-

Posts

1,498 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by archjofo

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

archjofo replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hello Doris, a fine collection of ship models that you have created in the course of your life. I admire your artistic style and precision with which you build your excellent models. I hope that you will show us a lot more of your art.- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

Hello Nils, you're doing an excellent job.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

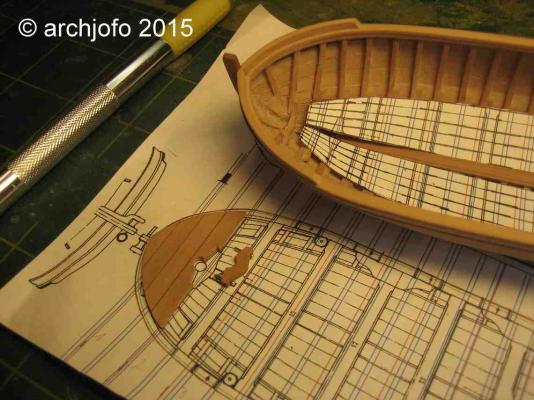

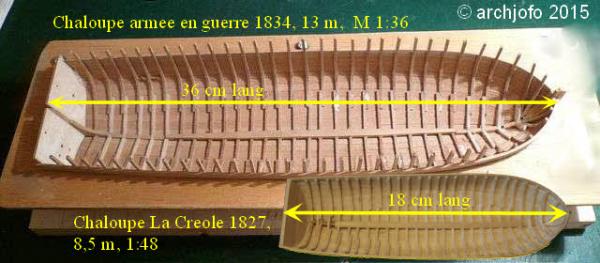

Hello, to build the sloop for my French corvette I have a lot of research on the Internet. I have seen this many wonderful plans and construction reports of a large long boat. This sloop can carry a 24 pound cannon. With a length of 13 m was used on large ships of the line. Many of these modelers build this sloop "Chaloupe armee en Guerre de 1834" according to the plans of Gerard Delacroix (Boudriot series) in scale 1:36. Current construction reports are good studio objects for all the details, just only bigger, like my small sloop for La Créole. Many of these models are fantastic works that have been produced with absolute precision. Therefore, I felt the need to compare the two models in terms of size. This I have done with a picture assembly. That's interesting?

-

@redshirt @JesseLee Indeed, that's a little confusing. But I actually use "Elsbeere". Hi Christian, Carl, Mark, Greg and Nils, thanks for the positive response. The planking is now ready. The finishing touch still missing. Here are two pictures. The removal of the boot shell of the mold will be an exciting moment.

-

Hi Nils, the hull is very well built. I am eager what happens next.

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

THE 74-GUN SHIP by Jeronimo

archjofo replied to Jeronimo's topic in - Build logs for subjects built 1751 - 1800

Hi Karl, I wish you good luck for the new project.- 194 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.