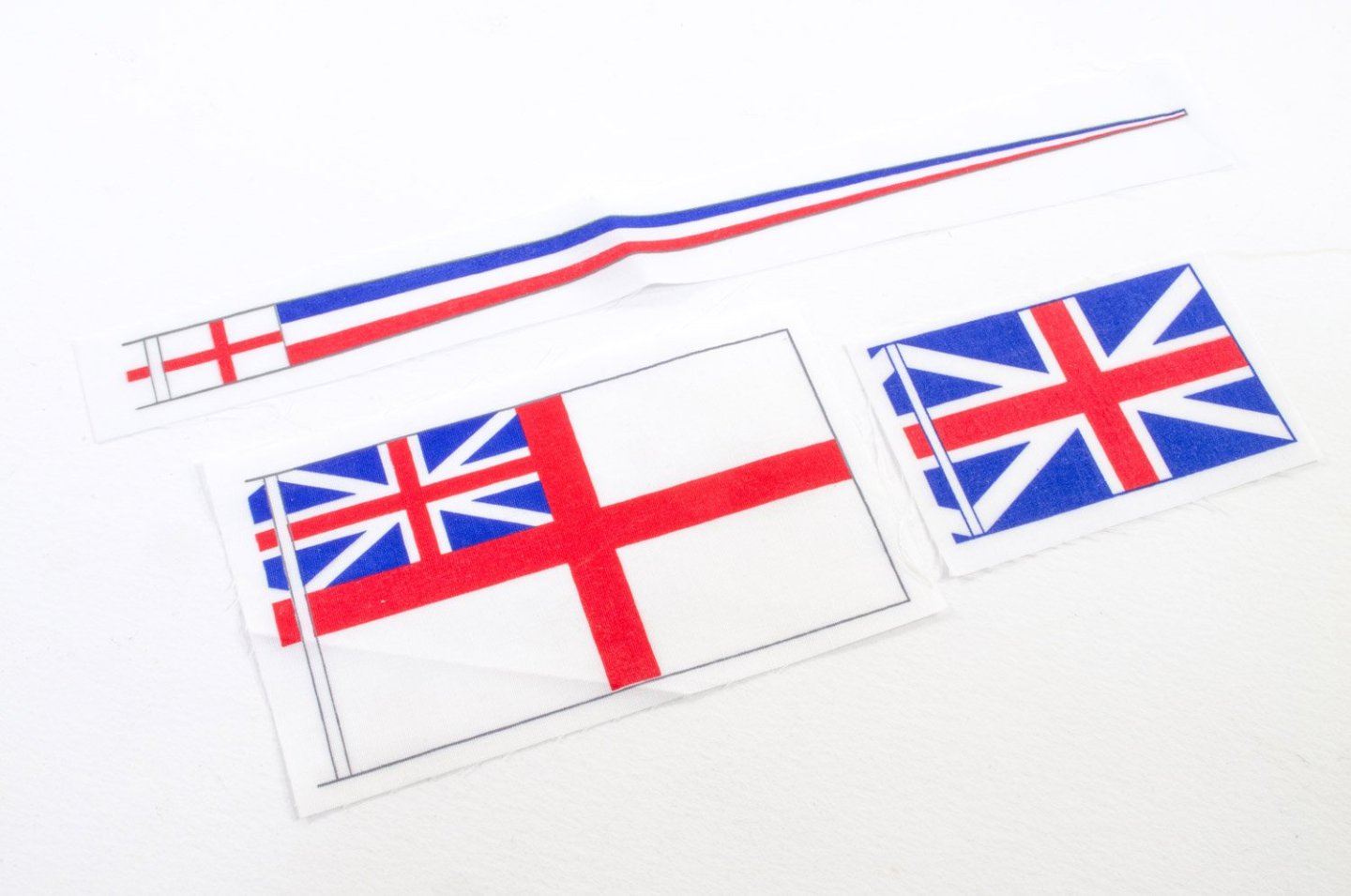

Another little update. I am certainly getting quite a few by products from the Indefatigable development - figures, paint sets, and now flag sets. I initially purchased the flag sets as an optional extra for the Indy kit (and they will be), but as I have them here, they are now for sale. I have a red ensign set and a white ensign set. I may get a blue ensign set for completion at a later date. They are: Red or white Ensign (120x70mm) 1707 - 1800 Union Flag (75x50mm) 1606 - 1800 Tricolour Pennant (255x17mm) 1661 - 1850 Flag sets – VANGUARD MODELS And talking of Indy, today I finally completed all plan sets, there are 26 sheets in total, all 680x980mm in size. Next week, I shall start on the manual. And finally, moving on to decks... OK, regarding pre-engraved decks. I need to rethink these due to batch after batch I order being no good. The maple veneer of late is like the picture attached, so is useless for decks, and the maple sheet scrap rate is now way, way too high. I ordered enough 0.8x200x800mm maple sheet to produce 60 Indy kits worth, but in reality, I can get about 15 kits worth from the whole batch, due to knot holes and too much colour variation and/or 'tiger striping' the same as can be seen in the maple veneer pic. I ordered very large sheets (1.5x2.5 metres) of both maple and birch veneer from another supplier, but again, no good for decks due to too strong a contrast in patterns and colours. With this in mind, pre-engraved decks for Indy will be very few. My last option is to try limewood, as this is the most neutral of woods for colour variation. What I do know is that I am done wasting literally hundreds upon hundreds of Pounds on veneer and sheet that I cannot use, hence scrap. With this being a natural product, I have no comeback, so I cannot afford to keep gambling with each order I make any longer. The smaller kits are fine, up to Sphinx size, but for anything larger, it is a problem. I have one more avenue to go down for Indy, and this is with limewood and alder. I have ordered some sample sheets to see if this would do the job.

-

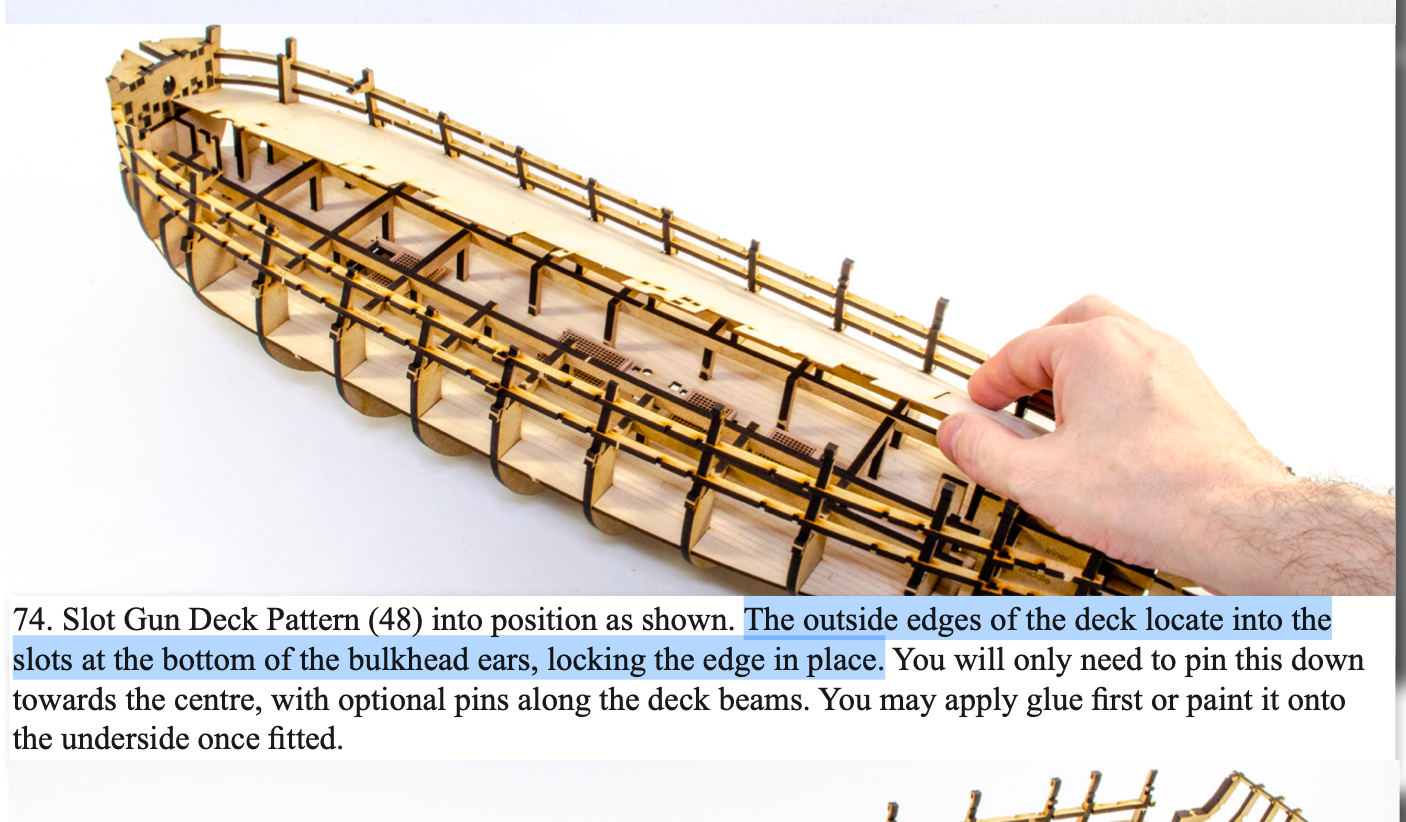

I cannot stress enough just how important it is to thoroughly read the text in the instruction manual. Each model has been built twice (at the very least) before it even enters kit form, so we know the methods and parts work well - but this is very dependent on the modeller reading the text that accompanies the pictures in the manual.

- 426 replies

-

- Vanguard Models

- Sphinx

-

(and 1 more)

Tagged with:

-

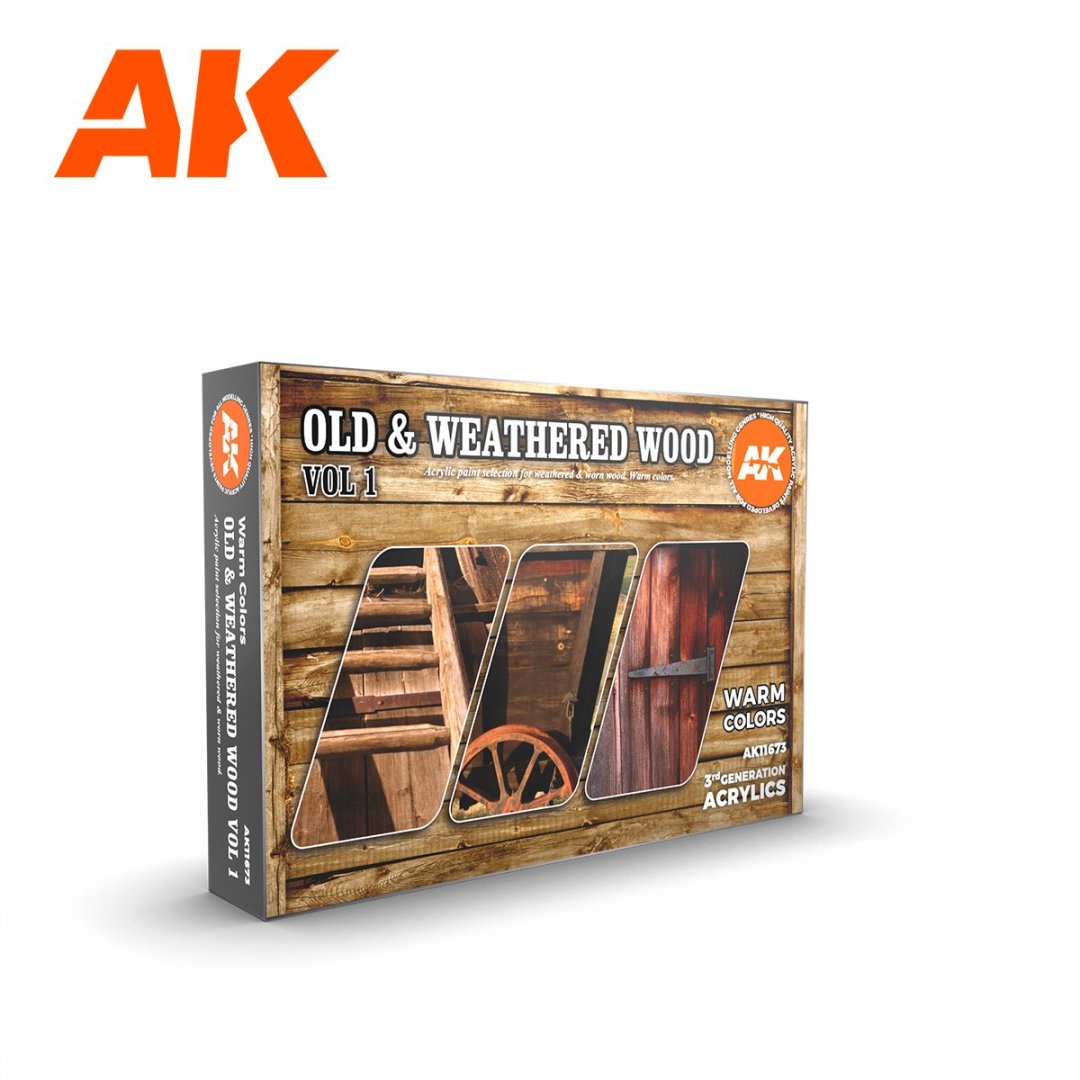

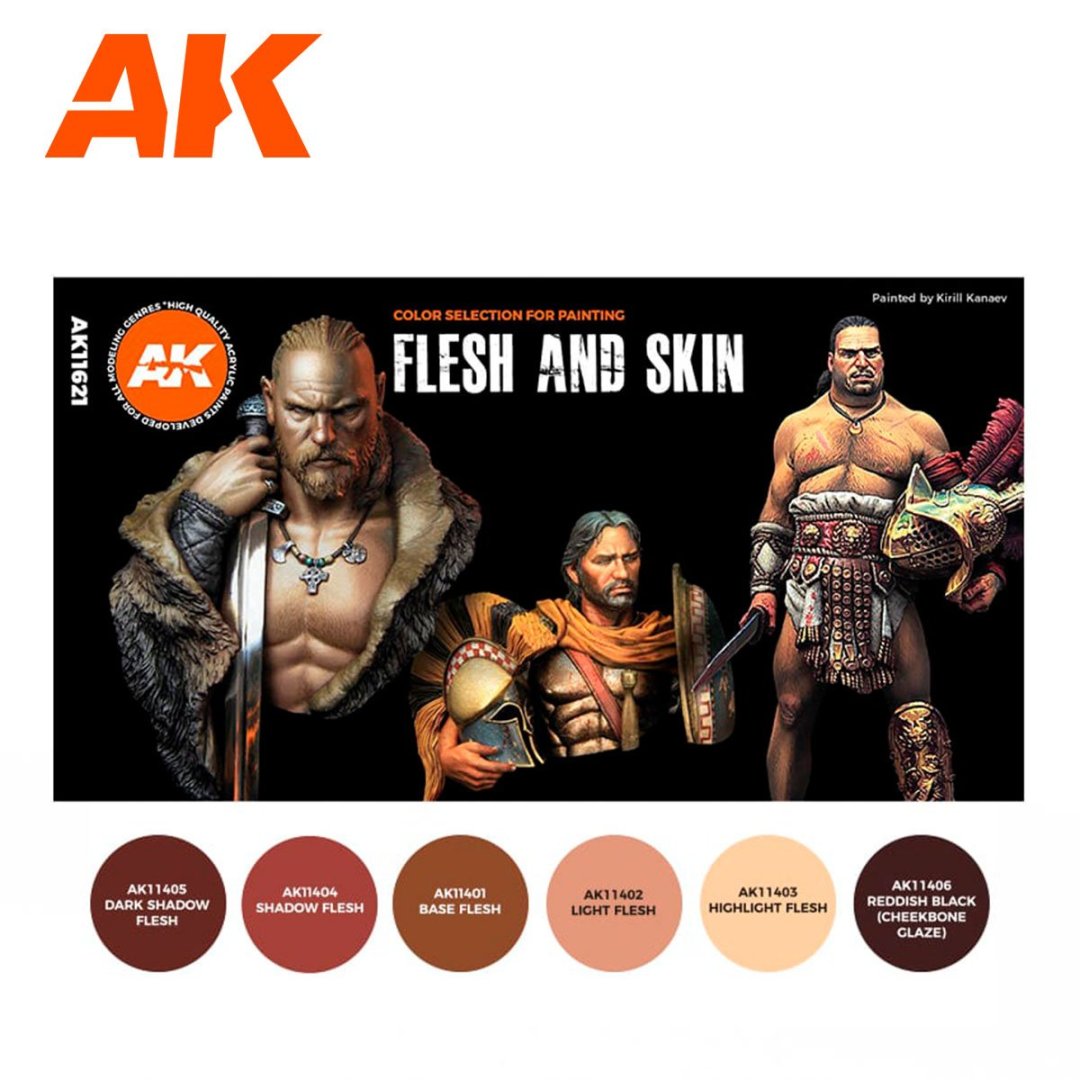

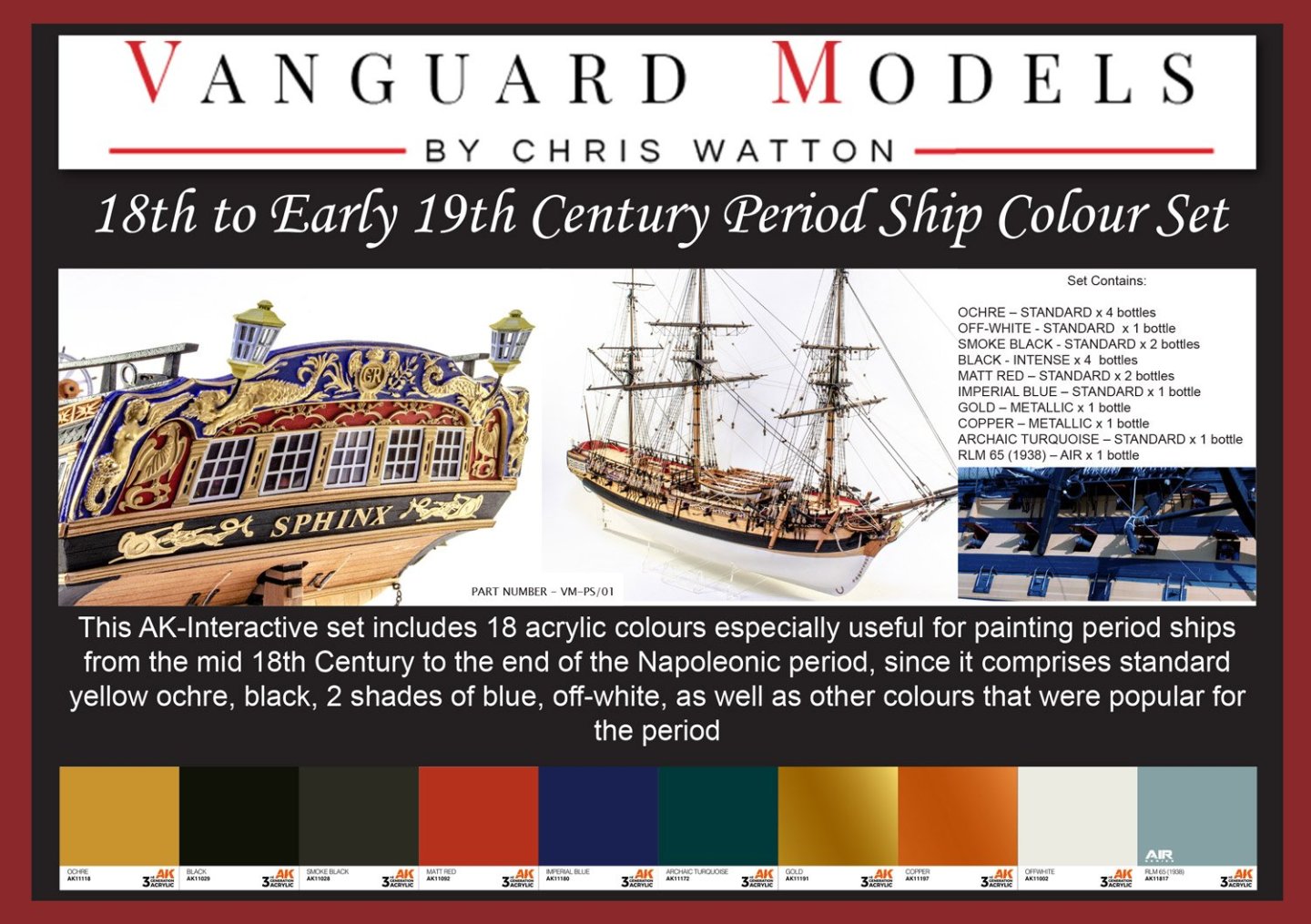

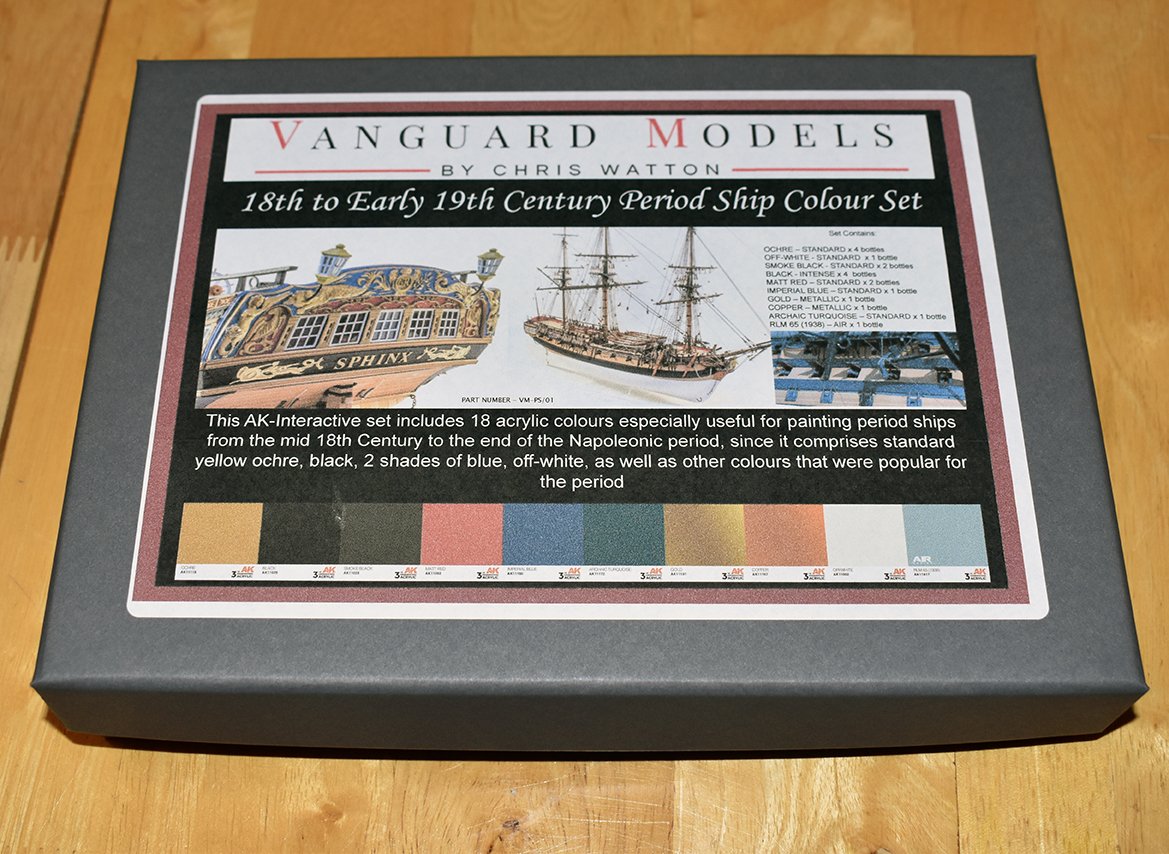

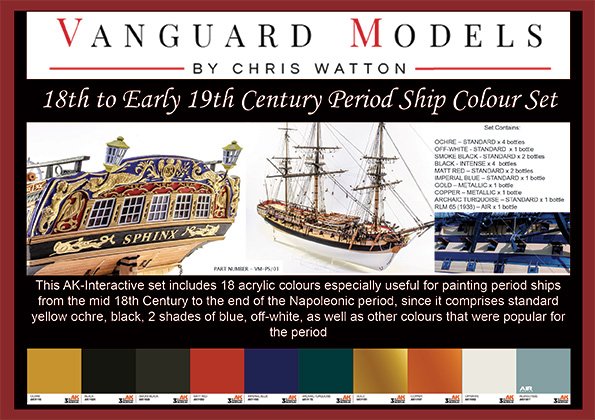

In the next week or so, I will be adding an 18-bottle paint set to my range. These will be AK acrylic paints, which can be thinned using ordinary tap water. The set includes all paints used on Indefatigable, but also used on the rest of the range. The bottles shown in the picture are not the ones that will be in the set, I am awaiting shipment of my specially chosen paints from AK Interactive, which is imminent. The set should be more than enough to paint a model as large as Indefatigable.

-

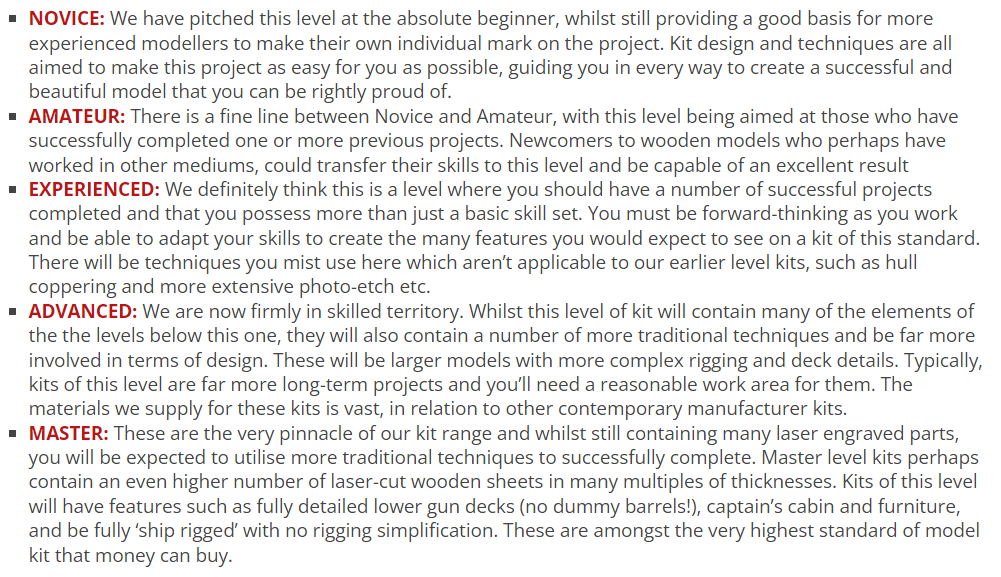

Just a little update. We have listened to some customers, not being sure of skill levels for my kits, so we now have skill labels for each kit: I am hoping this helps some modellers. On the Indy side, this is still progressing. Yesterday I received the photo etched sheets (25kg worth), dowels, first planking and red alder deck planking.

-

At some point, yes. However, I am currently so snowed under I am having difficulty in finding the time to produce all my current stuff! (Not that I'm complaining). Laser cut anchors will be slowly phased out in favour of 3-d printed ones.

- 857 replies

-

- Sphinx

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Looking very good, Glenn, you should be proud of that!

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

I can tell you how tall he is in 64th, around 27mm. Have to guess a little due to hat, but my carver was given full details, including height. No Hardy figure for the foreseeable future. I commission the figures, the captains/admirals especially, for my own developments. As I have no plans to ever develop a Victory again (already done two in the past), I very much doubt I would pay to have a Hardy figure commissioned. When you say 'many' would buy, the hard truth is that I may sell 5-10 Hardy figures per year, taking many years before I even broke even for the cost having the figure sculpted in the first place. Anyway, no more figures for a while, all hands on deck for Indy development...

-

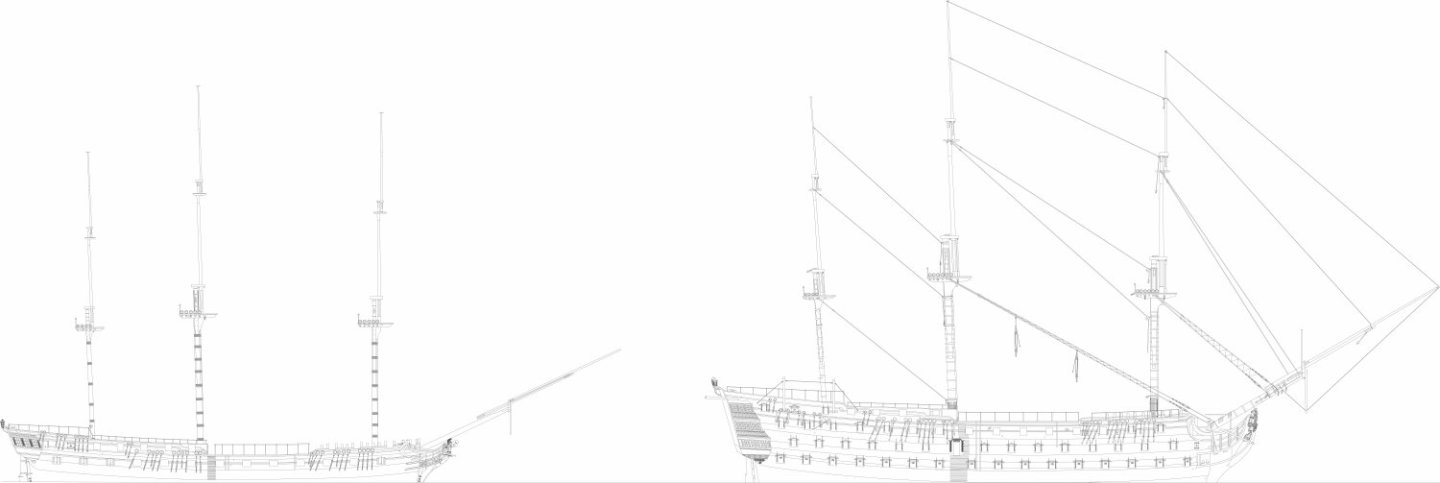

I note Jim has compared the hulls of Indy and Victory in previous posts - Here is another comparison, both at waterline level.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.