-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rvchima

-

The hull is looking good sir! What kind of wood did you use for the base? It looks like cherry to me.

-

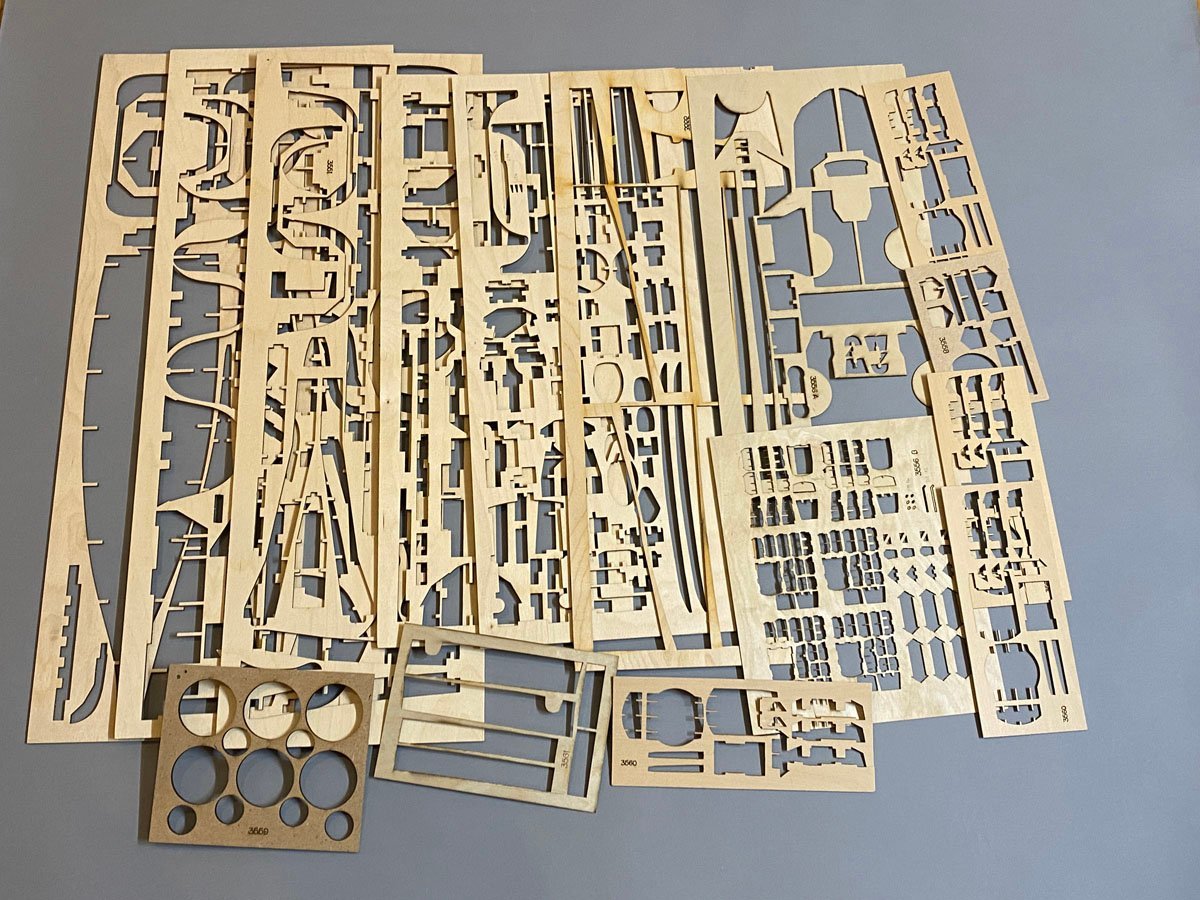

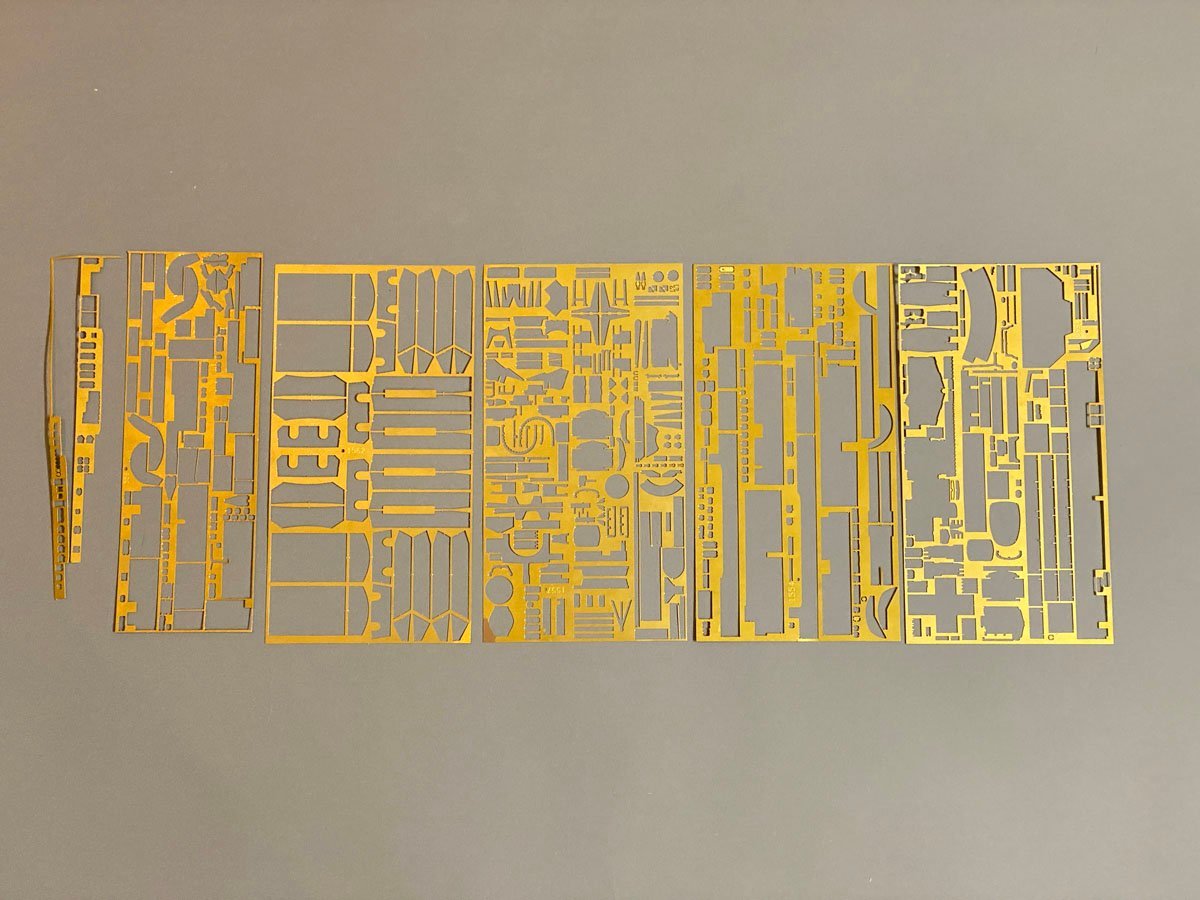

What's Left To Do After 320 Hours and 115 Days The guns finished off my last piece of laser-cut plywood and my 5th sheet of PE brass. I must be nearly done, right? Wrong! I still have several sheets of brass to go and countless sprues of plastic parts. Looks like I'll be busy for awhile.

-

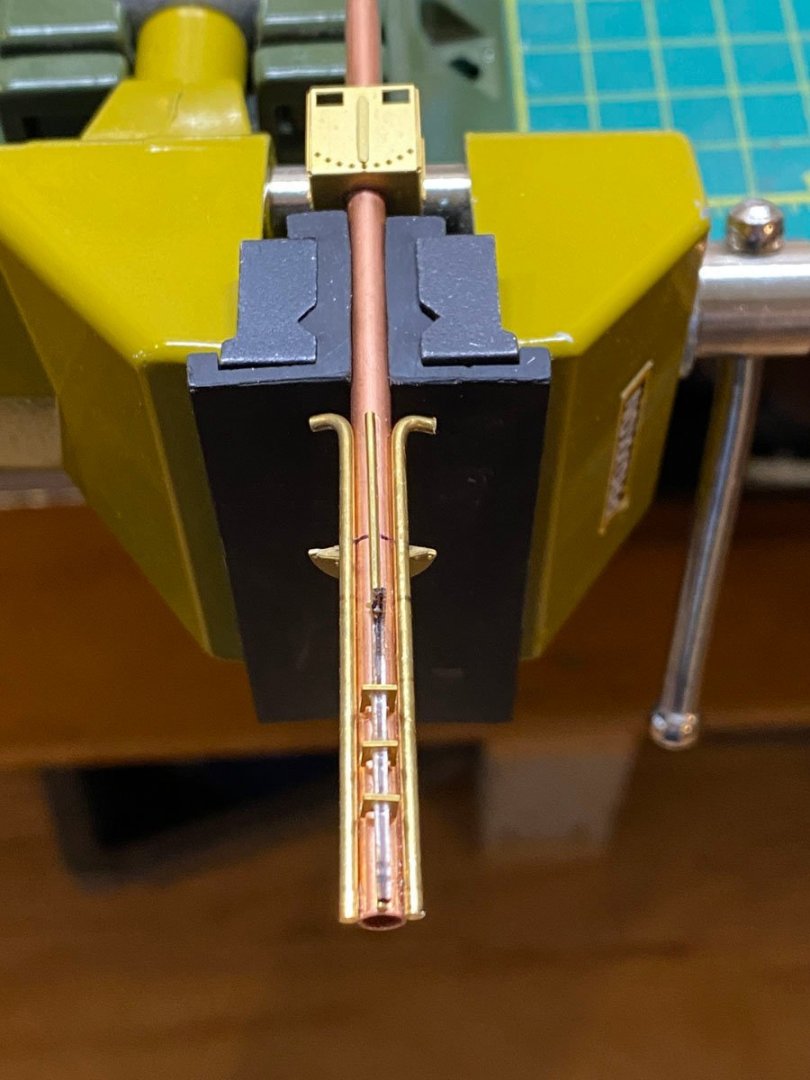

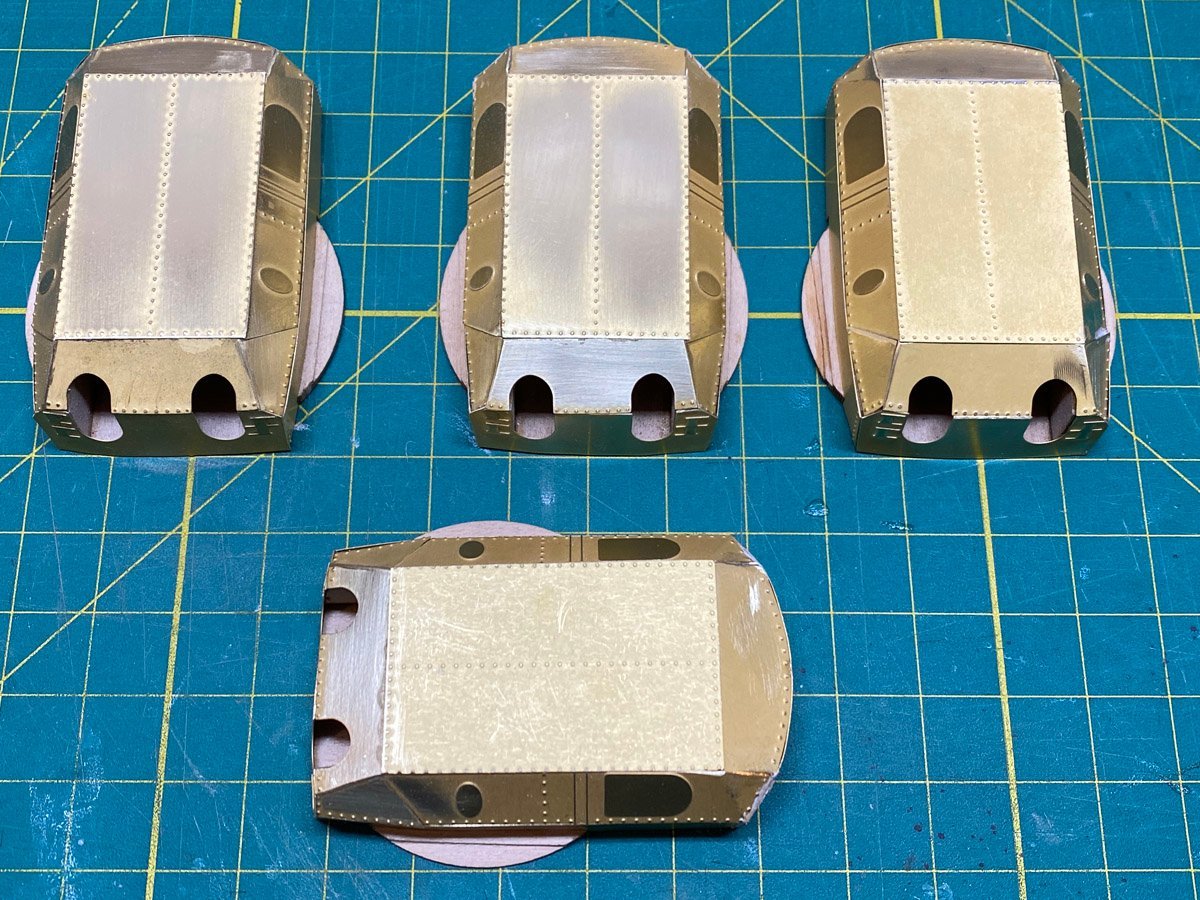

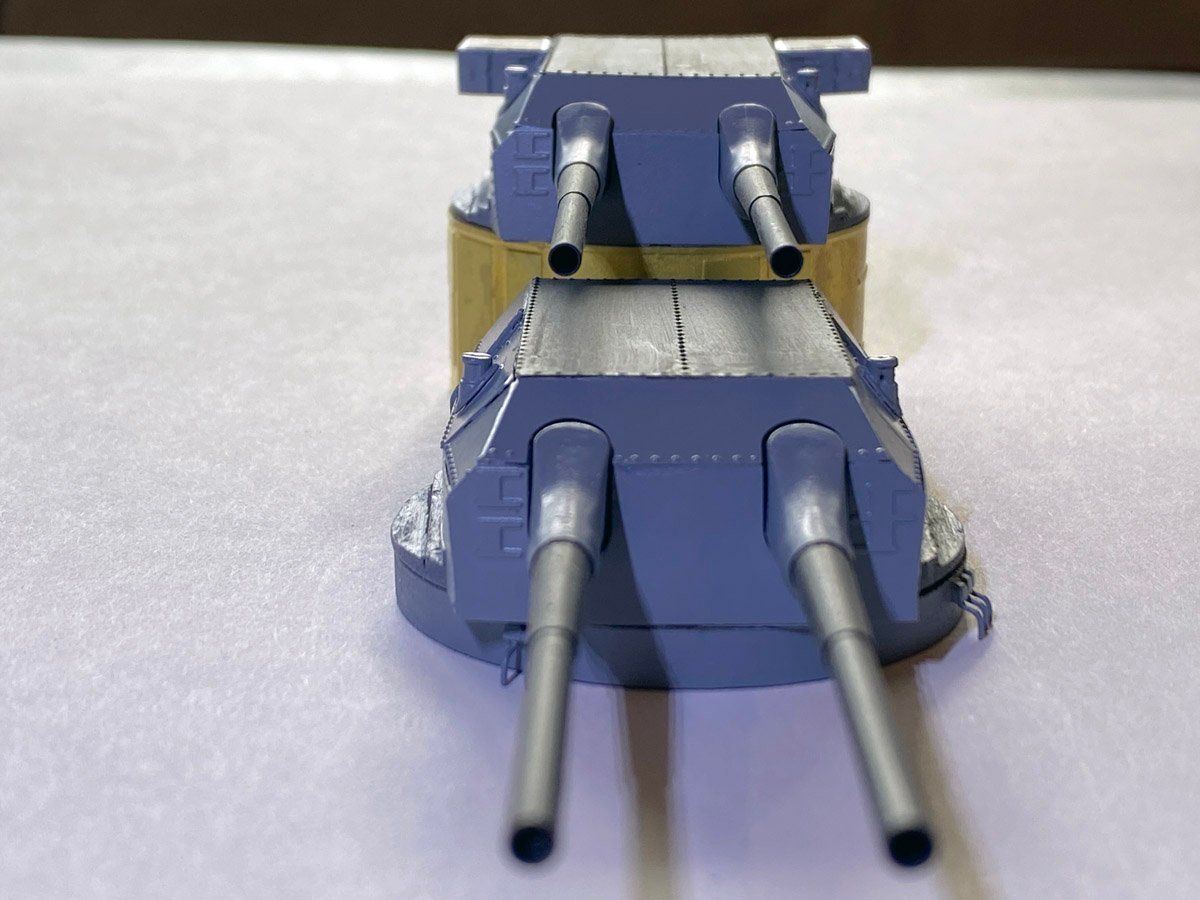

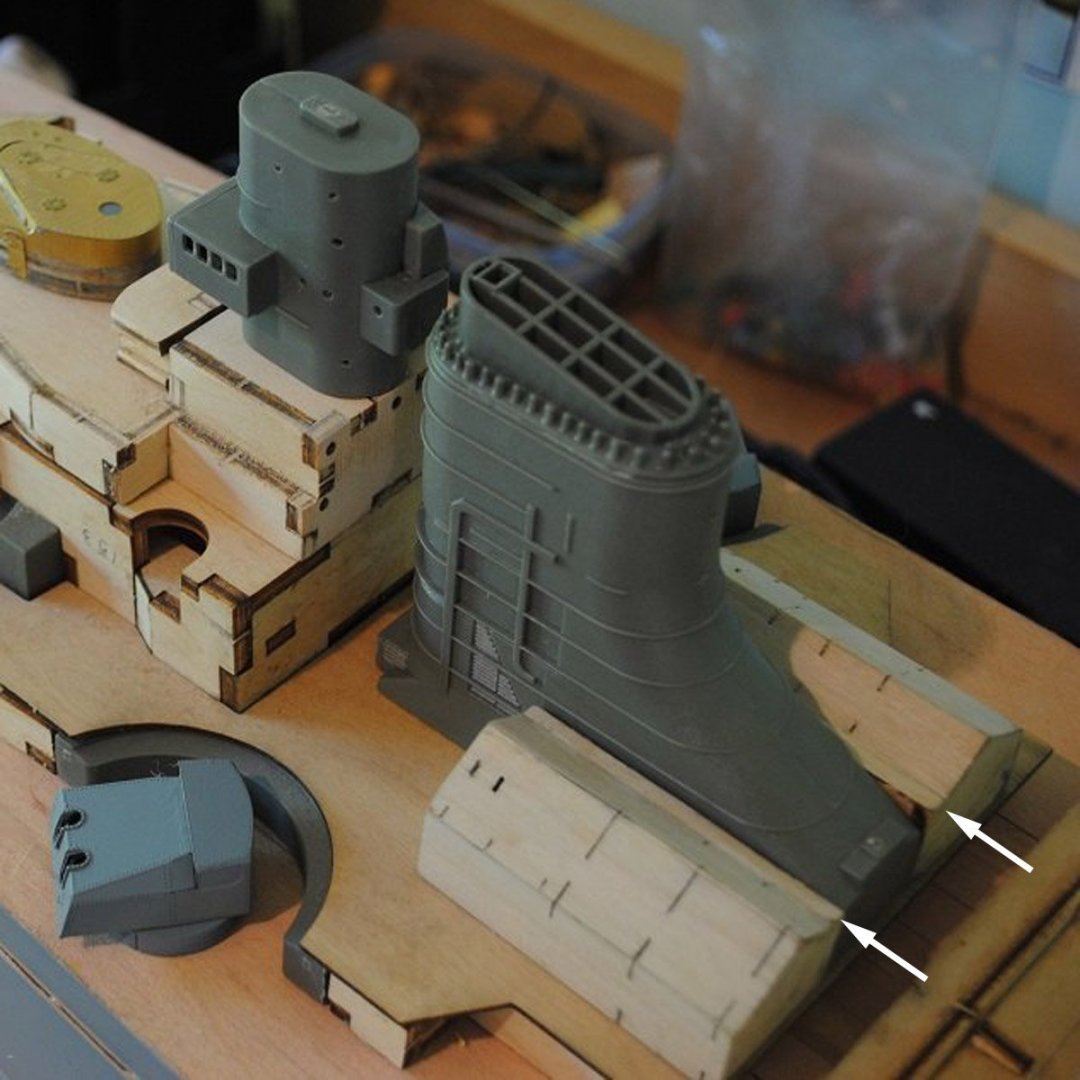

Small Parts The six small guns are made up just like the four large ones - complicated honeycomb framework made of thin plywood skinned with brass. Those are the plastic periscopes on the sides of two of the guns. The barrels are aluminum tube painted black but weren't installed yet for the photos. The watchtower is made up of dozens of tiny brass parts. Attaching brass to existing structures is relatively easy, but building structures completely out of brass is a pain. Started on the main mast today. Still lots to do on it.

-

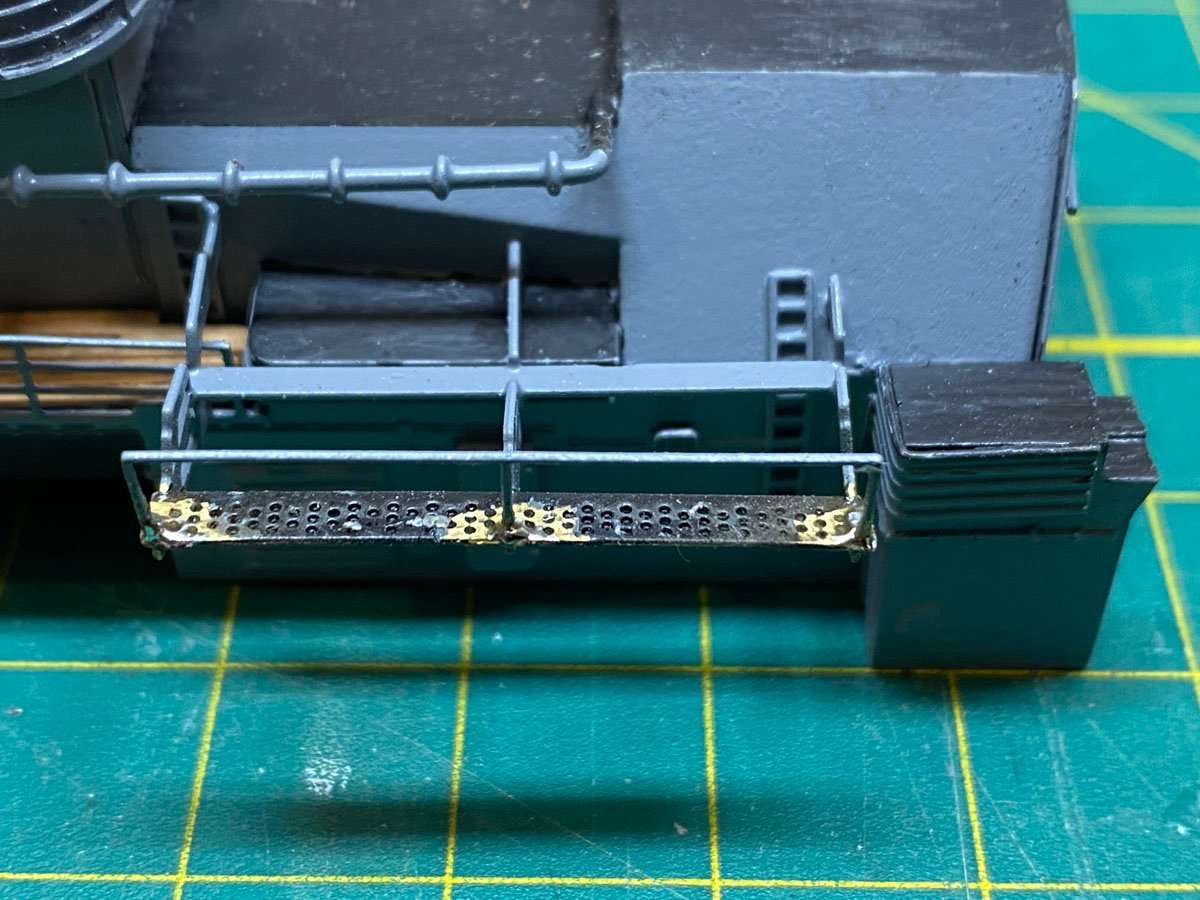

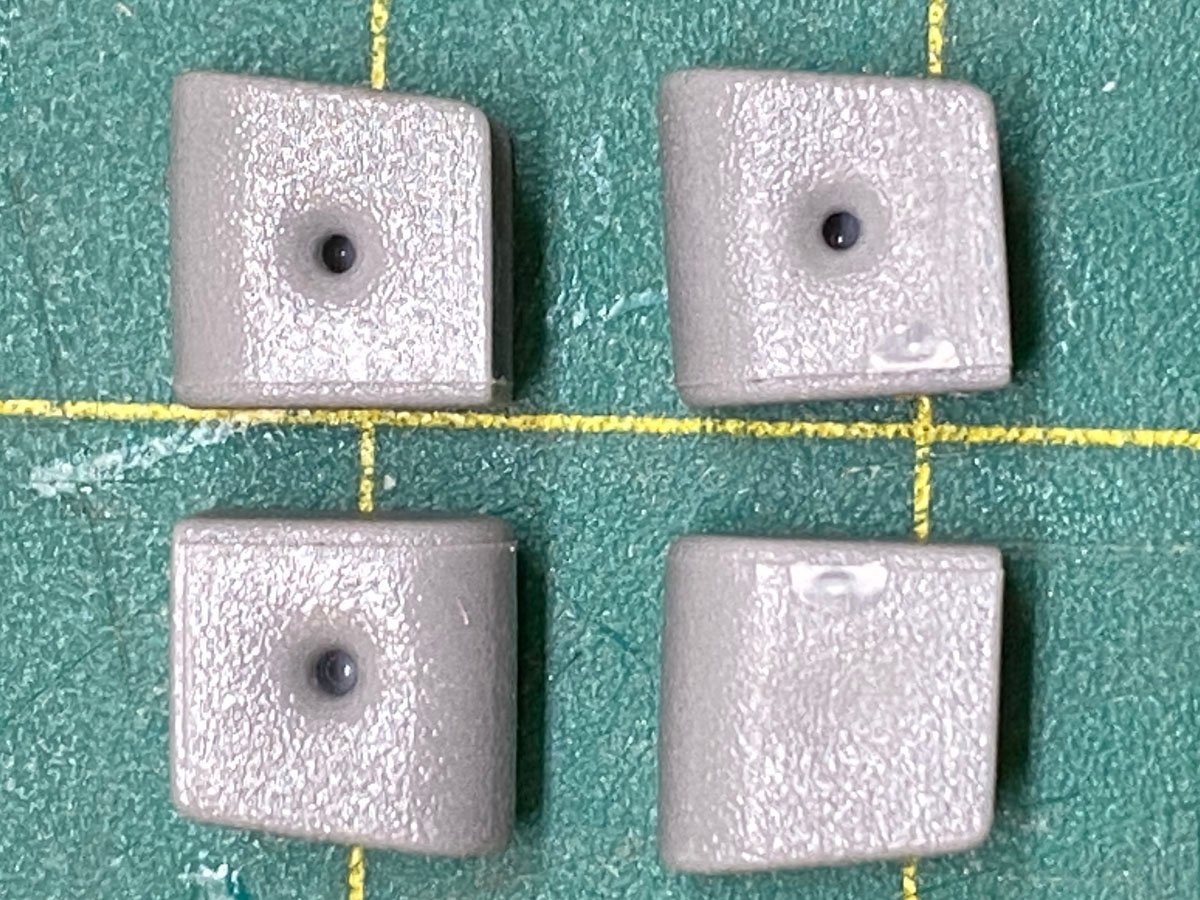

Railing Repair February 3 I described a PE brass lifeboat rack that was tricky to build. I must have struggled with it a little too much, because yesterday after painting it the railing fell off in my hands. I tried to glue it three times but every time I bumped it it fell off again. So I scraped off some paint and soldered it. That took less time than one glue attempt and is far stronger than the original bent brass reinforced with a drop of glue. Wish I'd done that in the first place. Plastic Parts Back in January I hinted that the plastic parts in this kit leave something to be desired. These periscopes for the small guns should be solid but 4 out of 6 have a large void in the center. It's not a big deal to fill the holes but you do have to stop and wait for two coats of filler to harden. Not too many parts were like this - just enough to be a nuisance.

-

Harry, You must be getting close with the hull. I'll hop over and have a look in a minute. Yes, I painted the stern camouflage wave. I only used Amati's templates to make a new template out of wide masking tape. I applied the tape with a gap around the rails and paper outside the tape. I put another strip of tape over the rails knowing it would leak. After spraying it wasn't too bad and just needed a little touch up with a fine brush.

-

We're happy to see you back Ted. There's nothing like moving to waste a lot of time. I hope that the new place has a better spray booth. Your turrets look great. I sure wish that you'd posted your advice before I built mine. Mine have a few seams filled with Vallejo acrylic putty. It comes in a tube with a very fine nozzle and works well to fill gaps like on your first attempt. I'll bet you could touch it up with some brass paint or even a marker and no one would be the wiser.

-

Harry, I just discovered the gallery for your magnificent Cutty Sark build. Wow, what a beautiful model! Cutty Sark Gallery by HOF00 Your profile says that you are also a cabinet maker. Did you make the cabinet that the Cutty Sark is in?

-

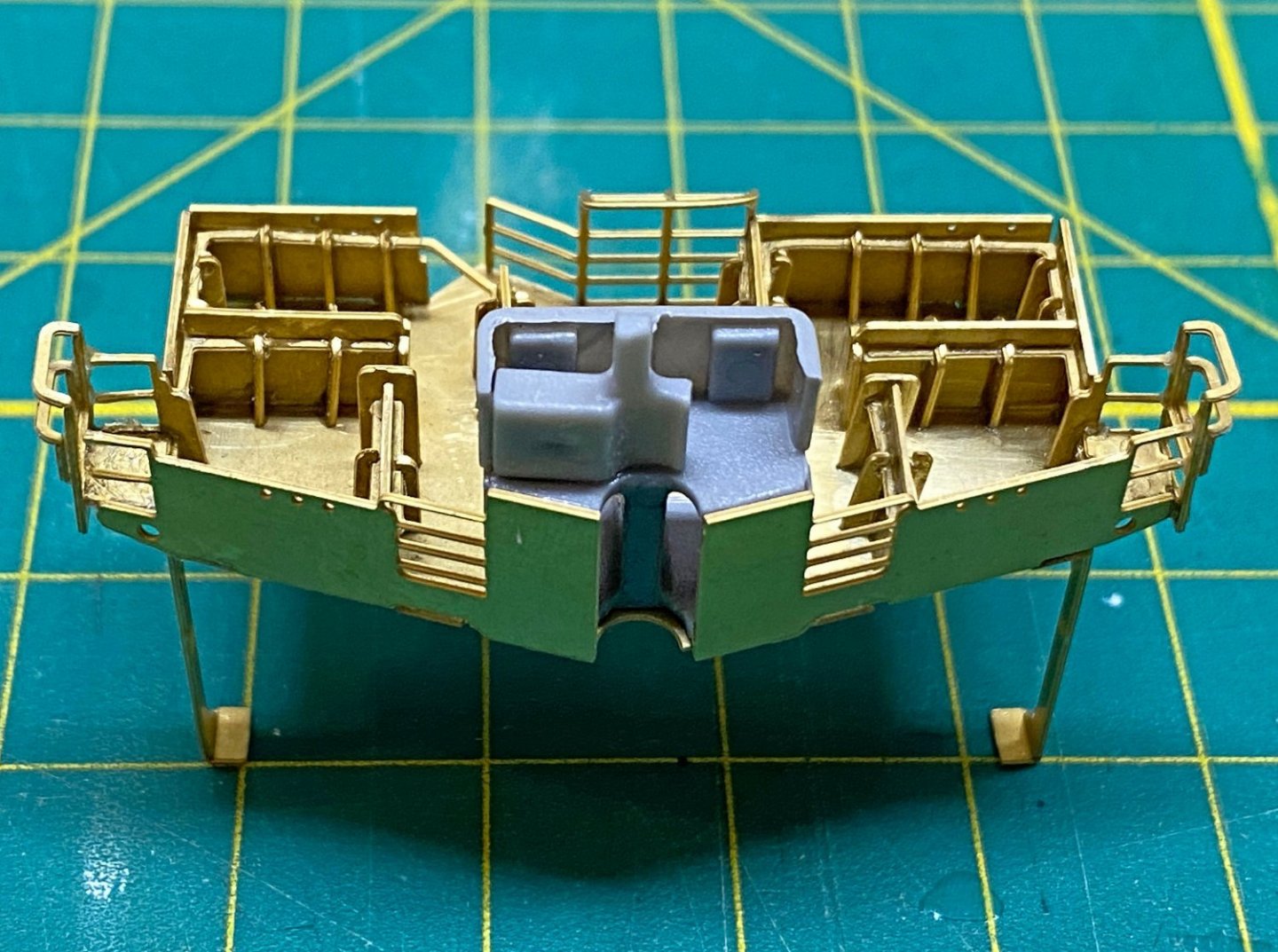

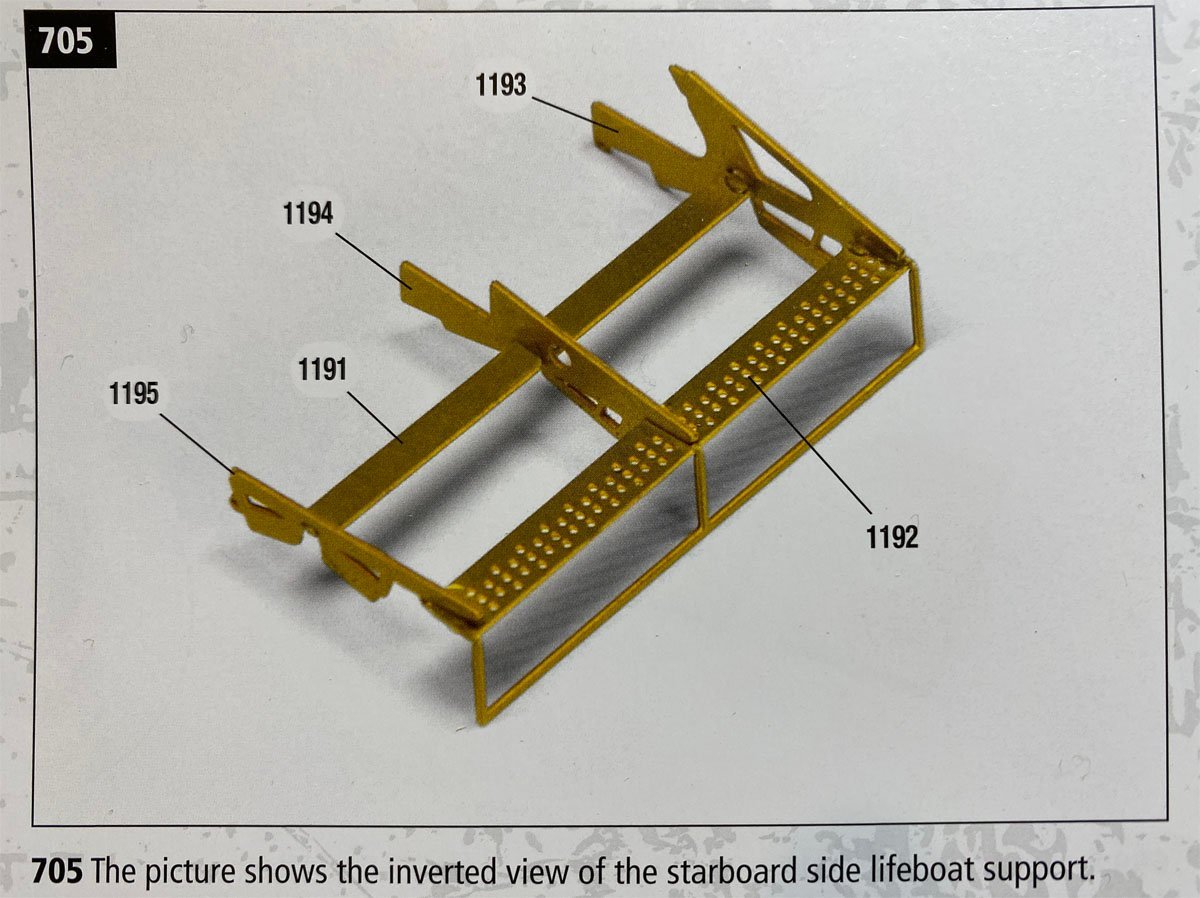

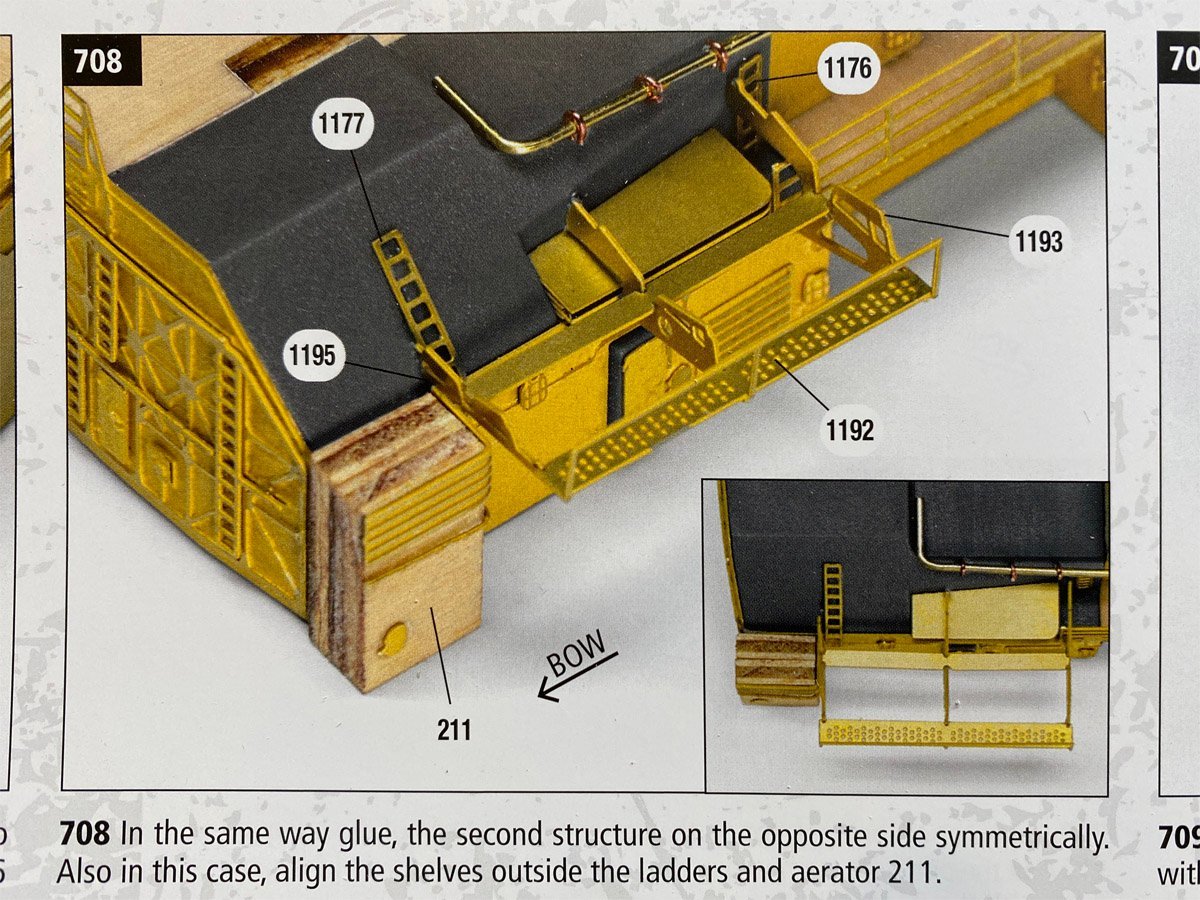

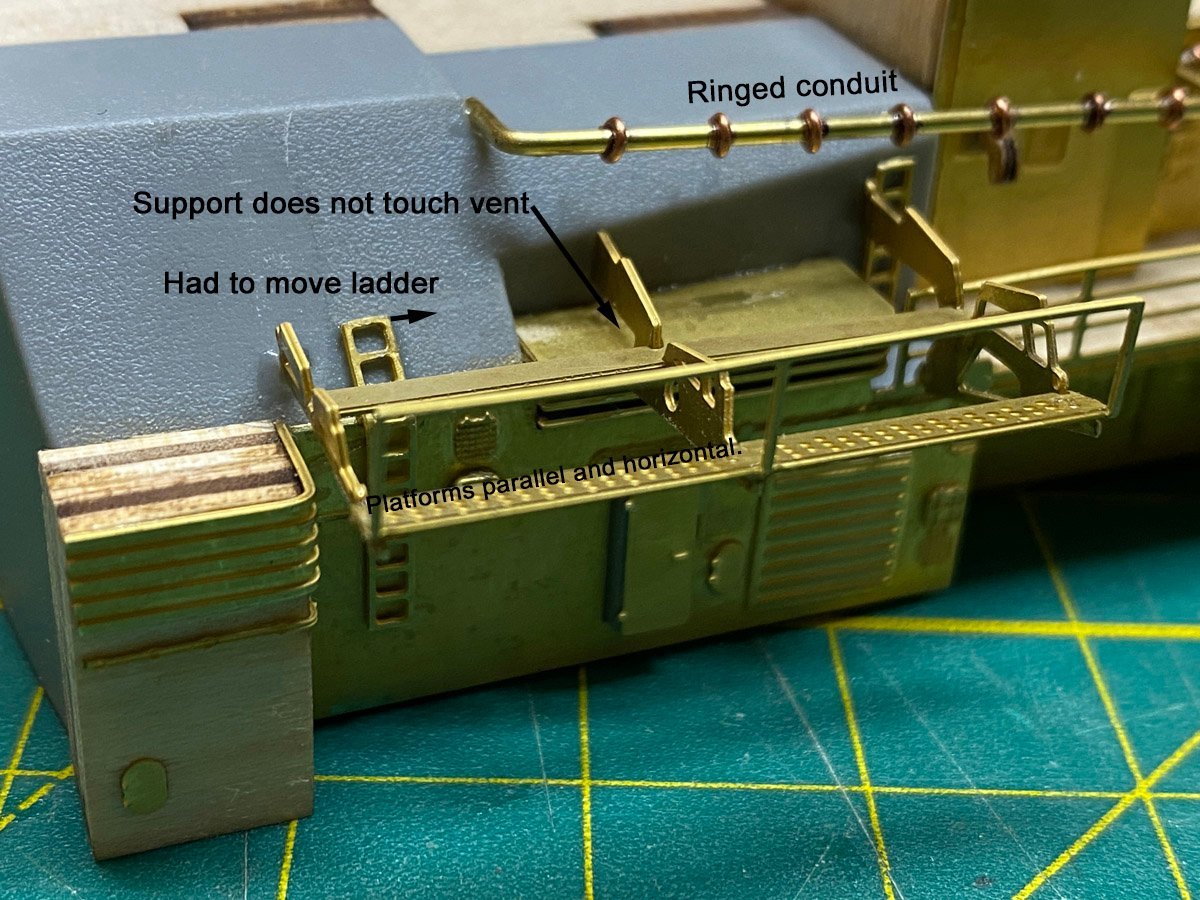

Tricky Lifeboat Rack I struggled with these photo-etched lifeboat rack for several hours today. (There are actually two symmetrical racks.) The instructions show them built up out of five pieces. Easy, right? The triangular supports are different sizes. First I built them with their bases flat on my bench, but the platforms ended up twisted. After some deconstruction I rebuilt them by first attaching the center support to both platforms, and then attaching the end supports while keeping the platforms parallel. This ends up with flat, horizontal platforms when attached. Then you have to attach the racks to the rear superstructure next to some existing ladders and vents that get in the way. I had to move two ladders. The instructions tell where the triangular supports should attach to the superstructure vents and rails. When I followed those directions the platforms ended up sloped a lot. Instead I attached the racks so that the platforms were horizontal. Here's the final result. Incidentally, I thought that the construction of the ringed conduit at top right was pretty clever. It's made from 1mm brass rod bent according to plan. The rings are 1mm eyelets glued in place with a drop of CA, then the shanks are cut off. Nice effect.

-

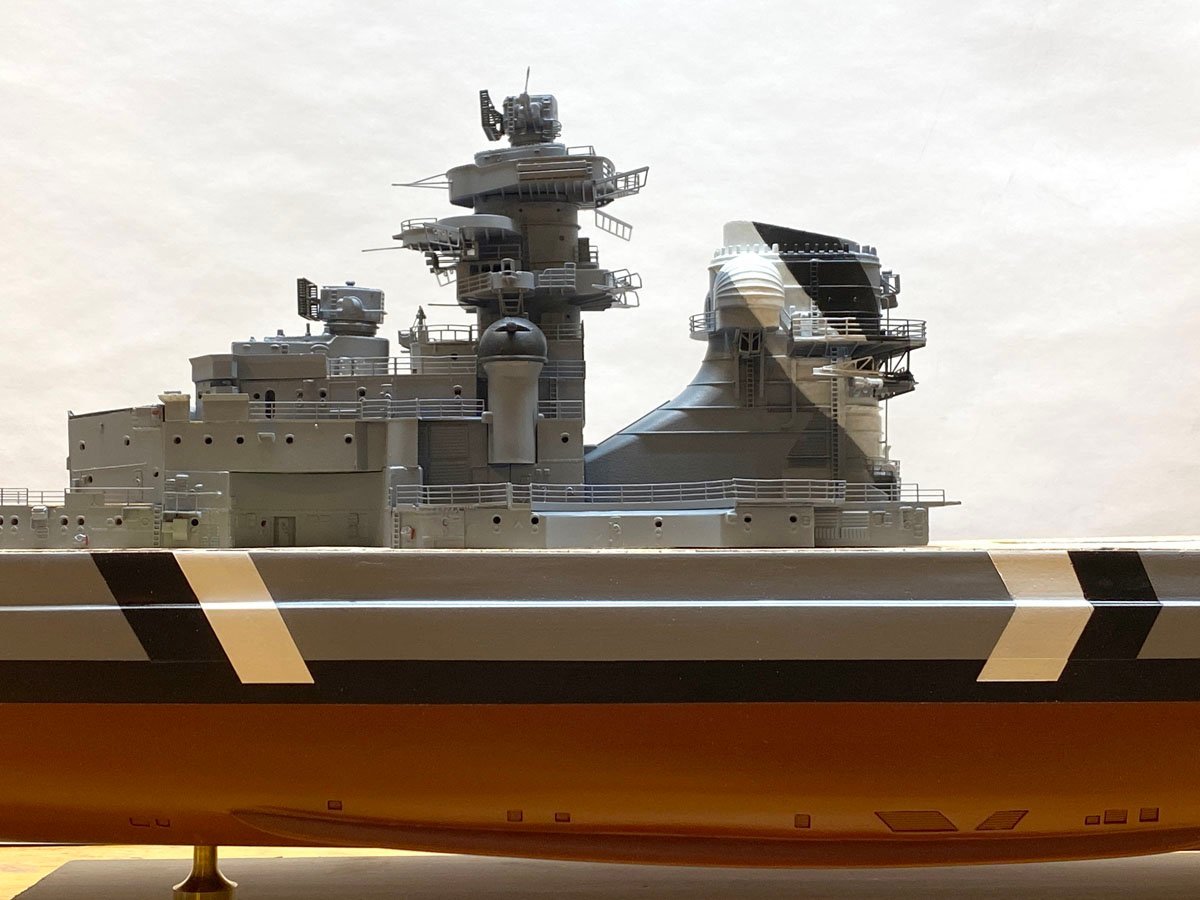

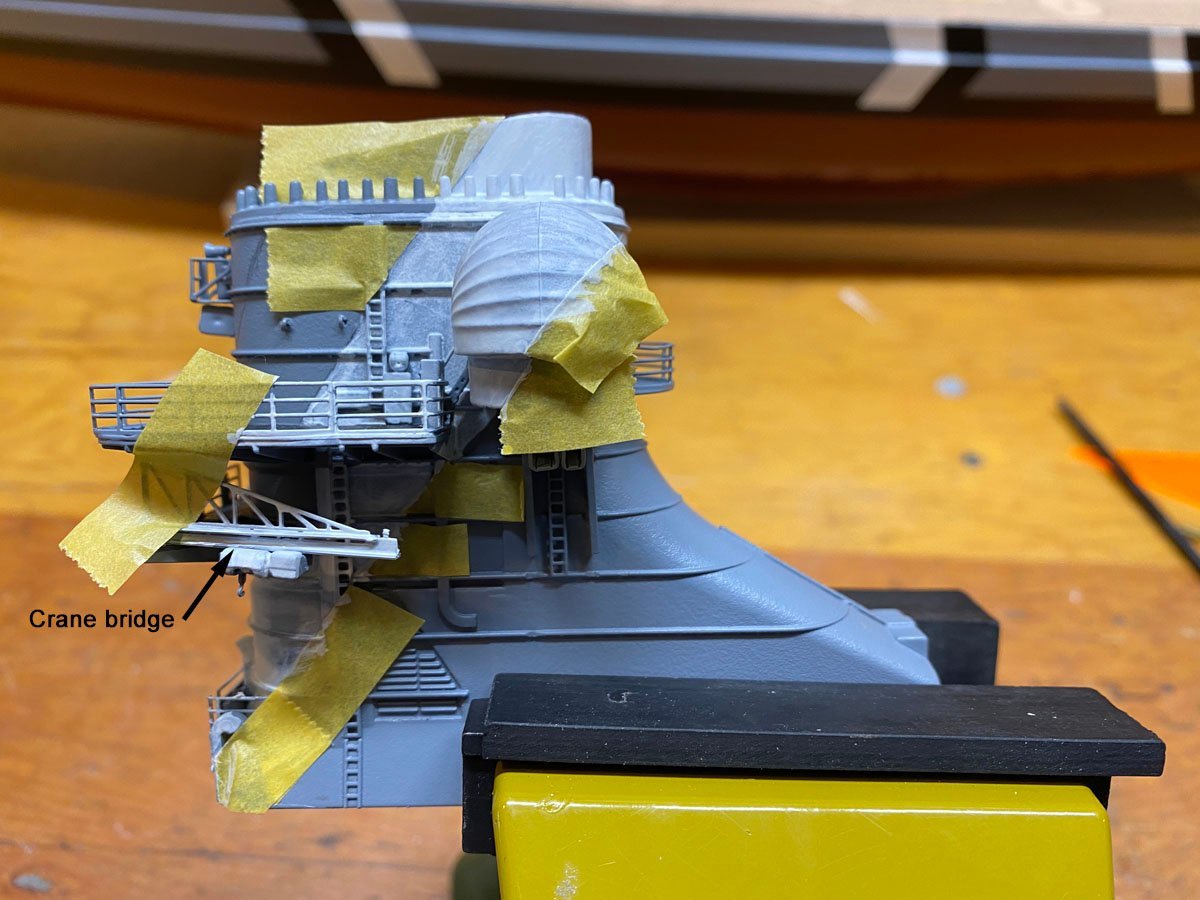

Dazzling Camouflage A few days ago I painted one set of dazzle camouflage stripes. It wasn't easy. I used some thin tape to temporarily mark the edges, then used a thin rule and penciled them in. I masked what I could and brushed the white first with thin acrylic. That took several coats. Then I outlined the black with a thin black marker, masked the black, and brushed that on. The black covered in one coat. Then I used my finest brush to touch up the gray. Note to other builders: If you plan to paint the dazzle camouflage, paint the stripes before you install the crane bridge. Here's the front superstructure with the stripes on the funnel. Regarding previous questions about what color gray I used, all gray parts in this image were painted with the same paint, but there is a huge variation in shade across the image. The one LED light I used is daylight white. I did adjust the white point in the levels for the photo to brighten the image.

-

Hi Harry, Take a pair of small flat jaw pliers and give some of the rungs a twist so that they are all parallel. You might be able to bend them up/down a bit to adjust spacing. Hit them with a tiny drop of thin CA with a glue looper when you're done. They'll be fine.

-

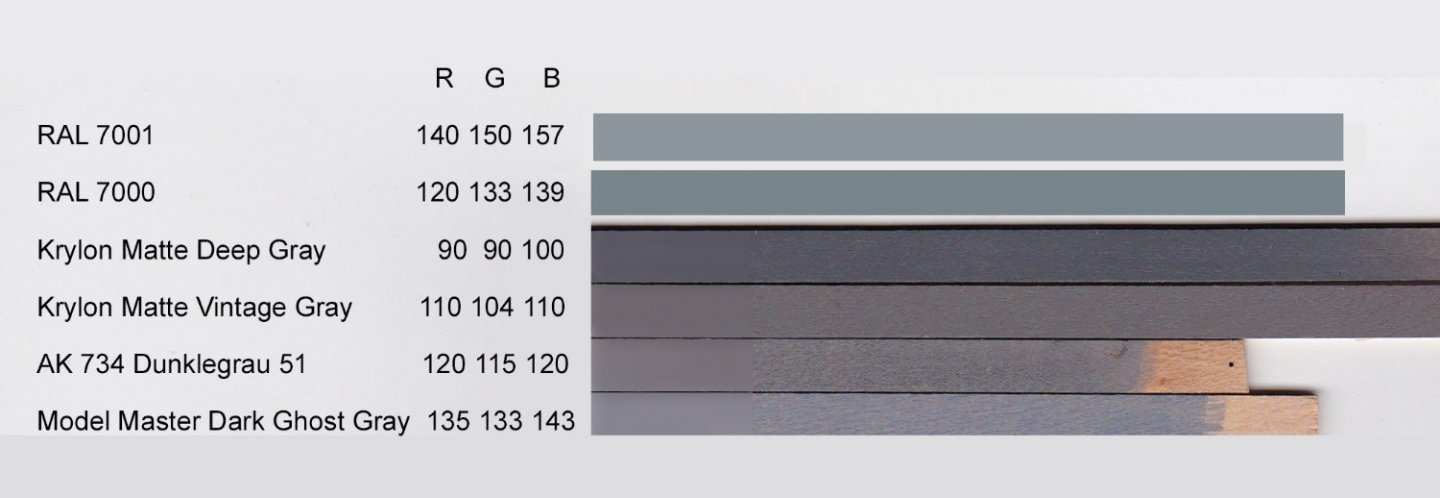

I agree that the photo seems very blue. I special ordered a can of RAL 7000 for the hull. When it came time to paint the superstructure I realized that it called for RAL 7001. I made up this comparison: On my monitor the RAL colors look almost identical, so I used my existing can of RAL 7000 for everything. In my shop the ship looks dark gray and not blue at all. I used an LED shop light for the photos. It seems to be bright white but may be adding a blue cast to the photos, even after white balancing with Photoshop. I'll experiment with lighting for the next batch of photos, but regardless it's too late to repaint.

-

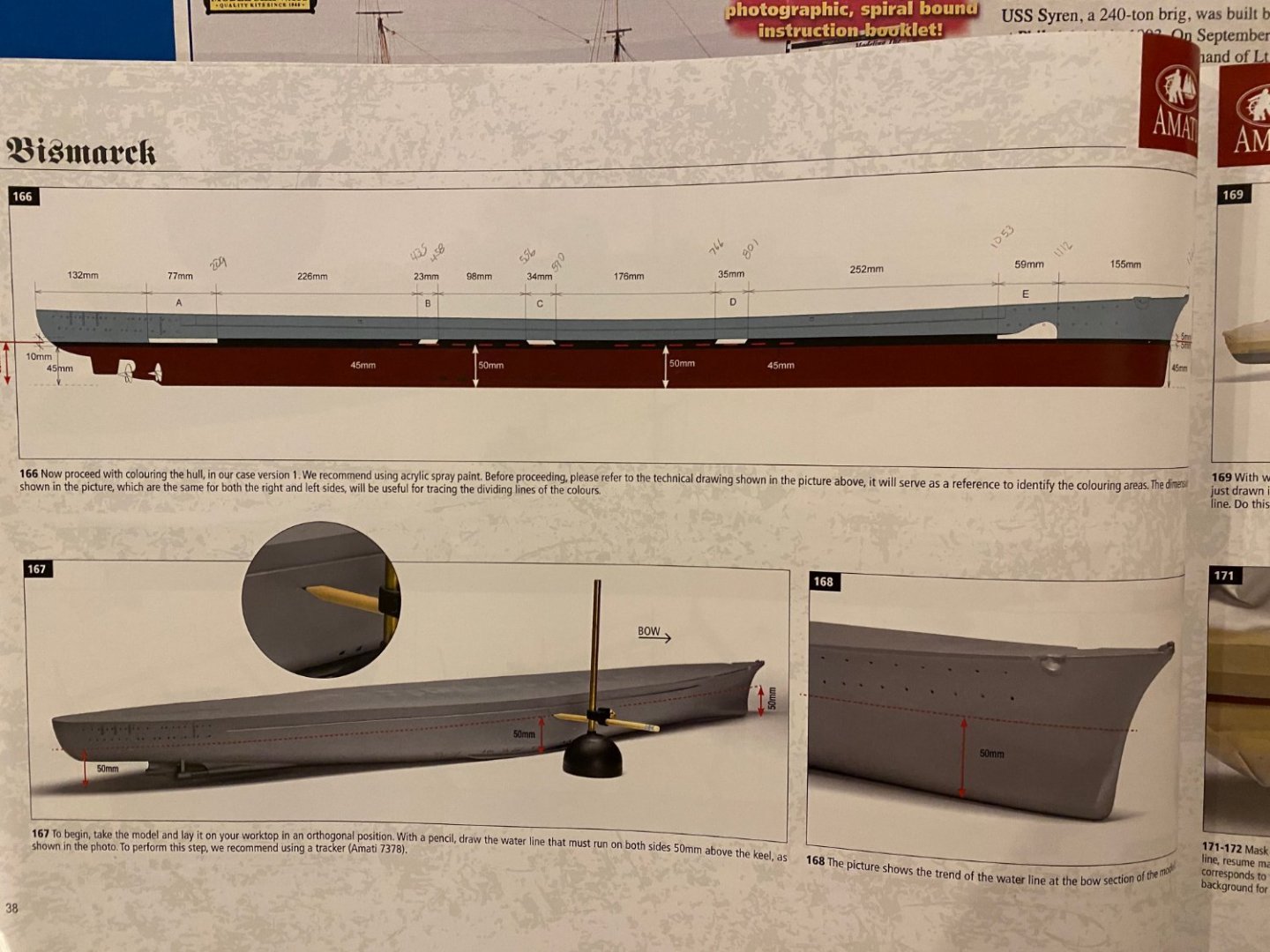

Here's the instructions from the manual. The centerline of the stripe is at 50 mm, and the stripe is 10 mm wide.

-

In my humble opinion you should complete the hull. While you are waiting for paint to dry you can spray some gray on the superstructure and hand paint the dark gray decks. It looks like the hull is nearly done, so in a week's work you will have a half-completed model rather than a stack of half-completed parts. Just look at how good your mast looks after a coat of paint - it's a mast-erpiece.

-

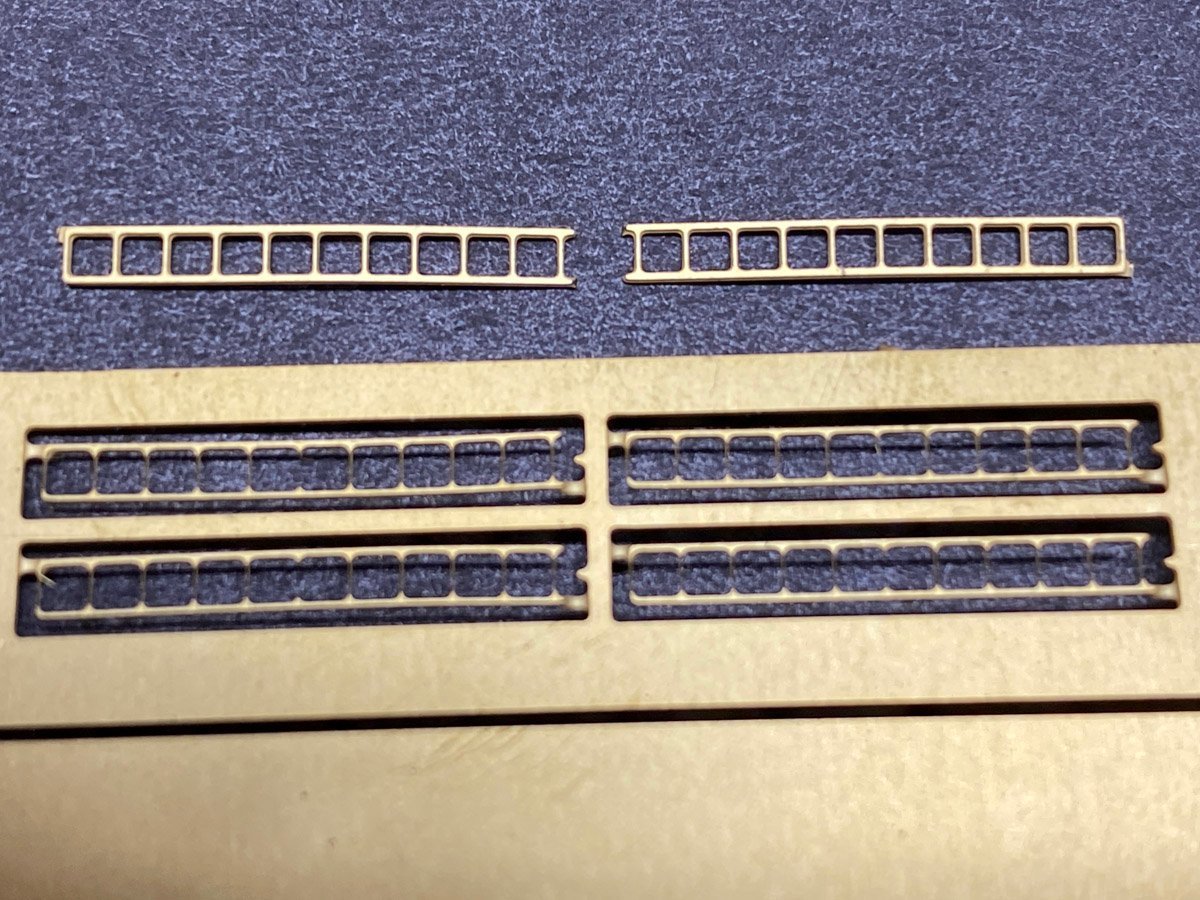

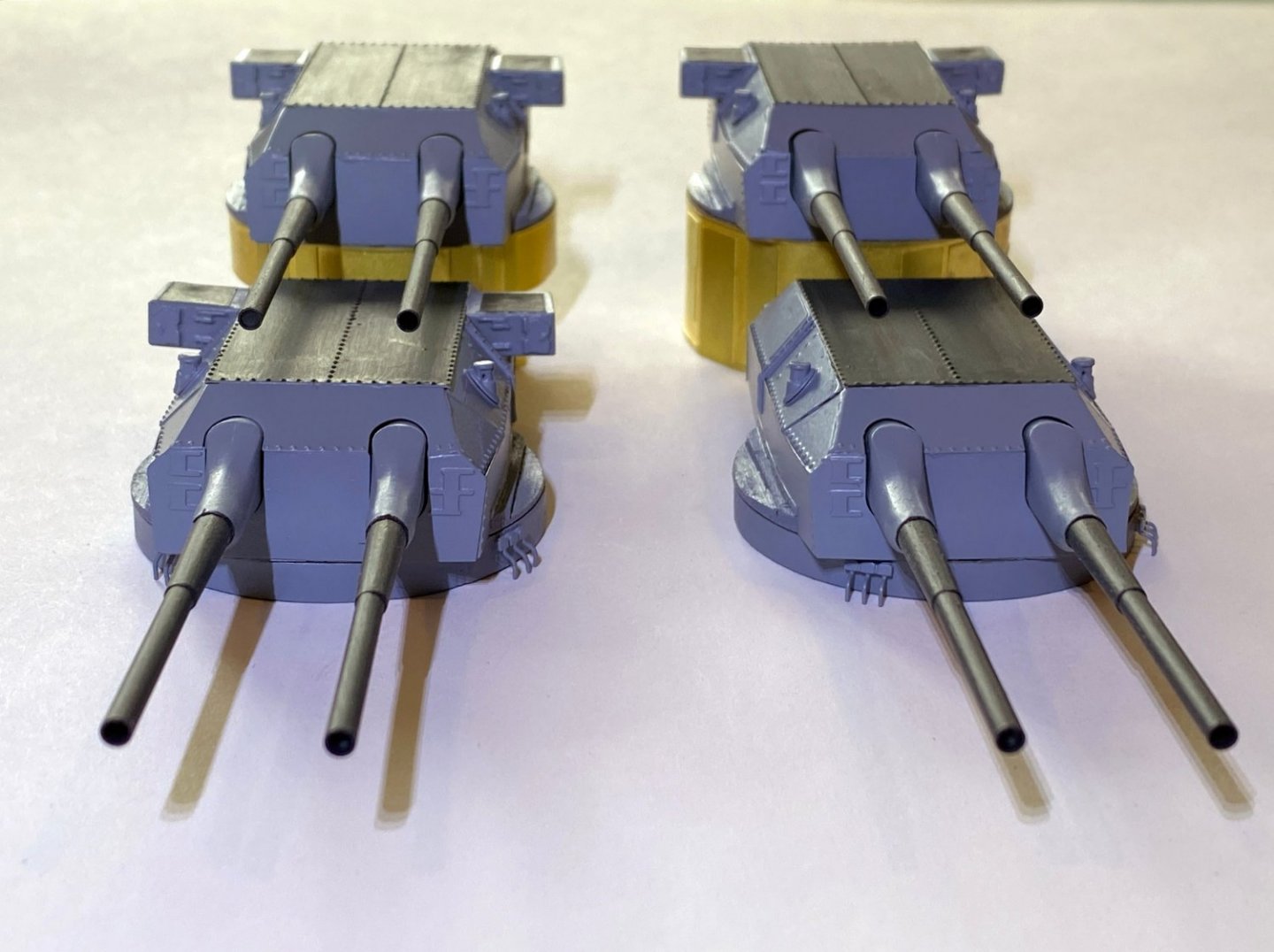

I Should Be Painting Camouflage, But ... Joe100, yes I plan to paint the Baltic Stripes. I know that they didn't last long but they look so cool. And I know what a pain they will be to paint so I decided to build the big guns instead. As usual, the Amati construction uses an over-complicated wooden framework skinned with PE brass and decorated with PE details. Each turret has two ladders about 15 mm long. There were 8 ladders on one sheet of PE that must have been left in the acid too long - the rungs were about the thickness of a spider's leg. There were 2 "spares" on another sheet that were OK so I put them on the first turret Anton. I managed to use the other ladders, but it wasn't easy. So far this is the only problem that I've had with the PE. I'll complain about the plastic parts in another post. Here are the finished turrets with guns and incomplete bases.

-

Nice work on the hangars Harry. The little staircase and railings are a difficult build but you got them done.

-

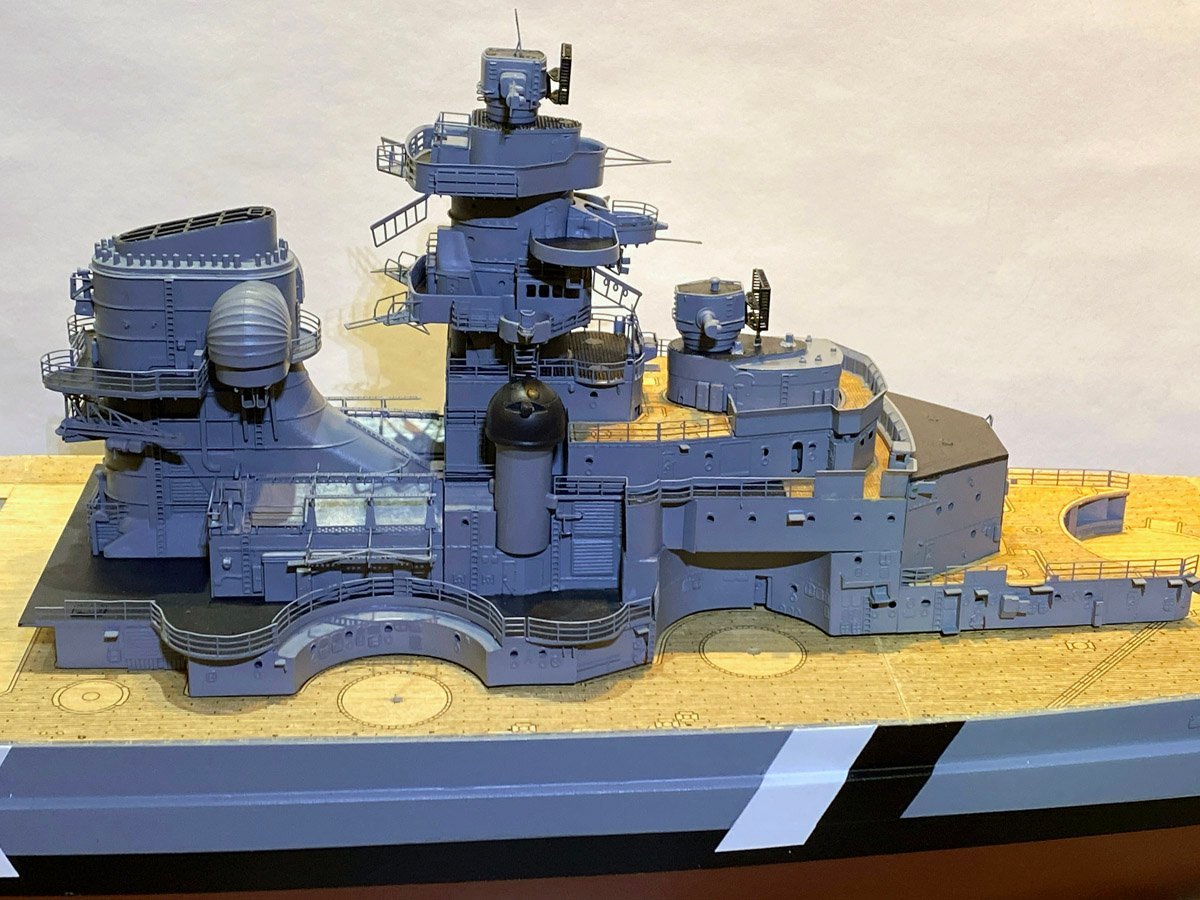

Forward Superstructure Nearly Complete - 225 hours, 93 days I got all the major components and painted, and have assembled a few sub-assemblies. There are a few fiddly parts left that need to be added. I will leave the sub-assemblies unattached for now until I paint the dazzle camouflage. It might be easier that way.

-

Mini lathe for mast making etc.

rvchima replied to Charlie pal's topic in Masting, rigging and sails

Charlie, Try using an electric hand drill/screwdriver at its highest speed for short masts and yards. You may want to clamp it to a bench and find a way to lock the trigger. Leave a little extra material on one or both ends for the chuck. Use coarse sandpaper for rough shaping and a sanding block for final. Experiment with some scrap and see what you think. I've made all my masts and yards for several models that way, except with a drill press. -

Brilliant! I'm glad that worked out so easily. Did you use the disk sander? This PE very easily with a heavy pail of scissors.

-

Piet, I used Minwax Polycrylic satin spray. The parts came flat, curled a little when I sprayed them, and flattened in a few minutes when they dried. Can you flatten yours in a book or something?

-

Hi Piet, Thank you for helping both Harry and me with some build errors. Now we're all curious as to how far along you are on this model. Have you posted anything?

-

I'm going with 2 1" pedestals on 14" centers. Same as my Prinz Eugen. I already have them attached but with a temporary base.

-

Yves, I just watched the Wellington Trust video presentation on models in the collection of the Royal Maritime Museum by Curator Simon Stephens. He showed two photos of their magnificent model of the Bellona. They might serve as an inspiration, or might make you want to give up. They have been posting previous lectures here: https://www.thewellingtontrust.org/whats-on/events-past-lectures-and-exhibitions/ Today's lecture was recorded and should be up soon.

-

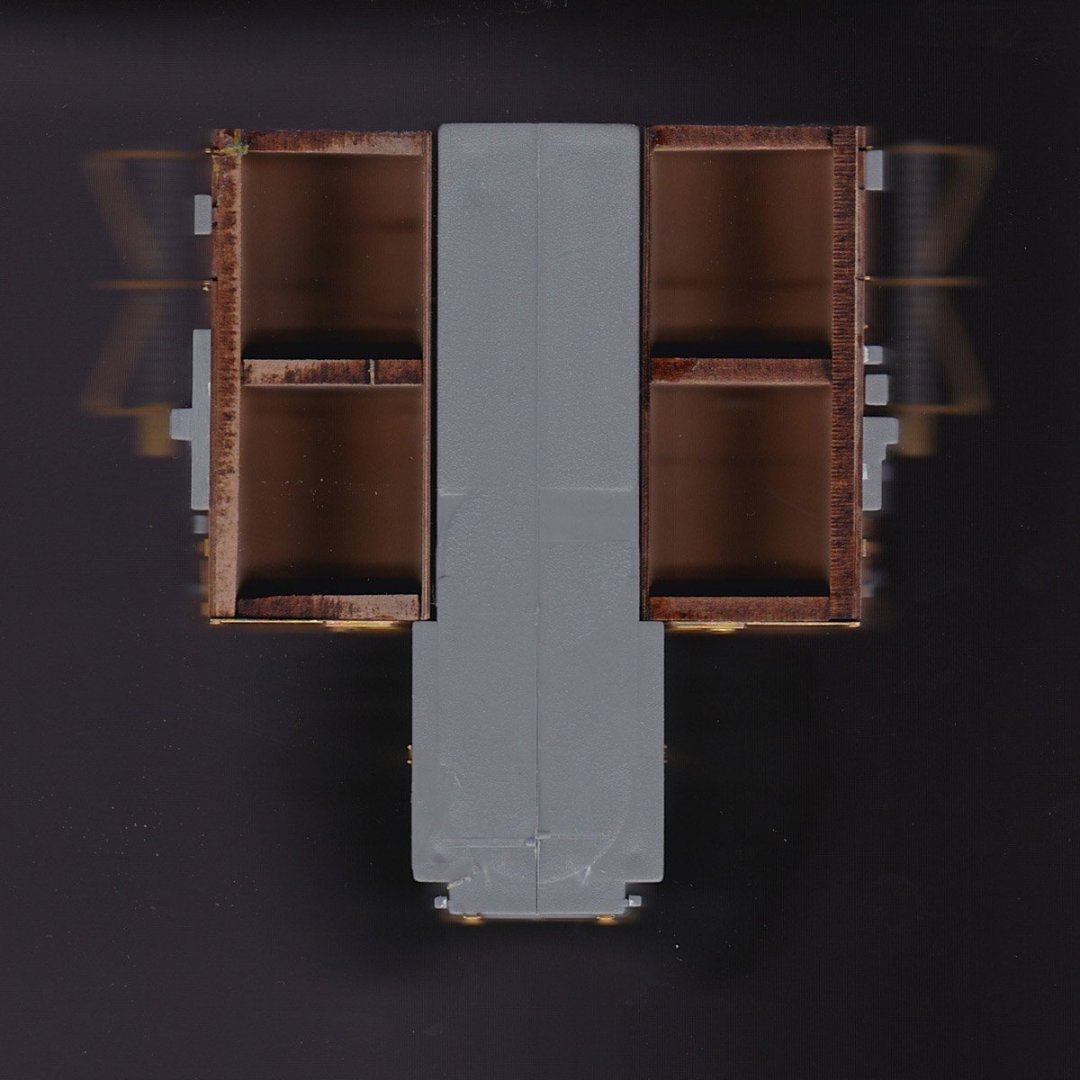

Harry, Don't know if this will help but it's worth a try. I set my hangars and funnel on my scanner and got a bottom view. The inner walls of my hangars are thinner than the other walls. They are NOT sloped. The PE hangar doors do have a triangular notch. I didn't know what it was at first, thought it was a fabric door or something but it matches the slope of the funnel. Here are your hangars (before funnel repair.) The slots in the hangar roofs all seem to be correct with respect to the funnel if everything is rotated 180 degrees. But you have extra flats on the inside edges of the roofs, marked with arrows. They must be due to the thick ply wall mentioned by Piet. If you remove those sides right up to the sloping roof and replace them with thin ply (or even card stock) everything should fit. But check the PE doors first.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.