-

Posts

2,339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

No problems at all, it at the very least gives me a chance to explain certain aspects of design/material choices. ETA - I did the top of the ship's pumps for the same reason. I designed them initially in 3-D CAD, but the people who do the casting for me told me the parts were too fine to be cast correctly, they would need 'beefing up'. I preferred to keep the scale appearance, so opted for PE parts instead, as they look better, more 'delicate' when in place and painted. Again, commercial choices were out of the question.

-

I know that for the Amati 64th scale Victory, I had to choose the smallest belaying pins Amati did. Up until then, they were hardly ever used, as most 'chubby' wooden ones went into the kits or shiny turned brass pins. What I used for Victory I just about got away with, scale wise, as the model is so large anyway. I just about managed to add every belaying pin that the full size ship had. If you look at most commercial models, there are a lot less pins than the real thing, this is because what is used in the kits are comically over size.

-

Hi I am sure I explained my decision to go for PE belaying pins. Top be honest, I have no problem buying standard belaying pins, cost is definitely not an issue, they are so cheap. The problem was one of size, the smallest belaying pin I could buy was a lot larger than the actual scale size pin. Perhaps we are all too used to seeing oversize pins on model kits, and think it is the norm. When drawing the pins from scale drawings, I was initially surprised at just how small these were in 64th scale (As I too am too used the standard fare). This is when I took the decision to make them in PE, for true scale appearance. What is the point of endeavouring to design all parts as accurate as possible, scale-wise, and then using big fat oversize belaying pins. Cost doesn't enter into the equation, as far as I am concerned, I just was as much scale accuracy as my budgets will allow - and costs for standard belaying pins doesn't even come into the equation, so please do not think for a second they are in PE due to cost. In fact, the PE is one of the most expensive materials that go into kits.

-

Hi Guys (and gals), Thank you for all of your very constructive comments, they are all very much appreciated. I have been very busy, but busy doing many things. Regarding the friezes, I will look into this once I need to look into it, and I promise, I will be like a dog with a bone. My gut instinct is telling me that very thin high quality decals would be the best choice to give the impression of a non-kit finished model. I want the models to look as if they were not built from a kit. But I have no idea of costings for such decals yet, and I do not need to think about this for at least another 6 months. I know how I want the finished models to look, I just need to find the right solutions to achieve this. PE works well because it is nigh on fool proof. What I have been concentrating on is getting the two little kits ready (working on manuals right now), and learning more about what is and is not possible with my laser machine. I have spent a lot of time trying to figure out a better way of lying the materials on the laser bed. The one that is specific to my machine has the optional honeycomb bed, to which the material rest on during cutting. My issue has been that the honeycomb grid is spaced to close, about 10mm square. This gives the back of the material a 'char grilled steak' effect'. To counter this, I am having a set of conical stand offs made, so the material is only sitting on a few points. I have experimented with some makeshift stand offs, and they seem to work very well. What I want is both sides of the material to look as clean as possible, and this problem is sorted. I have to still lay very thin materials like 0.8mm ply and 0.6 veneers on the honeycomb bed, as they need taping down, but for the rest, I can lift up from the main bed for a much cleaner cut, especially to the underside of the materials. I have looked at some of the earlier cut files for Alert and Speedy, and tweaked where necessary (Alert 3mm MDF now have less tabs on the bulkheads, and the tabs are all located on the top of each sacrificial bulkhead tab). After the two fishing boats are released (all laser cutting and PE has already been done for these), HMS Flirt will follow, I have ordered all of the wood and other materials for 18 very special Master Shipwright versions of this particular kit, and I think that some may appreciate the material chosen. The standard kit is different enough from Speedy that it will have new plans, manual, PE and box - but I do have a very good friend building this for me, so I can concentrate on the next main Vanguard Models kit. Talking of boxes, due to the current situation, I cannot use my usual printer and supplier, so I have had to order plain white corrugated boxes for the Lady Isabella and Lady Eleanor, and will have to paste a large colour label of the box front. And that's it, that's what I have been doing. Fishing boats will be ready for release in around 3 weeks, then Flirt, and in the meantime, I will concentrate on the next main kit. Right now, though, I am knee deep in Abobe InDesign doing the fishing boat manual... One last thing, I have an Easter offer on all kits at the moment, with 10% off kits, including Master-Korabel. Cheers! ETA - regarding flags, they are something I will give more thought to, as I would like to include them at some point, but right now, material costs are high (as I am bringing out three kits very close together, time wise), so need to make every penny count.

-

I have always been of the mind that I do not care what materials are used in the making of a scale model as long as the finished model looks accurate. This is one aspect of modelling that I have never changed my mind about - As long as it looks right, I really do not care what the material is under the paint as long as it is stable. Plastic strip is used a lot, especially for thin upper rails, and 1x1 wood can look a little too rough, sometimes even split slightly when curving around the bow area. Ribs for boats are usually done in 0.5x1 plastic strip with the end result being better scale accuracy in most cases. For commercial, you cannot assume too much, and you most certainly cannot assume the modeller is going to want to paint on the frieze work themselves, that would almost equate to a 'semi-kit'. So it's either PE or decals - but not paper. But bare in mind that these are my own thoughts, many others will have differing views, depending on what works best for them.

-

I first did the thein PE brass friezes with Fly 16 years ago, and it does seem to work well and look good. However, I was always aware that the friezes were painted onto the hull. A few of my future developments have this painted frieze work shown on the original models and in some cases, the plans, too. To my mind, the best solution would be high quality waterslide decals (not paper). I have a couple of contacts for this, and when the time comes for me to look into this further, I will weigh up the options.

-

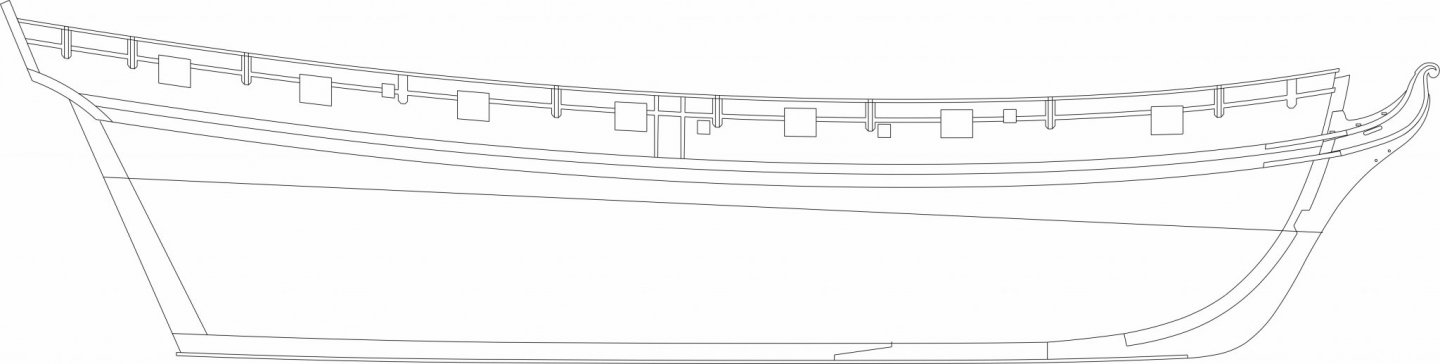

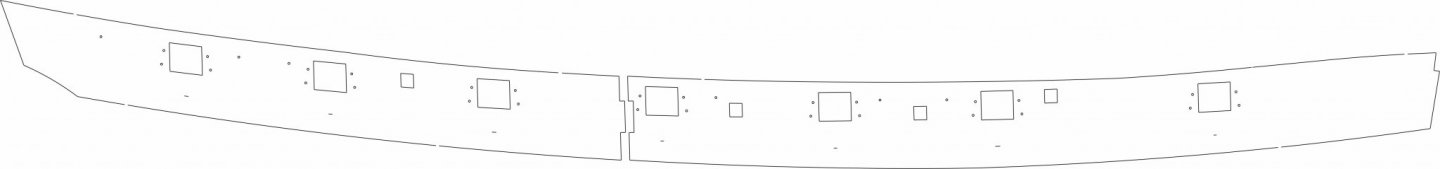

Here is a line drawing taken from Speedy designs, please note the gun ports, they are the same for the pre-cut patterns, as they are taken from the pre-cut patterns. They are the same as the original Admiralty draft. I am assuming optical illusions come into play with some pics. They are all 90 degrees to the keel, vertically, but almost follow the sheer, but not quite, as per the original plans. ETA, Just included the actual laser cut patterns for the gun port parts

-

Agreed, the stern doesn't look half bad at all, they have made improvements. Regarding parts of the stern interfering with the windows at the centre, just mark and cut some of that area away both on the main keel at the stern and the pattern that intersects it, It will make little difference at all to integral strength, and you can use your LED's.

-

Rigging, for the most part, is easier than some think. Once all the blocks have been added to the masts and yards, it really is almost as simple as a 'joint the dots' drawing. Once shrouds and ratlines are out of the way, it is 'plain sailing'

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

-

Hi Ian, Same with upper decks, they were all just laid in their lengths, but I know many prefer to use shorter planks to simulate the correct lengths for each plank, to create the 3 or 4-butt shift planking patterns. Regarding scuppers, Vanguard is 72nd scale, so the holes would be tiny. There is nothing stopping you adding them if you so wish, though. I think I added them to my old Bellona prototype

-

Cyano has always made my eyes water, like Sea Hoss, I now use a fan and it isn't so bad. Looking great, by the way!

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

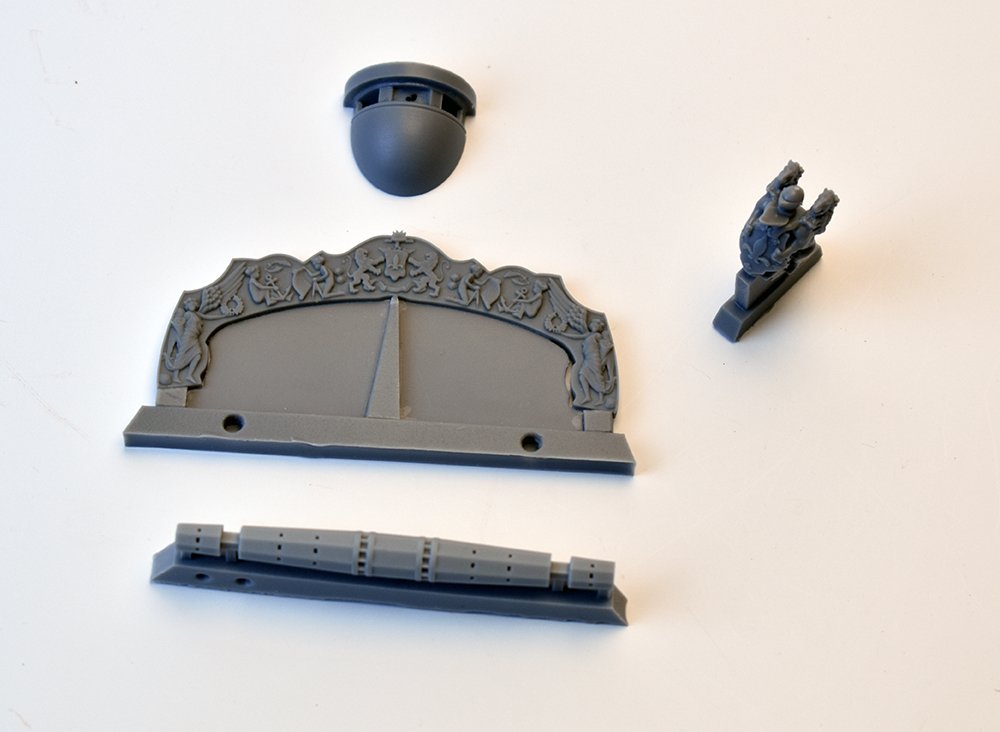

As soon as I have completed the two little kits, that one you shown is next, that is what the resin castings I posted up yesterday are for. And after that, I will be concentrating on the larger stuff. ETA -I decided to do the two smaller kits first, as there were a couple of new things/ideas I wanted to try out, to see if they worked well enough to implement with the larger main kits. They do, so they will be integrated in with my third main kit.

-

You are right, thank you. I will leave things as they are. If I'm honest, I too wasn't sure I liked it. I know some do not like stands at all, and prefer columns, but I also know that some kits come with no stands, something I never really understood, and the majority will use the acrylic stand provided. But of course, a few will use columns, which is also perfectly fine.

-

Bristol stern would be larger, Bellona larger still. here is Bristol stern above the other.. ETA - I am sure I have never shown this, it looks a little worse for wear now, but here is a pic of the original Alert prototype main winch drum that I designed using laser cut and PE parts. It made up great, but decided it may scare some novices off, as it is made from quite a few parts. It was replaced with the white metal version, which in turn was then replaced by the resin version..

-

Oh, almost forgot, I had these arrive this week, resin casting samples for me to build the prototype model, which will be the next main VM release (after the 2 little fishing boats, which I should be able to complete over the next three weeks - but then have to wait for other things related to them, due to lockdowns..). cannot wait to continue with the kit development these castings belong to, though..

-

It is actually Speedy's sister, Flirt. As I have a little more time on my hands that I thought I'd have, I decided to compile a set of cut files for Flirt. There are changes, as the vessel will be depicted 'as built' rather than the later guise that Speedy is depicted. No copper plating for the bottom, but 'white stuff', and no flying jibboom. Stern frames are cut in 2mm birch ply, this will be incorporated into future Speedy laser cut runs, including the lower deck 2mm Ceiba or poplar plywood with etched deck detail. In the meantime, I am finishing the two small kits... Am thinking about a different stand, what about this, the base is 4mm MDF and oak veneer, and the acetate cradles are a push fit, no gluing?

-

Not quite in a position yet, but my aim was to get the Zulu for around the £145 price range and the Fifie for around £125. They may end up costing a little more, as the amount of pearwood in the kits, the Zulu especially, is quite a lot, but what the hell... Sails will be sold separately as they are very expensive to have made, so if they were included, the cost of the kit would be a lot higher, and perhaps some do not want, or would prefer to make their own.

- 100 replies

-

- zulu

- vanguard models

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.