-

Posts

624 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Javelin

-

I knew it was the penguins you were talking about. But shouldn't you continue the build instead of watching movies???

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

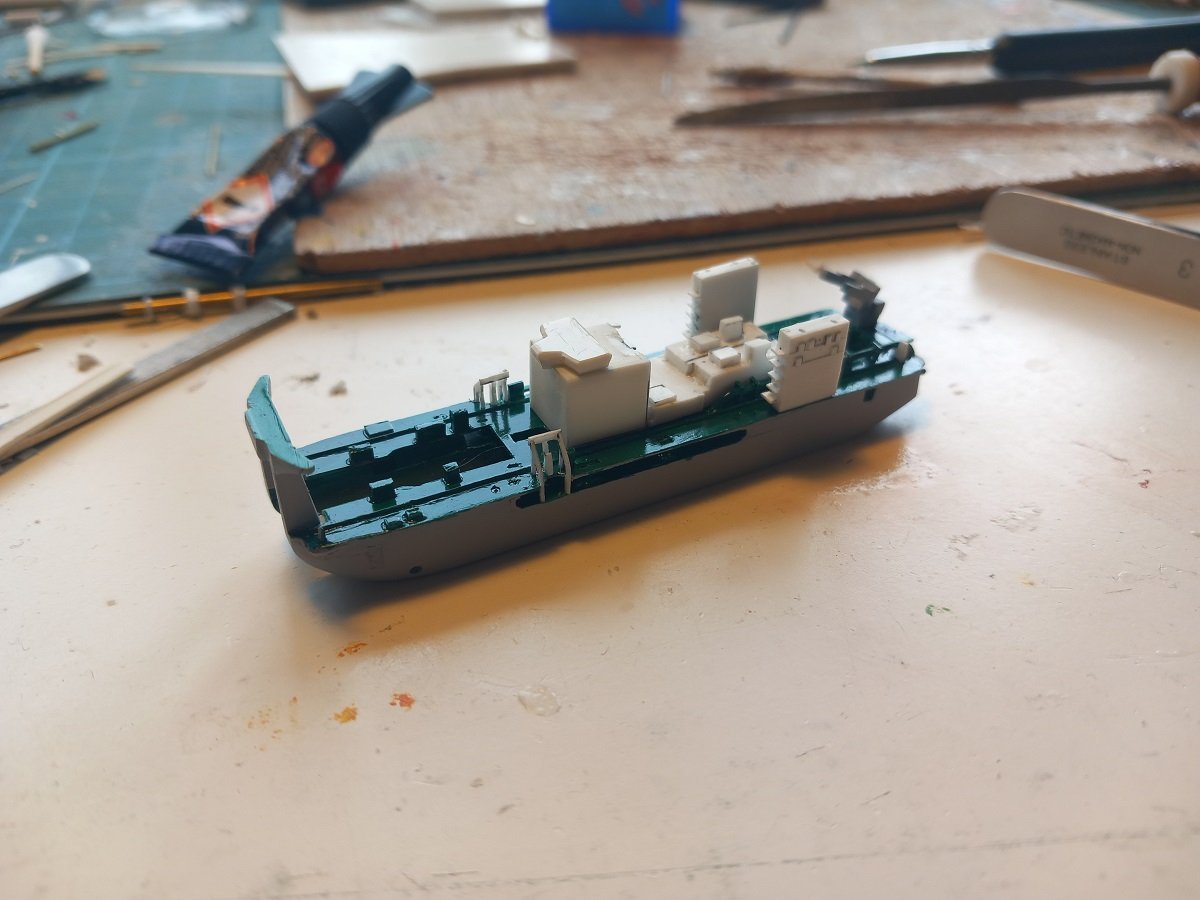

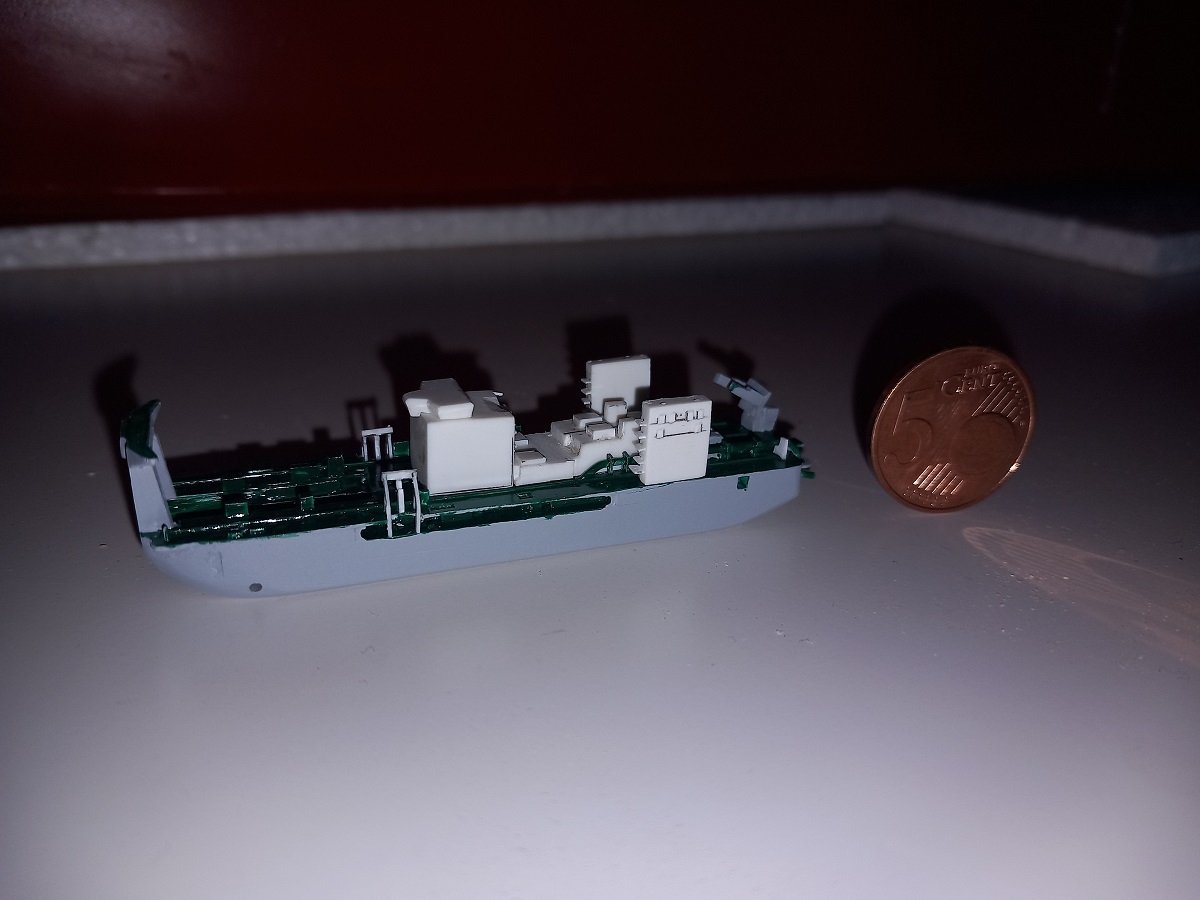

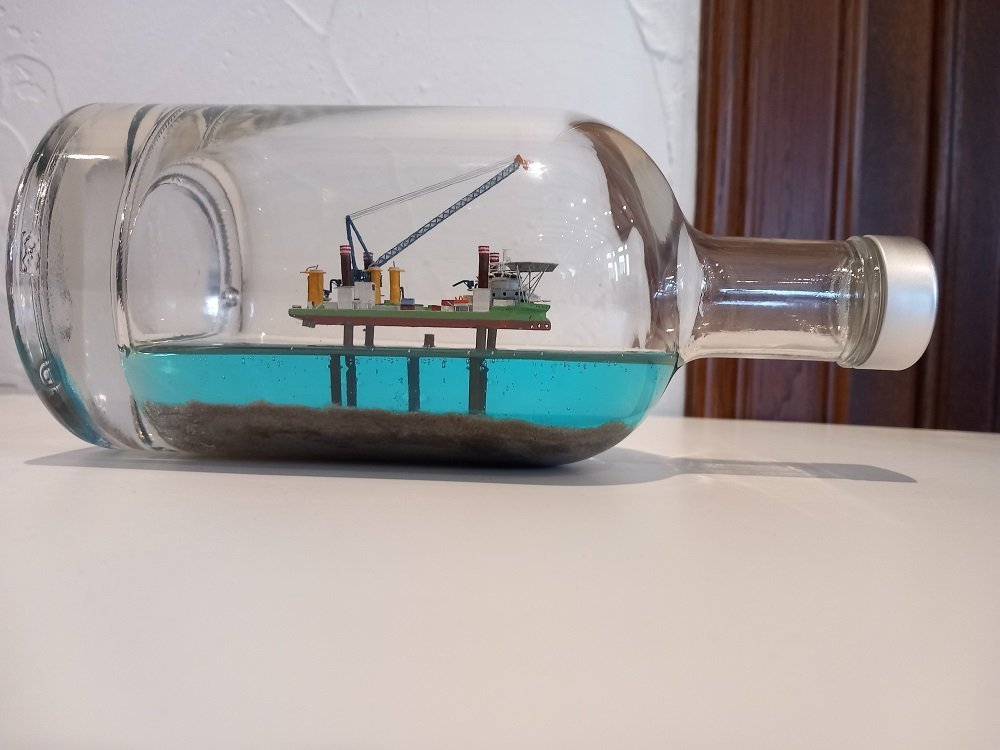

Another small update. Looks small, but did a lot of detailing. I'm now working towards application of white primer. I'm using white primer instead of grey for parts that need to be white in the final coat. Additionally I've applied the grey primer to the hull and started with the Moss Green deck. I don't like glossy paint and normally I simply mix it with colourles matt paint to tone down the glossy effect. Unfortunately my matt dried out and inside the bottle, everything looks glossy after all. This is not the final coat of the Moss Green. In reality of the course the ship is less than half the size of this picture. As you can see I'm forced to work at about 0.1mm accuracy to make everything fit. The printer didn't really succeed in printing a lot of lines on this scale. I've also finished the anchor chairs in front of the accomodation now. Next step will be working towards finishing the hull to a level where I can paint the yellow-green. The installation sequence for now, in my mind, would be: - Install base plate (pre-coated with sand-acrylic mixture) - Blend base plate into acrylic base on the bottom of the bottle - Insert lower part of main spud - Insert hull and mount it on top of main spud, lowering the pre-rigged ladder to keep the vessel up - Erect auxiliary spud - Deploy anchor booms and anchors - Pour Epoxy to steady the ship - Mount funnels - Deploy barge loading pipes - Erect crane - Mount accomodation block Conclusion, the bottling process has a lot of chances to get screwed up... and definitely won't be a 5-minute job. Still a while to consider changes in the design/sequence since I'm a long way off from completing the vessel itself. (but at least we have a plan)

-

Great progress Glen, rapidly catching up with me! That's a lot of patience drilling that many oar supports and making that many oars

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

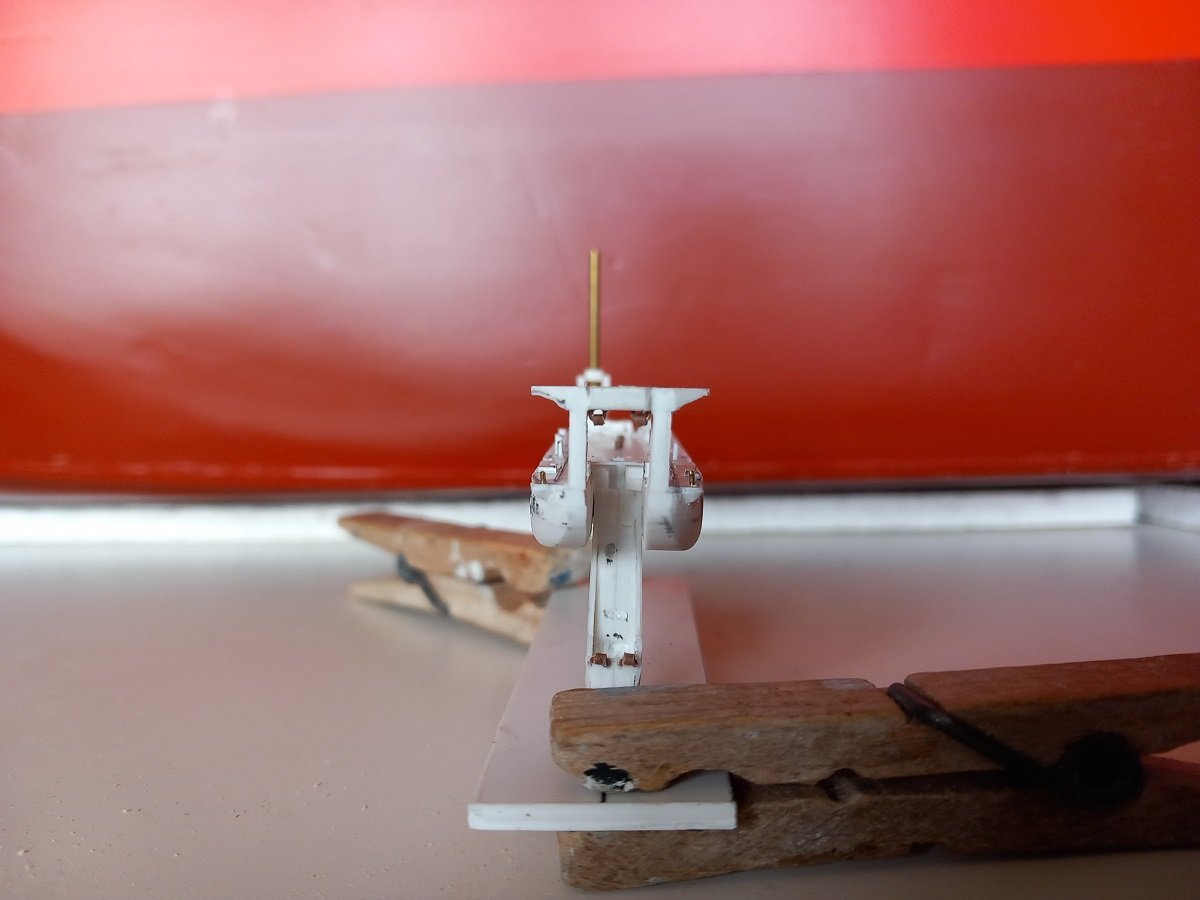

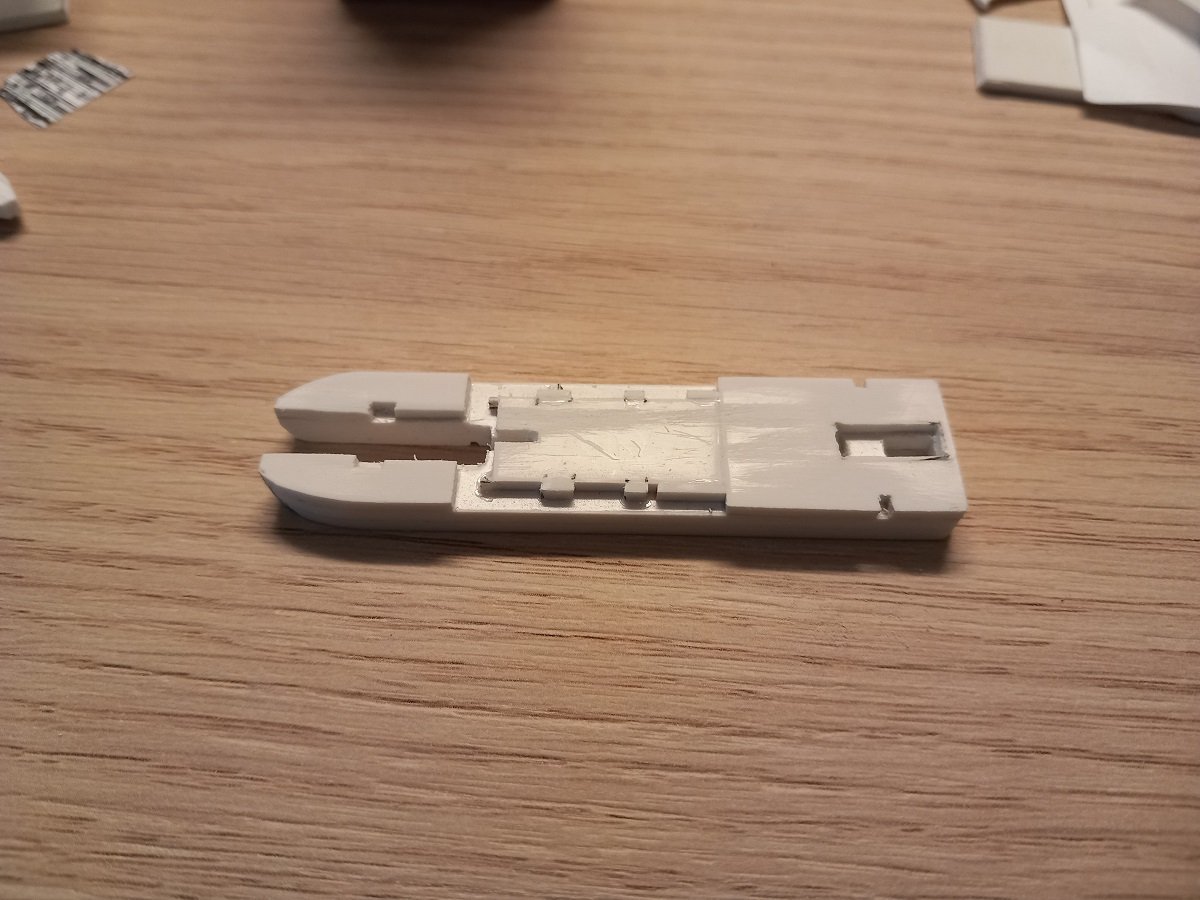

@Glen McGuire, that's correct indeed. The nautical anchors in this case are recessed into the hull to avoid getting tangled on them with the wires or worse, having them caught by one of the workboats or barges when approaching the Spartacus. In normal merchant shipping, when the anchors are recessed instead of sticking out of the hull, it means the ship has an ice class. (where recessing the anchors is done to avoid them from being hit by ice that is pushed up by the hull). @Thukydides, thanks. The secret is often the manipulation of parts while shaping them. Unlike with kits, where you cut out the parts from a sprue, in this scale you often have to create a handle on them. I often make a sort of strip, shape one side of the part I want at the end of the strip, then shape the rest, all while using the strip as a handle. The last action is then to cut the last side of my part to part it from the strip. It's way more easy then to cut a piece the size of the part you want to make and then try to shape it, as you will have great difficulty to hold it while shaping. Another small update prior to primer. Must admit I'm rapidly losing interest in this project. Not entirely sure why. I primed it today and put some green on it and I was genuinely feeling annoyed during the painting... Here is the stern with the stern discharge pipe mounted. The bent piece at water level is where the floating line is connected. It can swivel and has a quick release ball-joint on the pipe. The Auxiliary spud is in it's final position here. Of course it won't fit through the bottle neck this way. That's why I created a hinge on the holding mechanism. In the following picture you see it hinged down. The lower ring will be glued to the spud, so it'll arrive at the correct height and look like it's attached to the hull. On the real ship, there is a big door that opens when the spud is tilted down. And a bow shot of the finished gantry with the sheave packs (little brown cylinders at the top) underneath. They are mounted on 0.3mm copper rod, which were then bent in a U-shape and drilled into the gantry. They'll be used to rig the ladder, with similar sheave packs. I've also built a slightly longer bottom plate, so it works better with the temporary laundry pins. I'll be mounting a piece of styrene in place of the forward laundry pin, which will then be covered by "soil". In reality the cutter is also sitting partly in the seabed, so that's not going to be an issue.

-

Penguins are seabirds... Might as well add some too, for realism

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

He is right though... Or perhaps a greenish sheen near the bottom? In any case an amazing construction job. The stones really look like they are made of limestone rather than "painted" in lime....👍

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

But you persevered and got it nice! Great job on a handsome ship! Very crisp and clean build.

- 166 replies

-

- Maine

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Time for a small update. Got distracted by garden chores and it's quite hot over here. Made the two dredge anchors. This type of dredger has its "nautical anchors", which fulfill the requirements for a ship, and "dredge anchors", which are required for the dredging activity. The dredge anchors are waaaaaaaaaaay larger than the nautical anchors and weigh 60t, with the option to add another 30t of ballast in order to give more holding power in difficult soil. They called Stevshark anchors and are normally used to anchor floating structure on a (semi-) permanent basis offshore. I had to make tiny versions of it and the only reason I could produce something resembling the real thing, is that in reality they are quite huge. When not in use, they are stored in the anchor chairs on each side of the vessel below the anchor boom. You can compare to the guys walking by... And here is my version of them. Each anchor is made of 7 parts for now. I'd like to add a bit more detail, but am somewhat reluctant to screw it up. Would also hardly be visible inside the bottle I guess. And both of them, laying on their backs. It's my intention to have one of the anchors in the midst of its deployment sequence, with the anchor just on the bottom, while the other anchor would be hanging around waterlevel/epoxylevel underneath its anchorboom. Up till now I've always had in mind to have the PS anchor deployed, but now that I think of it, perhaps its better to have SB deployed... Something to think about. Finally possible to paint, so I'm preparing to put some primer on the hull.

-

hmm, kind of makes me think: Just kidding, great paint job and thanks for explaining your technique.

- 562 replies

-

- vanguard models

- alert

-

(and 2 more)

Tagged with:

-

Of course I'm in too. One question though, are you going to have the water level (and ship) in the bottle level with the bottle side, or angled with the bottle and level with the sea surface underneath?

- 290 replies

-

- Quinquereme

- Finished

-

(and 1 more)

Tagged with:

-

They started using spherical trigonometry or spherical goniometry. It's a very different beasty from planar trigonometry. Distances between two points a sphere's surface are measured in angles. They can later on be converted to distances, depending on which sphere you use. Practically this is still the way we navigate today, except of course that a lot of it is automated. Not sure who or to what degree they used it back then. Gorgeous build by the way! Been following along for a while now.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

That depends. Preferably a floating pipeline is used, this ranges from a few 100m till several miles. Occasionally, when distances get long and traffic needs to pass, the floating line is connected ho a sinker line on the bottom, so traffic can pass over it. You do still need a floating line to give flexibility to the dredger. The pipeline is connected to a swiveling connection on the stern of the vessel. Spartacus Stern Connection In cases where this not possible, the dredger can either load barges using 1 or 2 barge loading pipes, T shaped on PS on Spartacus, or pump it in trailing suction hopper dredgers using the stern connection and a pontoon. On Spartacus, the pipes are 1.2m diameter and she can pump between 14 and 19km depending on material density and pipeline diameter. I still need to build the barge loading towers, I'll have to hinge the inwards to pass the bottle neck.

-

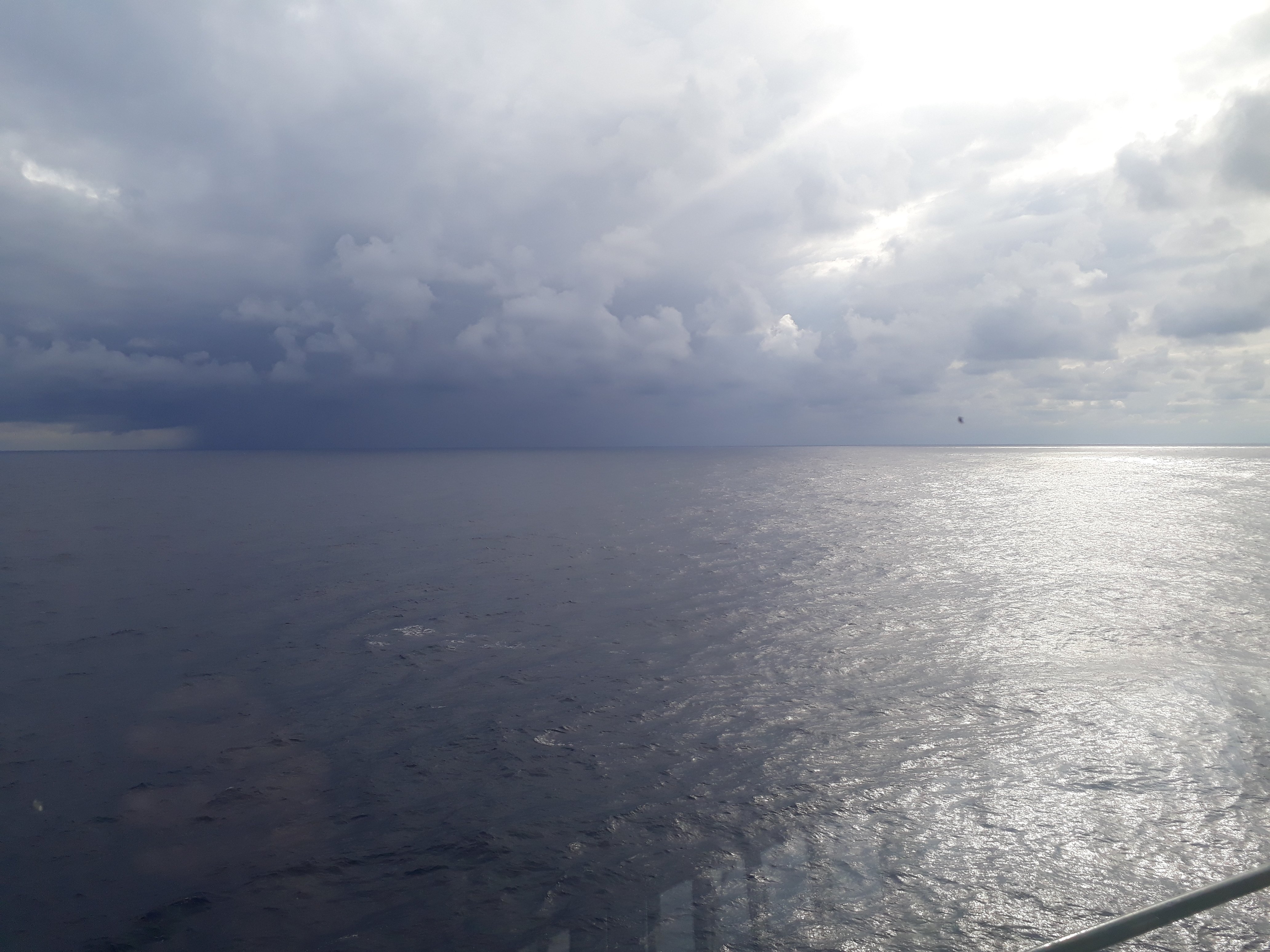

Hi Glen, it's a mix of circumstances I guess. I used to sail in the Merchant marine, however those ships (large tankers) aren't very suitable for bottling, you have to reduce the length so much to fit inside a bottle, that you automatically end up with a tiny scale. That in turn makes for a very low height and width of the subject, which means it would simply fit through a bottle neck without any "special" features, they also don't really fill a bottle very well, apart from their length. When I changed career to dredging, I got a wider view on these working vessels with very irregular shapes and dimensions. They're also generally smaller, which allows for larger scales. Although it is forbidden for me to post onboard pics, I guess I can post pics of the vessel itself as practically anybody can see it, and take pictures, this way. The above picture is more or less what I'm aiming at in my bottle. The main difference would be that I want the ladder on the bottom and 1 anchor on the bottom (ladder is up in this picture, you can see it behind/inside the forward dark green platform). Funny you'd ask for the material. It's sheets of styrene/styrol of different thickness glued on top of each other. It's funny because my technique is more or less stolen from you The only difference being the styrene instead of your method using wood. I got inspired for the gallery on this ship, as well as the small rooms aft inside the hull by your work to insert cannons in one of your builds. Currently working on the dredge anchors themselves and then one of the main remaining items is the large travelling gantry crane. The idea is to mount it with two pins to the superstructure, with the crane laying down, in order to be able to rotate it upwards when the vessel is inside the bottle. Haven't really completely thought this one out, but I guess it might work this way. Just need to take into account that the auxiliary spud will also be folded forward. I've also built the gantry version 3, I made it thicker with each consecutive version to attain proper angles on the small wings on the sides.

-

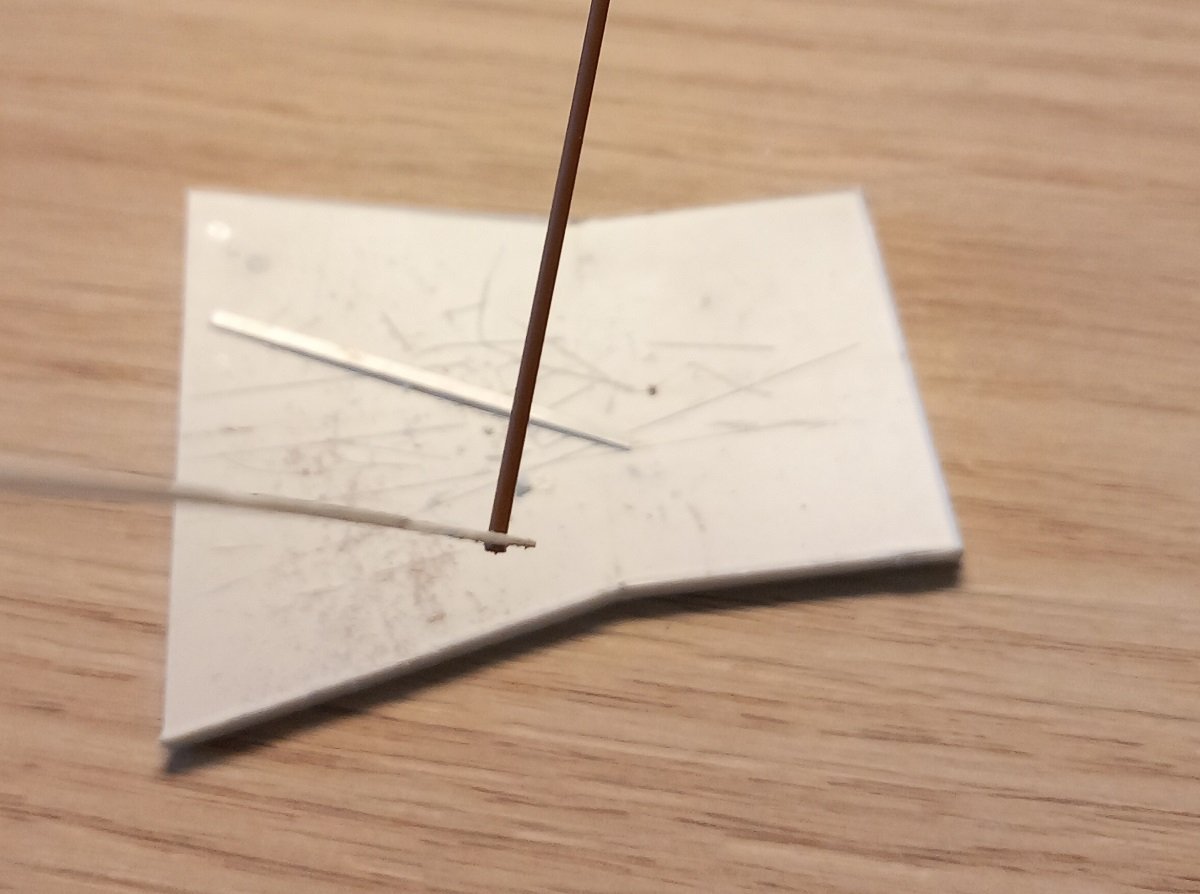

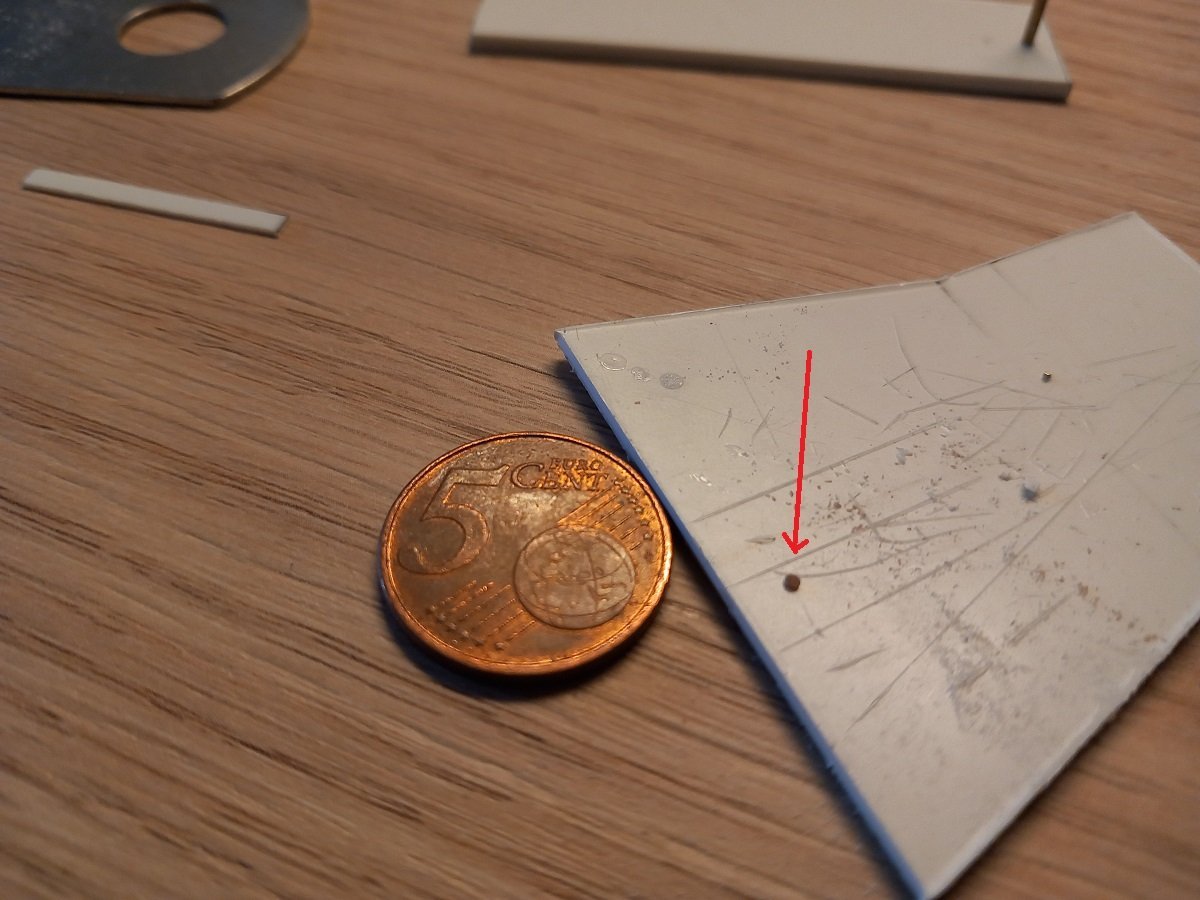

Not much progress to report. I've been mainly building 20 20ft containers, of which I'll probably use around 15 or so. I still need to make some half-height containers and probably a tank-container which is also frequently used on this vessel. Furthermore I've finished some of the main winches (Anchor Hoisting Winches and Guy winches, the latter of which are used to move the anchor boom in/out). Remaining are the largest, the Side Winches, the ones that pull on the anchors to move the ladder and vessel back and forth. For today's post I decided to share my way of making small sheaves or nice equally sized pieces of wire. I use the same way to make the end of a rod flat, which is a difficult thing to make nicely at a 90° angle. For large diameter discs, I use a normal leather punch for making holes in belts. However for small things, like 0.5mm, 0.8mm or 10mm pieces or sheaves, I use following method. Drill a hole in a piece of styrene with the same thickness as the length you require. In the example below, I wanted a 1mm-diameter disc with a thickness of 0.5mm. So I drilled a 1mm hole in a 0.5mm thick piece of styrene. Then you insert the rod and just let it protrude. Later on, I put it on a flat surface and cut it off using the sheet as a knife guide. Then, while pushing the styrene down on a flat surface (steel ruler) I file along the sheet until the rod is flat with the sheet edge. I then punch it out using a piece of wire. If you want them thinner (in this case I went to 0.3mm thickness) I insert my small disc into a 1mm hole in a 0.3mm thick piece of styrene and I repeat the same process. In this way I ended up with 4 identical 1mm discs for use on the vessel. When making a flat surface at 90° on a rod, I use the same method, except that I don't cut off the rod. I simply let it protrude along a piece of styrene and file it flat against the sheet. In that case I often use a 2mm thick piece and pay particular attention to drilling the hole straight. Same works with 0.5 or 0.8mm brass rods.

-

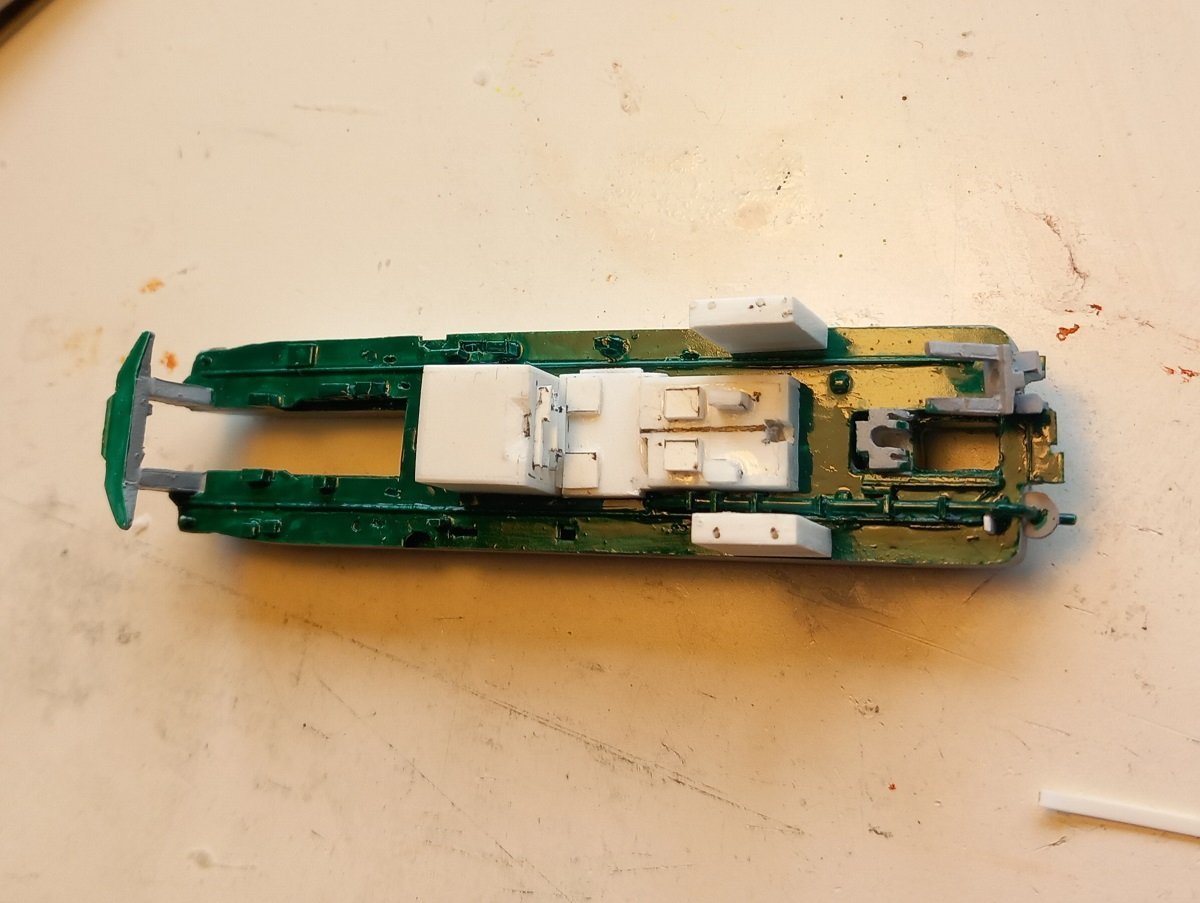

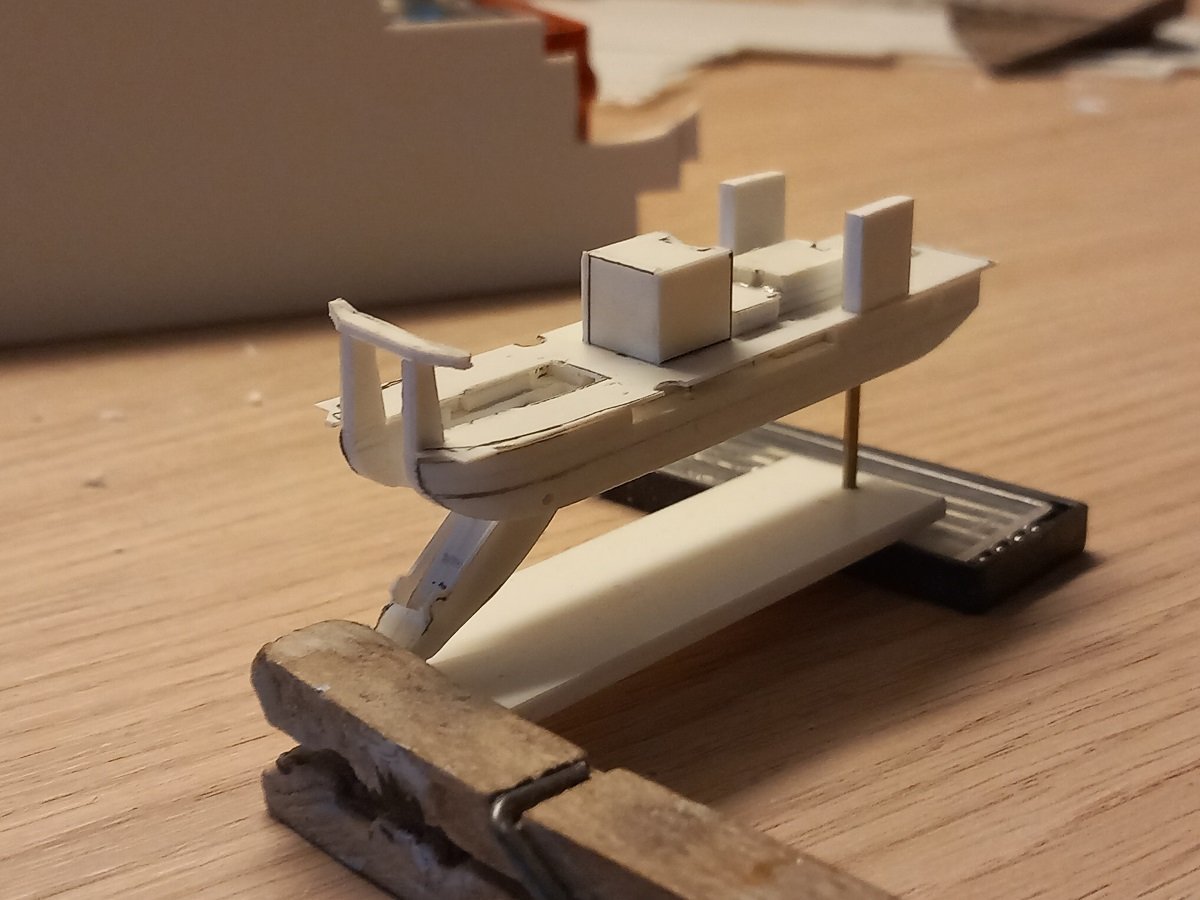

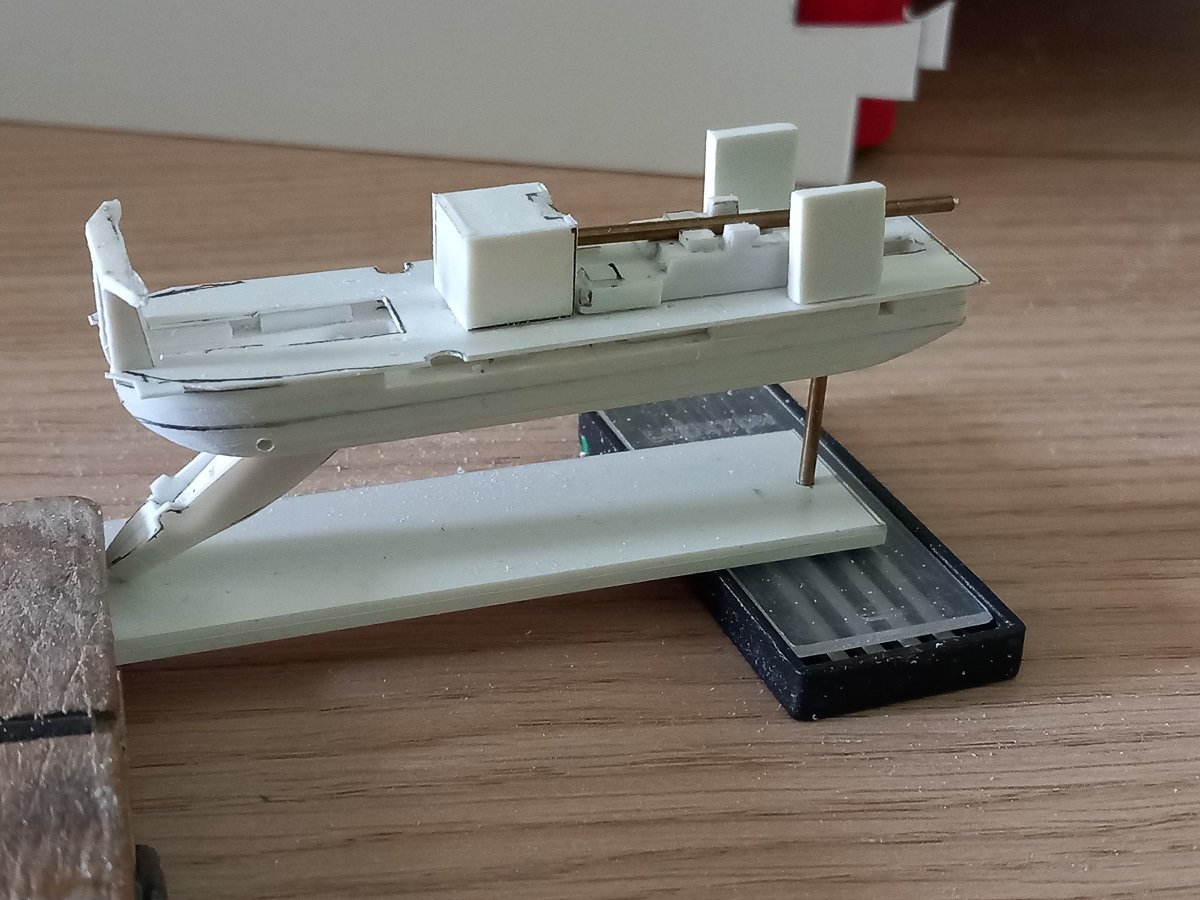

Made some more progress. As mentioned before, I mounted the crane deck. All in all I should be ok for the painting, as almost everything below it is very dark green (Moss Green), so painting won't be that delicate. In the meanwhile I've mounted the anchor booms. Small idea of what they're used for. As I've mentioned in last post, the dredger swings from port to starboard and back around its spud, moving the cutter ladder and the big cutter. These swings are done by pulling and veering (big) anchors. in Spartacus' case, the anchors are 60t Stevshark anchors (which are used to permanently moor offshore vessels as well). These anchors are connected to the ladder through sheaves just behind that cutter. The winches are mounted just in front of the accomodation block. As the dredger moves forward, the angle of the wires between the ladder and the anchors becomes worse, certainly when the dredger is in a corner. The pulling vector to move out of that corner becomes bad as the dredger moves forward of its anchors. At some point the anchors have to be moved forward, along with the dredger. At that point the anchor boom is swung out, while at the same time pulling in the neuring wire (to pull the anchor out of the bottom). Once in the corner, the anchor is pulled up, hanging in the anchor boom and the anchor boom is then moved forward. Once in a more forward position, the anchor is lowered again and the wire to the ladder is pulled tight. The boom is swung back in while veering the neuring wire, to lay it on the bottom and out of the way of the cutter. Then the dredger moves back to the other side. The two small 0.3mm steel wires you see represent the gantry crane track. Here they are still dry fitted, but I will glue them early on. This will help me divide the deck in fixed parts and force me to stay to scale with all small structures that come around the tracks. This will avoid cumulative (and very visible) errors later on. In general all large components are now ready (but dry fitted). So I can continue with small components like hatches, deck houses, containers, pipelines etc. to give her her typical cluttered look. The idea is to rig the anchor booms in outward position and then fold them inside, to be deployed again once inside the bottle. I'll probably depict her with one dredge anchor at the waterlevel and 1 on the bottom. A moment when the dredger arrives on a new cut. The challenge will be to make, and keep, the rigging tight.

-

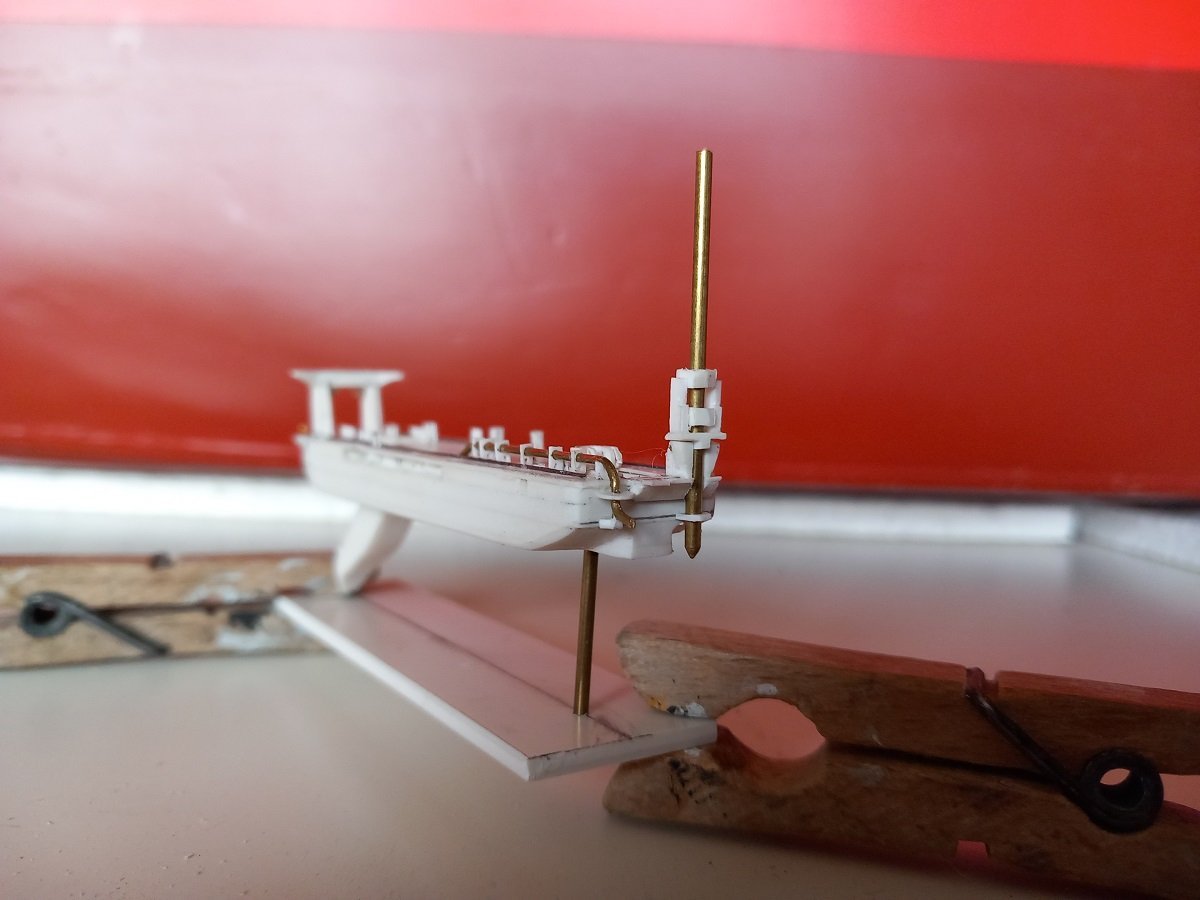

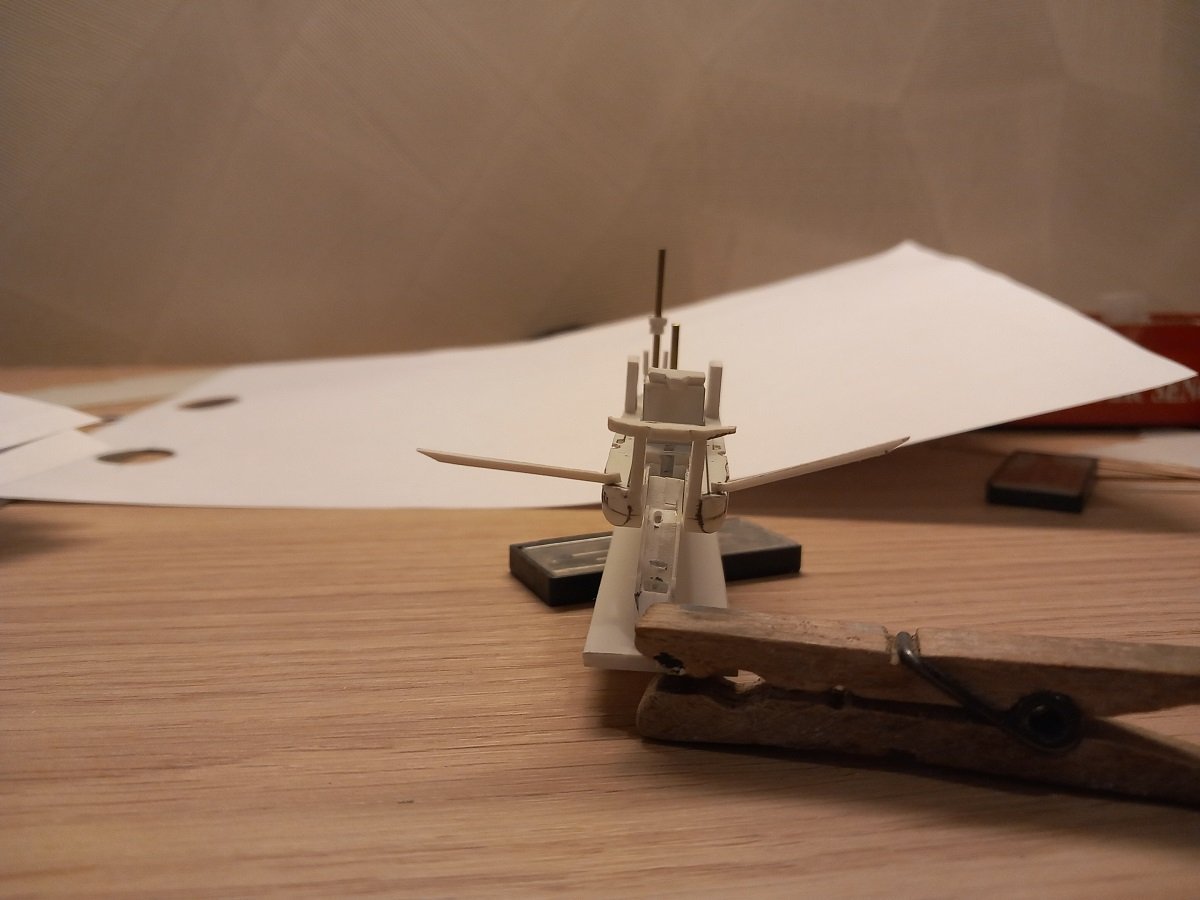

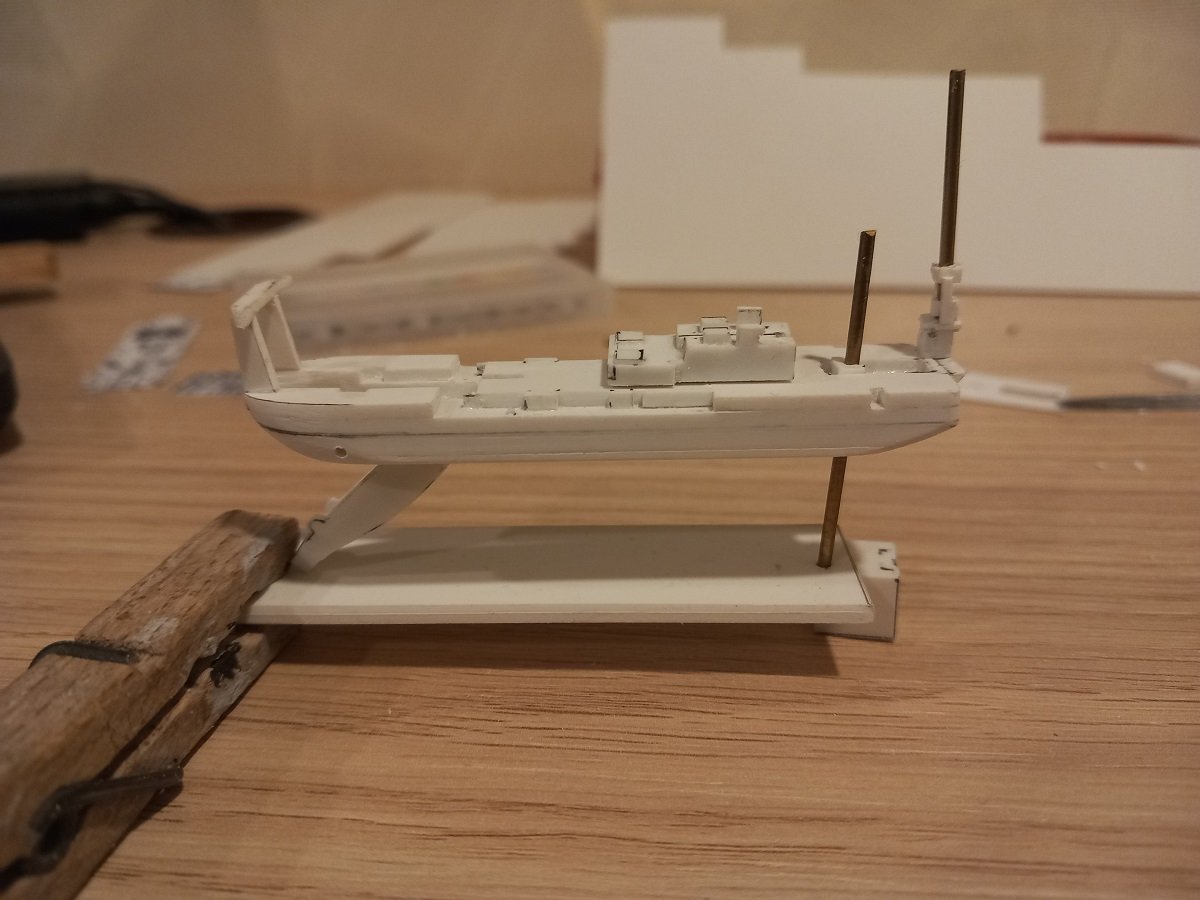

Guess it's time I'd give some more explanation about how this thing is supposed to work. Essentially it all started with the well known bucket dredgers. An evolution of those was to have a rotating cutter head, with the broken soil being pumped away. In the beginning they were small stationary barges, with only their spud poles to keep them in position. When they were finished in one area or when they had to move for traffic, they were being towed, mostly astern, to a new position, where they'd position their central, main spud and deploy the anchors to start working again. At long distances from shore or reclamation areas, they'd use booster pontoons, equipped with 1 or more pumps along the floating line in order to get the soil where it was needed. Slowly the cutter suction dredgers were growing in size, additional pumps were added to the vessel itself. Additionally they'd get barge loading facilities so they could work in areas where pipelines couldn't be used (traffic etc.) or when the soil had to be dumped somewhere far away. Due to this, also the supporting vessel, which was used to deploy anchors, bring logistics, move the vessel and arrange the pipeline, had to grow as well. At some point, it became more practical to give the dredger its own propulsion and make it a real ship. This way it could transfer from one place on the planet to another without being towed or transported on a heavy lift ship. It also gave more freedom to move the dredger, while the supporting vessel could tend to the pipeline. Recently I've been working on the spuds for the tiny model. There are two spuds, 1 is forward and centrally mounted on a carriage that is being pushed forward and backward by a hydraulic piston (in reality, when the spud is in the ground, it's the ship that's being moved forward or backward). The other spud is called the auxiliary spud and this one can only be pulled up and lowered, no longitudinal movement. The vessel moves from portside to starboardside and back while the main spud is in the ground. The spud keeps the ship from being pushed backwards by the force of the cutter. Once the cutter comes in the port or starboard corner, the ship steps forward and then swings back. When in the opposite corner, it steps again forward and swings back, this is done until the spud carrier (hydraulic cylinder) is at the end of its stroke. Then the auxiliary spud is lowered in the ground, the main spud is lifted and the carrier is brought forward again with the spud off the ground. Then the main spud is lowered in the ground again, the auxiliary spud is lifted and the ship starts swinging again. Below you can see the spud on the model. The main spud is made of two parts, the lower part holds the ship up, while the upper part is just part of the model. You can actually see the ship lean back due to the backwards force of the forward support/cutter ladder against the laundry pin. I will however fix that spud upright by adding another layer on the base plate. For the auxiliary spud, I needed a different solution, its supporting structure has a hinge in it, so the spud will be lowered horizontally to pass through the bottle neck. It will almost look realistic as the spuds are both put in a horizontal position when the ship has to sail from one port to another. When it shifts during dredging, both spuds are simply hoisted as high as structurally possible, but they stay upright. This is all still dry fitted. I have in the meanwhile decided that despite the difficulty to work on the lower level afterwards, I will mount the main deck/ crane deck anyway. Otherwise I'd already be stuck. If I do mount that deck, I can continue the construction much longer with my mobile equipment.

-

A small update. Started the forward gantry, which is also the limit of my intended bottleneck. I also started the superstructures. However I'm stuck with a semi-finished deck. I can't mount the main deck yet, since I'd need to paint and add additional detail below it. I therefore shaped it a little oversize and keep it in place centered on 2 pins to proceed with further structures. It does mean I can't really mount anything yet. All is dry fit for now. The horizontal part of the gantry is a bit thin and "light", so I'll lower the main verticals and add a thicker and better shaped top part. The ladder underwater is supported by this gantry, so I'll need to make rigging between those two parts. I intend to make that rigging fixed, then hinge the ladder in upper position to insert it into the bottle, then extend it down again once in the bottle, where it will act as the second support. As you can see, I now use a laundry pin to keep the ladder from slipping forward and the ship from leaning over. I intend to glue a fixed piece of styrene to hold that ladder in place and cover that with sand to hide it. The last pic shows the main spud in normal sailing position, this is however just for the placement of the details. I will be displaying the spuds upright.

-

Hi all, Although the Sea Installer isn't quite fully completed yet, circumstances don't allow me to continue on that build. I'm currently restricted to a "mobile modelling set" consisting of scraps of styrene, a couple of knives, files, drills and pliers, so bear with me on my next venture. This time I'm going for the Cutter Suction Dredger Spartacus. The most powerful one of its kind. Practically a big underwater rock drill. It's mainly used to deepen ports or build new ports in harder soil types, where "regular" trailing suction hopper dredgers (TSHD's) can't do the job or where very large volumes of sand need to be dredged to build up new port areas. It's probably the most complex vessel I've ever tackled as a modelling subject and this is also partly the reason I'm going to try to put it in a bottle. In my regular larger scales 1/400 or 1/700, it would become such a long build that I'm unlikely to ever finish it. The tiny 1/2000 scale allows me to leave at least some of the extensive details off. Getting it into a bottle is of course a challenge by itself. I'm not going to "just put it in", I'll be showing it doing one of its operations underwater. I don't have a bottle for it yet, but I'm using the dimensions of the Sea Installer bottle for my reference and design ideas. Here is the website of the beast itself (yes, it even has a website😁😞 CSD Spartacus I would like to display her when installing/moving her anchors. One anchor hanging free, the other on the bottom along with the cutter ladder (center part supporting the big drill) Spartacus project Overall I'll go for a similar look as Sea Installer, having a bottom part at the bottom of the bottle, with epoxy for the water layer. I will however try to cover the sand with a tiny layer of liquid acrylic gel, hoping to make a smooth transition and either expel or trap any air bubbles before putting epoxy inside. Initial idea is to mount the whole thing on a base plate, which will hold the spud pole aft of the vessel and the cutter ladder forward of the vessel. I would then cover that plate with sand-acrylic mixture and insert it without the spud pole. I will insert it into a sand-acrylic mixture in the bottle to make it blend in. I will then try to mount the lower part of that spud pole in a pre-drilled hole in the plate, so I'm sure it'll stand upright and is held firm. Afterwards I'll mount the ship on top of that spud pole. The hull normally fits into a bottleneck, however, due to the square section of the vessel and its superstructure, I'll need to mount a couple of things separately and other will have to rotate etc. Hopefully an interesting process. Initial effort and size. Start of hull build-up: As you probably noticed, that is one hell of a complex hull. Splitting it could make things a lot easier, but that's not an option here, as the central cutter ladder will have to hinge (insert in bottleneck in "seagoing position" and then lowered to the bottom) and is hanging by wires on the huge forward gantry. I will have to make those in 1 part to make that work. Below is the hinge part for the rudimentary ladder. One 1mm layer is below that to hold it in place. And here is where I currently am. The lower layer in place, but not glued. Since I don't have any paint in my mobile set, I've decided to make a decision I don't like. The ladder needs to be painted before I insert it, however I don't want to wait to continue the hull until I have paint available. I will therefore cut small pieces from the bottom plate, so I can mount that bottom plate, sand and shape the hull, and insert the ladder hinges and the cut out pieces afterwards. I admit this project may be over ambitious considering the amount of detail and rigging all around the vessel and my lack of experience in this tiny scale. It may turn out impossible, but we'll see where it goes.

-

Thanks Auger, your opinion is much appreciated as I, myself, am also still undecided. The hub is heavy, and does draw a lot of attention away from the model. I might go the middle road, keeping the stand, but leaving off the hub. I'll perhaps put the model's details (vessel name and scale) on the front of the stand later on. In any case I'll attempt to complete the hub.

- 51 replies

-

- Sea Installer

- Bottle

-

(and 1 more)

Tagged with:

-

More lanterning, the matt black background is part of the colregs nowadays. It's obligatory to avoid reflections, which would then ruin the angles of the lights. Not sure since when this was part of colregs.

-

I slowly continued work. Built the base, as this would give a better view on the complete picture. It's built up of a skeleton of styrene ribs using 2mm and 1.5mm thickness. This skeleton was mounted on a base plate and later on a 0.5mm thick sheet was wrapper around that. I first made a paper template for that sleeve. I broadened the initial design a bit, to give more support. The heavy glass bottom plate of the bottle is somewhat compensated by the weight of the hub, so the base can be placed more forward on the bottle. The hub was then further built up with the cylindrical holes and yesterday with two-component epoxy filler. Unfortunately I ran out of filler in the end (the positive side of this, is that for the first time in ages I actually used up a package of this filler before it turned bad 😁). Next up is the first sanding and then I'll order new filler and touch-up (and complete), the filler layer where necessary. After the sanding I'll see if I use a coat of spray filler or just go for regular primer followed by satin white. As I'm going into a busy period, this will go in hibernation for a while. In below picture you can see something I didn't pay enough attention to. Through the hole you can see a rather large piece of the rib around the bottle neck. I wish I had made those ribs less sturdy and visible. Since they are 2mm thick, it's a bit late to decently correct that. On the positive side, I dropped the hub on the floor during filling and it didn't have a scratch...

- 51 replies

-

- Sea Installer

- Bottle

-

(and 1 more)

Tagged with:

-

Thanks for the likes. Here's an update on the project. Reached a major milestone now. So the "hub" is progressing. Here you can see the blade entrance holes in place. I'll build up a cylindrical edge from the hole in this straight plate outwards. I will then continue filling some spaces with scrap styrene in order to use less filler. Eventually I'll add the filler and sand it to shape. Here is the inside, which tightly fits around the bottle cap, with the three "light holes" visible. Not entirely convinced of the size though. The hub looks a little too large. It looked ok on my drawing, but then the bottle I drew was actually too long compared to the real one. Somewhat afraid the hub will take too much attention... On the other side, I did decide to complete it, if not for this project, perhaps I'll use it on another in the future. Too much fun not to complete it. And then the milestone, I completed the model itself. In the above picture you could already see I poured the epoxy. After some minor setbacks, like losing one of the small blue cranes etc. I did manage to complete it. I was not very happy with the crane missing hooks and I tested some CA on the small threads, but none wanted to stay straight. Eventually I decided to put the hooks in the uppermost position, basically on the boom itself. At least it's something... The etched sign on the back is not very visible on the pics with a white background, so I'll take some with a better background later on. Time to continue the hub and the support now.

- 51 replies

-

- Sea Installer

- Bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.