-

Posts

538 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SGraham

-

Thanks Joe. I just took a look at your Prince de Neuf. That's the level of expertise I'd like to work up to. I especially like your paintwork on that build. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

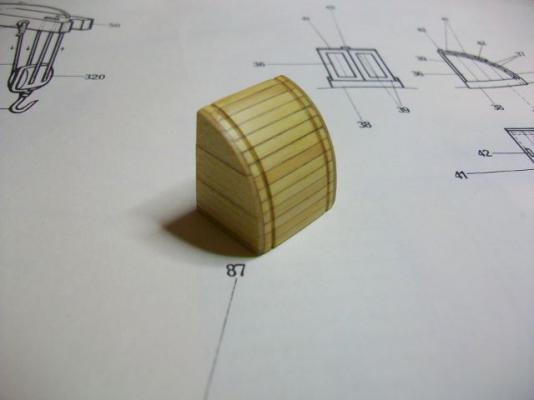

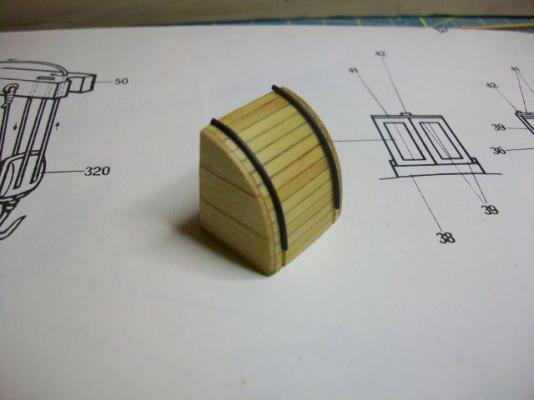

And a little bit more today. I've started on the boobyhatch, if that's what you call it. It's the forward companionway. Here's a view of the back side of it planked up and slotted to take the rails for the sliding hatch cover. I decided to use wire for the slide rails. I think they'll look OK when the cover is on them. I used amber shellac on it and rubbed it out with #0000 steel wool. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Here's the rudder post made of maple and a desert ironwood tiller. Brass ring blackened and blackened brass bolts as well. Thanks for looking. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks David. That's helpful to know. Next up is the tiller. I've got a piece of desert ironwood I'm planning on using for that. The question I have is about the ring that is let into the deck around where the rudder post emerges from the deck. I don't know its name. The kit supplied one made of brass. Were these commonly made of brass? Copper? Iron? Wood? Take your pick? I'm leaning toward blackening it like iron. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Well, I finished the pintles and gudgeons, I guess. I redid the Brass Black using an 8:1 ratio on the pintles. On the gudgeons I used undiluted Brass Black and immediately after rinsing wiped them with a coat of wipe-on poly. It's funny, I got corrosion on the pintles and none at all on the gudgeons. Both stood up to handling pretty well, probably due to the wipe-on poly. I think I found what works for me. I also redrilled and filled the plugs on the trailing edge of the rudder with darker colored putty. The pintles and gudgeons aren't quite straight, but I'm happy enough with how they look right now. Hanging the rudder was the trickiest step yet for me. Sorry for the low quality photos. Thanks for looking. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I'm pulling up a seat too. Fascinating ship and I'll enjoy seeing this built from card. Steve

-

Sam, That naphtha is pretty amazing stuff. I've used it to remove duct tape residue from a guitar finish. It did the trick with no effects on the finish at all. Still, in the esoteric world of chemically treating metal surfaces, I'm not sure it wouldn't interfere somehow. I'm going to try diluting the Blacken It per David's suggestion too. That makes a lot of sense, Jesse. Your handwork is beautiful, and you work very quickly. It's a joy to see your Scottish Maid taking shape. My dad and grandpa were both watchmakers. Speaking of naphtha, they used it to clean watch hairsprings. I called it hairspring cleaner for years and only learned it was called naphtha when I tried to buy a can of it using the wrong name. We had a wonderful old bench jeweler who learned his stuff after WWII on the GI Bill. He could make anything and fix anything. Great, patient, kind man. He taught me just enough to be dangerous. I learned to shape things with a file from him. When I wasn't soldering broken chains, I was repairing clocks--learned that from my dad. It was all interesting and fun work. I'm so sorry that lyme disease took you away from the bench. That's a heavy loss. I'm glad you're able to keep working with your hands--even after your recent surgery. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks Sam. I used to work in my dad's jewelry shop when I was in high school, soldering chains, sizing rings, doing minor repairs. It was all metal work, but actually a lot like woodworking: shaping, filing, sanding, polishing. There was a lot of soldering, but I found that quite easy at the time. Gold, silver, and platinum all behaved themselves pretty much. Still, I guess you could say metal and me broke up in high school and it's been awkward ever since. I've used naphtha for years and wasn't aware of it leaving a residue. It very well may. I may try the muriatic acid and distilled water and see how it works. I'll check out your tale of woe. It'll probably cheer me up. I remember I had a terrible time with a musket barrel sweating after I browned it. I finally got it stopped with baking soda. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks David. I was using Blacken it straight. Looks like I've got some reading to do. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks for the comments, David, Nils, and J. David, I cleaned the parts with soap and water and then hit them with naphtha just to be sure. I cleaned my tweezers too before touching the parts. The blacking went on well. I got a uniform blackness. It took 3 applications with rinsing in between. I left it all for a day to cure and then started to handle the pieces. The blacking started to come off after a few minutes of handling. Maybe I should have clear-coated them before handling? Is that what you do? J, what was your solution? Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

I don't know about this metal work, Sam. You can coax wood along and get it to do what you want. Metal, on the other hand, has an attitude. It fights you the whole time you're working with it. Very uncooperative stuff. Humph. I got a tiny bit more done in the Glacial Progress Boatworks. I made some pintles and gudgeons from flat brass straps. They were a bit of a challenge to drill. Like I said, I'm not used to working with metal and I'm slithering all around on the learning curve. The holes are nowhere near in line with each other. I blackened them with brass black and found that it rubs off fairly quickly, of course (paint stays on wood much better...). So, after I'm done installing the rudder assembly, I'll touch up with black paint and probably put on a coat of wipe-on poly to seal it all on there. On another build log, I found a technique for assembling the pintles and gudgeons that looked like it might be within the scope of my abilities. I can't remember right now which are which--are the pintles on the rudder and the gudgeons on the hull? I'll continue, assuming that's correct. After installing the pintles on the rudder with round-headed brass pins, I notched the pintle on the inside edge. This notch is to conceal a wire that will be used to connect the rudder to the hull. I've got the wires installed now and the rudder dry-fitted to the hull. Next comes the gudgeons and some kind of gasket where the rudder post enters the bottom of the hull. Thanks for looking. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks, J and Sam. Onward to metal work--about which I know nothing. This hobby is turning out to be at least as much about learning as it is about relaxing. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

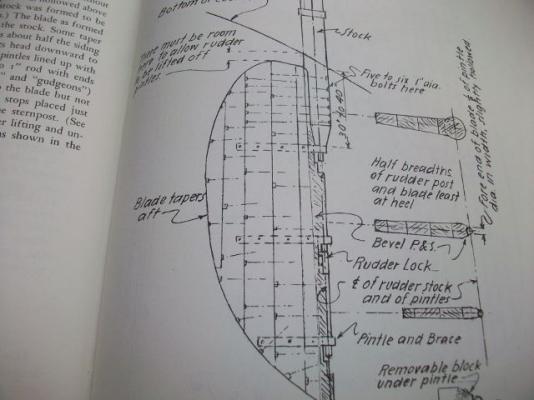

Well, I got a very little bit done today. I scratch built a rudder from some maple. I didn't like the thought of the plywood trailing edge being visible. There is a nice diagram in Chapman's American Fishing Schooners book showing how the rudders were fastened together. I tried to simulate the wooden plugs hiding the bolt heads on the trailing edge. Darker putty might have looked better. Thanks for looking! Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks for the kind words, Mark. I'm going to give the modeling a go again this weekend. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Thanks J and David. It's taking me some time to process. As far as coming to terms with the situation goes, these things, it seems, won't be hurried. Maybe building a rudder this week will be just the thing. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

Looking so good, J! Steve -

I've been out of the shipyard for a few weeks. My wife Suzie, isn't doing very well. She's in the end stage of Huntington's Disease now. I've known this was coming for a long time, but that doesn't make it easier. Her doctor says she could hang on for 3 - 4 more years. Still, it's sad, and I've found it hard to get creative lately. I'm going to try to get something done on the Shenandoah this coming week. We'll see. In the meantime, I found an old scroll saw. It's a 1938/39 Walker Turner 24" with a direct drive. Instead of a belt, the motor arbor attaches directly to the crankcase. This means it should run and cut smoother than my old Craftsman. The crank sticking up on top is for adjusting the tension of the blade. I've been fixing it up, which doesn't take much thinking. It only needs to have the table attached and the basic wiring replaced and it'll be ready to try out. I painted it institutional green. It sort of gives me a fresh minty feeling every time I look at it. Here it is minus the table. Steve

- 569 replies

-

- shenandoah

- corel

-

(and 1 more)

Tagged with:

-

Beautiful work, Pete. She's simply beautiful. What a great choice of a modeling subject, and finely executed too. Thanks for sharing the pics. Steve

- 296 replies

-

- herreshoff

- buzzards bay

-

(and 1 more)

Tagged with:

-

HALF MOON by jct - FINISHED - Corel

SGraham replied to jct's topic in - Kit build logs for subjects built from 1501 - 1750

The ship is looking so good, J. Thanks for detailing how you make cleats. That makes sense and is going into my how-to-do-it file. I've been thinking, half of "moon" could be "MO," "ON," "MN," or "OO." Have you decide yet which one you're going to call her? Steve

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.