-

Posts

697 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rvchima

-

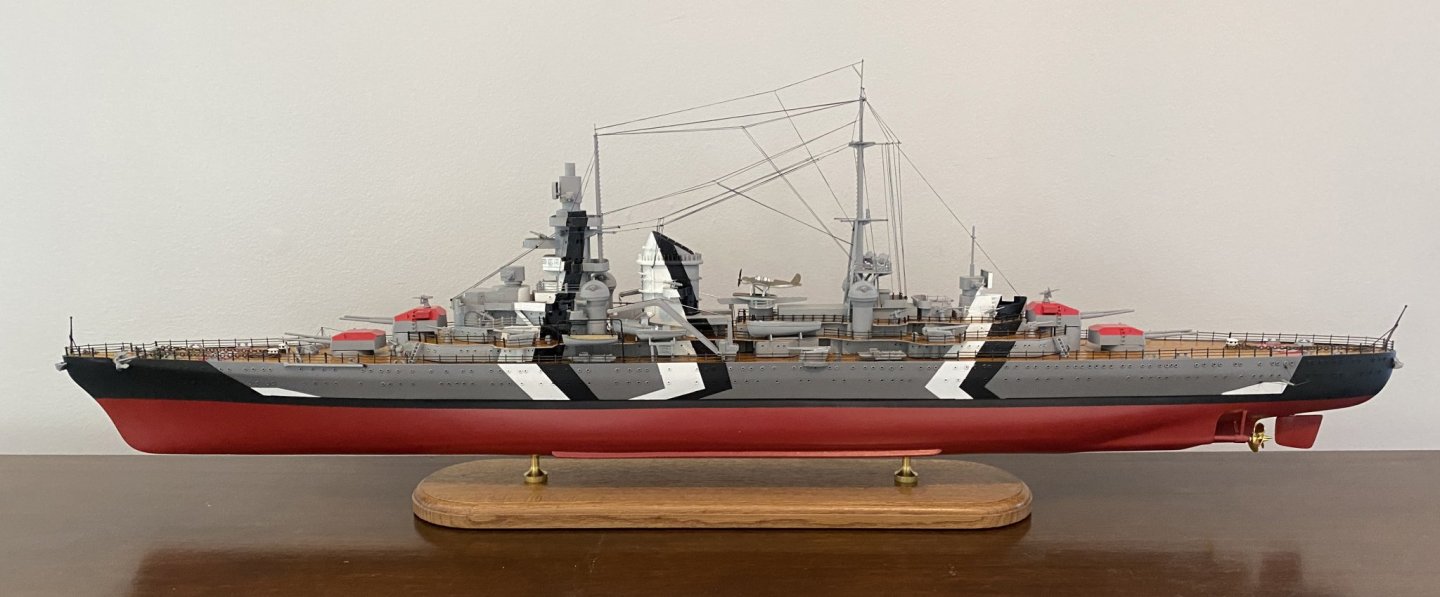

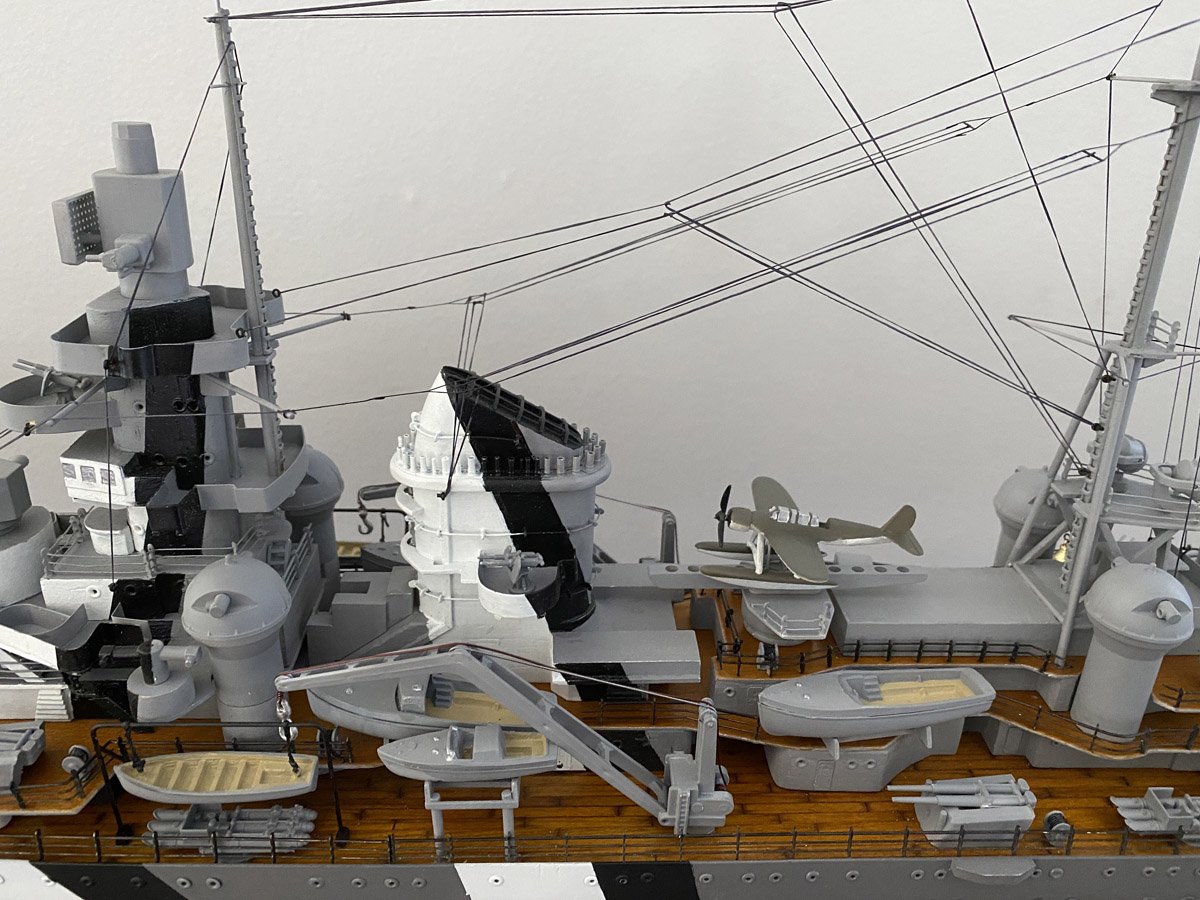

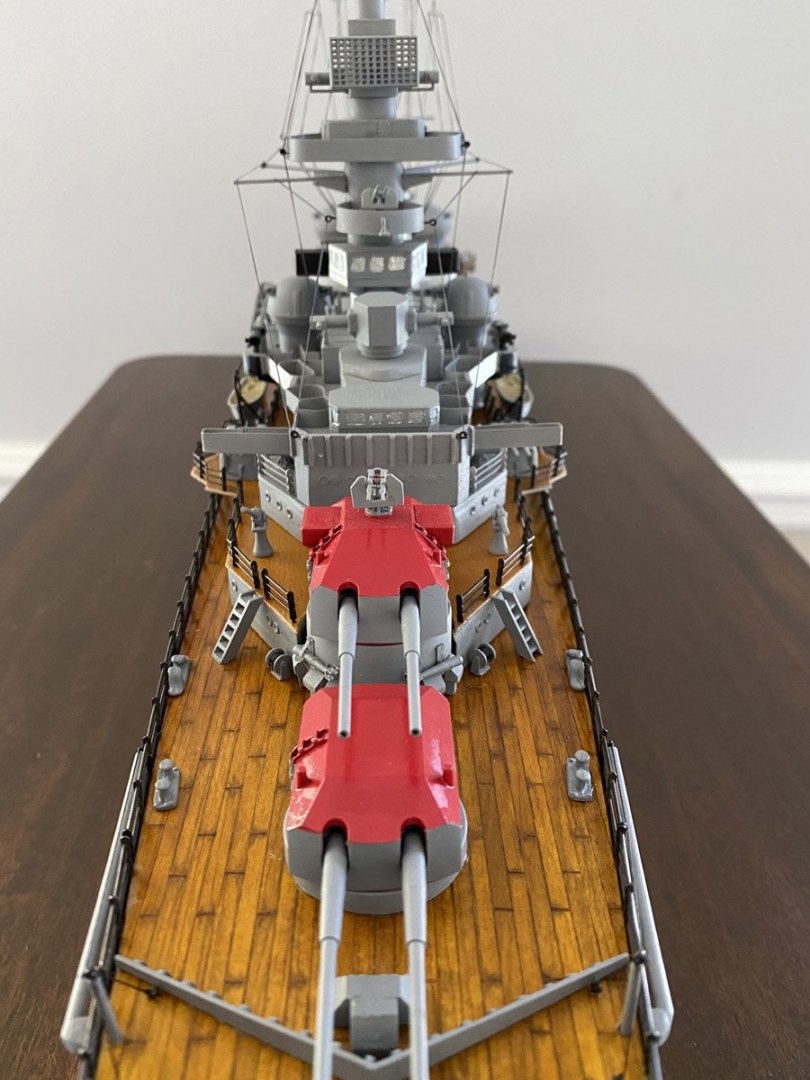

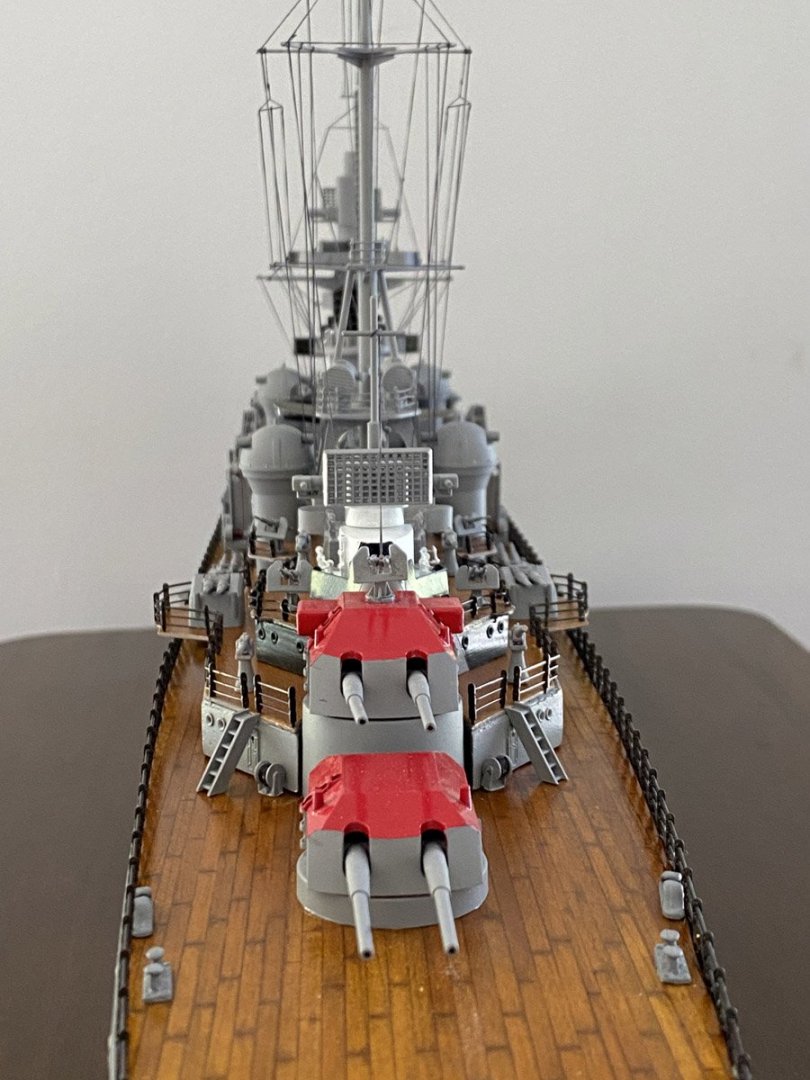

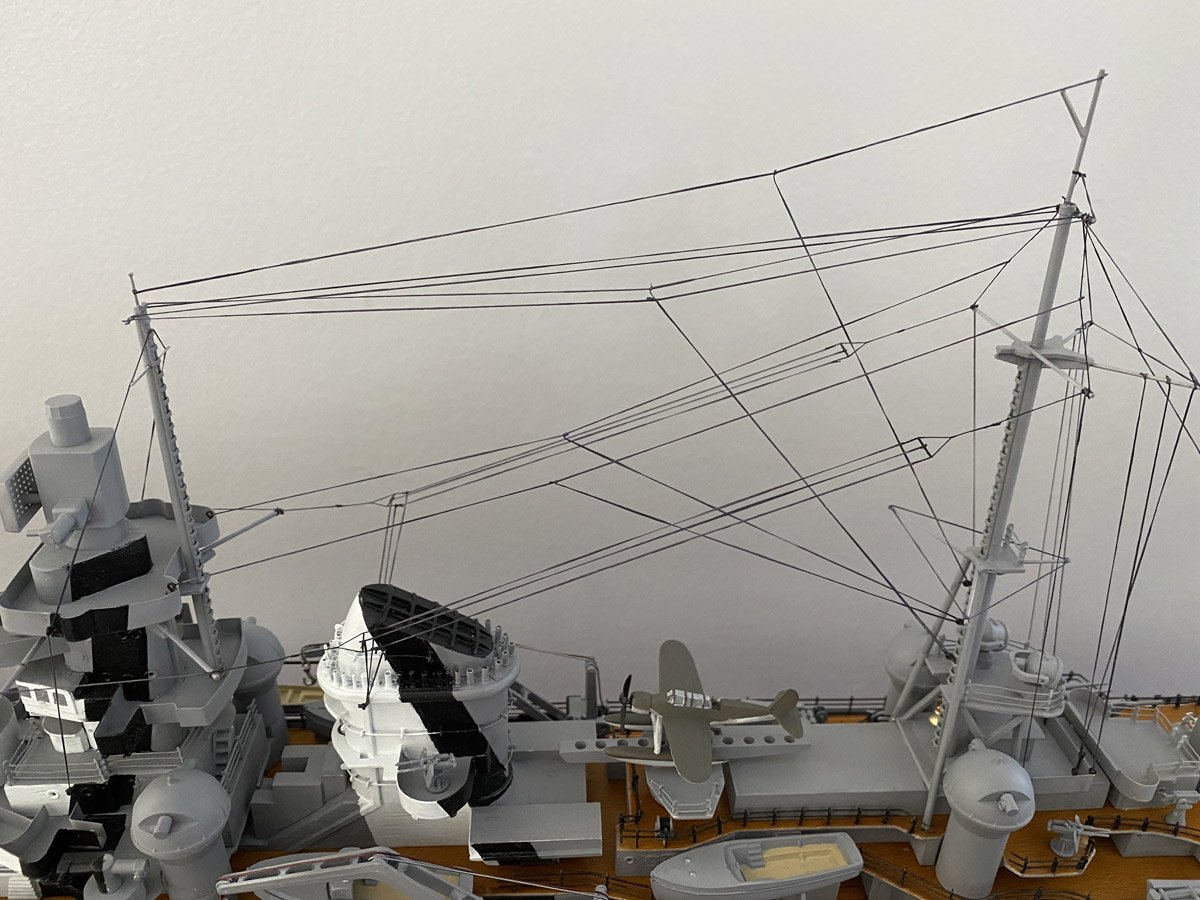

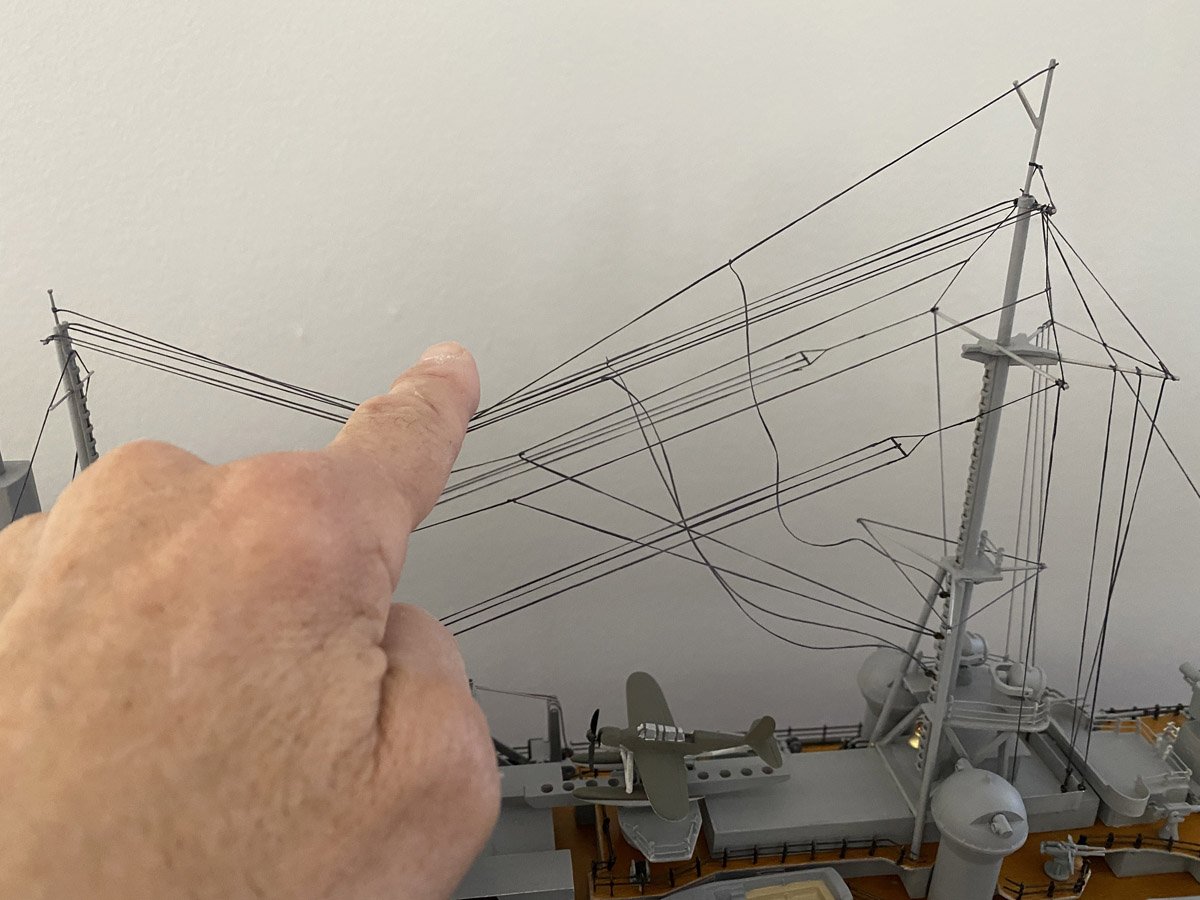

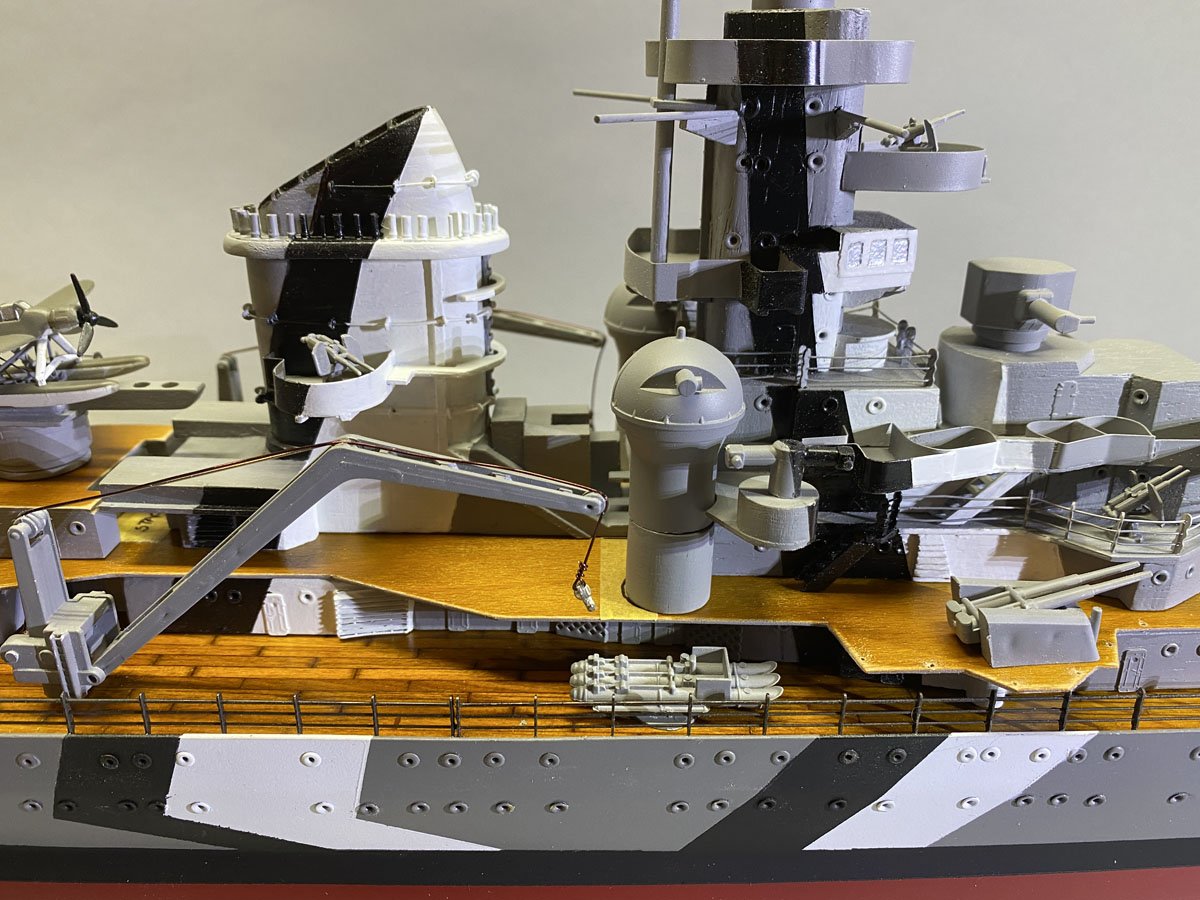

Q: What's Black and White and Red All Over? A: The Prinz Eugen in it's 1941 Baltic Camouflage! My Prinz Eugen model is complete! I've been very busy since my last post. Here's what I've done. Finished and attached all 8 ship's boats. Attached all the superstructure components. Attached dozens of smaller plastic components. Built some custom vents that go around the B turret, and found and attached a ship's bell. Rigged miles of antenna wires with EZ line. Here are some photos of the completed model. You can barely see some of the vent shafts around the second turret. Here are some of the 8 boats and the Arado 196 on the catapult. The ship's bell is hanging on the rear mast. I would not like to see this view in person! The Pontos props were worth their weight in gold. That's about how much the accessory kit cost anyway. And see, I really did install the aft anchor. The stern looks a lot like the bow. I rigged the antenna lines with EZ line. It's an elastic polymer thread that supposedly can stretch up to 7x it's original length. You can get it on Amazon but it's a lot cheaper on eBay from Burbank House of Hobbies. I bought the thick, 0.5 mm material but it still seems quite thin. I rigged the triple antennas first using tiny PE Delta-shaped fittings from the Pontos kit, but I ended up throwing out two complete antennas before I got it right. The line tends to curl so it was hard to control while gluing it to the fitting. The instructions say to use a fresh bottle of thin CA, but I had a large bottle that I'd been nursing for a couple of years. I pulled a new bottle out of my freezer and man, what a difference! I found that I if I licked the EZ line it would stick to a piece of wax paper. Then I dipped the PE part in the new CA and touched it to the line. Voila, instant attachment. The only trouble with the EZ line is that the lead wires from the antennas to the ship tend to bend the antennas. In a couple of places I used thread for the antennas to help keep them straight. I am concerned that the rigging might become brittle with age. Please let me know if you've had any long-term experience with EZ line. The Aeronaut plans were pretty worthless for rigging. One side view shows some rigging but you can't tell if you're seeing a single antenna or several side-by-side. Instead, I used The German Heavy Cruiser Prinz Eugen by Waldemar Goralski for most of the rigging. To be honest, I took some liberties with the rigging and left out a few lead wires. You'd never do this with thread rigging! I made a nice base out of quarter-sawn white oak. I bought the brass pedstals from Bluejacket Shipcrafters. The model should probably be in a case but you can only have so many big cases laying around your house. I'll probably put the model on top of a bookcase somewhere.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

I am truly amazed - I had no idea that kits like this existed. Your meticulous work is just perfect, and it's only taken 14 months so far. I'll follow along to see the finished model.

-

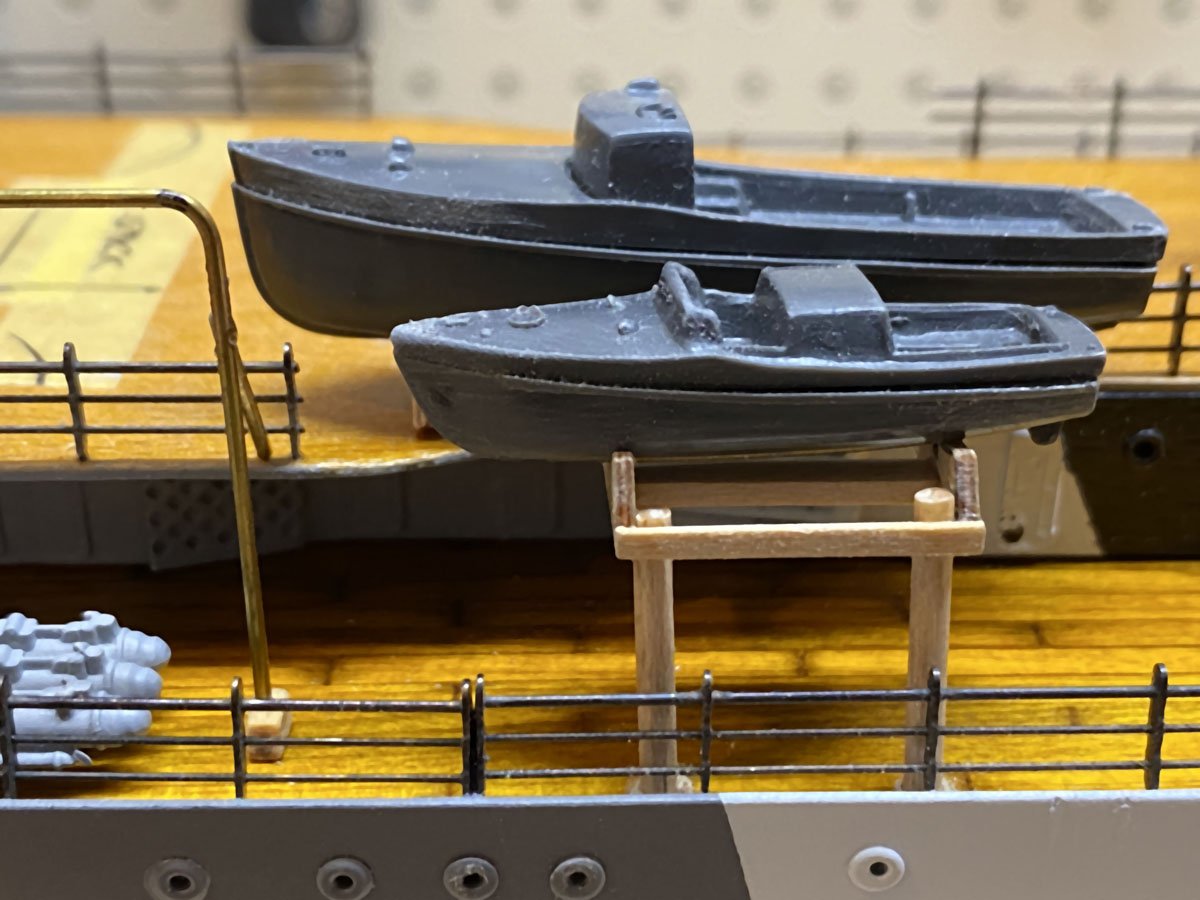

Toy Boats The Prinz Eugen carried 8 small boats on board, and the Aeronaut kit had ready-made plastic models of each. In fact my kit had 9 boats, but I think that one was a mistake. You should always wash plastic parts before painting to clean off any residual mold release. I think I'll just play with the boats like this for a while. So far I have completely ignored the ships boats. When I looked at the plans I found that 6 of them were on racks on deck 2, right where my railings were. So time to construct some racks and deconstruct some railings. This rack holds 2 boats. This rack holds 1 boat. The boats look pretty dirty close up. That was another good reason to wash them. Those racks are duplicated on each side, accounting for 6/8 boats. The remaining 2 boats hang from davits. As usual, there is nothing in the kit for the davits so I soldered a pair up out of brass. Spent a few hours today painting toy boats.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

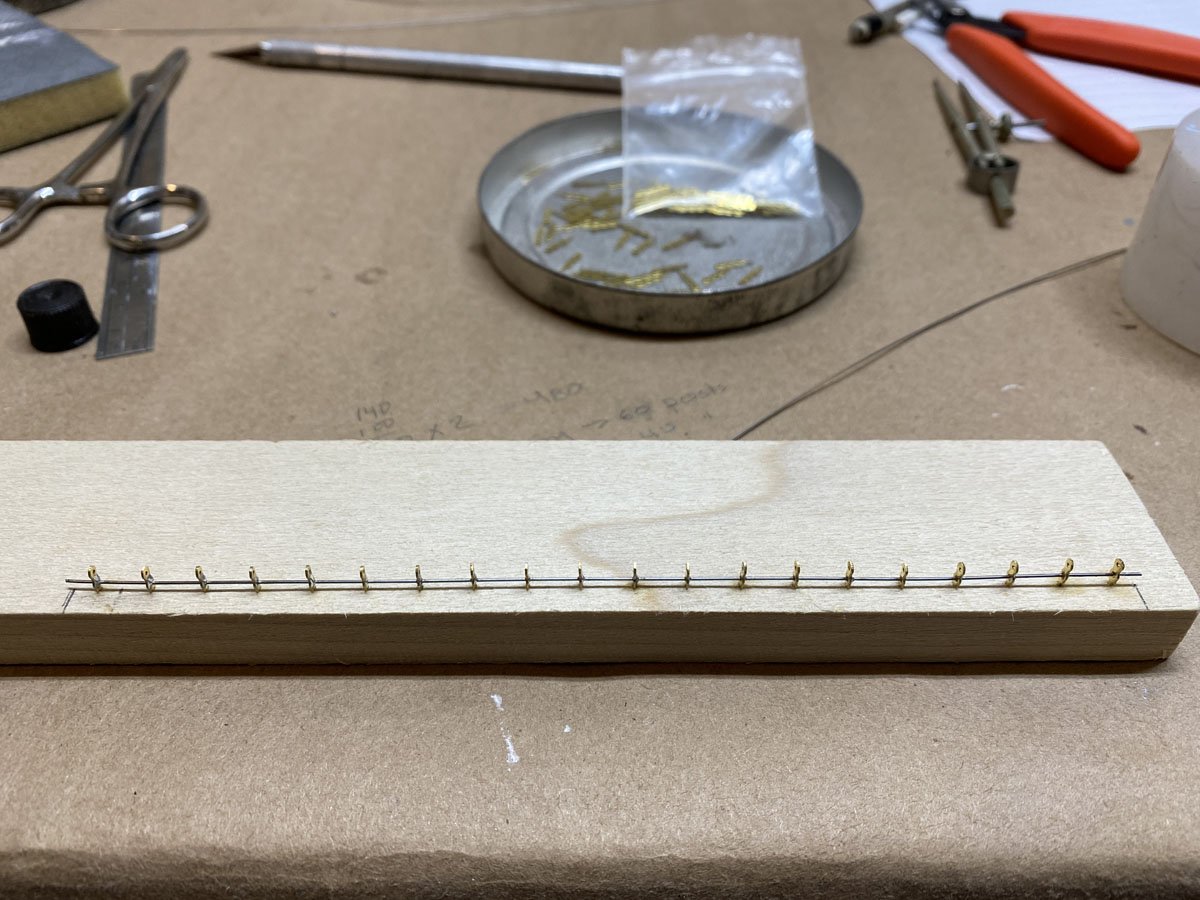

Railings The Aeronaut kit came with 14 pieces of prefab railings, each 250 mm long. I knew that would not be enough but I wasn't sure how much I would need, so I avoided using it for miscellaneous railings. The 14 pieces circled the 1st deck completely and finished the second deck with inches to spare. One deck to go. A couple of stores in England sell the prefab railings but I was in a hurry, so I made my own using the brass stanchions and music wire included in the kit. I decided to use a shorter double railing on the 3rd deck, so I cut the 3-hole stanchions down a notch and sanded them smooth. I made this jig to solder the railings together.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

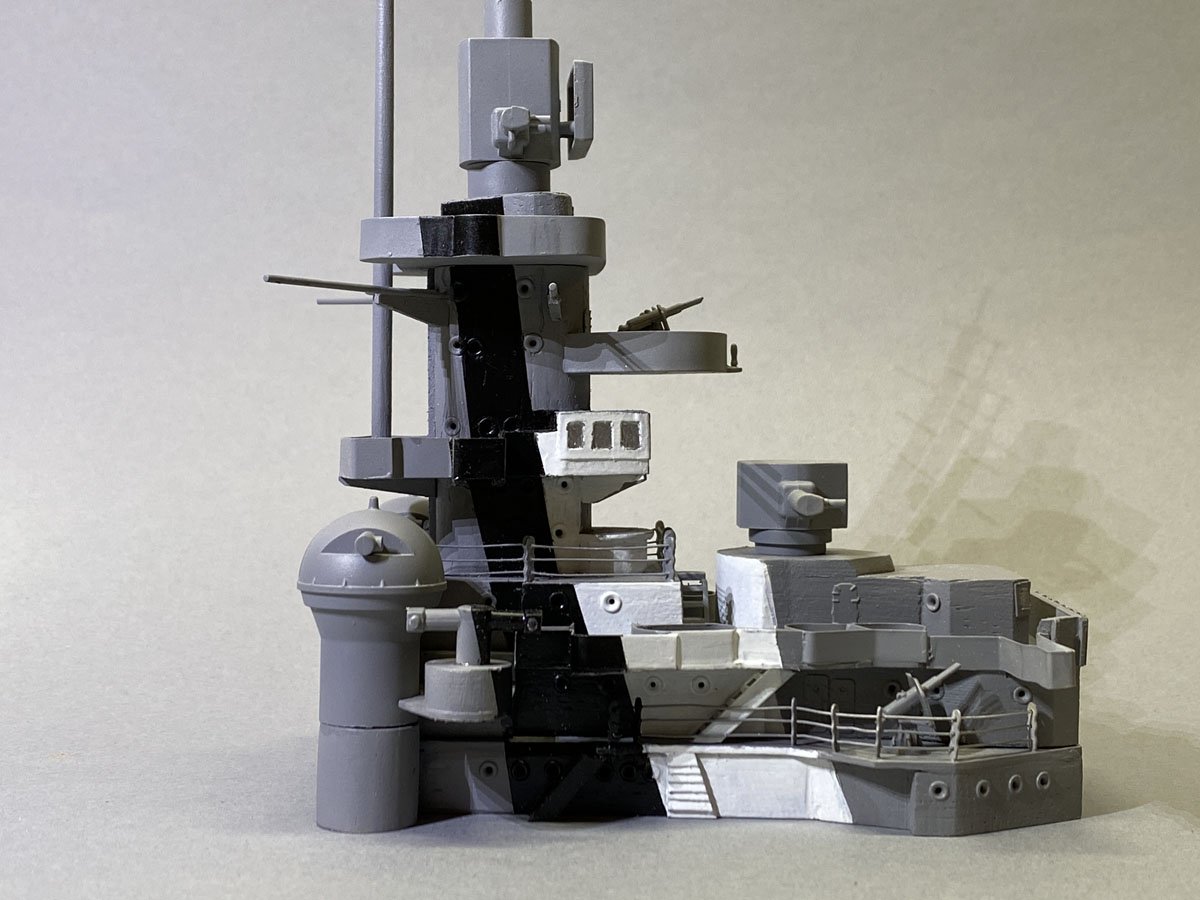

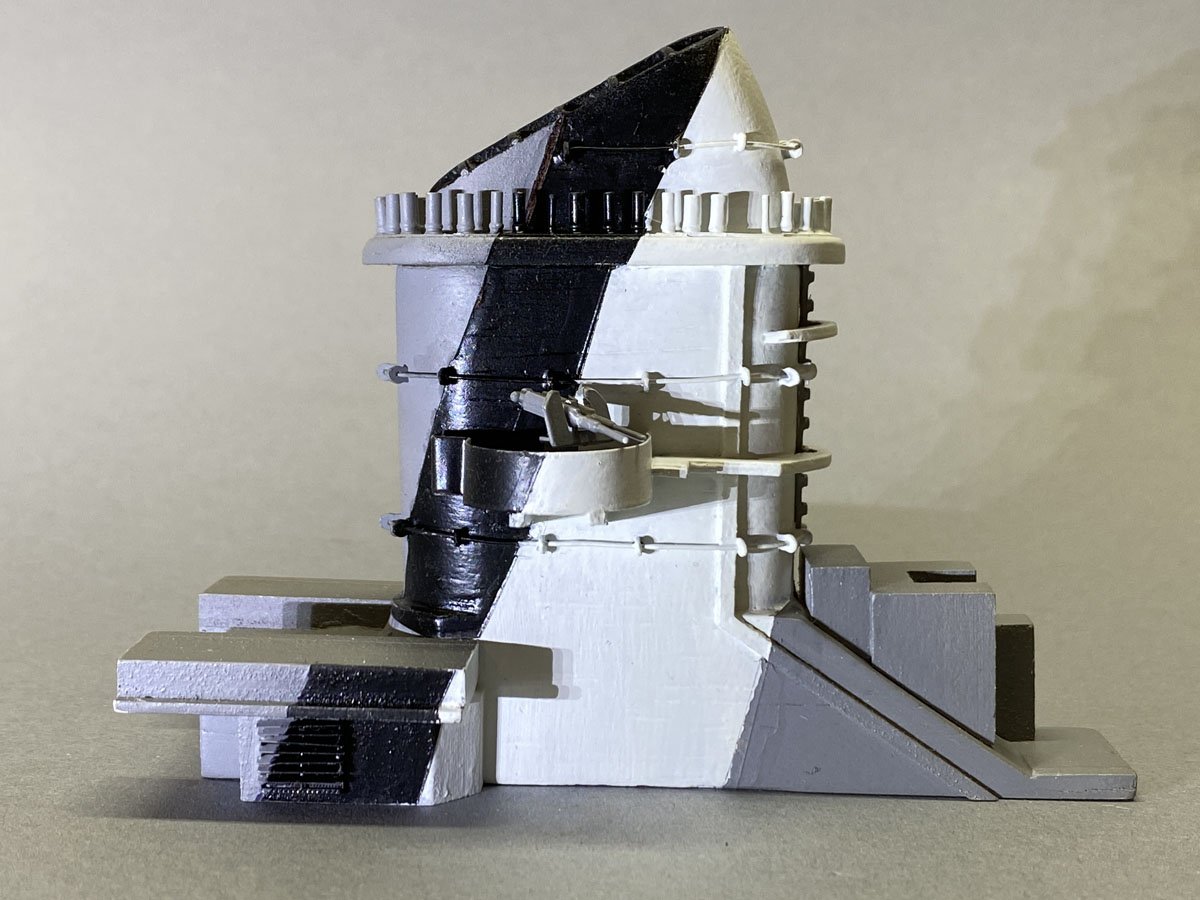

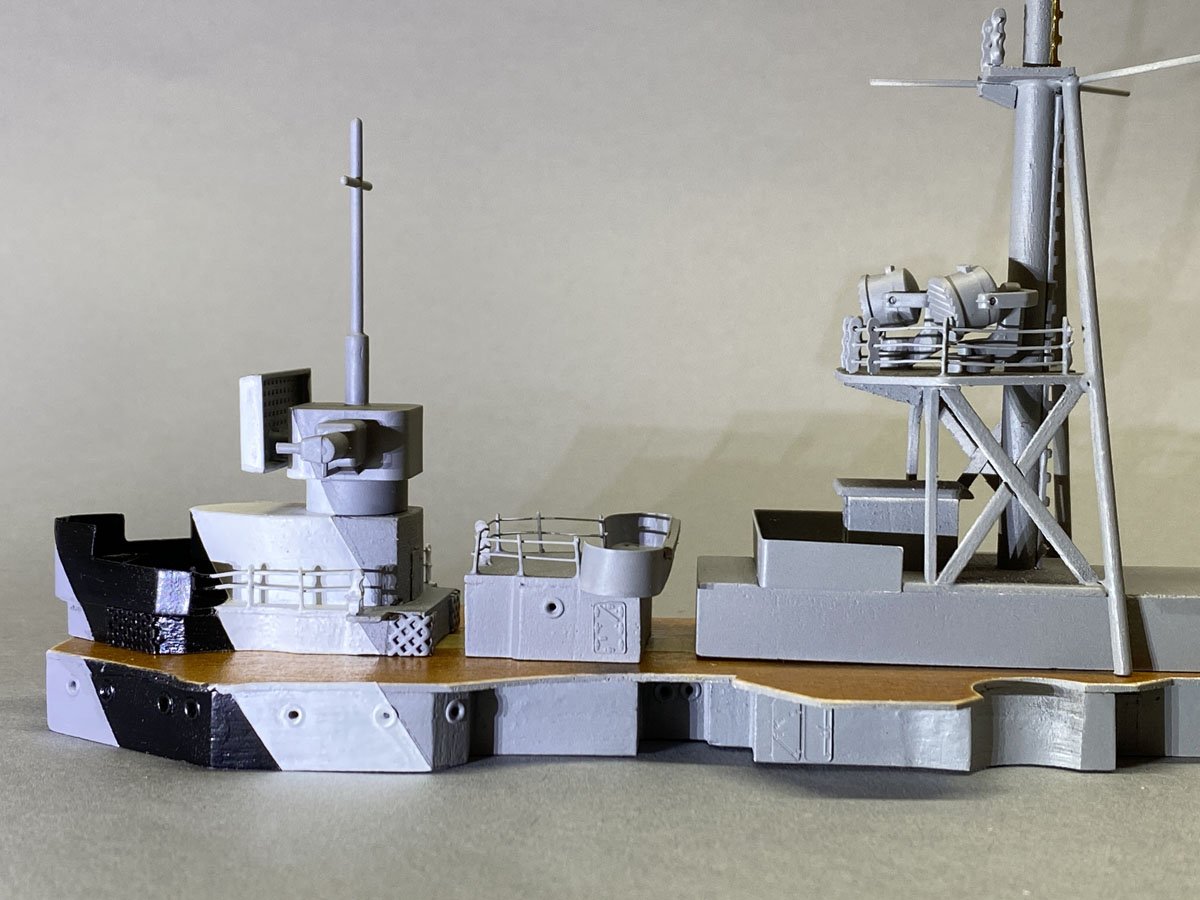

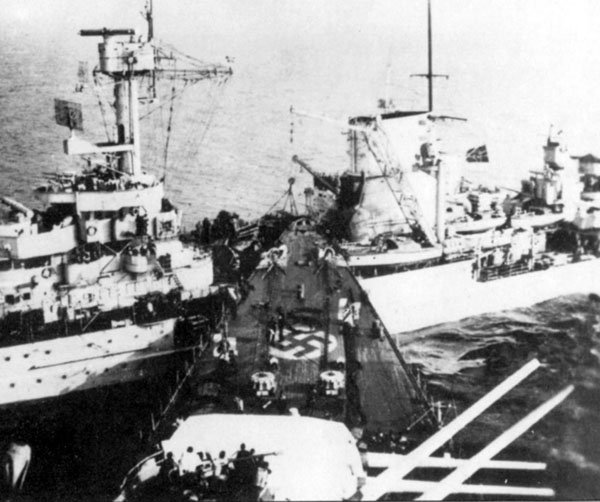

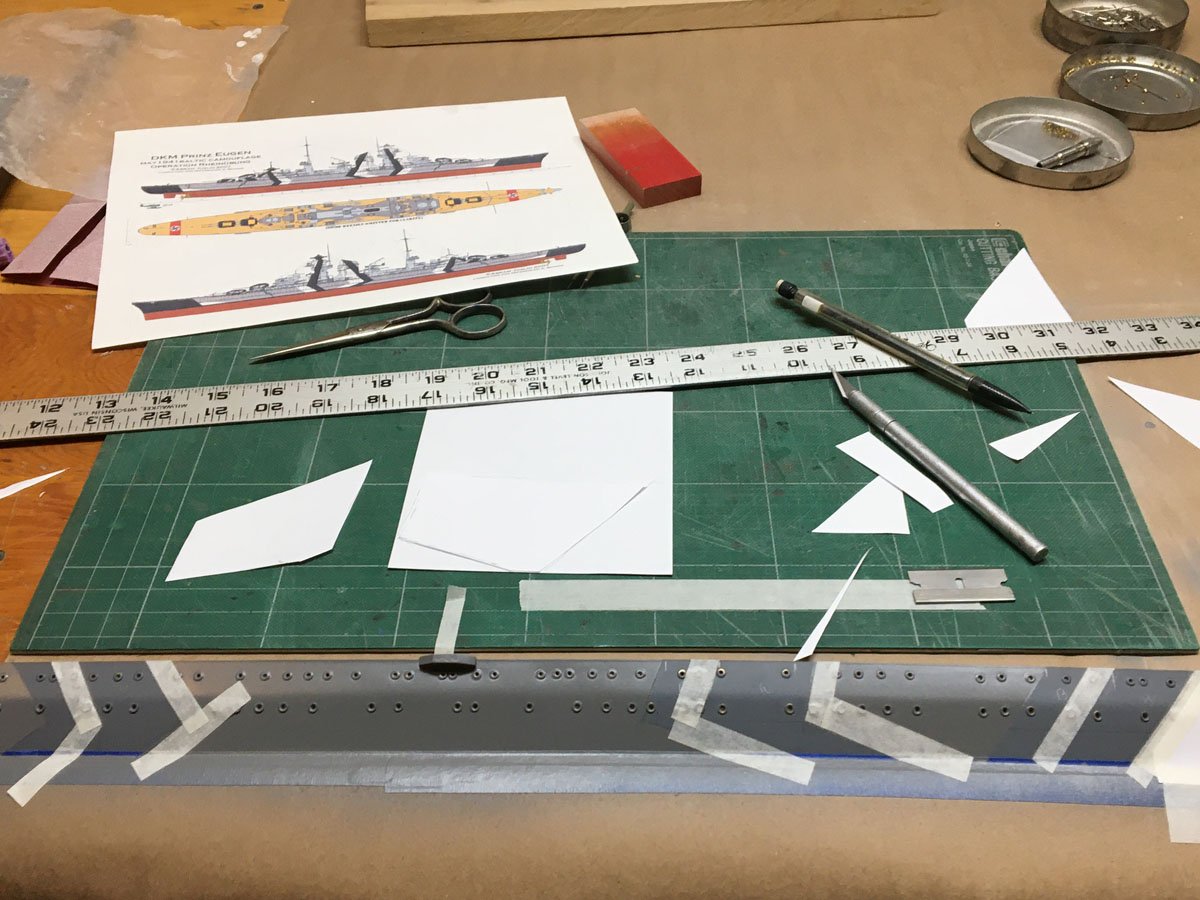

Dazzling I bit the bullet and painted the dazzle camouflage. It took a full day to mask and paint each of the diagonal stripes. I stacked all the components with 3-M double-sided tape to hold them in alignment. I made a skinny pencil by gluing a bit of pencil lead in a 1mm brass tube. Then I used a thin ruler and my skinny pencil to mark the diagonal. Very difficult to keep the pencil perpendicular to the ruler as it stepped over each layer of the superstructure. Lots of Tamiya masking tape and several hours later I was ready to paint each stripe - by hand. I also painted the tops of the turrets red. They were painted red briefly for recognition by German aircraft. I didn't realize that this overview photo was so grainy until now. I'll try to get a better image later. Here are some other shots that look better. Forward superstructure Funnel Aft superstructure and mast Aft end with painted turrets All the components are stacked temporarily in position. I have been adding railings to the second and third levels. More on that in the next post.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Hi Yves, Welcome to the build log. It's a little short on detail but I wanted to get some information out there about the Aeronaut kits. And thank you for the the welcome to Asheville. Our son lives in Apex so I am very familiar with the Raleigh area. I am always interested in finding new shops, shows, or museums related to aircraft or ships. Please let me know if you have any suggestions. Rod

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

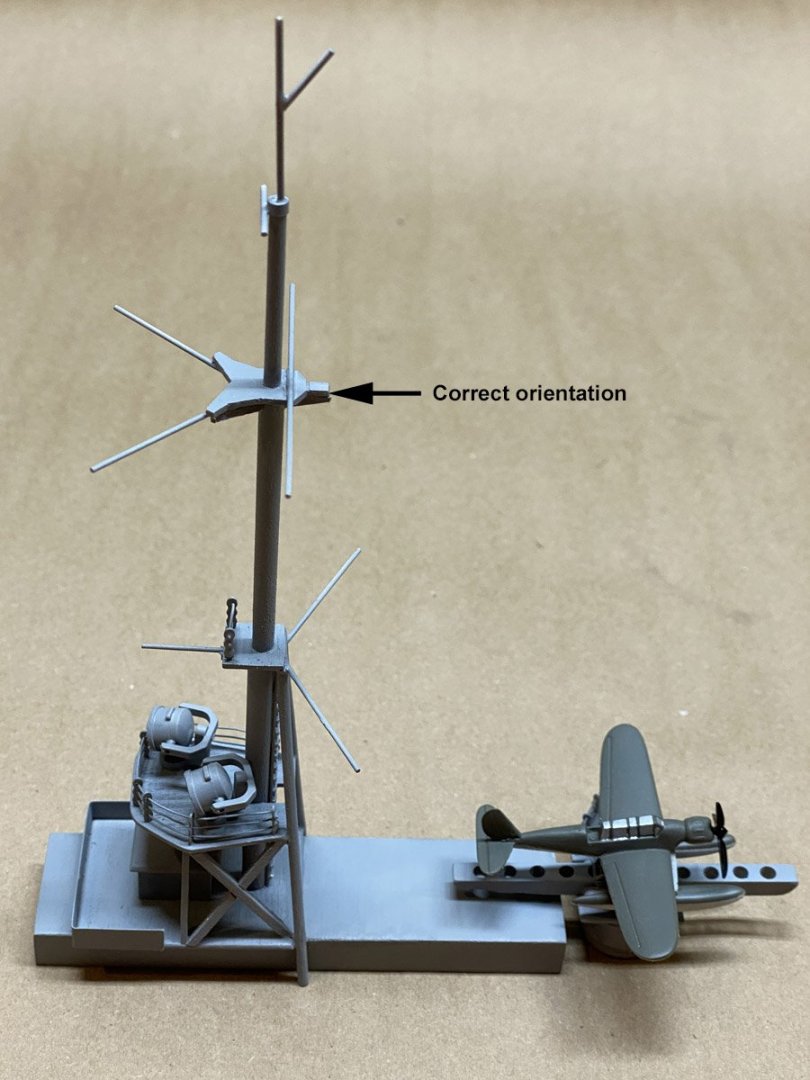

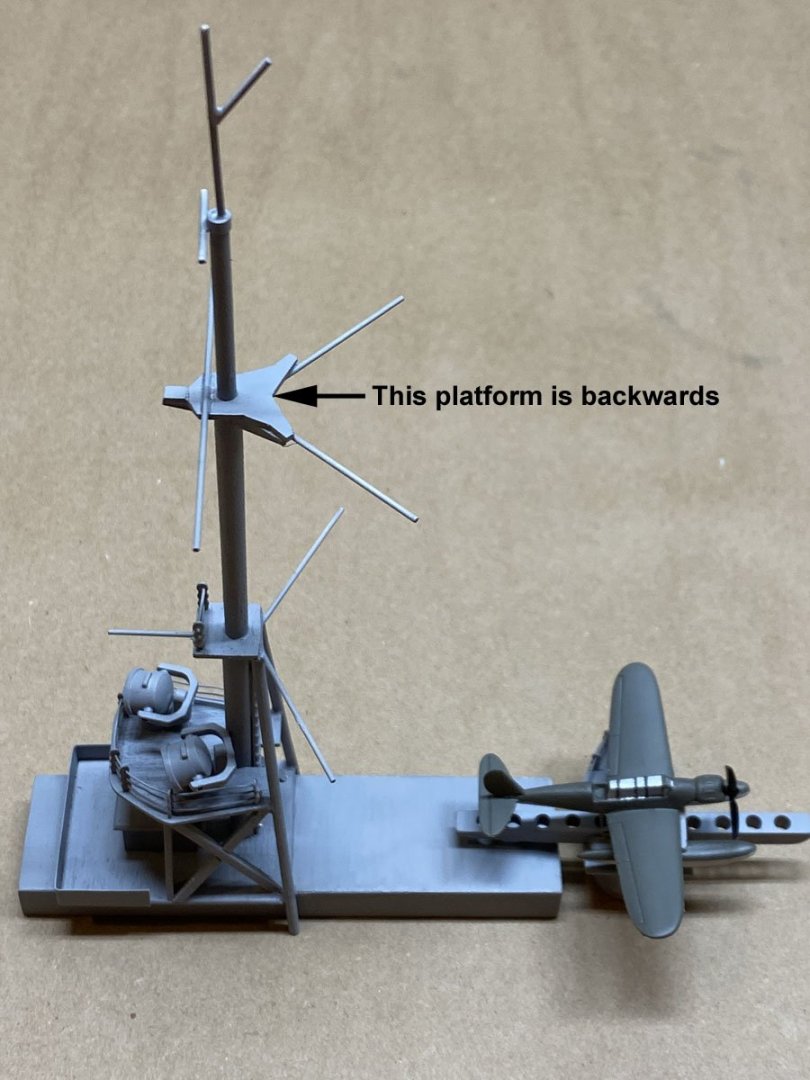

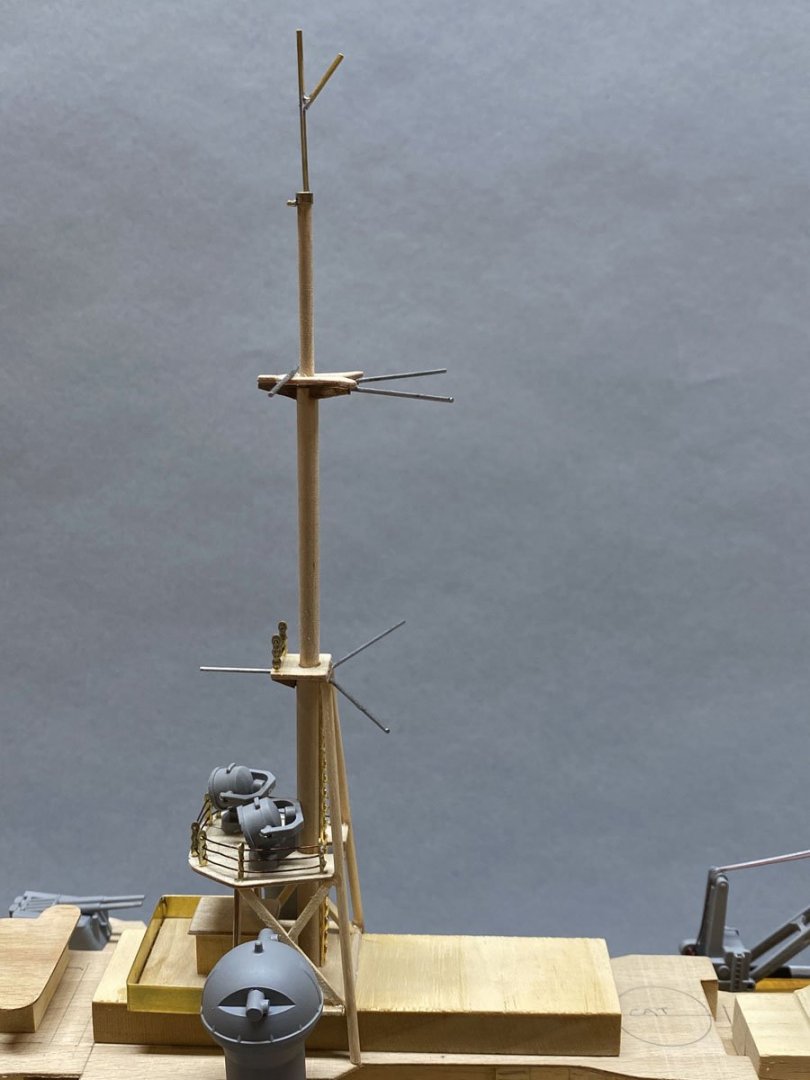

Oops, I Put the Platform on Backwards I've been standing the mast on top of the plans for a month and just realized that I installed the lower platform backwards. So how to fix it? I broke off 3 triangular gussets on the bottom, then gently twisted the platform until it broke loose. Cleaned up the glue, rotated the platform, glued everything back together, and touched up the paint. 15 minutes tops. And while I was fixing things I installed the rear anchor. Well, you can't see the anchor, but it's there.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

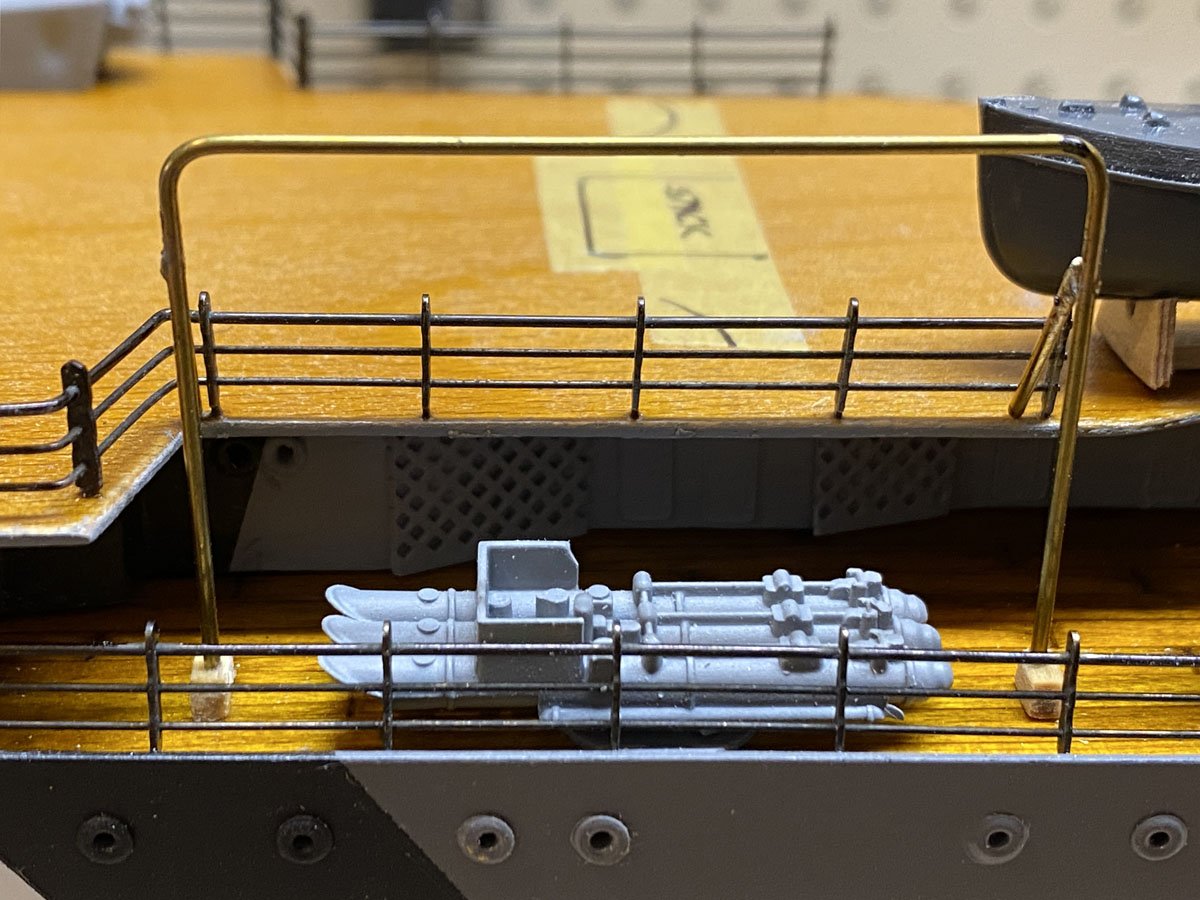

Catapult and Arado 196 Floatplane I spent a full day building the brass aircraft stand that comes with the Pontos detail kit. They actually give you enough parts to build 4 of them although you only need 1. Good thing because I screwed up 2 1/2 of them before I settled on this one. Then I built the catapult (from scratch) and the Arado 196 floatplane (came with the Aeronaut kit). Hey! what happened to my aircraft stand? The real catapult rail is about 15 m long and the catapult launch speed is 130 km/hr. I did some quick calculations that show that the pilot would pull 4.3 g's at takeoff, about the same as an F-18 pilot on a modern carrier. Must have been quite a ride!

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Bob, 1. Put a coat of primer on everything. Sand and touch up as necessary. 2. Paint the white stripe at the waterline. When it's good and dry, mask it off with high quality modelers masking tape. I like the Tamiya brand. Rub the edges thoroughly with a toothpick, then paint both edges of the tape with white to seal it. 3. Mask off above the waterline and paint the green below. If you're very confident of your airbrush skills you could skip the masking part, but I wouldn't. 4. Mask off the green, remove the tape above the water line, and paint the black. 5. Say a little prayer and remove the tape. Rod

-

Nelson, Could you post a photo of your porthole? I'd love to see it. Rod

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

References Since the Aeronaut plans show very little detail, I've searched online for anything I could find on the Prinz Eugen. Ironically, the main thing that comes up is this scantly-clad anime character named Prinz Eugen, from a side-scrolling shoot-em-up game called Azur Lane. It's set in an alternate timeline of WWII where the characters are anthropomorphic versions of WWII warships. Enough said about that. The German Heavy Cruiser Prinz Eugen by Waldemar Goralski is the best reference I could find for the model builder. It has 27 pages of detailed B&W line drawings of every part of the ship. The Heavy Cruiser Prinz Eugen, also by Waldemar Goralski, has an eight-page history of the ship and about 80 pages of color images of various parts of the ship. Mr. Goralski must have an amazing CAD model of the ship. It takes a while to find the view that you need, but the images can be very helpful. The last 8-10 pages are 3-D images that require Red-Blue glasses. They're fun but less useful for reference. Admiral Hipper Class Cruisers by Steve Backer has a little bit of everything - history, B&W photos, reviews of plastic models, photos of completed models, and camouflage patterns for 5 ships. 64 pages. This is the book that got me searching for a photo-etched detail kit. Warship Pictorial Kriegsmarine Prinz Eugen by Steve Wiper has a brief history of the ship and 74 pages of interesting B&W photos. Heavy Cruisers of the Admiral Hipper Class by Gerhard Koop and Klaus-Peter Schmolke is more of a reference book. At 205 pages it has a chapter on each of the five Admiral Hipper class ships, with technical specs, photos, and a few detail drawings.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Not at all! The photos are fascinating. Is that you sitting between the props?

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

I have also been away for too long. I am so pleased to see your completed Endeavour model. It is absolutely beautiful! Your attention to every little detail make for an outstanding model. Congratulations. Last November and early December my wife and I took a cruise down the east coast of New Zealand and over to Tasmania, Melbourne, and Sydney. I was so hoping to see the Endeavour replica in Sydney harbor, but I learned that it was on a tour of New Zealand for the 250th anniversary of Cook's voyage. Our cruise ship and the Endeavour replica were in the same ports on almost the same days. We probably passed each other one night, but I never saw her. However, I got to talking to a young man in the San Francisco airport who had just sailed on a leg of the Endeavour's tour. He had hundreds of photos on his phone and I saw them all.

-

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

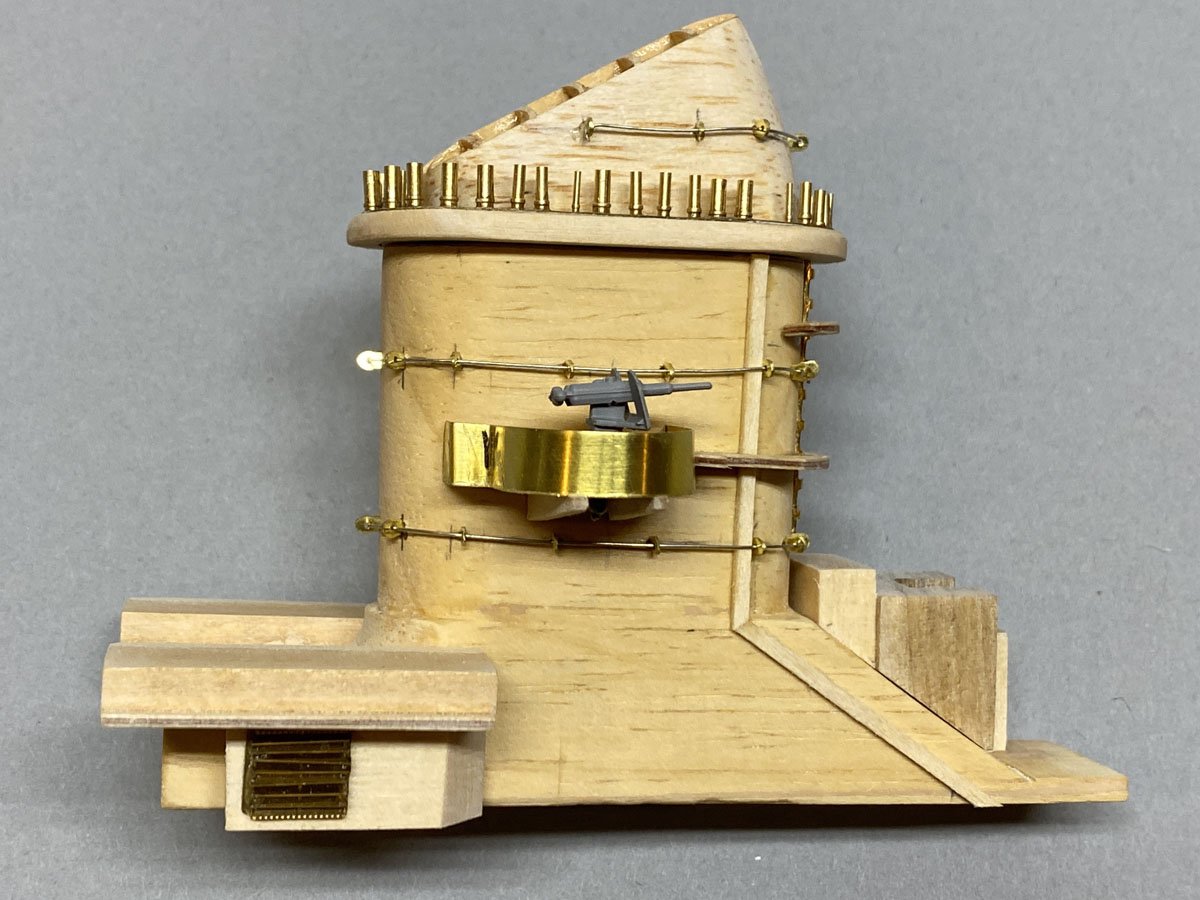

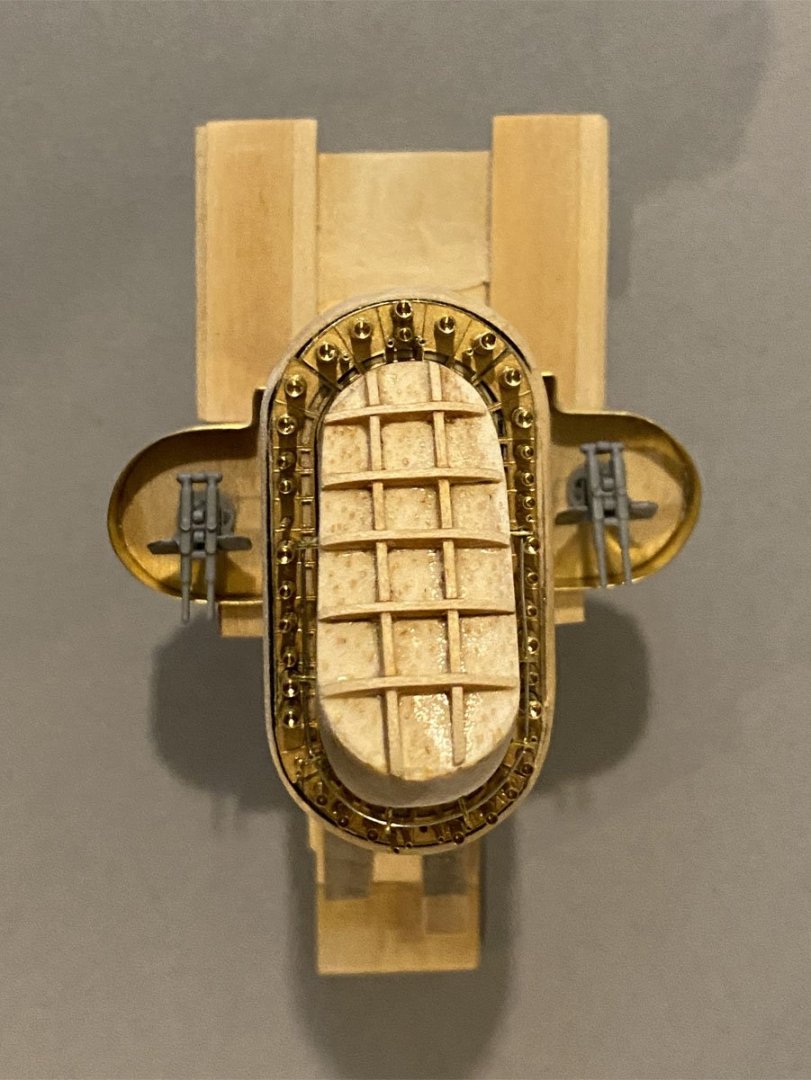

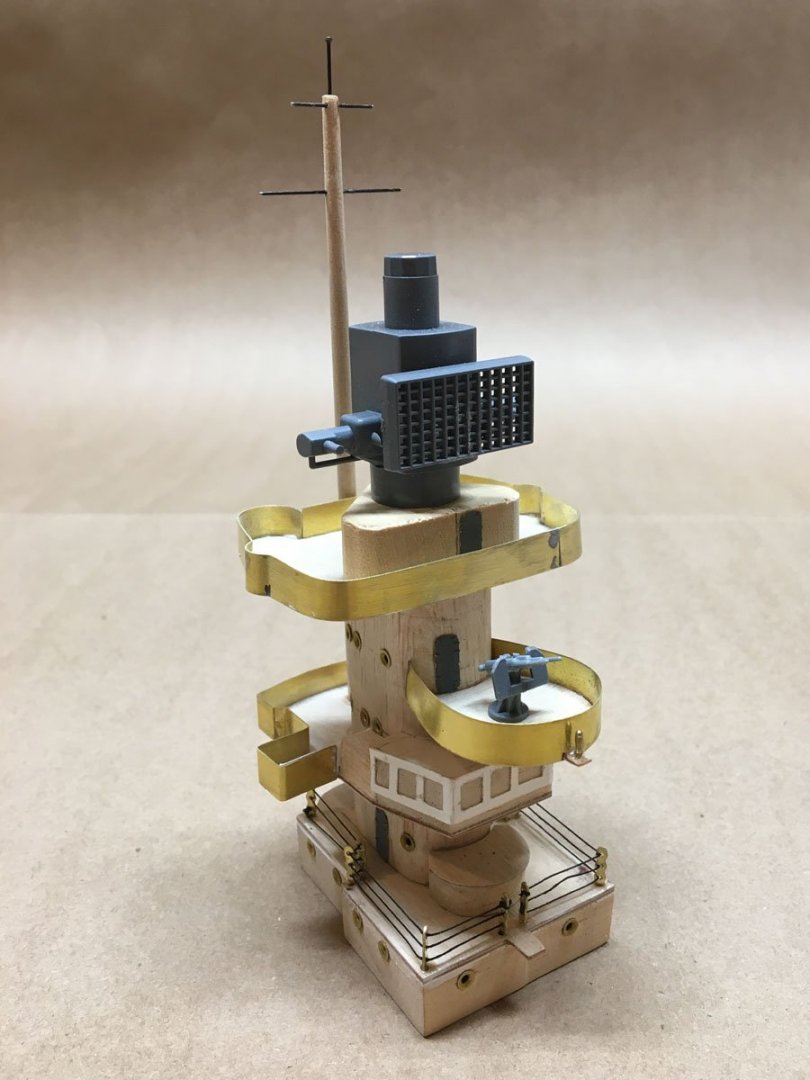

Funnel The funnel is laminated from two pieces of 12 mm limewood carved to shape, with lots of little pieces added later. The Pontos detail kit had a brass ring and about 45 individual pipes in three diameters for the top of the funnel. The detail kit is made for the Bismarck but it fit the Prinz Eugen perfectly. Whew! Various books show many handrails around the funnel. I only added three - enough to give the impression of detail while keeping my sanity. The Pontos box shows a complicated brass grid across the top of the funnel, but the kit does not seem to have those parts. I made a simpler grid from thin wood strips. The view in this photo is odd and my grid is actually aligned with the funnel.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

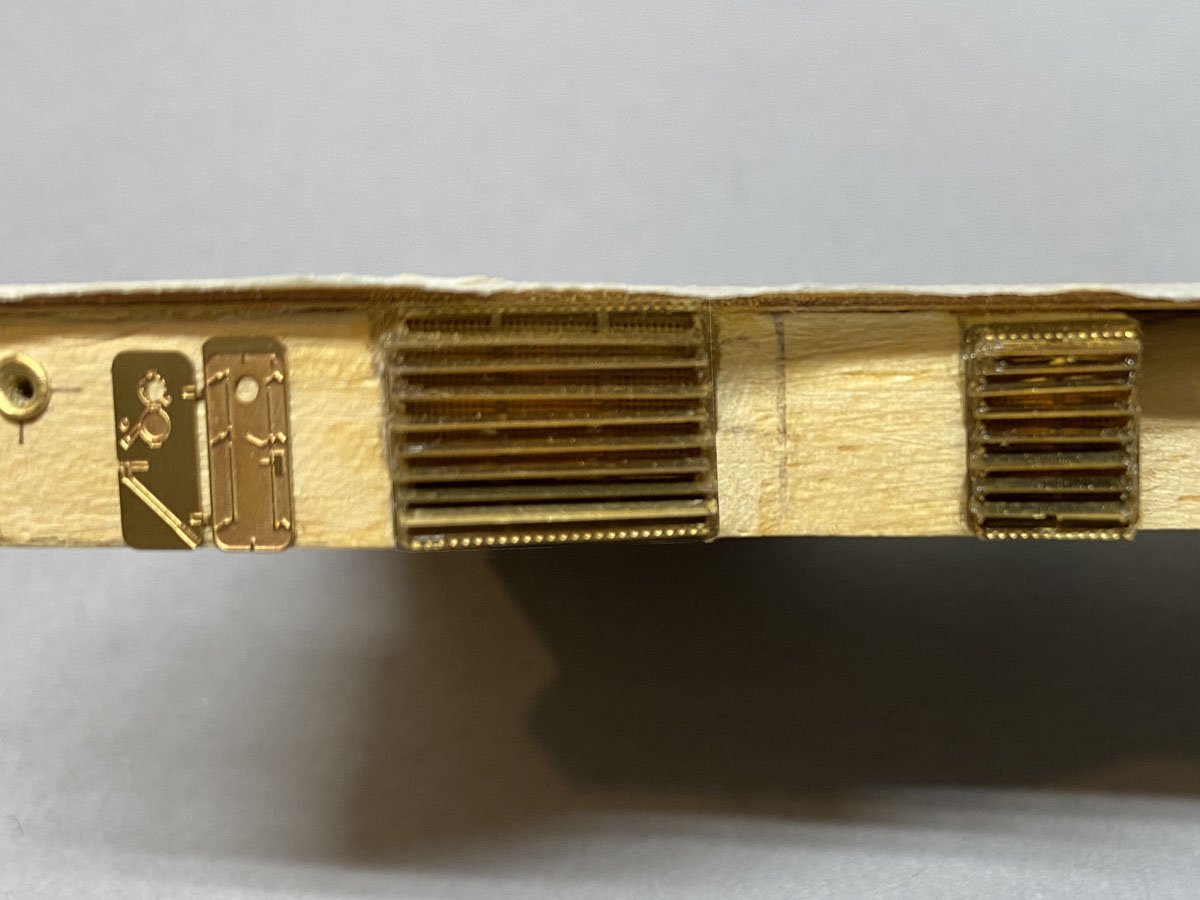

Doors & Louvers I added the doors and louvers from the Pontos detail kit. The louvers were very difficult to make. They comprise a backing plate about the size of your little fingernail, tiny sawtooth rails that have to be bent 90 degrees, and 9 individual slats. They look sloppy here but I got pretty good at them by the last one. The heavy grid came with the kit in a long strip. I don't know what it's supposed to be but it resembles the drawings.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

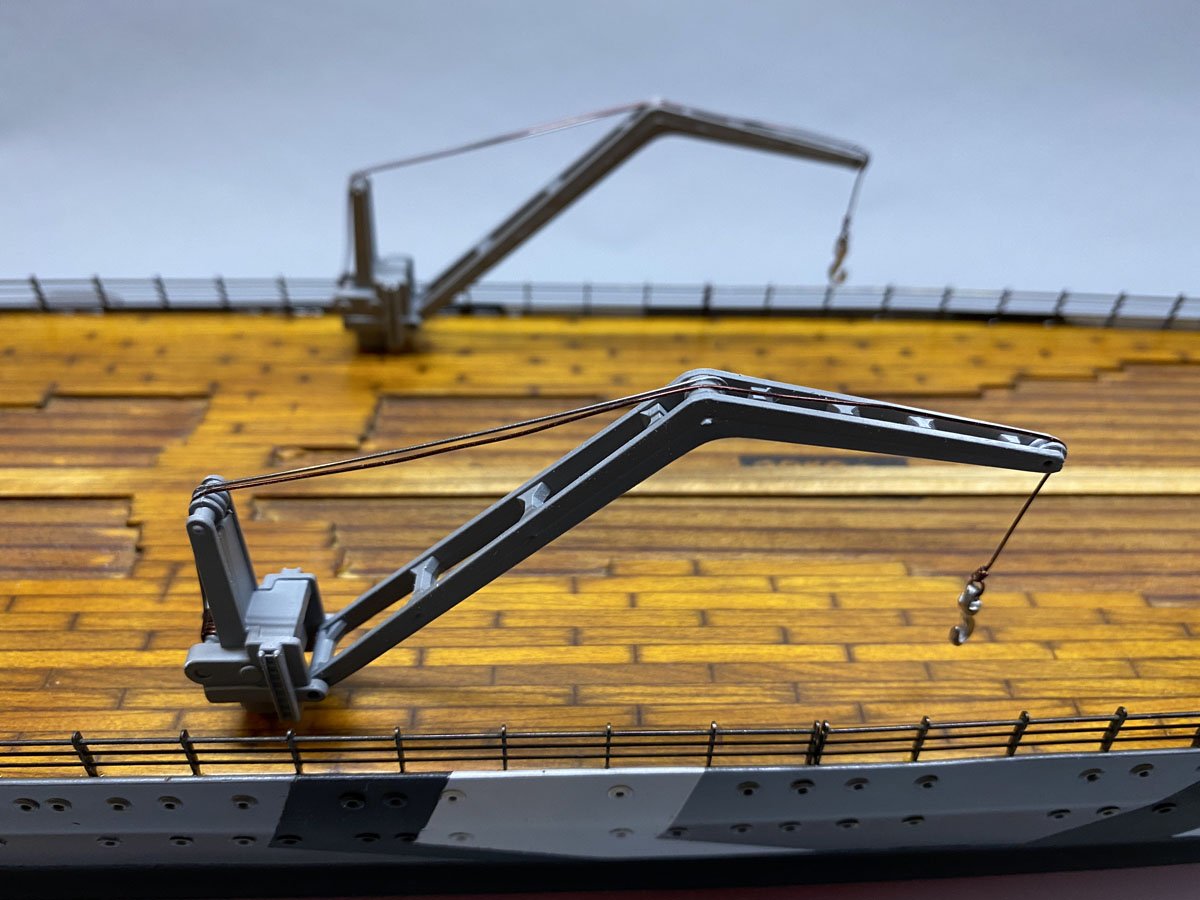

Deck & Rails I glued the deck into the hull using E6000 cement. It's smells like a dry cleaning shop but it has a fairly long working time and makes a strong bond. It took a lot of clamps to hold everything together. Isn't my workbench colorful? Then I attached those railings and anchor chains that I blackened earlier. There was a tiny gap, < 1mm, between the deck and hull in most places so I just put a spot of epoxy on the railing stanchions and pushed them into the gap. The railing conveniently hides the gap. Pure luck. The kit came with some oval shaped eyelets (grommets?) for the anchor chains, but the chain wouldn't fit. I used some black eyelets instead. I made the breakwater on the bow from scraps. Mid deck with cranes temporarily in place. Aft deck. After the Prinz Eugen was torpedoed, a blunt stern was welded with twin rudders operated by the crew turning a capstan on deck. Capstan? Oh no, I forgot the aft anchor! I wondered why the kit had an extra capstan and anchor. I'll have to add those later.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Mast The Germans expected their cruisers to be way out in the Atlantic raiding convoys, so they had very tall masts and lots of antennas for communication. Instead the ships spent a lot of time in Norway where the tall masts weren't as important. The mast was fun to build. I started with a large diameter dowel, spun it in my drill press at top speed, and sanded the three sections to smaller and smaller diameters. Five minutes, tops. That's how I make masts and yards for sailing ships. The antennas are brass rod, soldered in a few places. There is a brass ladder up to the first platform. The other platforms should probably have ladders and rails too, but I think I'll just skip those details. The rectangular block is the aircraft hanger. The plane will sit on top of it. The large block was pre-cut, but the grain goes side-to side. I just painted it and the grain is too obvious, so I filled it with wood filler and will have to repaint. I probably should have sanded those X-pieces better before assembly.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

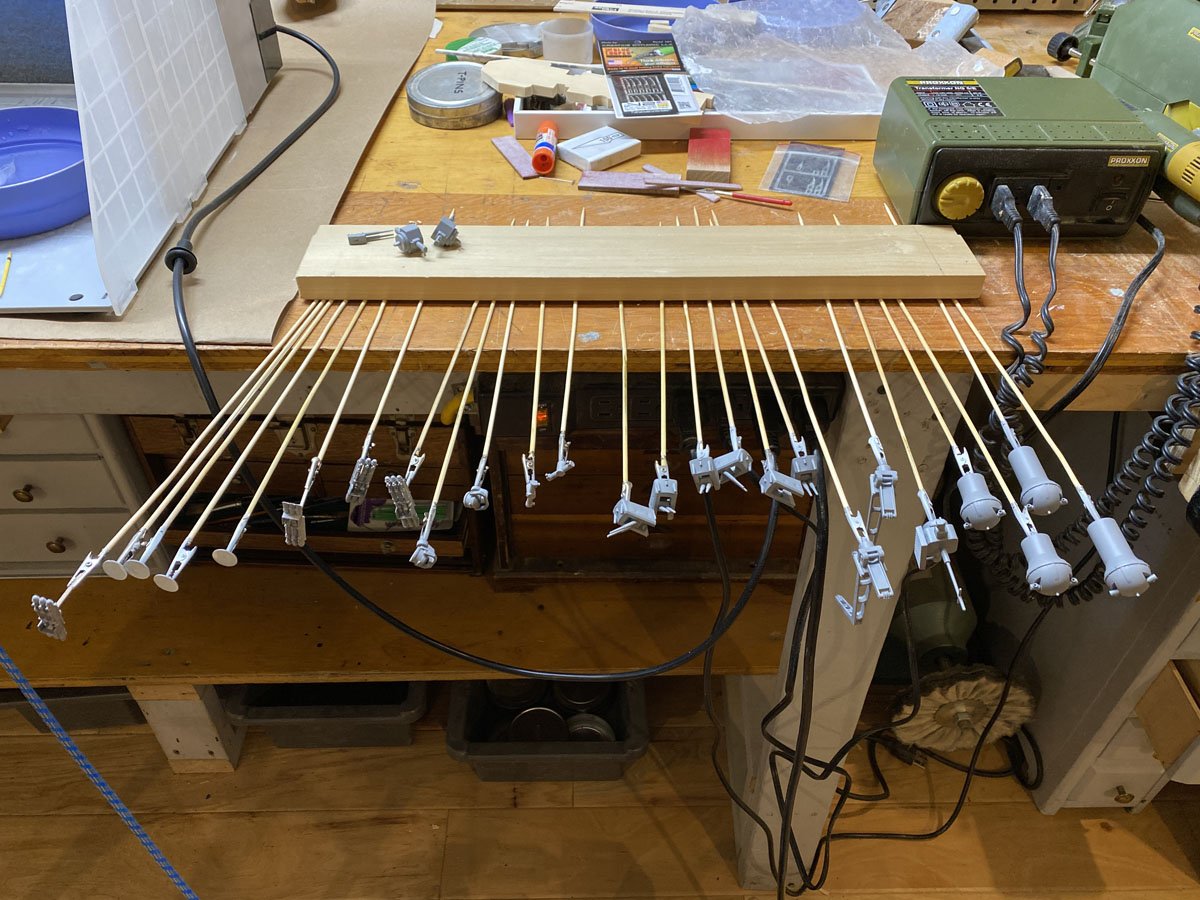

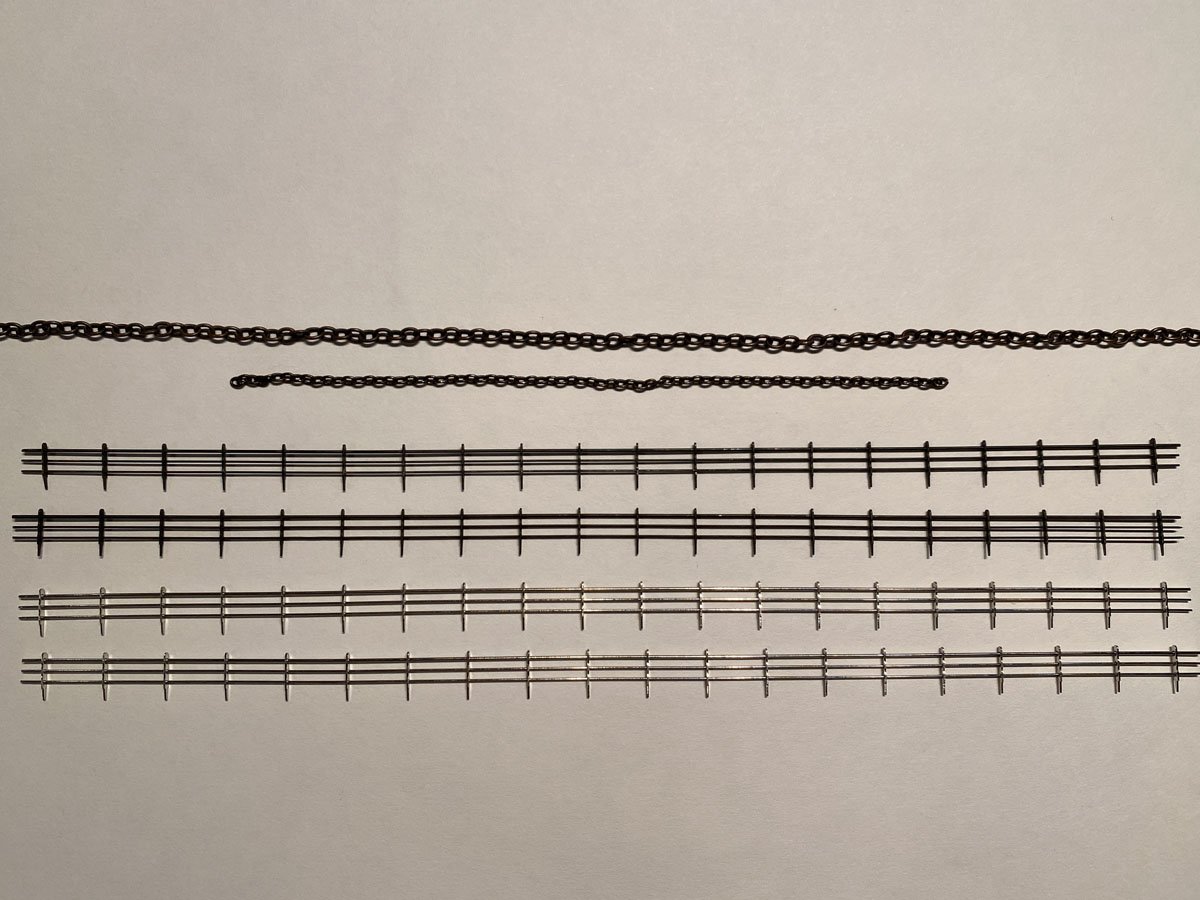

Painting Little Parts I recently took a break from building and decided to paint a bunch of the plastic parts instead. Here's a photo of my work bench and about 25 plastic parts. I started with a coat of Tamiya white primer from a rattle can, then used an Iwata air brush to spray the parts with AK International acrylic, color AK734, Dunkelgrau 51. I had one 17 ml bottle of paint and had trouble finding more anywhere online. Eventually I ordered 5 bottles from 3 different companies. Now it looks like I will enough left over to paint a (real) battleship. Here are the painted parts. The kit came with 9 sets of stairs that look OK until you realize that the steps would be knee high at 1:200 scale. I had hoped that the Pontos detail kit might have some scale stairs. It has 4 sets, not nearly enough. I'm using the plastic ones. Rails & Chains As I've mentioned, the Aeronaut kit comes with 14 lengths of nicely made rails. There are 2 problems, 1. they're silver, and 2. they're as tall as person at 1:200 scale. The Pontos detail kit has lots railing stanchions that would be about chest high at scale, but the pieces are microscopic and I don't want to deal with hundreds of them. So now my deck planks, my stairs, and my railings are way off scale, but no one will ever know except you and me. The Aeronaut kit also comes with 2 sizes of brass chains for the anchors and anchor hold downs. The links are probably way off scale too but I just don't care anymore. I blackened the rails and chains using Novocan black patina for stained glass, another hobby of mine. Hard to tell, but the top 2 rails are black and the bottom 2 are silver.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

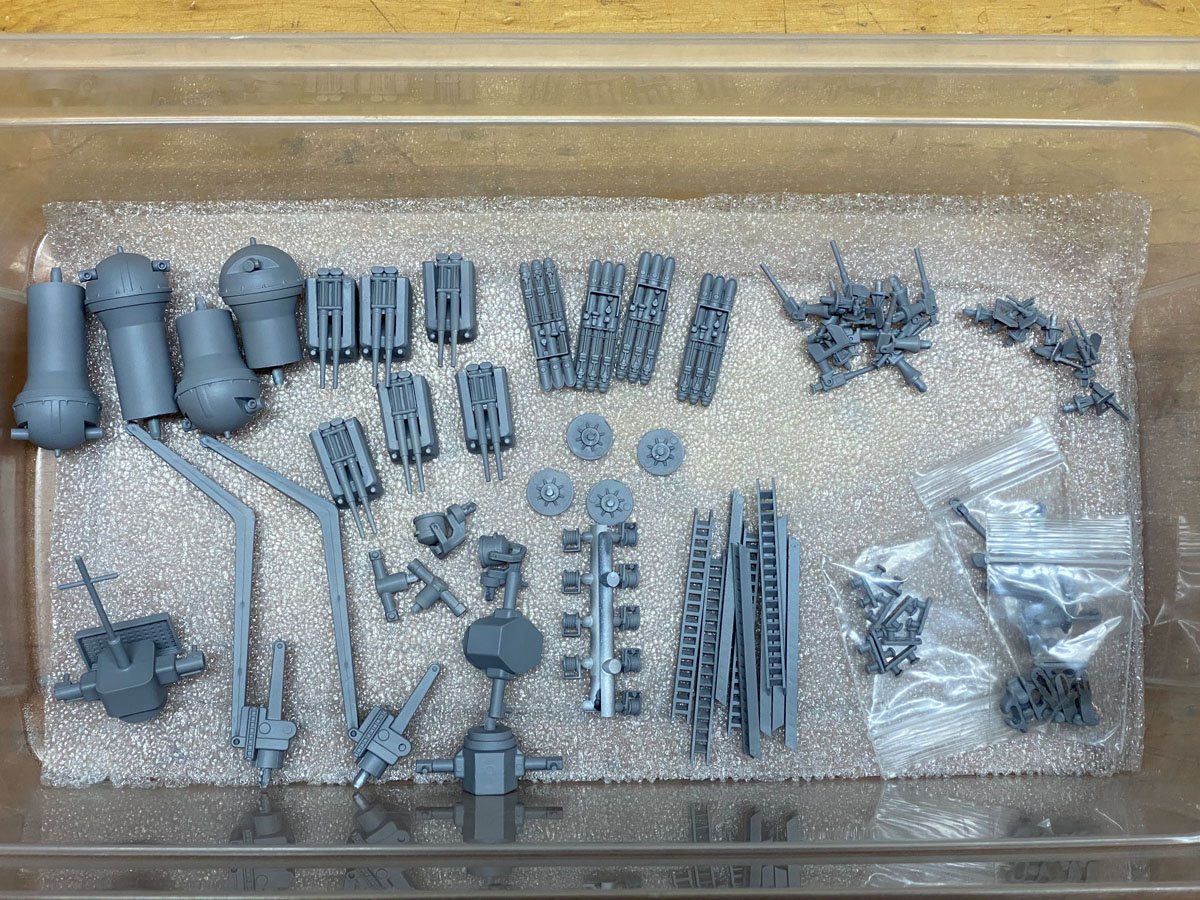

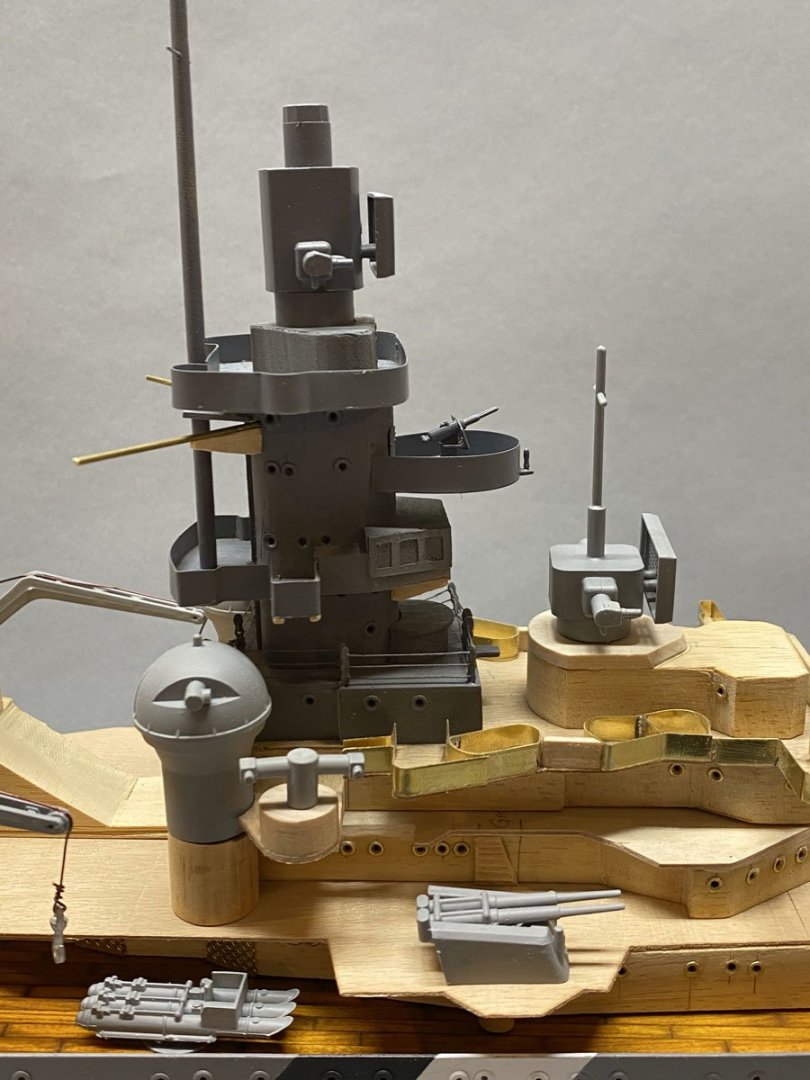

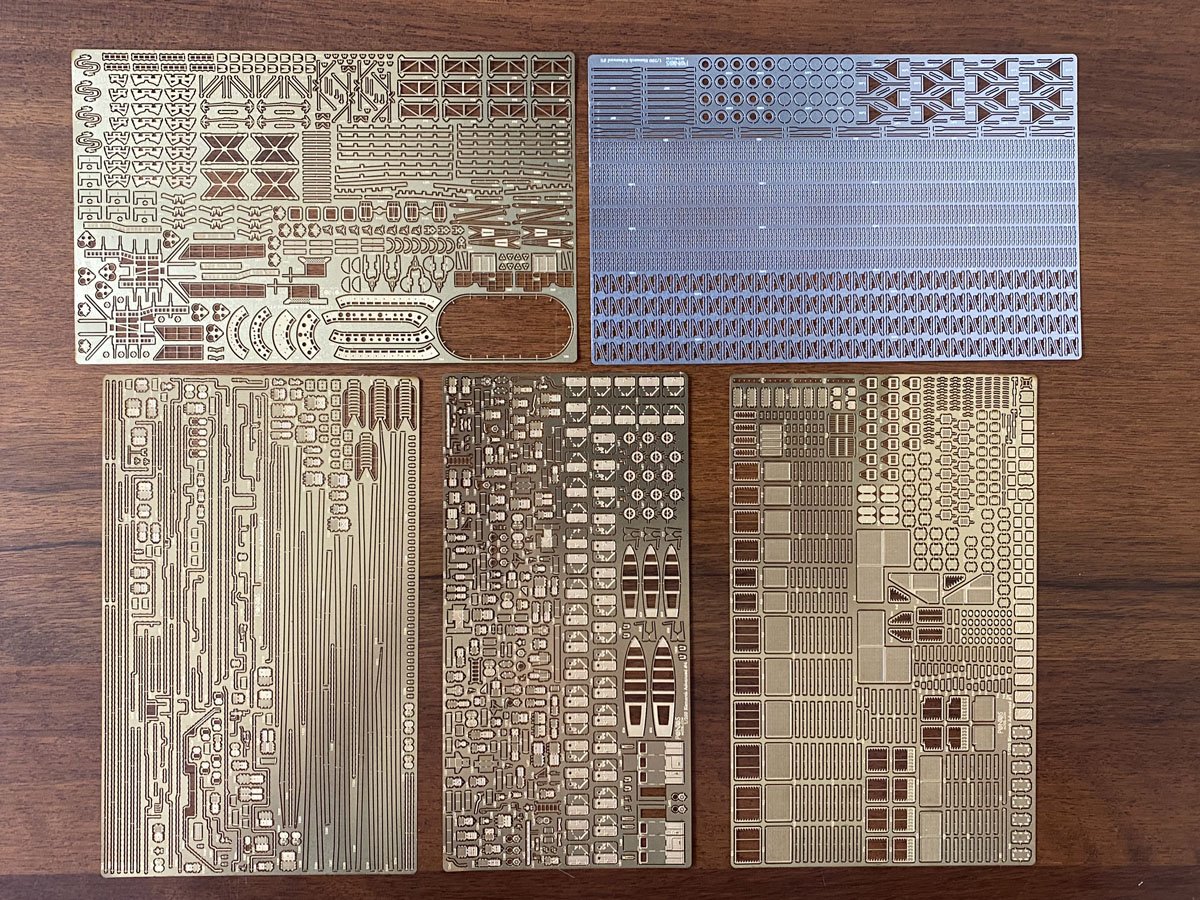

Forward Superstructure & Bridge The kit came with wooden blocks to carve for the forward superstructure, but the main block was crushed. I used a balsa block and attached the various bridge pieces. The drawings show railings, doors, portholes and windows, but there is nothing in the kit to use for those things. I used thin sheet brass for the railings, eyelets for the portholes, and cut card stock for the windows. I had some photo etched brass doors left over from my Arleigh Burke build and attached them. I really wanted to see something completed so I glued everything together. Big mistake. I should have filled the balsa grain and painted everything before assembly. The kit comes with 14 very nice pieces of pre-made railings but I wasn't sure if there was enough for all the little fiddly pieces. More on that later. It also includes a bag of brass railing stanchions and I used those here. I have experimented with thread and several kinds of wire for the railings and am not totally satisfied with any of them. I primed the tower with dark gray spray paint. Here you can also see sheet brass rails on the lower deck. The drawings show lots of louvered air vents all over the ship. I tried to make some using thin balsa strips glued to card stock. Not bad but could be better. The plastic modeling industry has some beautiful battleship models with very complex add-on detail kits. I couldn't find anything for the Prinz Eugen at 1:200 scale, but Pontos Models from Korea has an accessory kit for the Bismarck at 1:200. It looked like a lot of the parts would fit my model so I took a chance and ordered the kit on eBay from https://www.bnamodelworld.com/ in Australia. Their price beat anything in the US and they shipped immediately. Then, because of the pandemic, the box sat in customs in Melbourne for almost a month. Very frustrating but I got it. Pontos 1:200 Detail kit for the Bismark The detail kit is nicely packaged - much nicer than the Aeronaut kit. The kit has five sheets of photo etched parts. Four are brass and include pipes, funnel parts, holders for the ships boats, doors, windows, and louvers. One sheet is some silver metal and includes stanchions for the railings, oars for the ships boats, and antenna pieces. The kit has a bag of parts for the funnel, another bag of parts for the paravanes, and three props. Two of the props turn one direction and one the other way. I attached the props first.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

A Brief History of the Prinz Eugen (gathered from several books - maybe I can post some references later) The Prinz Eugen was laid down in April, 1936, launched in August, 1938, and commissioned in August, 1940. He took part in the first raid of the battleship Bismarck in May, 1941 when the British battleship HMS Hood was sunk and the Prince of Wales was heavily damaged. (The German navy refers to ships in the male gender.) He spent a lot of time in various ports with boiler and engine problems. In early February of 1942 German battle cruisers Gneisenau, Scharnhorst, heavy cruiser Prinz Eugen, various destroyers, torpedo boats, and other ships made a dash from Brest, France through the English Channel to Kiel, Germany. A massive escort was provided by the Luftwaffe. On February 22 many of the ships departed for Norway. On February 23 the British submarine HMS Trident torpedoed Prinz Eugen. The stern of the ship was almost severed but the ship limped into Lofjord, Trondheim the next day. A repair ship made emergency repairs by welding a blunt stern with twin rudders operated by the crew turning a capstan on deck. (This would make a cool model!) Prinz Eugen returned to Kiel under his own power and was completely repaired by the end of October. After returning to service he served as a training ship in the Baltic, and provided artillery cover for retreating German troops. On October 15, 1944 Prinz Eugen was returning to Gotenhafen, (Gdynia) Poland at full speed in the mist, and rammed the light cruiser Leipzig which as adrift making a routine engine coupling transfer. The ships were locked together for 14 hours. Prinz Eugen continued to Gotenhafen under his own power and had a new bow fitted in less than a month. Leipzig was towed. Prinz Eugen continued to provide artillery support for ground troops, and ended up in Copenhagen at the end of the war. The ship was decommissioned and taken by the British to Wilhelmshaven, Germany for inspection by engineers from all of the Allied Powers. The ship was desired by all, but the USA won her by drawing lots from a hat. In January, 1946 a crew of 40 US navy sailors and 574 German personnel sailed him to Boston and later to Philadelphia, where he was hit by a US Navy tug. The tug was severely damaged. In March he was sailed to California via the Panama canal. In May he was sailed to Pearl Harbor, Hawaii, and then to Bikini Atoll in the Pacific. On July 1, 1946 Prinz Eugen and a fleet of other ships were bombed in an air burst test of a "Fat Man" atomic bomb like that used on Nagasaki, Japan. Prinz Eugen was 1200 yards from the center of the blast and received only superficial damage. On July 25 it was bombed again with an underwater detonation of a second atomic bomb. Prinz Eugen was 2000 yards from the center of the blast and again received minimal damage but high radioactive contamination. Occupation of the ship would be lethal, so it was towed to Kwajalein Lagoon nearby. A small leak went unrepaired because of the radiation. By late December the ship was listing, rolled over slowly, and sank on a reef with parts of the stern out of the water. It remains there still and is no longer radioactive. Search for "Wreck of the German cruiser Prinz Eugen" in Google maps and look at the satellite view. In 1974 the German Navy League requested the removal of one propeller. It is now on display as part of the Laboe Naval Memorial in Kiel, Germany.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Thank you for your comments Lou. I obviously don't know the distinction between a battleship and a heavy cruiser, but I'd like to learn. Mostly I just enjoy making things, and a heavy cruiser looked like a challenge. Please continue to correct me when I get the history wrong. Rod

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

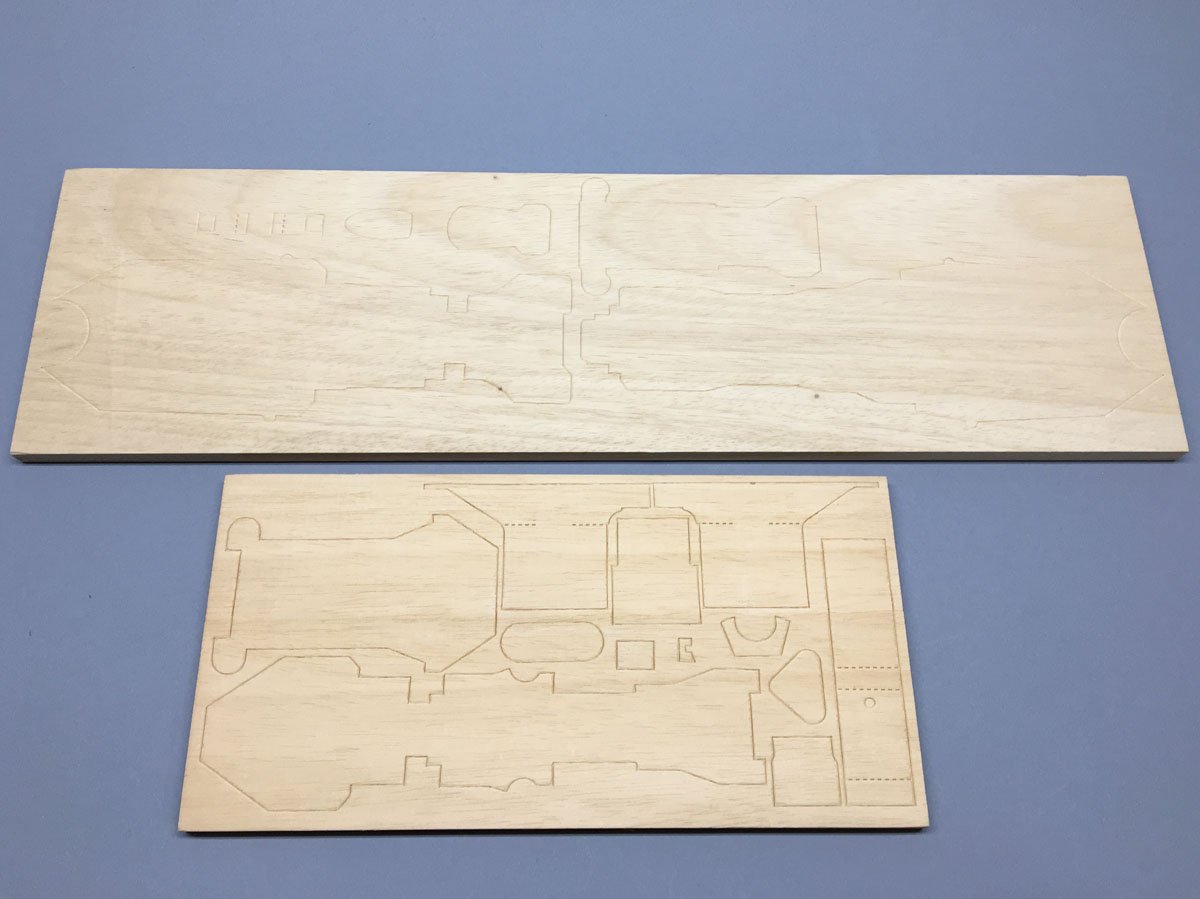

Rough Superstructure Superstructure parts for the kit are made from sheets of limewood either 10 mm or 12 mm thick, plenty high enough for a 1/200 scale sailor to walk under. The parts are stamped about 0.25 mm deep, but you have to cut them out with a scroll saw, and then sand, sand, sand. The superstructure layers are sandwiched between sheets of 1 mm 3-ply that constitute the decks. In some places the deck is flush with the structure below, and in other places it overhangs, often to hold a gun. The ply pieces are warped so it's hard to hold the sandwich together to sand the flush edges. I started gluing each layer to it's upper deck after this photo was taken.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

-

Painting the Hull and Deck The Prinz Eugen was painted with 20 different paint schemes over its 6 year lifespan. This web site has drawings of all of them. http://www.kbismarck.org/forum/viewtopic.php?t=470#p10532 I chose the dazzle camouflage scheme used in the Baltic in May of 1941. You can see it in the photo below. I carefully chose all of my colors and went searching for paints online. Between the worldwide pandemic and the fact that there are few hobby shops left in the US, I had a terrible time finding what I wanted. After several disappointments with online shops I walked to my local hardware store and bought four rattle cans of Rustoleum - Colonial red, granite gray, black, and white. h I painted the red and then the gray. Here I'm masking off for the white parts of the camouflage. Painting the superstructure is going to be a b****. I planked the deck using long strips of 4 mm lime (bass) wood left over from another model. That's still 5x too wide for scale but it looks much better than the stuff that came with the kit. I glued down long strips with CA, and then notched the strips every 30 mm with a chisel to show individual planks. I sealed the surface with Timbermate wood filler, sanded, wiped off a quick coat of dark stain, and airbrushed everything with 4 coats of orange shellac. Much of this was not exactly planned, but it came out pretty good in the end. The ship had big swastikas painted on a red field on the deck for identification. I printed the swastikas on an ink jet printer, sprayed them with clear, and pasted them on.

- 40 replies

-

- aeronaut

- kriegsmarine

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.