-

Posts

867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaltyScot

-

I am happy to have you aboard, Steve. I like the way she is shaping up too I must say.

- 257 replies

-

Yep, I like those davits too. I intend to do a similar thing with the catheads on my build. The kit supplied plywood ones just don't to the model justice.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Glenn, she has come together very nicely. Well done sir.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

Wow, a lot has happened while I was otherwise occupied. She is starting to look quite regal. As I have said before, quite the inspiration for us newbies.

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

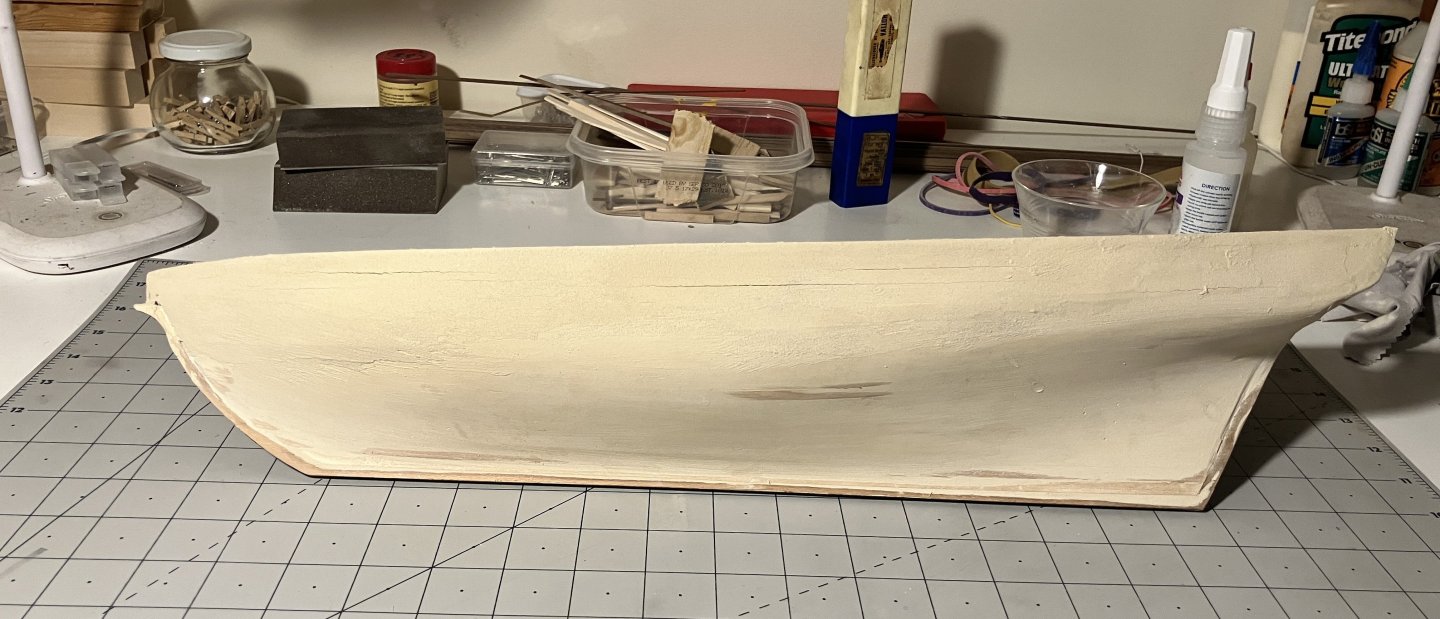

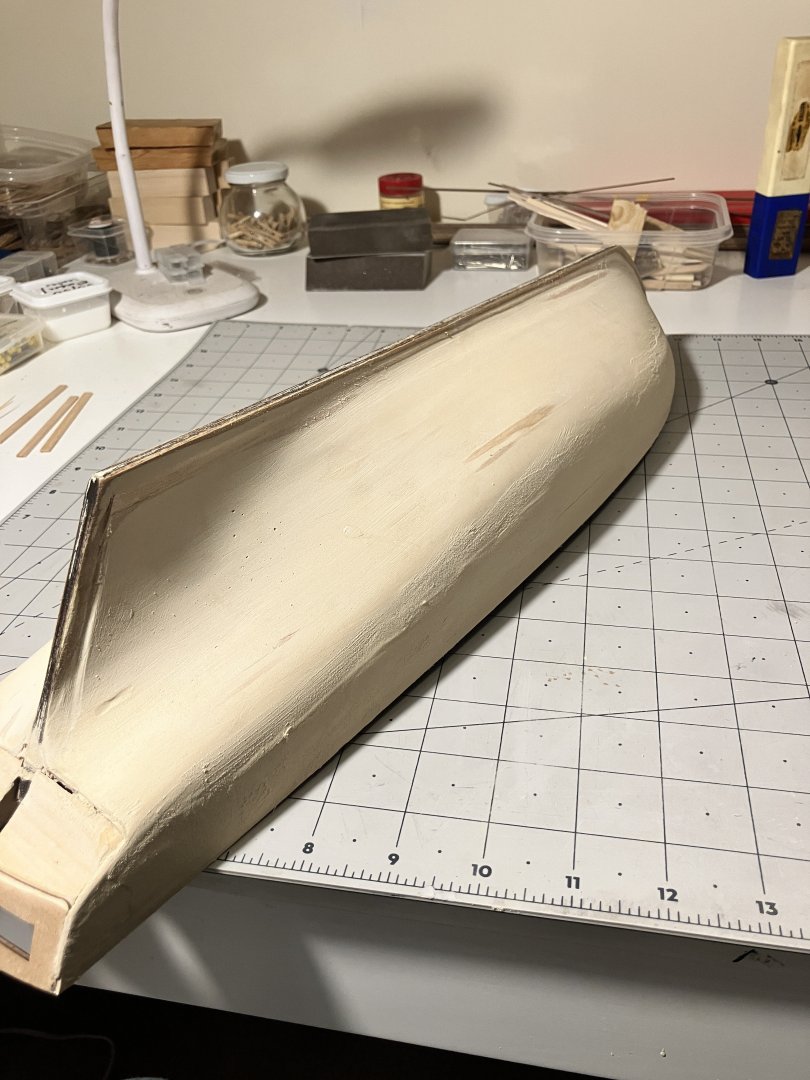

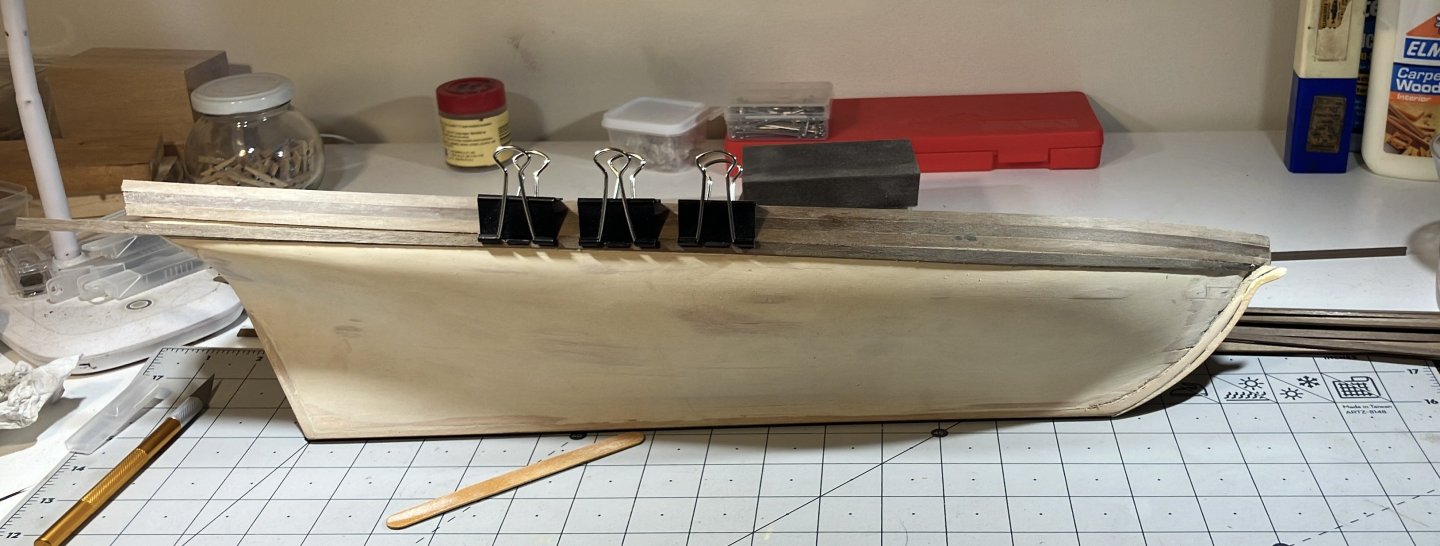

Good morning, folks. I managed to squeeze some time in the shipyard these past couple of days as things are slowing down now that the house is finally sold. The move, at least as far as I am involved, is complete and I no longer need to be running back and forth between here and DC. The other main job we were concerned with that was keeping me from my build was our deck at the back of the house. It was made with composite decking and the water was pooling on it quite badly when it rained. We had to remove all the boards, replace some of the joists and then refit new 5 1/4 decking planks. In effect I guess it was good practice for my deck planking on the build Anyway, on with the build. I finished the first layer of planking and covered the hull with a fine wood filler before sanding the whole thing smooth to accept the second layer of walnut strips. I am not using the material that came with the kit because the quality of the wood in this kit really does leave a lot to be desired. I then started adding the second layer: Because of the position of the deck hatches I had to adjust one of the deck beams so that it wasn't going across the middle of the hatch opening, that looked a little weird when I laid the false deck on. It looks better now: Today I hope to continue with the second planking. Stay tuned

- 257 replies

-

You did a very nice job with that sail, Trevor, your usual meticulous approach has paid off. I shall red through your recent posts when I have more than 10 minutes to spare (we are into our house reno again now......)

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

A joy to read and observe. I missed this!

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Welcome, George. Enjoy the journey.

-

Welcome to the forum. As stated above, don't be afraid to ask questions, it will help you along your way. Enjoy!

-

I am finally home and have the moving truck full of stuff that we are keeping from the house unloaded, Trevor. I haven't been able to get in the shipyard just yet, the CEO's list of to-do's seems to grow longer instead of shorter Tomorrow is a rainy day here (no sudden, unwanted snowstorms for us!) so I will be bale to sit down and get on with my build. I am very much looking forward to that.

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

You made a fine job of that, Trevor, I really like how the sail turned out. I don't have sails on my current build but this post will go to my "aha, that's how it's done" folder

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I agree, Phil, those railings really add to the overall look of your build. You are doing a fine job with this one.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

My fellow modelers, the CEO has declared that my presence is needed elsewhere for the next week (at least). Her mother's house is under contract with the closing date set for April 28th. She plans to move out on the 23rd. The plan is to spend a good part of next week up there in DC to get the final bits and pieces out of the house that are either being sold or donated, before the moving company gets there. There always appears to be something else to be done up there and both myself and the CEO are counting down the days until the 23rd rolls around. Because of all this, I will be away for an as yet undefined period of time, that matter is not under my control....... I go where I am requested because, as we all know, happy wife, and so on......

- 257 replies

-

I know exactly what you mean, Glenn. On my Endeavour build I had fully finished the hull, painted and varnished it and was very happy with the result. While I was drilling the holes for the stanchions at the stern of the boat I slipped with the tiny drill bit and went through too far. When I saw the drill bit sticking out through the underside of my nice shiny hull (and the hole that got made when a piece of wood got punched out by the drill bit), I nearly lost it. I had to just take a very deep breath and tackle the issue otherwise I would have thrown the drill against the wall, or something worse.......... Like you mentioned, getting on with something enjoyable and uplifting is the way to go. Your build looks good mate.

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

Been there, Trevor. My shipyard is in a spare bedroom here in our home. When I get the vacuum out and get in here, I hear all the bits of nails (and the odd tiny cleat) scuttling on up the vacuum hose.

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

I agree with all of the above, nicely done, Phil!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

There is definitely an unpredictability to our weather here right now. Yesterday and today we had 81F, fantastic weather to be outside doing stuff. Tonight we are expecting thunderstorms and highs tomorrow of 57F. Grab the sun while you can I guess I hope it shines up there, Trevor, so that you can get out and get your spraying done.

- 167 replies

-

- Norwegian Sailing Pram

- Model Shipways

-

(and 1 more)

Tagged with:

-

Received partially-built Corel Victory -- worth salvaging?

SaltyScot replied to SaltyScot's topic in Wood ship model kits

It is not in the trash yet I have a lot of other projects going on at this time, both inside and outside the shipyard. This may be one for a long, cold winter's day.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.