-

Posts

68 -

Joined

-

Last visited

About bizibilder

- Birthday August 28

Contact Methods

-

Website URL

http://Bizibilder.blogspot.com

Profile Information

-

Gender

Male

-

Location

Norfolk UK

-

Interests

Model Ships, Clockmaking, Astronomy, Astrophotography

Recent Profile Visitors

-

daHeld73 reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

daHeld73 reacted to a post in a topic:

HMS Bellona 1760 by SJSoane - Scale 1:64 - English 74-gun - as designed

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

-

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

Obormotov reacted to a post in a topic:

HMS Victory by guraus - scale 1:48 - plank on frame

-

jud reacted to a post in a topic:

Cleaning needle files

jud reacted to a post in a topic:

Cleaning needle files

-

GrandpaPhil reacted to a post in a topic:

Royal Caroline by bizibilder - FINISHED - Panart

GrandpaPhil reacted to a post in a topic:

Royal Caroline by bizibilder - FINISHED - Panart

-

mtaylor reacted to a post in a topic:

plans for a 1/48th scale HMS Victory

mtaylor reacted to a post in a topic:

plans for a 1/48th scale HMS Victory

-

The plans used in Longridges book are available again in the UK: Here Mostly drawn to 1/96 scale but the frame drawings are full size for 1/48 scale. (Worth a look at Sarik Hobbies - Who now carry all the plans from the now defunct Model and Allied Publications in the UK - they also have plans for several other scale sailing ships - usual disclaimer, I have nothing to do with them apart from being a satisfied customer.)

-

clearway reacted to a post in a topic:

HMB Endeavour by bizibilder - Caldercraft - 1/64 scale

clearway reacted to a post in a topic:

HMB Endeavour by bizibilder - Caldercraft - 1/64 scale

-

echacarra reacted to a post in a topic:

plans for a 1/48th scale HMS Victory

echacarra reacted to a post in a topic:

plans for a 1/48th scale HMS Victory

-

mischief reacted to a post in a topic:

Finding the center of a dowel

mischief reacted to a post in a topic:

Finding the center of a dowel

-

CaptainSteve reacted to a post in a topic:

Royal Caroline by bizibilder - FINISHED - Panart

CaptainSteve reacted to a post in a topic:

Royal Caroline by bizibilder - FINISHED - Panart

-

Finding the center of a dowel

bizibilder replied to KenW's topic in Modeling tools and Workshop Equipment

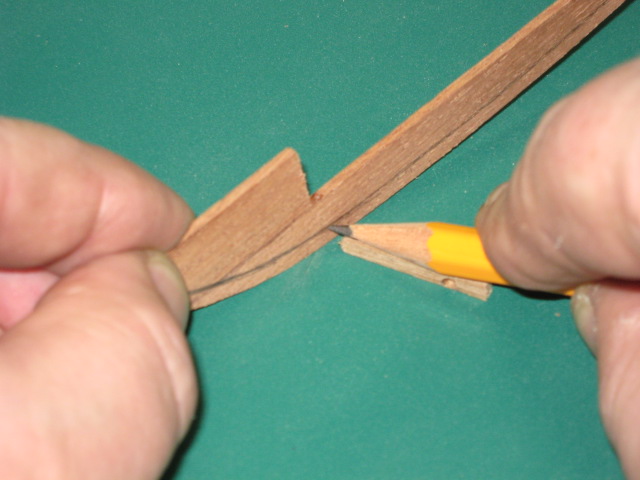

Just find something with a thickness about half the diameter of the dowel (Wood, metal, card or plastic will do). Place it on a bench with the end of the dowel against it. Draw a line across the end of the dowel using the guide. Repeat, rotating the dowel about a third of a turn each time (no need to be too accurate). You will have three lines drawn on the end of the dowel either marking the centre (if your guide was exactly half the diameter) or a small triangle that will allow you to estimate the centre quite easily and accurately enough for model work. No need for special tools! -

bizibilder started following Royal Caroline question , Finding the center of a dowel and hss vs carbon steel drill bits

-

AS I recall (It was quite a few years ago!) I simply washed the brass decoration in washing up liquid and dried it then painted it with Gold enamel - all over. it was stuck in place with a tiny dab of 5 minute epoxy. I seem to remember I did a side at a time in one "go" after making sure that everything was prepared and checked for fit. Some of the decoration was thinned down by filing before fitting as I seem to remember some pieces were quite thick. The "curved" pieces at the stern were simply filed to fit on the back as bending the castings was unlikely to be successful. I believe the current version of the kit has some of the decoration in laser cut timber rather than brass castings/ etchings but someone else would have to confirm that for you.

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

hss vs carbon steel drill bits

bizibilder replied to Kurt Johnson's topic in Modeling tools and Workshop Equipment

It really doesn't matter which you use. The major difference between HSS and carbon steel as far as we are concerned is that carbon steel can, if heated sufficiently, lose its sharp edge and can revert to its original "soft" state. However it would have to be taken to "blue" at around 300°C for this to happen. HSS can be run red hot and will still hold its edge. It is unlikely that in modelling - even with our small power tools - we would manage that unless we really abused our tools. If you are burning the timber with a drill bit something is wrong and you may well be in a situation where carbon steel tools would be damaged. Properly hardened and tempered carbon steel is actually harder than HSS - unless allowed to heat up and therefore become soft again. In the US carbon steel suitable for toolmaking is sold as "drill rod" and in the UK it is known as "silver steel". It is worth noting that carbon steel tools will probably be much cheaper than the equivalent HSS. -

The brass etch is, I believe, from older kits (mine had it and the kit was bought 15 or so years ago). The blue is the "resist" coating used so that the relief can be etched into the brass. The easiest way to remove it is with fine "wet and dry" abrasive paper used wet (very wet!) wrapped round a block of wood. Do this before you cut out the pieces so you get rid of all the "blue". If you wish you can then use a very fine abrasive paper or even polish the brass to get the finish you require. Cut the pieces out with either snips or strong scissors - this may lead to a little curling. If this happens turn the curled pieces over and gently tap them flat with a light hammer. Paint the "background" of the pieces - quite roughly if you like - and then repeat the abrasive routine to get rid of the excess paint. This will leave you with nice clean edges to the paintwork. I have appended a couple of pictures of my finished brasswork: The wooden parts are either laser cut or milled and are the more recent offering with the kits as far as I am aware.

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

- 22 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.