-

Posts

11,997 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Old Collingwood

-

-

-

-

I'll probably leave it as is. Given there is no detail, there is very little to work with. I don't want to weather it apart from bringing up detail and leave it as a builders model. Weathering is like being a little bit pregnant, you are or you aren't. This would have been a filthy ship given the times, and to do it properly it would be covered in streaks. Your thoughts?

Just a bit of lightning with almost like a artists powder white - just to catch the high points and details, but if you are like me I want my hull red around a dull satin colour, best achieved by buffing a mat sheen I think, , thats my approach with my hull and I would think yours is not far off that.

OC

-

Just an update folks minus pics though, I started on the lower hull by giving it a good clean down and blast with a hairdryer to remove dust, then i diluted a bit of vallejo Mat top coat and procceded to hand paint the hull, with the largest but managable brush I have to hand, I tried to follow defined areas with detail boundaries, and built it up in stages of thin coats added with the venerable hairdryer.

After a few coats it was covering quite well with just a light scattering of fine brush marks, these should rubb out with a cloth when its hardened.

OC.

-

-

-

-

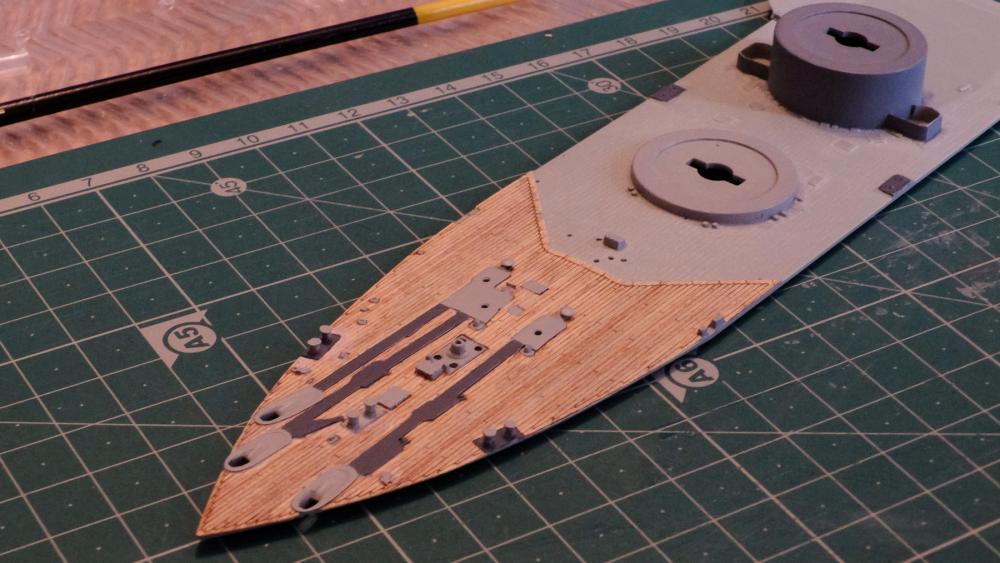

Decided later today i will firstly reduce the width of an overhang that was there for the 1918 fit, when she had more 6 Inch guns both forward and aft, in later life she had these overhangs reduced, and planked over close to her hull sides, after doing this i will dry brush a light grey colour over her upper hull before highlighting her details with a dull white.

OC.

-

Looking nice greg very clean and as you say - good to get the main hull painting out the way, always feels like an achievment when thats done, is that AP 507C on the hull? standard RN paint colour to help keep the temp down a bit on ship in hots climates.

OC.

-

-

Looks good mate

Thanks greg, Next stage will be to add the odd small additional things like the dropped ledge water break, then I will do a bit of light highlighting - dry brush style, then the hull will be turned upside down while i work on the rudders and props/shafts, then the attaching the transfer draught markings and finishing off the hull with a couple of flat clear coats the protect it, It will then be put away back in the box while I continue the deck section details etc.

OC.

-

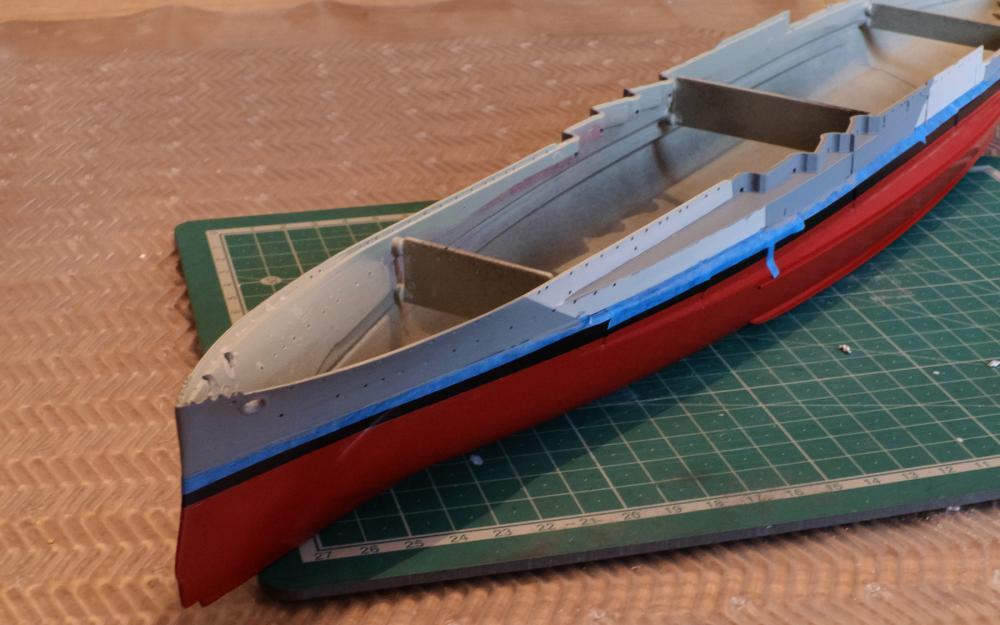

More work on the hull today - I started by re drilling out the port holes that had been blocked up a bit by paint, I then had to re build the front fairleads by drilling and shaping with a round file, this took quite a bit of time and lots of re checking under the magnifier, after all the shaping and fidling was done i got out a fine sharp pencil and worked on the recess lines to create a bit of shadowing.

Here are a few pics folks - I think its going in the right direction folks?

OC.

-

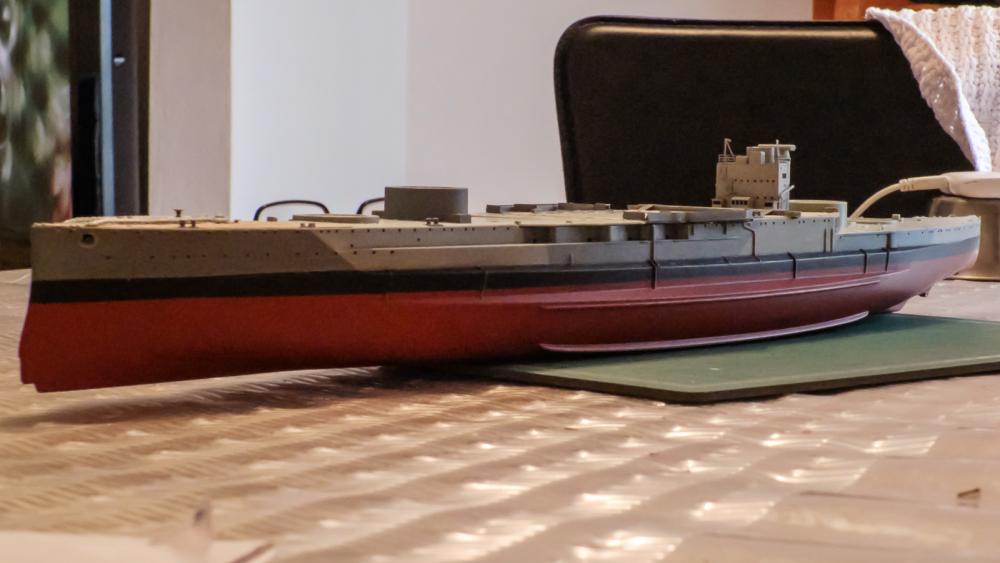

Right folks - I have done the other stage in the camo colour on the hull, basically just by putting some tape on the edge of the darker shade then applying the same thiness of acrylic with my brush, a bout the same amout of coats was applied with drying stages by the wifes hairdryer, this is a Fantastic way of speeding the whole process, as it allows me to put coats on more or less strait after each other.

I removed the tape but as expected there are ridges where the two colours meet, but I should just be able to sand these down very lightly, when the paint has hardened fully, I will then dry brush lightly along the edges to blend the two colours in, and also do some highlighting and a bit of shading to the hull.

Its great to see the hull 75% done as it was an area I was dreading

OC.

-

Hull Time again, I had only painted the starboard side before with both camo colours, so to give my deck parts a break I decided to get the hull out and start masking up then painting the mid grey colour, i painted by hand with a small brush and put on about 8 thin coats with hairdryer drying between coats so I could put on as many coats so quickly, I have only the one shade on but will add the light grey tommorow after maskin up the reverse.

Hers are a couple of pics.

OC.

-

-

Better day today folks - back at the table, it was anchor cable time, I cut one from the fret tidied it up and offered it up to the capstan/chain plate and chain tunnel surround, I had to bend part of the end then - "Ping" as it snapped and part fell to the ground, I managed to find it and super glue it back together, then i sanded the end where it wraps round/under the capstan cap and finished off by adding a coat of dull white paint.

When it was dry i fitted it in place with a few drops of super glue.

A lot of work/time just on a simple single item but it does look good in place though.

OC.

- popeye the sailor, cog, Canute and 2 others

-

5

5

-

-

- popeye the sailor, schooner, cog and 4 others

-

7

7

-

-

Loving your work greg, so much more complete when the deck and hull are married together, my desision to do s much detail to the deck sections is just for my own convenience of keeping seperate small sections that i can get my small magnifier over on my work mat.

I love your idea to build Dreadnought as she could have been considered the for runner to Warspite, so of particular interest to me.

OC.

-

You should be pleased, OC. Looking great, IMO.

RE: The dreaded Carpet Monster. Grab the vacuum and put an old stocking over the hose end, then vacuum the floor. The lost bit, if it gets sucked in will be captured by the stocking. Don't use a fishnet stocking... the holes are too big and it looks rather kinky.

Thank you mark - the vacume idea is great but come to late I am affraid - the wife has already vacumed up and emptied the bag, and no way am i gonna go through our dustbin with a magnifier in "honey i shrunk the kids scenario" I would be put in a mental hospital

.

.OC

-

I have to be honest I am quietly over the moon with my ability so far, yes its taking ages but I am learning new abilities with each task, its a completly different build from my old airfix 600scale Hood/Bismark kits I built when I was a teenager.

Im pleased folks

OC.

-

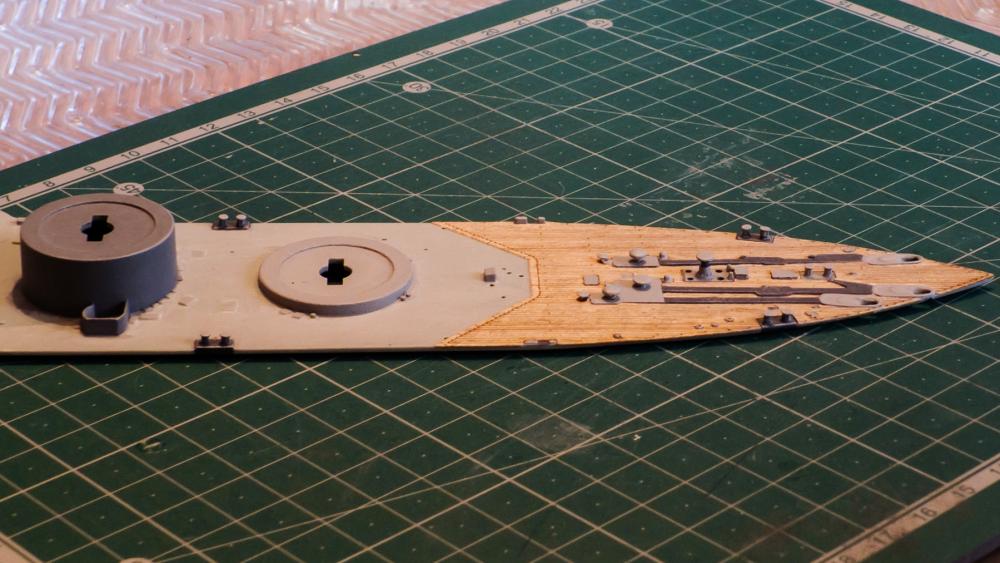

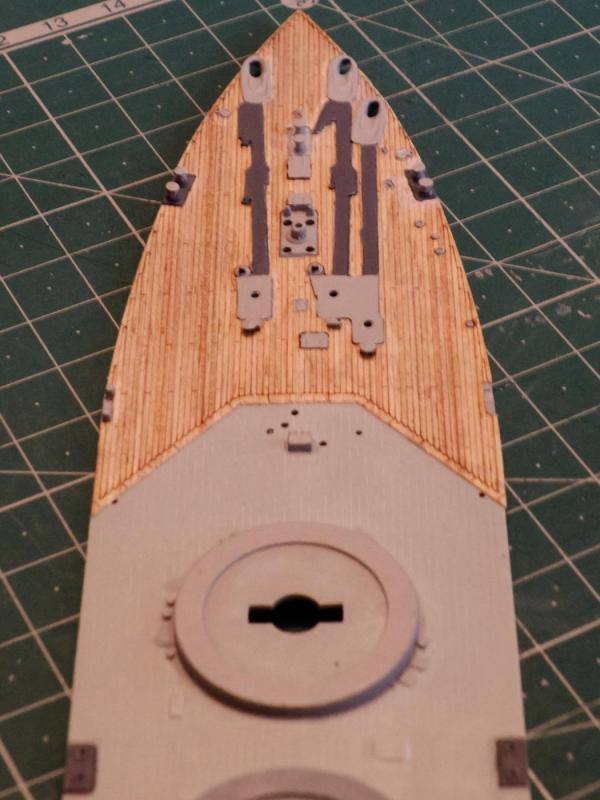

More progress on the bow section - i fitted the three sets of bollards then painted the steel base around them deck grey, and the bollards light grey, I have also decided to paint the anchor chain deck plates a deck grey colour instead of the red oxide anti rust color(as i dont have it and the captain wanted it uniform deck grey color) the Hawse Pipe and surround as well as the Capstan and plate have been painted light grey.

I also decided to return to the rear block area and give the top rail fittings a light coat of black paint, as the real cables where black colour in real life.

Here are a few pics.

OC.

- popeye the sailor, Canute, RGL and 6 others

-

9

9

-

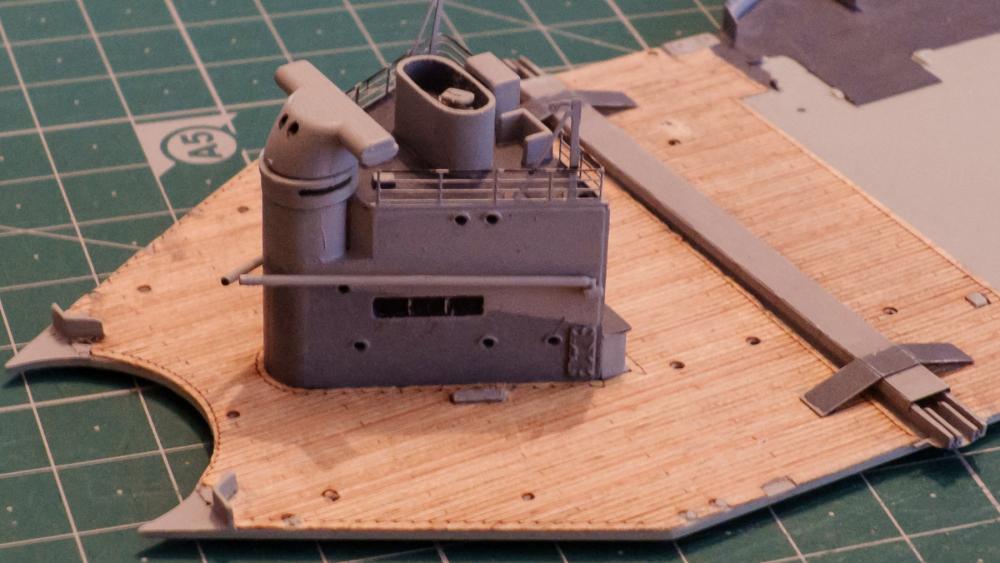

Carried on today with the Bow fittings including a few more hatch covers, two fittings towards the front of the bow that I have no idea what they are for, and the capstan wheel frames and wheels, one became a victim to the carpet monster so my Warspite will just have to rely on two anchors in action - mind you i doubt all three would be in use anyway?.

Here are a couple more pics folks.

OC.

- EricWilliamMarshall, RGL, cog and 4 others

-

7

7

HMS Warspite by Old Collingwood - FINISHED - Academy - 1/350 scale - PLASTIC

in - Kit build logs for subjects built from 1901 - Present Day

Posted

I started on the Rudders and Prop Shafts, I needed to do a bit of studying to see which shaft is which, but after looking at the instructions and dry fitting - it all came clear, I fitted the rudders first just a slight bit of drilling out for the rudder arms, then I glued them in place, next was the shafts, afterwards I touched up the paint around them.

I also fitted the bow bottom fitting (A counter weight)? not sure of its purpose.

Here are a few pics folks -

OC.