-

Posts

412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by oakheart

-

-

15 minutes ago, iMustBeCrazy said:

Keep a few cotton buds handy,

sanding stick is a fairly flexible

Good tip, Don't know about the spit, depends if I am drinking tea or beer, maybe a jar of distilled water might be better.

Sanding stick looks good, I have some sandpaper glued to a dowel for the lower curved part of the hull which seems to be working.

Tim

-

1 minute ago, iMustBeCrazy said:

I glue the plank edges.

Thanks Craig, I like that idea.

But as I am going to stain the hull, I would worry about glue getting on the front surface of the planks.

I need to do a test and see what happens if I do.

Tim

-

Could not resist, I started sanding the planking already done. Using 50 grit sandpaper on a small wood block.

But I have a problem with the 1.5mm thick planks flexing, while I am sanding the hull fair the planks are bending slightly in between bulkheads, I am not even pressing very hard.

This means that the plank on either side gets sanded a little bit more and becomes thinner.

This is sort of difficult to photograph, hope you get the an idea of what's happening.

On my next build I will use more bulkheads, meanwhile I have glued a small strip behind the planks to stop the flexing.

Has anyone else had this problem?

What have others done about it?

Tim

-

Thanks for the compliment Craig, and everyone for the likes.

10 hours ago, iMustBeCrazy said:a hair (literally) more off the highpoints of strake 5

I have only just noticed that gap between 4 and 5, things show more in photos than in real life.

Not sure if I will take it off and fettle it or not.Tim -

The planking continues.

I made a simple jig to aid cutting the planks into the correct taper.

here it is with the steel straight edge ready to cut the taper

A few planks make it begin to look like a cutter.

the shape begins to appear.

close up of the bow.

Doing the Bounty launch helped me with understanding planking.

I want to stain the Alaskan Yellow Cedar to look like the old models in the RMG collection, so I have been testing a water based wood dye.

Pleased with the result, also found I could not coat with brush on acrylic as the stain runs, so used a rattle can from Halfords.

Tim

-

3 minutes ago, iMustBeCrazy said:

Well, if I can pull this off the guns will have functioning carriages.

Now, I know you really are crazy.

Tim

-

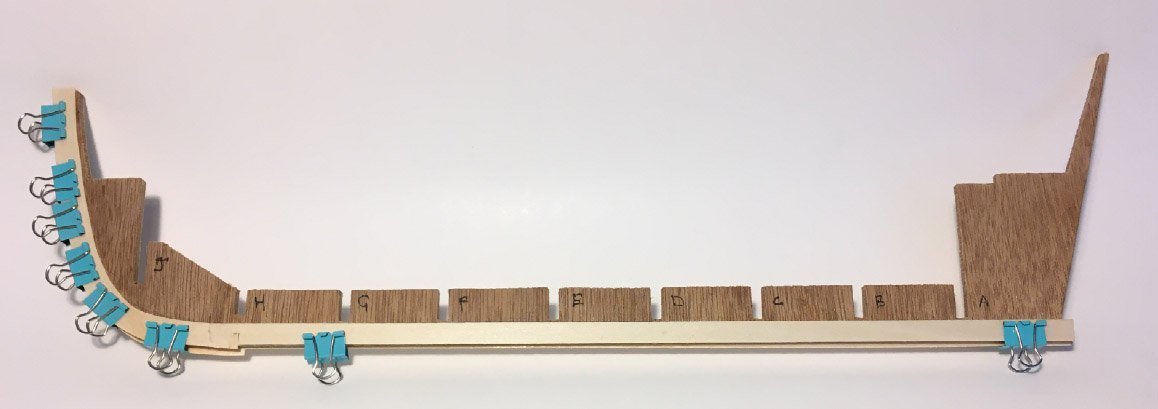

So here I am back, it's been a long summer, so much to do.................

Managed to get a bit done on the Speedy. Garboard plank in place on both sides.

while I am plodding away building this 1:48 scale model some people build full size Cutters. Here is the real thing

Luke Powell built the 'Pellew'

https://www.workingsail.co.uk/pellew?itemId=fihssy98q3833wr2jbjrsb17q7mzt6

loads of videos of it on youtube.

and some action video of other Cutters , really shows what it must have been like sailing these craft.

anyway, the sun is shining and I have more garden work to do.

See you soon

Tim

- allanyed, iMustBeCrazy, GrandpaPhil and 3 others

-

6

6

-

On 7/14/2023 at 8:03 PM, allanyed said:

If they were indeed Blomefields,

Thanks Allan

For this build I have just gone with whatever Bill Shoulders has shown on his plans.

I have no idea if they are accurate or not.

I will try and find somewhere in the UK where I can get things 3D resin printed, I have tried cannons at this scale on my FDM printer and they do not look good.Tim

-

18 minutes ago, iMustBeCrazy said:

just screw something (or some things) to the false deck

You are right, I need to : KISS

As the plywood is a bit suspect the blocks will be better.

Just some 4x2 ( measure it first ) blocks on the false deck would do the job.

thanks Craig

Tim

-

Managed to get some done to the hull over the last few days.

Masked up the keel ready for fairing the bulkheads.

Noticed a fault ( hole ) in the plywood

made a quick and dirty repair

I had to add some temporary beams to strengthen the bulkhead tops while I was sanding.

they will be removed after I have done the planking.

the planks now sit nicely on the bulkheads

I now need to make a jig to hold the hull upside down while I do the planking.

Off to do some research

Tim

- bruce d, iMustBeCrazy and Thukydides

-

3

3

-

On 7/4/2023 at 1:00 PM, chris watton said:

released in around 2 weeks

Now I know what my new build will be.

Tim

- mtaylor, Canute, chris watton and 2 others

-

5

5

-

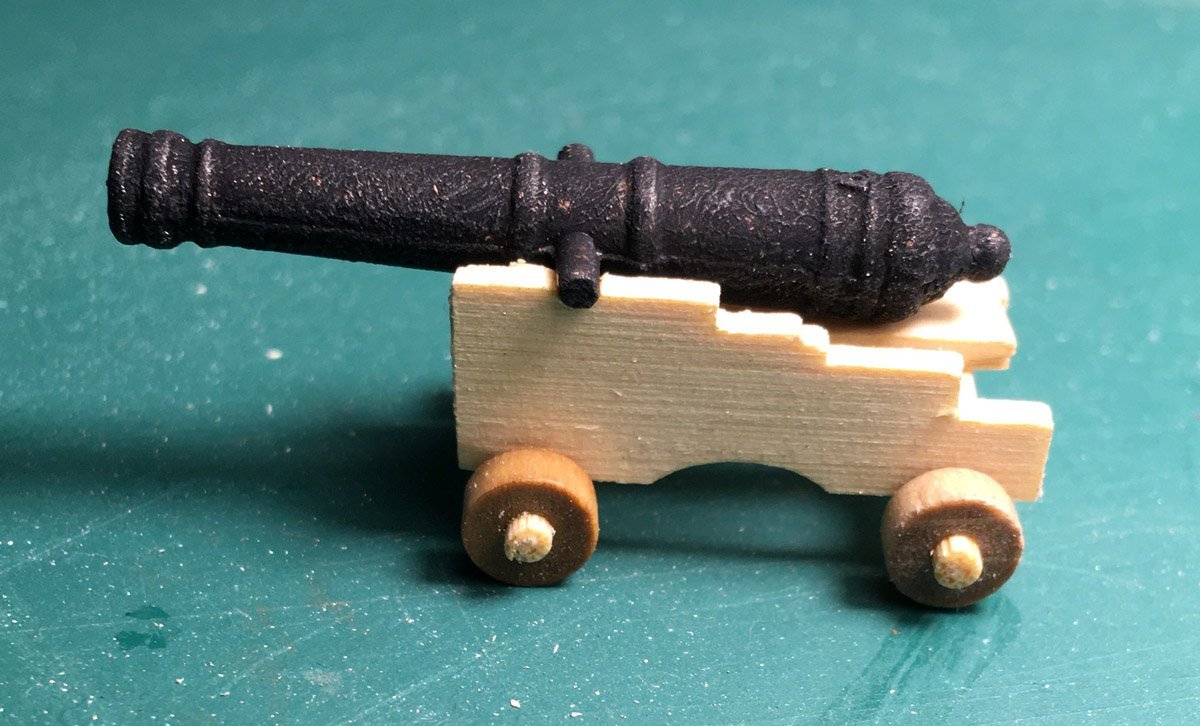

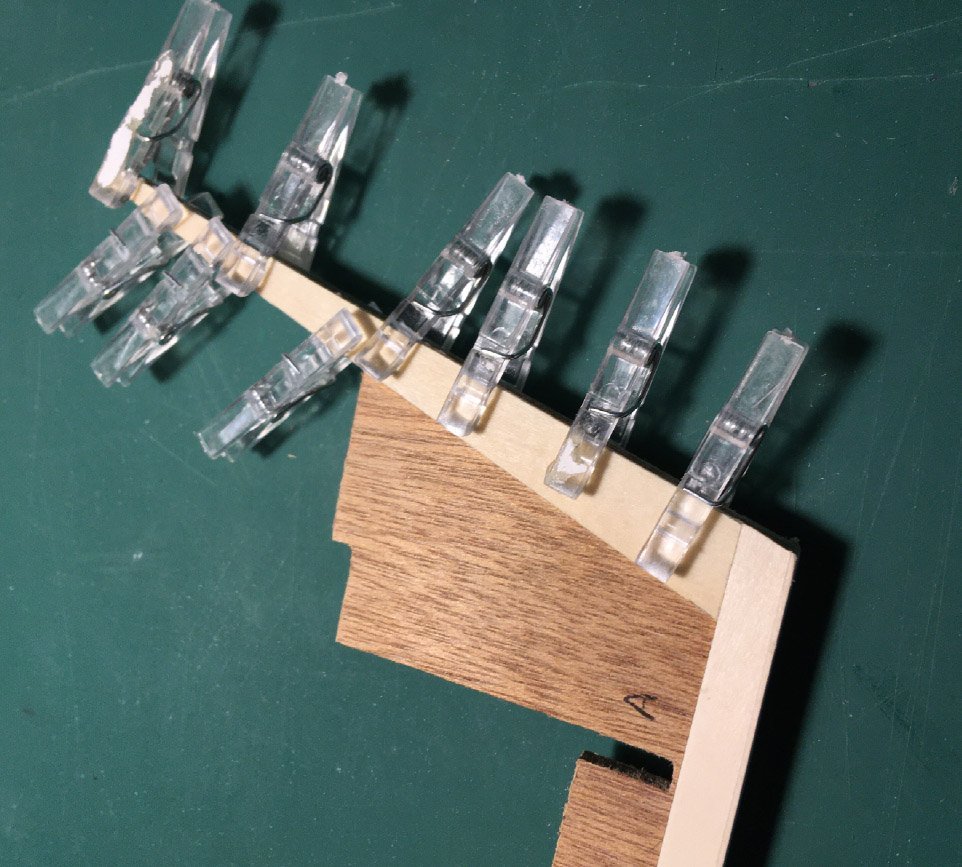

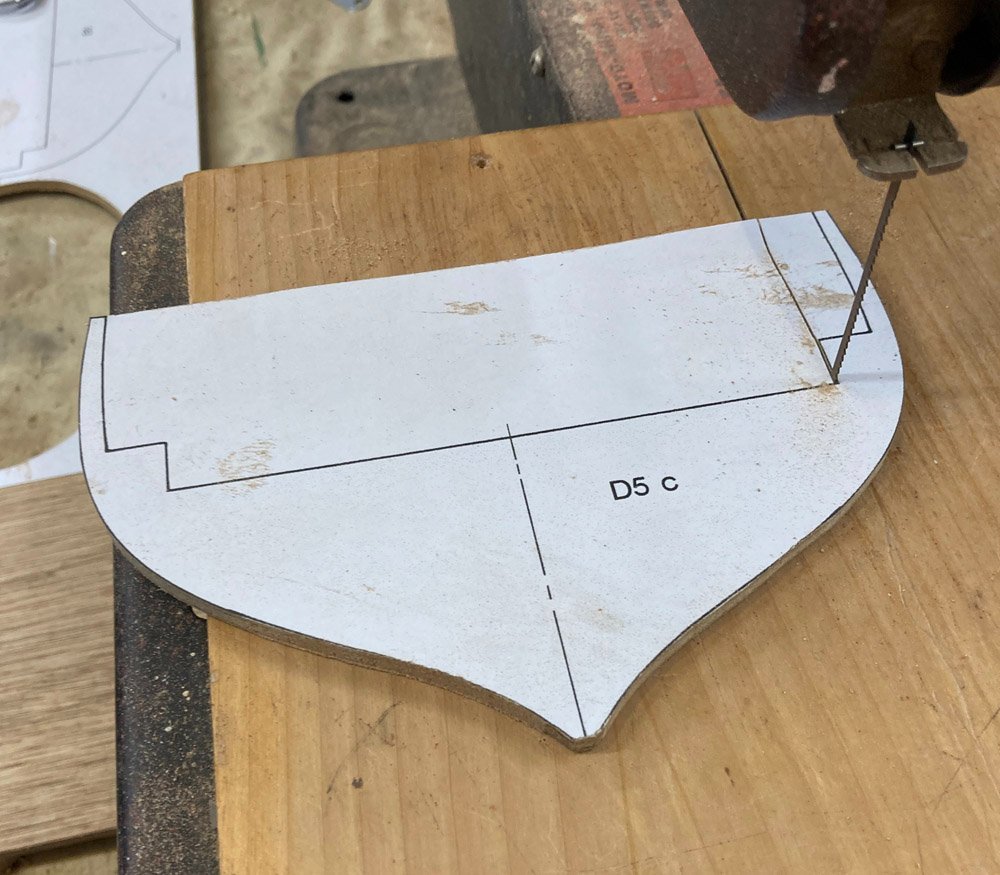

While the glue on the bulkheads was drying, I turned to the cannons.

I had ordered a set of Amati barrels and wheels from my favourite model shop

https://www.cornwallmodelboats.co.uk/acatalog/amati-cannon-barrels.html

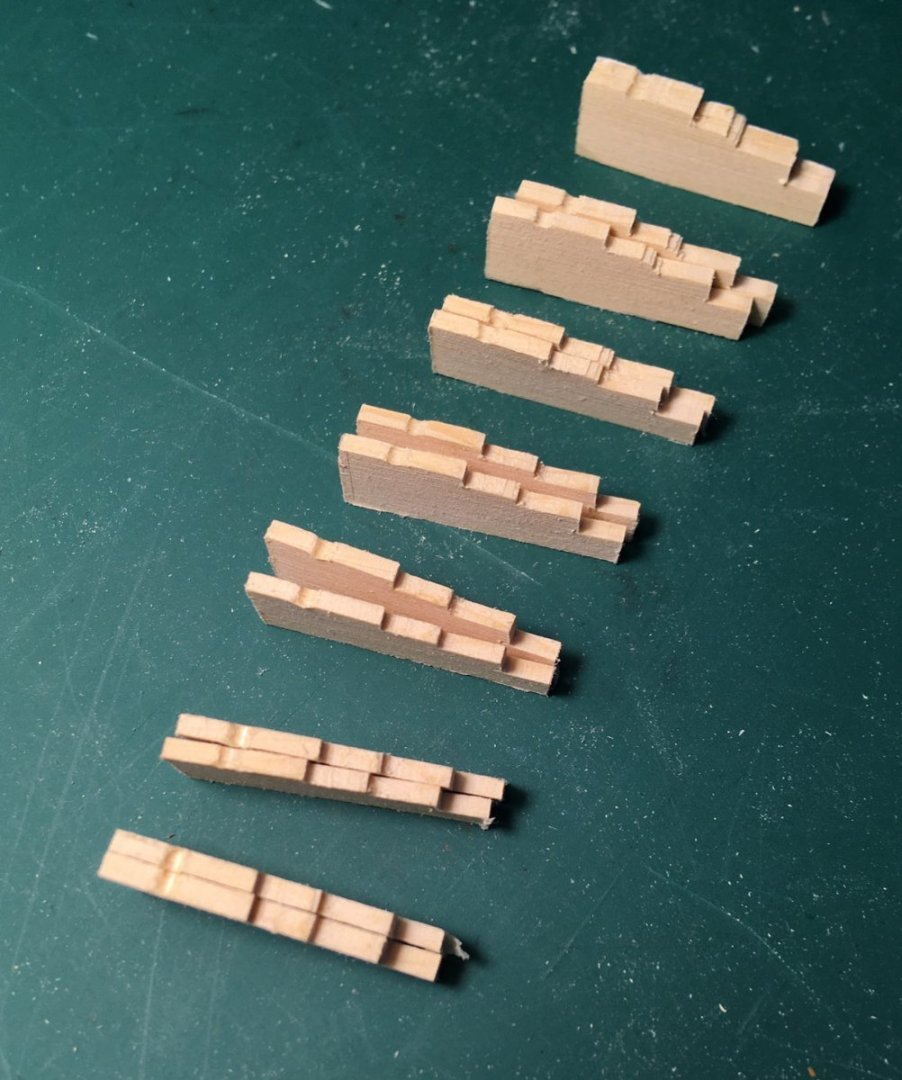

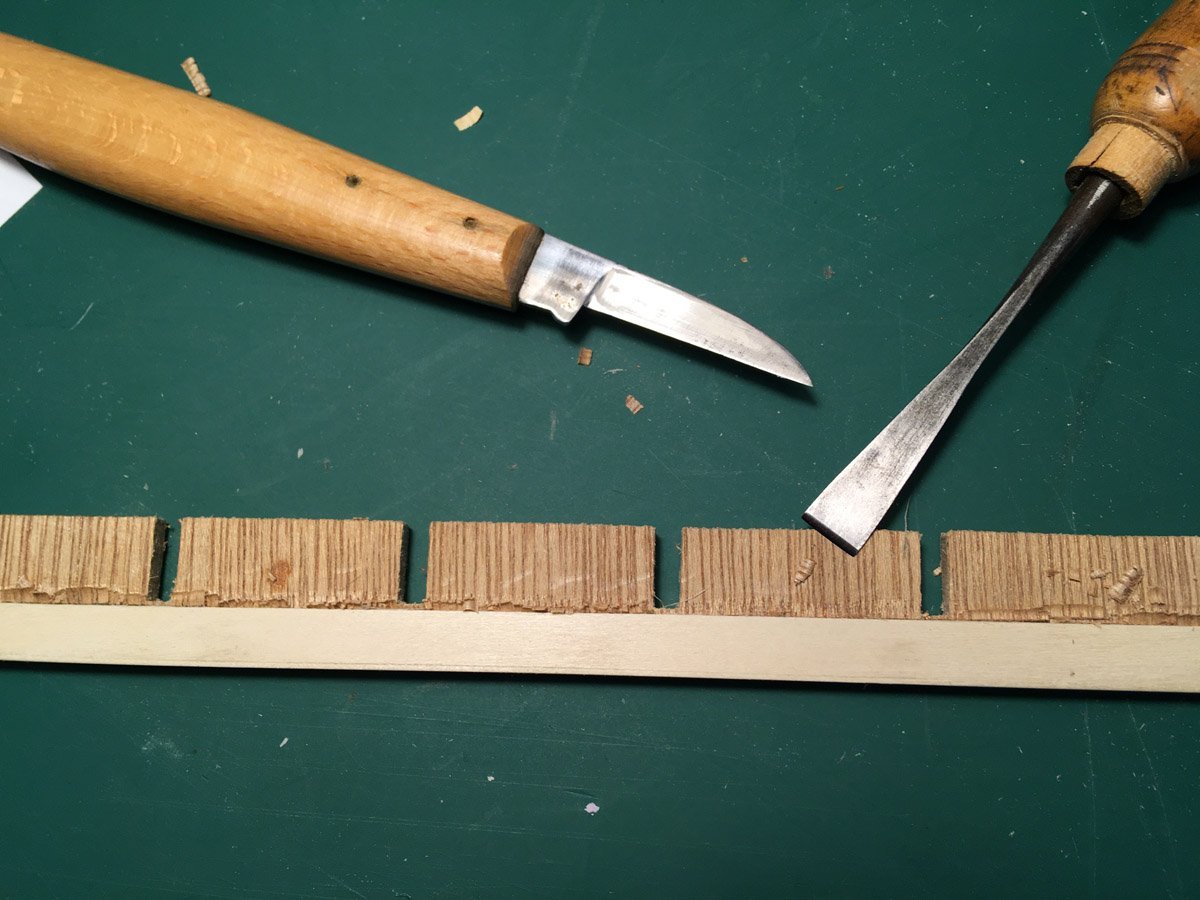

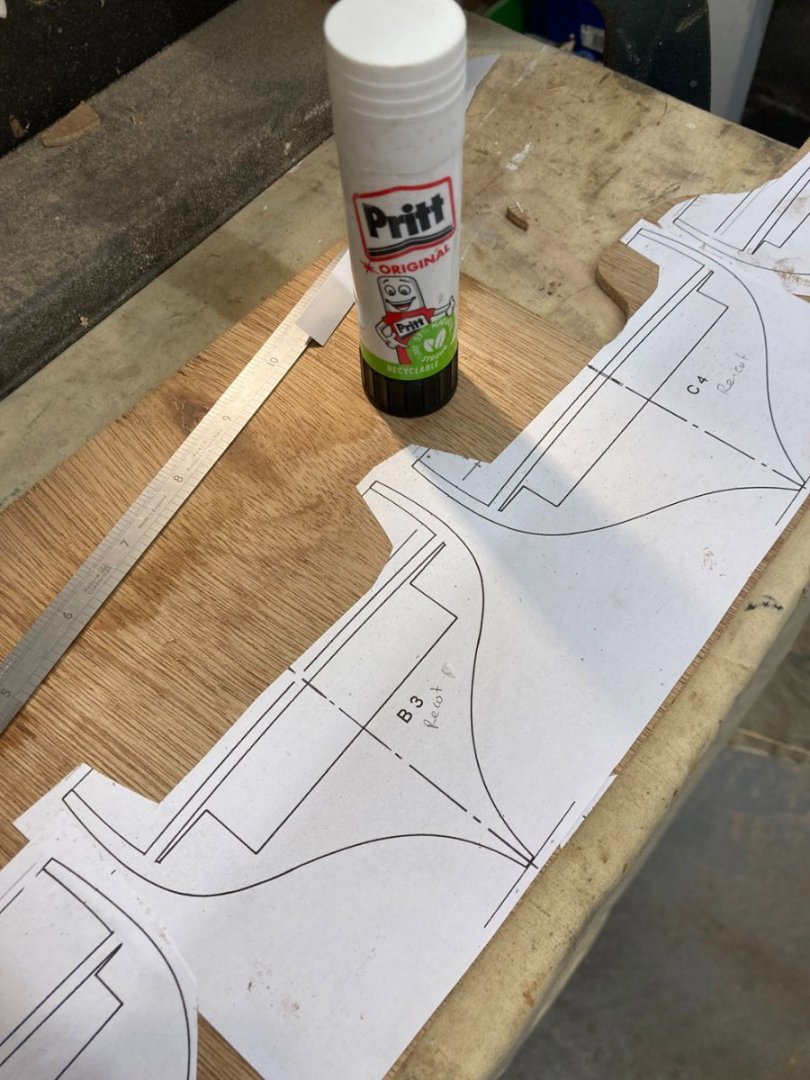

I drew out the carriage to scale, printed it out then assembled a stack of 2mm thick wood cut to those dimensions, a small strip was glued along each end to hold the block together. The template was pasted on one side of the block.

Then using a jewellers saw cut out the shape of the carriage.

There are a few errors with the cuts, but not too bad overall, a quick touch up with a small fine file.

I ended up with enough to make the required number of carriagesThese were assembled and with the barrel in placed look pretty good,

the barrels are a bit to garish so gave them a coat of matte black that I dabbed on with an old scrubby brush.

Looking good.

But I have just realised looking the photo that the wheels are on the wrong way round, should be the larger at the front, lucky I had not glued them in placeTim

-

- mtaylor, iMustBeCrazy and bruce d

-

3

3

-

7 hours ago, iMustBeCrazy said:

Yours also seems to sit a bit high, have you joined it the same as Thunder did?

Hi Craig

Well spotted, you have a very keen eye, it is high and I did not join it the same as either you, thunder the booklet.

I went off on my own and it worked out wrong, I have no idea where those angles came from?So back the the drawing board, printed out new templates and cut some new parts.

I now need to sand them to the correct angles and glue them up.

Back tomorrow

Tim.

-

-

-

- bruce d, iMustBeCrazy and mtaylor

-

3

3

-

Just a couple of small jobs to keep the build moving along.

Glued on a strip of limewood to cover the raw plywood edge.

then added a layer of limewood to the stern. In my next build I really want to make a solid wood stem, keel and stern post.

but for this simple cutter model that I am using to get some practice at planking, this will do.

Tomorrow I will cut a rabbet.

Tim

-

4 hours ago, Igmar said:

Hello.

I build models for customers. Recently I got the idea to open my own channel on YouTube.Hi Igmar welcome to MSW

I am glad to be retired, I used to build models for customers ( not ships )

Will go and have a look at your YouTube channel

Tim

- Ryland Craze, Keith Black and mtaylor

-

3

3

-

Yesterday in the workshop I managed to get quite a lot done.

Pasted the paper templates onto the plywood.

then made some sawdust

here are the bulkheads and the 'deck' which holds the whole thing together.

I then glued the rabbet strip on the keel using some 1mm limewood.

I will leave that to dry overnight , then cover the plywood edge grain as well.

A good days work

Tim

- mtaylor, CiscoH, iMustBeCrazy and 1 other

-

4

4

-

On 6/8/2023 at 11:00 AM, iMustBeCrazy said:

Update time.

That has turned out fantastically, congratulations.

Gives us all something to strive to achieve.

Tim

- iMustBeCrazy, Montaigne and mtaylor

-

3

3

-

9 hours ago, iMustBeCrazy said:

so I designed and built my small Cutter and learned a lot.

I was quite happy with that so I designed and am building my Bounty Launch

And your Bounty Launch is fantastic, I have just been over there to have another look.

So patience and hard work pays off.

For me, I definitely see this small cutter build a step in the right direction.

I am already having new ideas on how the Rattlesnake might be constructed for a PoB model.

Taking ideas from Bill Shoulders original model and mixing it up with modern ideas.

Tim

- mtaylor and iMustBeCrazy

-

2

2

-

12 hours ago, bruce d said:

Fun ! I think I may need that Aspirin now..........

Just spent a good ten mins looking for a way to search for a specific name?

Any clues?

I was looking for more detail on the cutter Rattlesnake ( I already have the profile and lines that Craig sent me the link too )

Tim

-

Le Renard 1812 by iMustBeCrazy - Artesania Latina - 1:50 - early kit version 20305

in - Kit build logs for subjects built from 1801 - 1850

Posted

Did you turn the barrel ?

How is your planking going?

Tim