-

Posts

867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaltyScot

-

@Coyote_6 @Keith Black Thanks guys. I strive continuously to reach y'all's standards of excellence 😉

- 257 replies

-

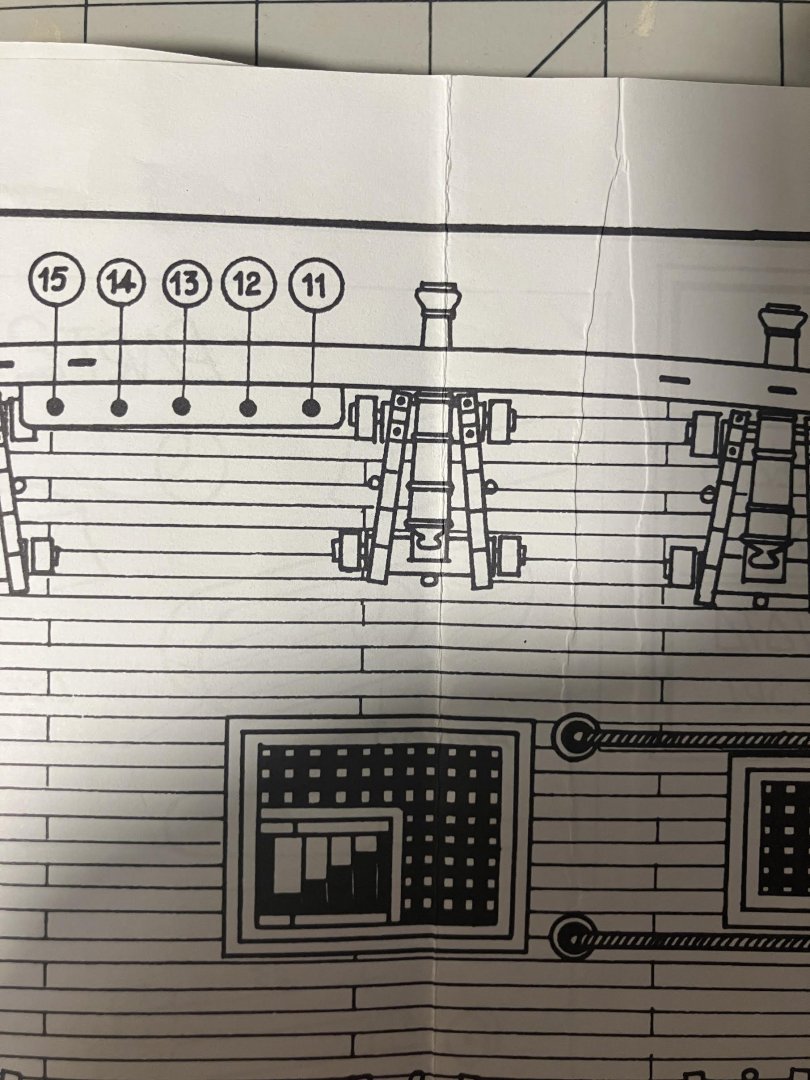

Thank you so much for pointing that out, Jerry. I don't know what possessed me to build it that way, the plans clearly show how it should be done: I am glad I only put the prototype together now. Thanks also for the images.

- 257 replies

-

A small update on my Lynx build folks. Once the hull planking was complete I started adding the bulwark strakes. I used walnut for these too. The false deck was fitted, glued and pinned in place to dry before I started: Once that was done I made a template of the exact dimensions of the inside of the deck surface area so that I could shape and bend the wood for the waterways. With that template (made of card), I traced the outer edges onto a piece of scrap wood to give me the two shapes I needed. I soaked two strips of walnut for 24 hours in hot water. Funny thing, I actually let them float in our hot tub for that period of time because I didn't have a vessel big enough to soak them or a way to keep water hot for that long. Luckily we haven't shut the hot tub down for the summer yet and it went very well! The soaked planks were bent edge wise and held in place using pins. They will remain like that for another 24 hours: While they were drying, I filled the small cracks in the hull, smoothed it all over with 220 grit and gave it a coat of white primer. She looks fancy in her new coat This was the initial coat so there is still some fine tuning to do with small inconsistencies here and there:

- 257 replies

-

I was thinking why the color scheme was very similar to, let's say, HMS Victory. Thanks for that wee tidbit of info, Phil.

- 257 replies

-

On that note, I found a beautiful old piece of wood here on our property that I intend to shape and use for my stand on the Lynx. I find bringing a natural aspect into something like that, without it being too distracting of course, lends the final display an air of "class". Just my 10 cents worth, Phil.

-

Hi folks. Just a very quick note on a decision I reached earlier today (while I was out in the garden prepping my planter beds for beans actually!). I have decided to go with the following color scheme for my build: Below the waterline will be white with a dark blue strip running between that and the tan/mustard/ochre ish (tbd) color on the bulwarks above. Very much like this one which is being so finely done by @Dr PR. I like those colors!

- 257 replies

-

Nice tutorial there, Glenn, a real eye opener. It's nice to see old Stadler and Waldorf having a chat next to your fish pond too

- 241 replies

-

- Vanguarrd Models

- Harpy

-

(and 1 more)

Tagged with:

-

The coloring on the inside of the wee boat is fantastic, B.E. You picked out the tones well, sir. I like the contrast between those darkish brown tones and the white on the outside. I am seriously considering a "lifeboat" scratch build at some time in the future and when done, I hope it looks half as good as this one here!

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That isn't the worst idea in the world, Tom. I guess it would be a little time consuming but what else have we got to do 😂

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

Your attention to detail is awe inspiring, Phil. Now I also know what baggy wrinkles are too

-

Tom, nice work. Looking at the last photo in your latest post I noticed how good the deck staining was. What method was used on that one, sir?

- 206 replies

-

- Endurance

- Shackleton

-

(and 2 more)

Tagged with:

-

I Have an Itch to Scratch

SaltyScot replied to SaltyScot's topic in Modeling tools and Workshop Equipment

I have those, Adam, and a slow grinder to keep them sharp (I am a wood carver by the way). Thanks for your feedback, sir. -

Well ya learn somethin' new every day! You did a good job on getting that done, Glen. Quite resourceful.

- 301 replies

-

- Constitution

- Bluejacket Shipcrafters

-

(and 1 more)

Tagged with:

-

I Have an Itch to Scratch

SaltyScot replied to SaltyScot's topic in Modeling tools and Workshop Equipment

Considering most of my tools are DeWalt anyway, this makes total sense (at least that is how I am going to present my case to the treasurer ) -

I Have an Itch to Scratch

SaltyScot replied to SaltyScot's topic in Modeling tools and Workshop Equipment

Yes, a good vise was the other thing I had thought a lot about, along with the scroll saw that is already on my list. I have a nice soldering iron already, Phil, and I have already purchased that sailmaking/wood bending tool that you had recommended. As far as the milling machine goes, I think I will start a kit, like @Jim Lad suggested, and see how I get on. -

I Have an Itch to Scratch

SaltyScot replied to SaltyScot's topic in Modeling tools and Workshop Equipment

You are right! A sound piece of advice, John, and one I shall heed 100%. The last thing I want is a pile of (sometimes expensive) equipment sitting around that I thought I needed. That would be very foolish. I have opted for a decent scroll saw, but only because my old one had seen better days. THANK YOU!! -

Welcome aboard. Have fun on your new journey!

-

Welcome aboard! If you have not already done so, start a build log so that others can follow along.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.