-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by goatfarmer11

-

That turned out beautiful, thanks for sharing your build.

- 56 replies

-

- Sea of Galilee Boat

- SE Miller

-

(and 1 more)

Tagged with:

-

Barncave Shipyard by mbp521 - Scale 1:1

goatfarmer11 replied to mbp521's topic in Non-ship/categorised builds

You're making good progress Brian. Hopefully you will beat that Texas summer heat. -

Thank you Bob and I appreciate what you are saying. I am truly not interested in the bread and butter method at this point for many reasons. The most important is this is not how I "imagine" building a model boat. I also feel that a 42 inch long hull as Miranda has would require far more carving to fair than my skills will permit. I foresee needing gallons of filler and lots of sanding and still not having a fair hull. However, after looking at the link you shared in the previous post I am now thinking building something similar to how that launch was built could result in the finished product that I so desire. Is this the "lift" method you mention? The look of the closely spaced bent frames is what I see in my head when I think of such a boat from this era. I think if I milled some 1/8" x 3/8" cherry to be bent for the frames the end product could be spectacular.

-

No apologies necessary Jack. I agree with you totally that more frames will make a better hull in the long run. The problem only comes from me learning to "design" them. Commentary is always appreciated and this time it is just pushing me to learn something new. As stated by Bob Cleek learning to loft opens up a whole new world of possibilities and that is a good thing. Thanks for following along and I too hope she ends up being a great build.

-

Ok...now we are jumping to conclusions that aren't really necessary. Let me start by saying that Miranda was a boat designed and built by Basil Harley in 1985. The build was published in Model Boats magazine and this includes the steam engine and boiler that he used in her. I am following these plans and the frustrations only began when it was suggested to me that more bulkheads would make for an easier to plank hull. I agree with this and have only been wanting to figure out how to do this. By removing the bulkheads and using frames instead, the inherent weight change in the hull should be minimal. The steam plant and the boat have been built by others and and she sails just fine. I am not designing this vessel but simply making some minor changes. As far as the engine and steam plant go I am very comfortable with the fabrication of these. I am fairly new to steam as in I have not yet built a steam plant. I have been studying steam engines, boilers, condensers, water pumps burners, etc. for a couple of years now. I am by no means an expert on the subject but I consider the subject well studied and am now ready to build my first engine and boiler. I will be using the powerplant designed by Basil Harley for Miranda so lets just say the plant "should" be just fine for the vessel. I am aware of the proper materials and methods to build and test a pressure vessel of this type in a safe manner. Live steam is what led me to Miranda so the model boat building is very new to me and once I am satisfied with her hull the rest can begin to come together. I appreciate the comments and concerns but lets not take this project too far off its course. Thanks

-

Thank you Bob for your well thought out reply to my problems. I had not given bread and butter a thought until now. It has been my intention of creating more frames as I go along but I've had problems understanding the basics of lofting new lines drawings. Perhaps a good book can help me through this. The reason I have ditched the idea of bulkheads is to keep the inner hull as unobstructed as possible so I will have plenty of room for all of the necessary equipment for this build. It may seem that starting with a scratch build is a bit over my head and starting with a kit may have been a better idea. However after looking at kits they do not fit in my budget for this summer. Maybe putting Miranda on hold is the best idea. Maybe I should get more complete plans for a different vessel and build some experience with that? I will say even as frustrating as it may seem I have still been enjoying this journey so far. Lots of food for thought and I appreciate the input. I have some decisions to make.

-

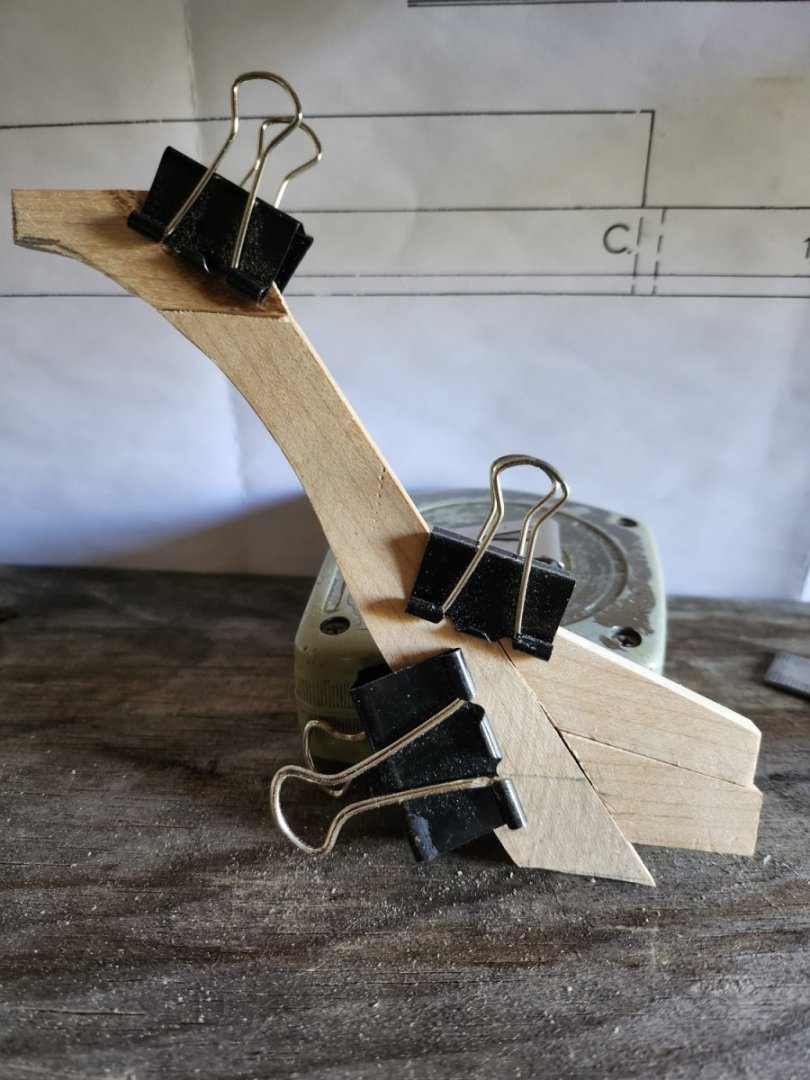

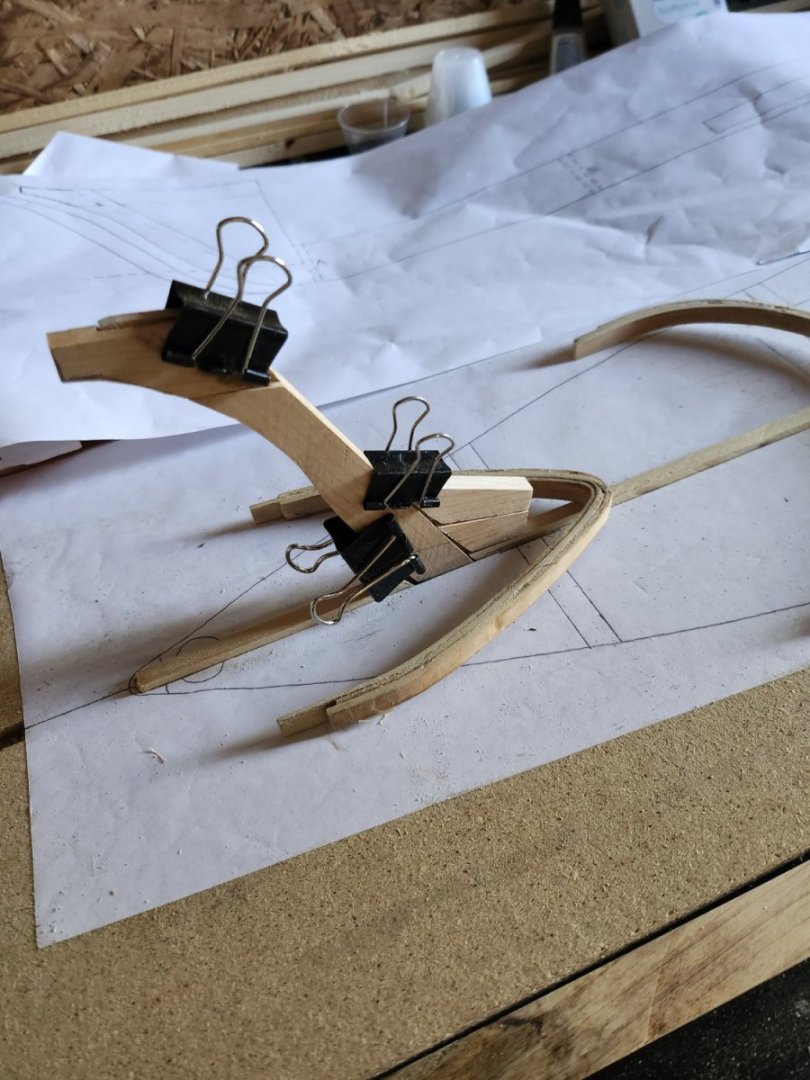

I hope those of you following along aren't going to get sick of me but I have, for the third time, restarted Miranda. For whatever reason, the plank on bulkhead method just isn't working for me. It doesn't seem to be what I envisioned when model ship building entered my mind. I want to make Miranda more in a style that she would have been originally built at the yard. My methods are certainly not authentic to the original but the finished product may be closer to the real thing. I have started by bending and laminating some of the ribs for her. And I have started to build up the Keel to make it stronger than the one piece board that I started with. I think I am going to be much happier having an open hull and after fiber glassing it should be plenty strong enough. It will also give me places to put things like radio gear and fuel in the stem and stern. I also took the time to make a build board from 3/4" melamine. I learned the importance of this so I can take accurate measurements as I progress through this hull to make sure things are following the contours and remain square, I have attached a sketch of the hull to the board to help maintain the lines. More to come in the near future and as always comments and suggestions are welcome.

-

This looks like a wonderful kit you are starting with, I would like to pull up a chair and follow along.

- 122 replies

-

- Artesania Latina

- Pen Duick

-

(and 1 more)

Tagged with:

-

Barncave Shipyard by mbp521 - Scale 1:1

goatfarmer11 replied to mbp521's topic in Non-ship/categorised builds

Oh how exciting. Building a shipyard from the ground up. I'll definitely be following along for this one! -

Another update to my build log. I got caught up to where I was before... And after trying to fit the extra bulkheads I tried to draw I found I am no good at lofting lol. I was not happy with their fit at all so I will not be using them. I did practice bending some 3/8" x 3/8" cherry and I think I may try to fit some "frames" between the bulkheads. I only got 1 minor crack and it should not be a problem. I will have to do it by trial and error but I think in this way I can adjust them to be a perfect fit. I began fitting the gunwales and am very happy with the curvature of them this time. Everything flows smoothly as it should. I have one more layer to put on those and I will lay some dummy planks to get the shapes for the frames I am going to add. Thanks for following along.

-

Todays progress was slow but unlike last time I spent more time cutting the bulkheads to get them as accurate as possible. I cut outside the lines and sanded to the lines. I now have 10 bulkheads instead of 5 but after fitting them I can tell that the 5 extra that I created are not going to work well. I do think I can modify them as I go but this will be a slow process. I have gotten a whole new respect for ship designers. I believe I may spend some time to learn proper lofting techniques. Life would be so much easier. Here is where I ended today...nothing has been glued as it only got up to 43* F today and I feared the glue would not hold well. I also want to do some more fitting of the bulkheads that I tried to create to smooth out some lines. Thanks to those of you following along and offering advice.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.