-

Posts

30 -

Joined

-

Last visited

About iaincwil

- Birthday 02/07/1947

Profile Information

-

Gender

Male

-

Location

Argyll Scotland

Recent Profile Visitors

-

rek reacted to a post in a topic:

Making your own Hobby Wood

rek reacted to a post in a topic:

Making your own Hobby Wood

-

Canute reacted to a post in a topic:

Sources for Boxwood Blocks

Canute reacted to a post in a topic:

Sources for Boxwood Blocks

-

popeye2sea reacted to a post in a topic:

Sources for Boxwood Blocks

popeye2sea reacted to a post in a topic:

Sources for Boxwood Blocks

-

mtaylor reacted to a post in a topic:

Sources for Boxwood Blocks

mtaylor reacted to a post in a topic:

Sources for Boxwood Blocks

-

Chuck reacted to a post in a topic:

Sources for Boxwood Blocks

Chuck reacted to a post in a topic:

Sources for Boxwood Blocks

-

Hi! I dont know if you managed to get the blocks you were looking for but thought I would pass on this address www.syrenshipmodelcompany.com they make the best blocks I have seen, then again I am sure there are many as good but this is a cert, all the best enjoy mick

-

Keith_W reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

Keith_W reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

-

Tadeusz43 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

Tadeusz43 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

-

Omega1234 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

Omega1234 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

-

Omega1234 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

Omega1234 reacted to a post in a topic:

Building the Australian Tug WATTLE 1:24th scale

-

Hi! Louie, I have family in Oz, most of my side are all gone now but wife's side are in South Australia, my great uncle Beck lived in Maroochidore have a paper clip of aunt as she broke her ankle surfin at 70 y/old and uncle who lived through 2 w/wars was hit by a car crossing the road, so guess I have a thing about Australia and would have been there but mum failed on the medical! end of story, i

-

iaincwil reacted to a post in a topic:

Le Fleuron by cabrapente - FINISHED

iaincwil reacted to a post in a topic:

Le Fleuron by cabrapente - FINISHED

-

iaincwil reacted to a post in a topic:

Bristol Pilot Cutter by michael mott - 1/8 scale (POF)

iaincwil reacted to a post in a topic:

Bristol Pilot Cutter by michael mott - 1/8 scale (POF)

-

The Wattle was built in Australia 1933 I didnt start taking pictures of the initial start of building as it had not crossed my mind at the time to do a build log its the first time and I am a bit shaky as to how to go on, so here are some of the first pictures, after final layer of glass tissue and propeller tube and shaft fitted sorry about the poor picture, this was quite a big jump to fitting the rudder and the sponson another leap in time whilst the resin was curing I built other parts wheelhouse, winch, lifeboat part of davits and l/boat cradle latest updates are brass-work on funnel more to come as I progress mick

-

I build small boats! like in the book from "warship to workboats" small working craft from around coastal areas, some are as small as 2" the largest to date is "9" motorized naval launch with kitchens pattented rudder" most are around 5" to 6", these are fit in between building larger R/C boats just for a break! I think SMALL may be anything up to 8" to 10" but this is just a personal thought. mick

-

just fantastic! I wish I had a bigger workshop I have a 10'square shed with plenty bits of machinery but its always a big fight moving this saw so I can use the bandsaw which is a put of to start with, my wife says take a bed a kettle she would never see me, just wish it was bigger, most of the time I am on the kitchen table under fire!, I love the open work boats of men o war and the fishing boats from all around the coastline so I will be watching this build closely for any good ideas I can pick up, mick

-

iaincwil reacted to a post in a topic:

Biloxi schooner model restoration by Russ - 1/24 scale - Finished

iaincwil reacted to a post in a topic:

Biloxi schooner model restoration by Russ - 1/24 scale - Finished

-

iaincwil reacted to a post in a topic:

Household blackening fluids.

iaincwil reacted to a post in a topic:

Household blackening fluids.

-

it must be great working in that scale the amount of detail is superb, I have made blocks the same way but a little smaller I have them rigged up on my side lamp just holding a weight at present also a memory stick. I used a large knitting needle first filing the groove then cutting it of in slices, building the body up almost identical but without the pins, I will try making smaller ones the same way, mick

- 2,196 replies

-

Hi! Michael, not much I can say as its already been said! it really is a fantastic build, I will be starting a Bristol channel pilot cutter as soon as I finish the 1817 naval cutter, Hilda is the one I want to build but have not seen any plans for her yet but I have the other ones plan but the name slips my mind just now! if you have seen or heard of plan for Hilda would be grateful for details, the other thing is what size thread did you start of with for making your rope, and did you use the same thread for them all just upping the number of threads, Mick

- 2,196 replies

-

iaincwil reacted to a post in a topic:

Hooks and blocks

iaincwil reacted to a post in a topic:

Hooks and blocks

-

Hi! Lambsbk the hook out back there looks perfic, making the ring smaller will be a trial but not impossible, always try to remember that the little turnback on the point of the hook is so you can put a whipping on the stop it jumping of whatever its hooked up to, I will look in my naval handbook to see if there is a drawing and the correct name for it,

-

Silver Soldering Tools

iaincwil replied to bundybear1981's topic in Metal Work, Soldering and Metal Fittings

bundybear there is a blowpipe that you may be able to find on one of the jewelry web sites which you use in conjunction with a spirit (meths) lamp, I used it for very fine work as a blowtorch can blow everything all over the place, it is good for soldering very small parts that do not require the higer temp. -

Did the build and its a great little boat have it alongside my whaleboat on the trestles they would make great little gifts "to the right people" mick

- 38 replies

-

- biloxi oyster

- skiff

-

(and 1 more)

Tagged with:

-

ships longboat by iaincwil - FINISHED

iaincwil replied to iaincwil's topic in - Build logs for subjects built 1751 - 1800

I think I will make another one now but using english boxwood and holly if I can get it milled, thing is we need a new bandsaw blade its been well used! not much good for any fine work also the thicknesser will need a touch up on the oil stone, aint winter a bitch!!!!!!!!! -

nothing much else to say you have all said it with the exception of making an drying cupboard you can build a frame with racks for the wood and in the bottombuild a box with two light bulb fittings in the top have holes for the heat then cover the whole thing with polethene make sure you have the ends of the wood coated either with wax or paint if in planks use strips in between to let air ciculate around plug in and tape up, another alternative is an airing cupboard if there is room in there, this is the equivalent of home kiln drying, I have stacks of holly been under my shed now for around 4 years ready to come inside for a while now, also best part of 1/4" ton of mahogany in my loft been there for about the same length of time will have to dig out a plank to cut up,

-

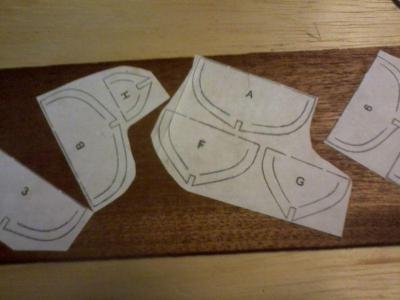

this is the first time that I have attempted plank on frame build, usualy I carve the hull shape from a block then fit keel and planking, then carve as much as I can from inside until I can see a light through, this project has taught me a lot, first I think I have the pics in the wrong order but here goes first I cut out each frame using a fret saw the where the slots were on the kit I drilled a small hole at each end and cut it with "ya guesed it a jigsaw" I cut out the keel and false keel glued it up then started fitting the frames using the jig shown it makes the job much easier, then came the planking well I dont need to say much about that there are enough articles on planking out there, next the fitting out the inside some bits are quite fidjety for my sausages but I manage, I made the mast and other spars from beech bbq sticks run them in my dremmel to get the taper, I drilled a hole in a scrap of wood held it in the vice and run the dremmel then used a sharp knife to take of the thickest and finished with a few different grades of wet and dry paper,

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.