-

Posts

2,336 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

Very nice work, a true scale model. Regarding the cupola, was it common for these to be copper, or specific to this particular class, do you know?

-

Well, I did have my pre-prototype parts for the third development arrive today. Unfortunately, the 3mm MDF was cut in the wrong thickness, and was in fact 3.5mm. This meant I could not put all of the structural parts together, as too much filing/sanding was required. Instead, I now have to wait until next Tuesday for the replacement 3mm parts . I did managed to just put together the bare bulkheads and decks. But I was hoping to check out a different way I have designed certain aspects to allow for a proper rabbet for the second planking, and see what you good people thought. This will have to wait until next week now.

-

The pictures of some of the build are on this very thread, the build starts at the orlop..

-

I remember going to a model boat show years ago, and one guy was asking about the kits on offer and then when I told him the prices, he was shocked and said something along the lines of 'But how does this one cost more, the cheaper one has a bigger box?' This is what we have to deal with occasionally...

-

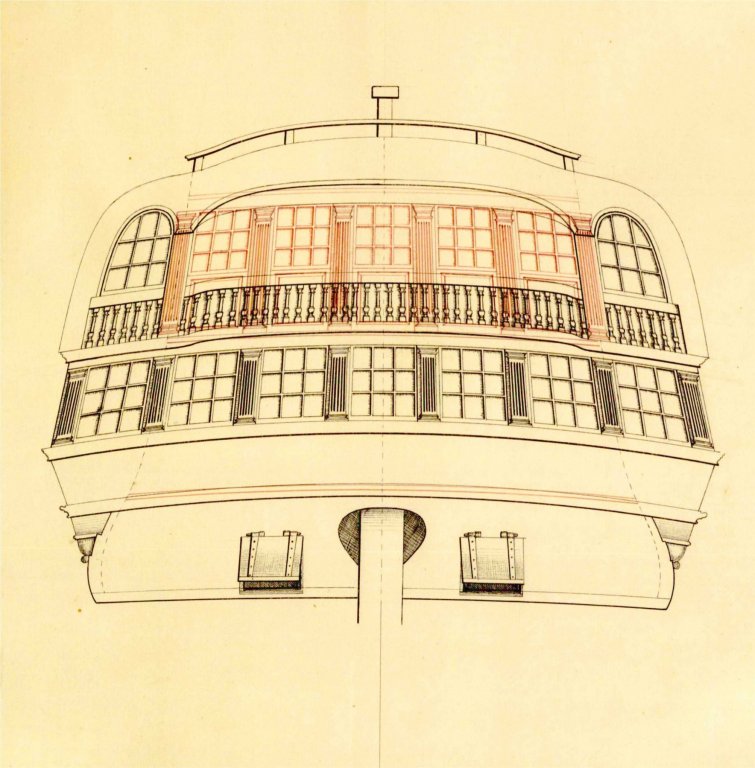

Very nice model! I know Rif Winfield's reference, but the problem is that the original Admiralty plans show 7 windows for the only official contemporary lines for one of the (full two decked, not razee'd) Ardent class. This is the conundrum.. Funny you mention HMS Temeraire, I have been reading The Fighting Temeraire during my tea breaks at work, and it is almost exactly like Victory, if a couple of inches longer. Not much of a career though, only Trafalgar and few much lesser actions. I will be glad to move on from models that have very fragile sterns! But Speedy isn't too bad at all. I designed that Aggy two decades ago, where does the time go....

-

I can say quite categorically that the stern on the 64th scale Victory is not too flat, it has the came curvature as per the plans. Regarding price comparisons with other kits of Victory, please bare in mind that there is a hell of a lot more to this 64th scale version, no other kits have full deck detail for all three gun decks - no dummy barrels.

-

Thank you. No, they were digitally sculpted using contemporary portraits/paintings as reference. Because they are in digital form, the scale can be changed. However, there is still a cost involved, as each master has to be 3-D printed in very high definition, so no details are lost for the production resin castings.

-

Easily done, Gary, as I said, it is very easy to get lost with these things, and I do really appreciate your input, which I think is very important for getting things as right as they can be, given the information we have! OK, the Lord Nelson figure is now available to buy on the website, if anyone's interested: https://vanguardmodels.com/lord-nelson-164th-scale

-

Cheers Gary I am sure that Magnanime was another (different) class of 64 (Magnanime/intrepid class, perhaps, Williams design, whereas Ardent was Slade), and not 74? I thought the second round of razees were 74's, the first three being 64's. Being a different design, Magnanime and all others in her class could well have had 8 windows. As the reason for these razee's was to save money and get powerful frigates as quickly as possible, I am not sure the shipyards would have spent time, or the navy money, on altering what didn't require altering. Problem is many of these ships look more or the same! ETA - the Magnanime/intrepid class did have 8 windows:

-

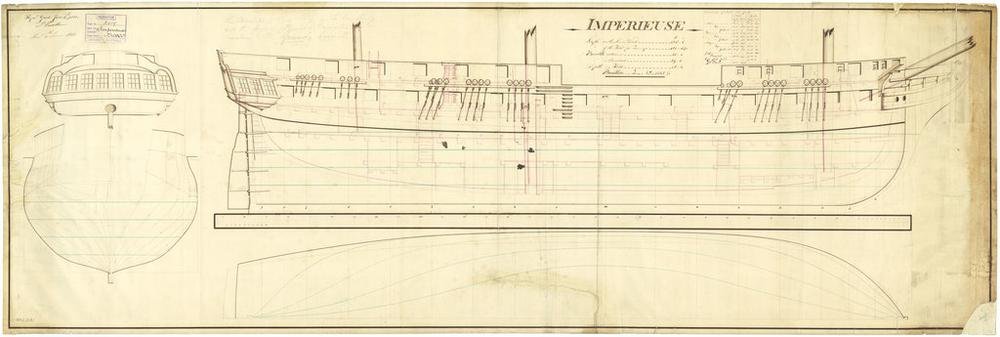

Hi Gary, Thank you. Yes, I have that book. Each new subject I choose, I get as much information as I possibly can for that particular ship. I am sure my book collection has increased by 50% in the past year, especially for frigates, 50 gun ships, etc. I also make sure I order the correct suite of plans, even looking at sister ships to see if they have any info that may be missing from the named ship plans. For Bristol, Royal George, Indefatigable, Royal Oak and Flirt and Speedy, I purchased everything that is available. Those, with the books, give me a wealth of info. I did buy The First Frigates, The Heavy Frigates, and the one you mentioned, which does give a lot of valuable into on the Indie. Will look a little odd with he shortened poop, and an extra gun port will have to be added to the quarterdeck, abreast of the main mast, both not shown on the plans, as they were Pellew's mods. Because I have been reading a lot about Cochrane, I would like to do this at some point, Imperieuse (1804), a large captured Spanish frigate, which Cochrane used to great effect in the med, helping the Spanish against the French. I thought it would be great if I included all of his special boats, and show them with the small carronades, that he used for his many inshore exploits..

-

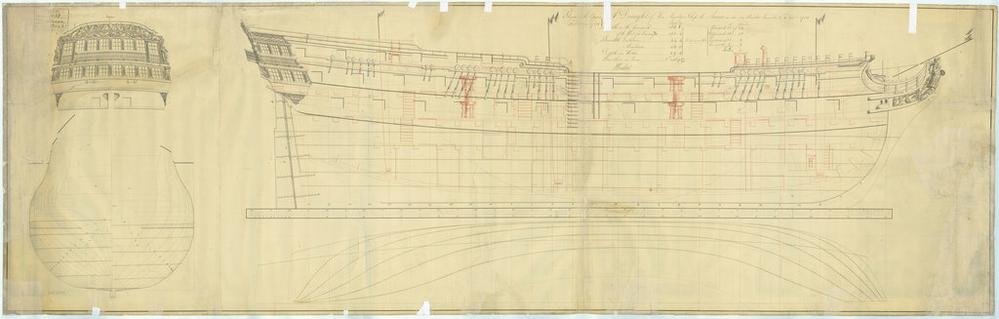

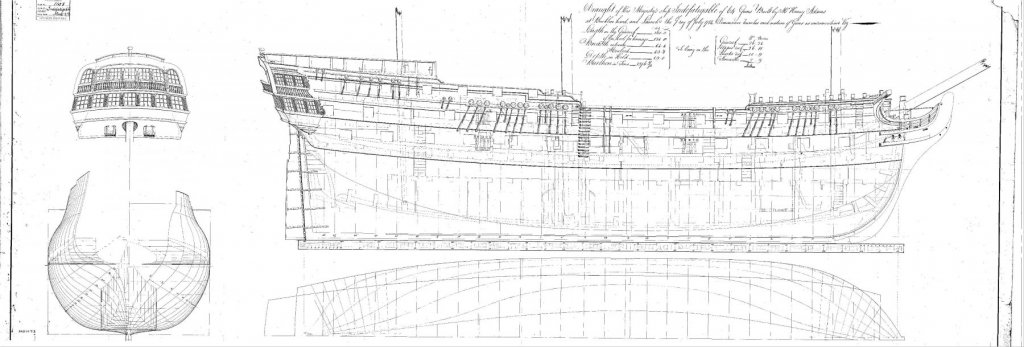

Thank you guys. I will keep the cutter in for the kit. This one I have tried to design to be as easy and as painless as possible to put together, but at the same time, keep all of the detail. This does mean it will be a little more expensive though (especially with the 34 cast resin cannon barrels and laser engraved deck..), but I think it's worth it if people enjoy building it, and it looks nice once complete. Regarding Agamemnon, I think I am edging towards the idea that it did have 7 windows, rather than 8. I know that when I designed my first one 2 decades ago, this info wasn't so easily accessible, so we ordered the Aggy plans, which have no stern detail, and I used paintings and the Bellona book to fill in the gaps. I would never do that now. Hell, I even ordered the Speedy upper deck plan after the main lines because I couldn't quite make out what the hatch was near the stern (turned out to be the bread hatch). I know Bristol (Portland class 50 gun ships) had 7 windows, but that is a full 14 foot shorter in keel length. I have double checked all available plans on the NMM site, and the Indi is the only one of the Ardent class of 64's that shows the stern. I feel that logically, knowing this, I should go with that. If there were alterations after the drafts, then surely they would have been highlighted on the plans? How many paintings, even the most famous, have we seen of ships we know well, Victory especially, where the details show them at a much later stage in their careers than they should be at the time of the battle depicted? I have attached a copy of the full lines plan for Indie.

-

What would you trust more, the original plans or paintings? I cannot help buy feel Agamemnon would have had seven window openings on the lower tier, as shown on the Indefatigable Admiralty plans. I know most ships, most third rates at least, had 8, so perhaps the artists just assumed this, as this is what they were used to seeing?

-

Bruce, I do not mind at all! This is why I put it to you guys on here, who may have more ideas or information than me. Getting the stern right on these ships is important, I just want to ensure all bases are covered regarding research and the correct conclusions - or, as correct as one can hope for. Right, I think I have gone as far as I can with the Speedy build, as I am waiting for the missing 0.4mm PE parts that include the pump, deadeye strops and other things. Here is where I am at, the cannons are not glued in place as I need to add deadeyes and chain plates first. I have my painted Cochrane figure standing on the deck. The cutter took around two days, and I have positioned it between for the fore and aft hatches, on chocks high enough that the keel clears the combings by a healthy margin. Should I keep this in the kit, does it look OK? I took a couple of shots almost side on, so you can see the great curves, more elegant than the later variants. The stand should be crystal clear, but it is a sacrificial building stand, and I sprayed varnish on it...

-

This is the page for the full Indie lines, complete with stern: https://prints.rmg.co.uk/collections/ship-plans/products/indefatigable-1784-j3954 Now, there is another Ardent (64), but slightly later at 1782, although around the same time frame as the launch of Agamemnon and Indefatigable with almost the same dimensions: https://prints.rmg.co.uk/products/ardent-1782-j3028?_pos=5&_sid=00da2bde1&_ss=r What do you trust, though, several drawings and paintings, many not entirely contemporary, or the original Admiralty lines for the class of ship but a different name?

-

Cheers I have all of these paintings (well, copies), and they all show 8 windows on the lower tier. But the original plans show 7. I have seen plans for the same class of ships, for example the Swan class, and all have the same stern framing with only superficial changes to the tafferal. Did they elect to draw the Indie stern because it was different, I wonder?

-

Have been back onto the Speedy over the past couple of days, after sorting some stuff for the third kit. Have been building the little cutter - damn why did I think it was a good idea to include this, they are so fiddly! Almost finished though, two a half days! I think that if I had the right software, I would design the shell to be cast in resin and offer it as an alternative, hate doing these, but they do look nice on the model when complete..

-

Cheers Bruce. No second guessing. The JPEG I posted is from a copy of the original Admiralty plans for Indefatigable, a 64 of the same class as Agamemnon (and only two years apart, launch-wise). The first Agamemnon I did I included 8 windows at the stern, as many paintings show this, but the actual Admiralty drawings show 7, albeit for the Indie. It is only on the Indie plans we get to see the stern of the Ardent class - but was this a one off, or the same for all. This is what I am trying to work out.

-

Hi, I do have the Lord Nelson figures in stock, 50 each in 1:64 (£12.50) and 72nd (£12.00). However, my website is not good at adding new stuff, so it will change to a platform that is more product based. If you want a figure, please PM me - not much more I can do until my website is sorted. On a different note, I have been studying my plans for Indefatigable. It seems the full hull and stern detail is only shown on this particular variant of the Ardent Class. I note the number of lower stern windows is seven (I know there is a later Ardent Class with eight, but not the 1764 class). As this is (apparently) the only contemporary set of plans for the class showing the stern in detail, would it be safe to assume that Agamemnon would also have seven and not eight windows? I ask because one day, I would like to have another go at Egg's 'N' Bacon, but in her as launched form and a lot more internal detail. (Once I have the lines done for Indefatigable and before I chop the bulkheads down, I have the lines for the Ardent Class)

-

Thank you. I am lucky to have found a decent digital carver, so I can change the scale of these pieces. The painting was done by a professional, but worth it I think, as they will be a great guide to painting. Regarding Cochrane, yes, the exact same amazing man. I bought this book and have read it twice over, highly recommended,his life was more action packed than most fictional characters : https://www.amazon.co.uk/Cochrane-Dauntless-Adventures-Admiral-1775-1860/dp/0747585458/ref=sr_1_1?crid=WFJXJ9X96PWE&keywords=cochrane+the+dauntless&qid=1564340749&s=gateway&sprefix=cochrane%2Caps%2C164&sr=8-1 It was this book that introduced me to the Speedy, I just had to do it!

-

Cheers guys Have had very bad sciatica all weekend (No idea where that came from)!, no fun, but have kept working (drugged up to the eyeballs on painkillers and anti inflammatory tablets ..) I am designing the hull, decks and stern fascia for my third kit. I needed to do this because I need a perfect template for the stern (and figurehead, in order for the digital carver to make the parts the perfect size for fit - but it means I need to design the whole hull structure to get this part, and know it will fit perfectly.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.