-

Posts

842 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by robdurant

-

Wow! What a brilliant job you've done of this kit. The quality of work at every stage is very apparent. Looking forward to seeing the finished photos, especially with the ingenious and very effective boat stand you've found. Just sad I didn't find this log earlier. Will you be moving back onto the ARM Cuauhtémoc now? She looks like a very handsome vessel indeed. Rob

- 33 replies

-

- Artesania Latina

- Whaleboat

-

(and 3 more)

Tagged with:

-

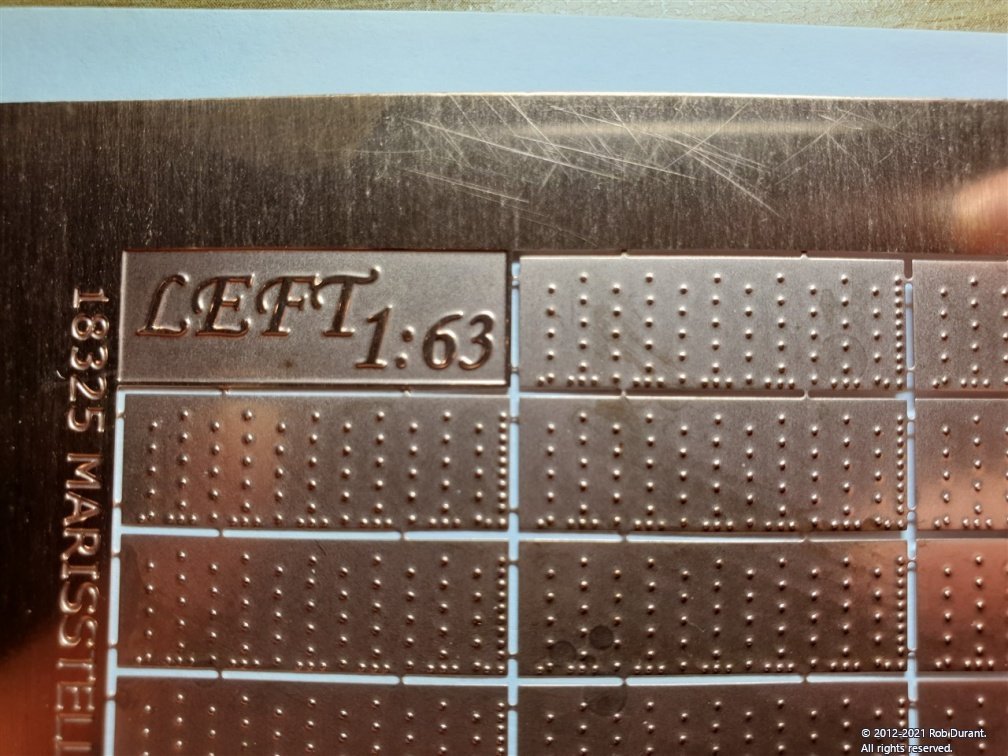

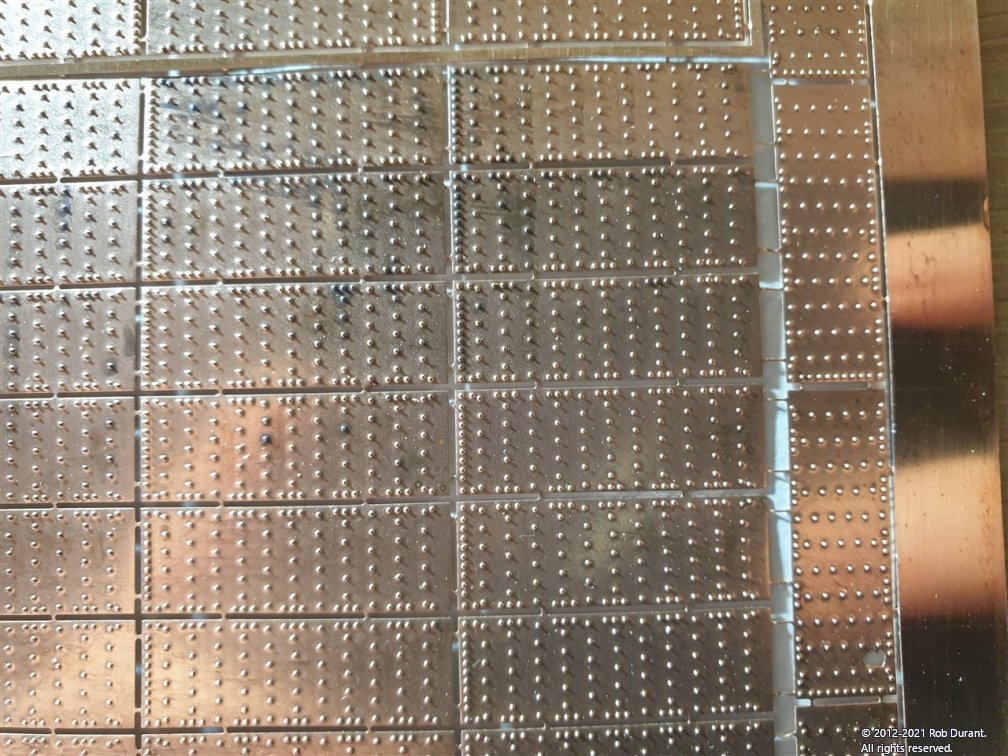

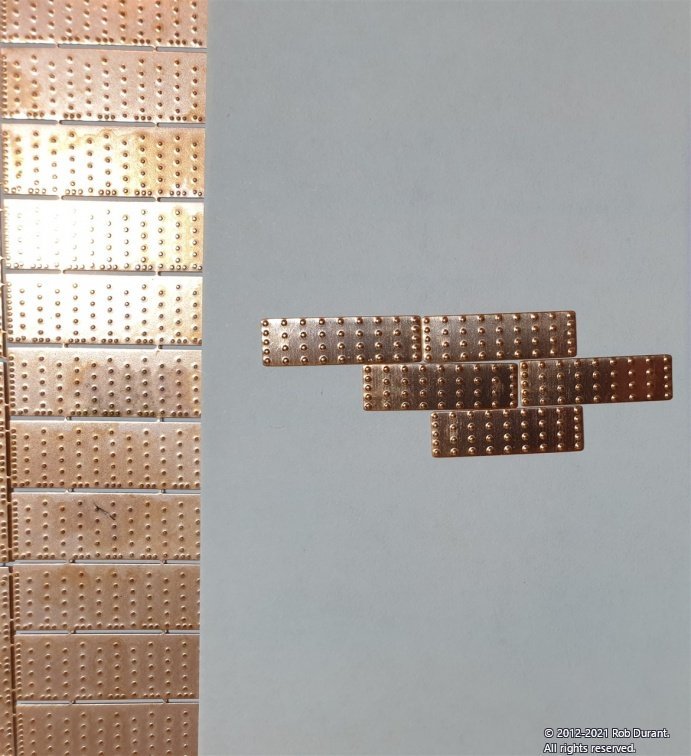

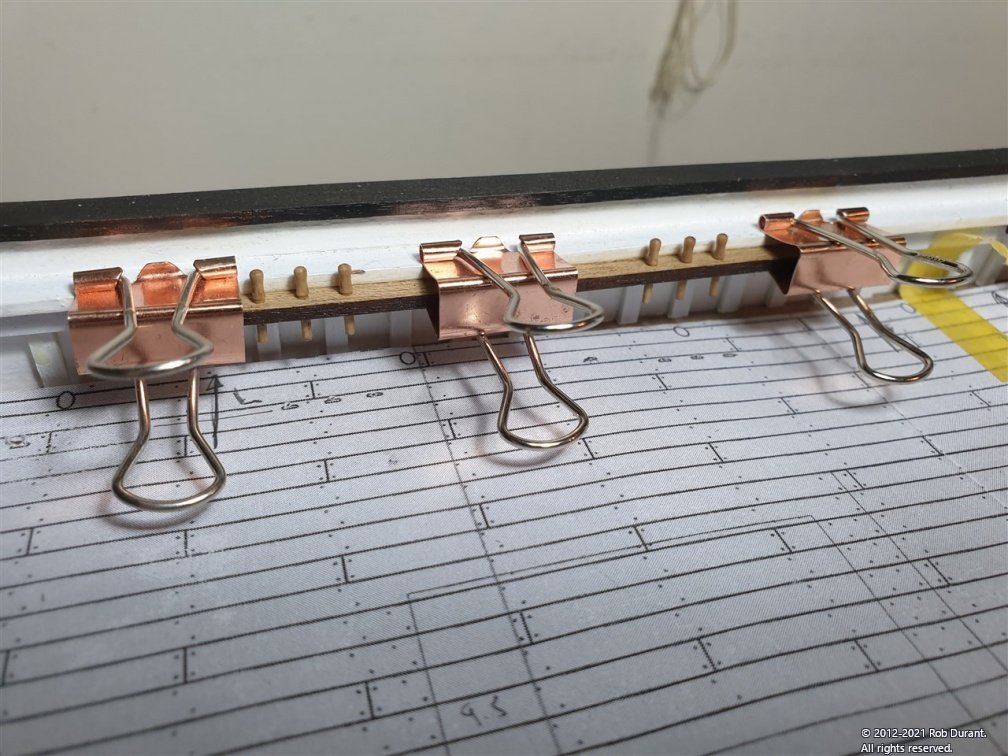

Thanks Eurus, and Jason. You ask and we deliver 😁 My digital micrometer tells me I've been tricked by an optical illusion... the plates are all the same height. Nevertheless, there are right hand, left hand, and finishing plates. Here are some close-ups of each... Right-hand... The Left-hand plates... And the finishing plates (because they overlap you need plates with rivets along the top and bottom to finish off the effect...) Finally, a comparison between these (amazing!) MarisStella copper tiles (on the left), and the Caldercraft ones I used on Ethalion (which I found fine, but are clearly not as refined as these ones). I don't have any Amati tiles to compare, but I've heard these are also very good. You can see that the rivet detail is much more pronounced on the Caldercraft tiles, and they also have rounded corners. Because they are not -handed, it's hard to overlap them, and so the rounded corners result in a tiny diamond gap where they are butted up against each other. I've also noticed, already, that the overlap makes it much more forgiving to go round curves with the MarisStella tiles. They're also a bit bigger, so they cover the area more quickly. All in all, they're an improvement. The MarisStella tiles seem to tarnish quite quickly, but I'm hoping if I'm careful with the superglue, and I give it a good clean when I'm done, over time this will result in a pleasing patina.

- 286 replies

-

Hi all, Just back from a lovely holiday, camping up in the Midlands (of the UK), but before I went I did manage to make a little start on the coppering of Stefano. She now has four bands of the starboard copper tiles. I was wondering how I'd get on with this, as they have to be cut out individually, but it was fine. I used some little sewing scissors to cut the ends and then bent a row off the rest of the fret. The scissors were then used to separate them and trim excess sprue. They overlap beautifully (being -handed), and the whole process is well described on the plans. Here's progress so far. (I put a little card in using carpenter's glue to make up the over-narrow stern and prevent a dip in the plates... it'll all be invisible, so only myself and anyone who stumbles upon this topic will ever know 😇 ) I'm quietly optimistic about how this is all going to work out. At some point I shall need to put the rows along the top, but I thought I'd put this off for a little while as I got used to the tiles themselves. It's worth nothing that the top row has rivets along the top AND bottom... also, there are specific tiles to go under the keel. Again, with rivets on both sides, and I think they're a little narrower, perhaps.

- 286 replies

-

Painstaking work but the results speak for themselves. She's looking great! Really nice progress.

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

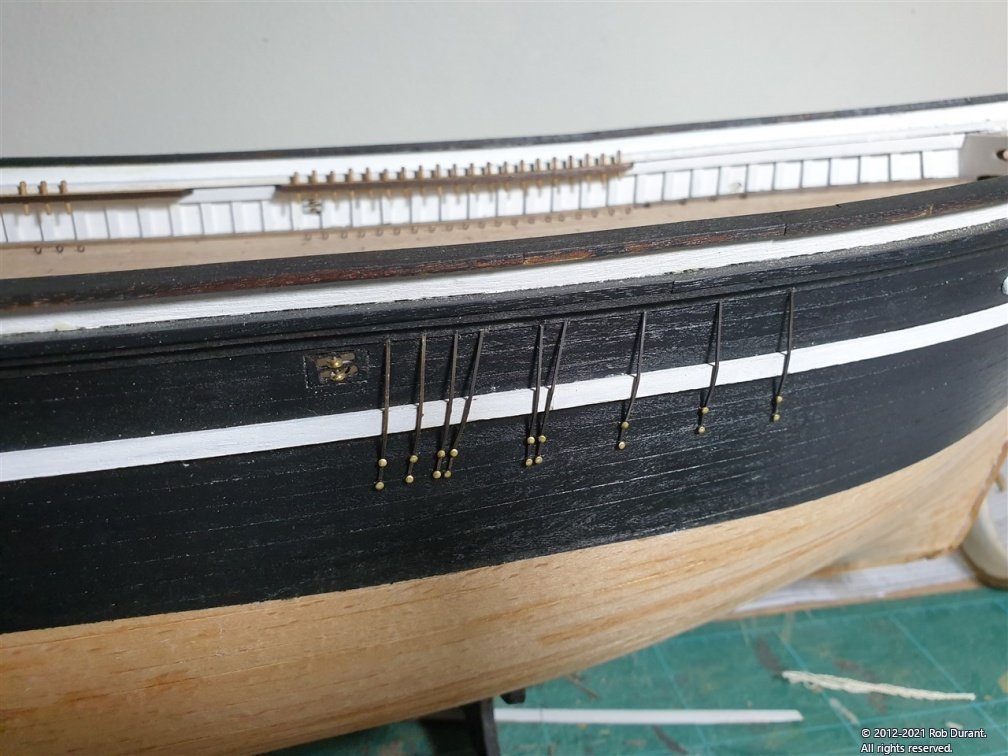

Hi George, I really appreciate the advice... I've just finished the other side, and some of these have been glued in place, as the holes were not quite so tight, but I will go over them all again and try and remove them to stick them in place. All things said, I'm really pleased with how they've come out. Here's the final sweep. (I'm also pleased that the drilling was much neater on the port side! - a little more care and attention in marking things up) I have a few eyelets to put in place, and then it's on to the coppering! I anticipate buying a large number of superglue bottles over the coming weeks! And I'll need to dig out my vapour mask again. Thanks for the likes, advice and support Always much appreciated. Rob

- 286 replies

-

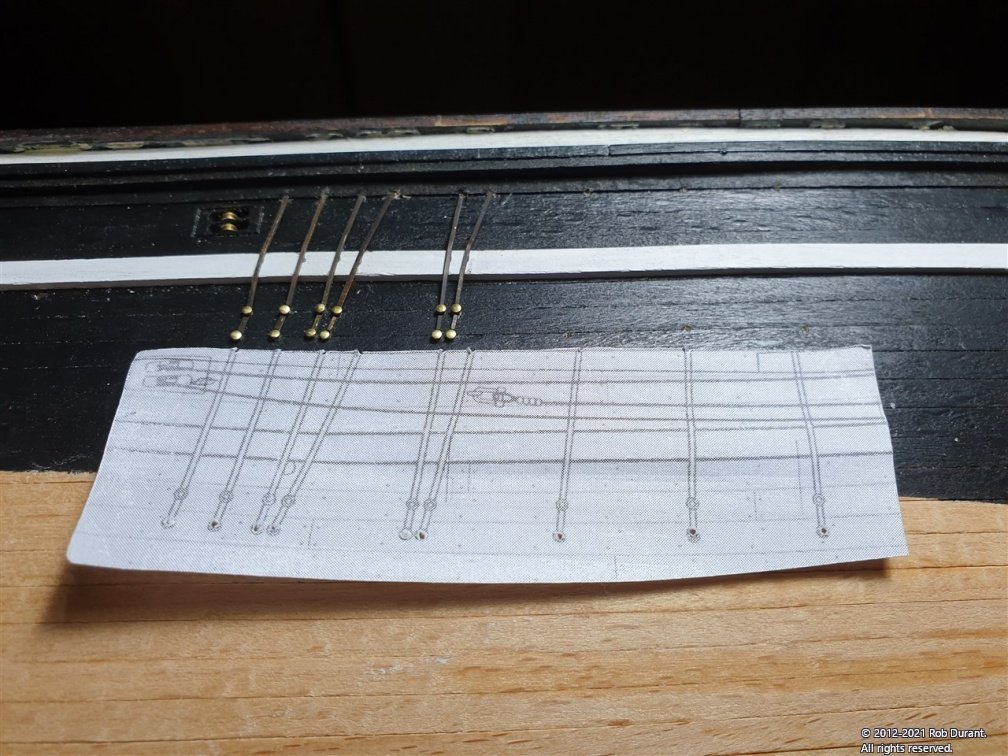

I've been working on the deadeyes. The instructions call for twisting wire to mount these to a 2mm eyelet. However, this seemed like it would leave a twisted wire at the top, or perhaps between the deadeye and the eyelet. Would this need soldering? And how would I blacken it, if so. In sum, I wasn't quite sure how to neatly attach blackened wire to the deadeye, and at the same time be confident that it wouldn't come undone at an inopportune moment as I was rigging stays, or similar. So, I decided to forego the eyelets in the rail and directly mount the deadeyes using the cutoffs of the chainplates (as these were plenty long enough for the purpose). This way, the metal would look identical to the chain plates mounted to the side of the hull. Here's my progress so far. They are (tight) push fit into a 1mm hole, but remarkably solid. If any so much as wriggle I shall glue them in place with superglue, but I have exerted a fair amount of force and they don't shift so far.

- 286 replies

-

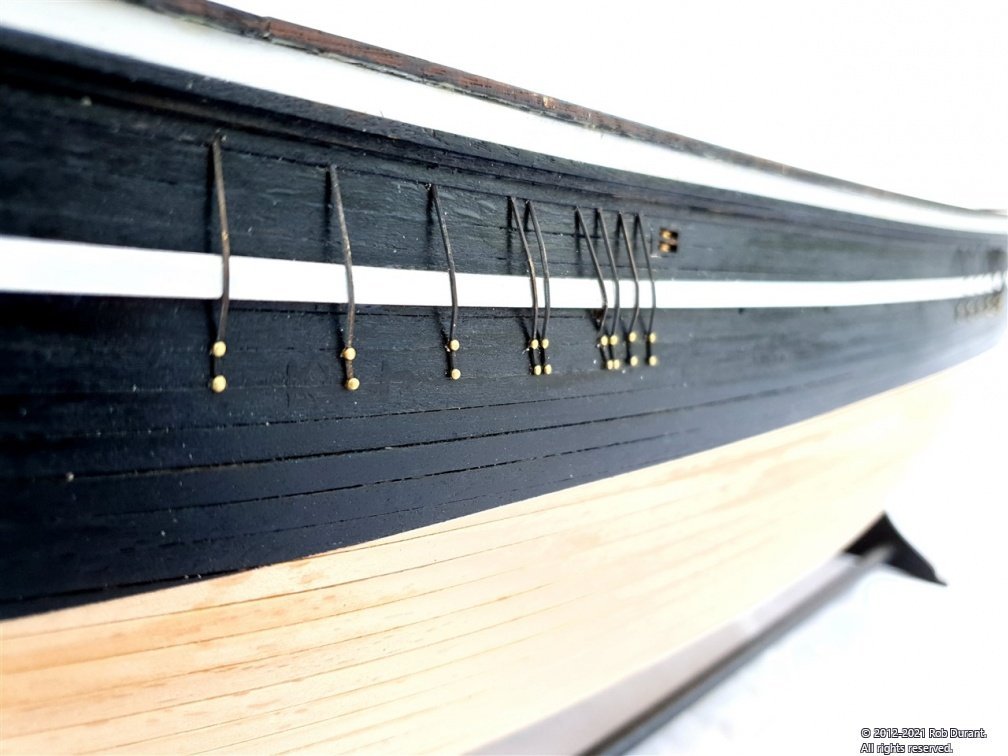

I've finished the simulated chain plates, so I thought a few progress shots were due. I ended up with one chainplate photo-etch part left, so do be careful with these parts (especially that you don't cut them too short, which would be easy to do if you forget to take into account the angle in towards the hull from the wale) There's a little painting to do at the stern to touch up where I've sanded down the detailing to make it flush with the wales, but otherwise Stefano's looking quite smart. Next step, attaching the deadeyes to the main rails to complete the illusion that the chain plates pass through the hull. Rob

- 286 replies

-

Divers Discover 2nd Century Military Ship off Egypt

robdurant replied to Ian_Grant's topic in Nautical/Naval History

Really fascinating - not least that the underwater city they're investigating was only discovered because the underwater archaeologists were looking for remnants of the Battle of Aboukir Bay. Thanks for sharing! Rob -

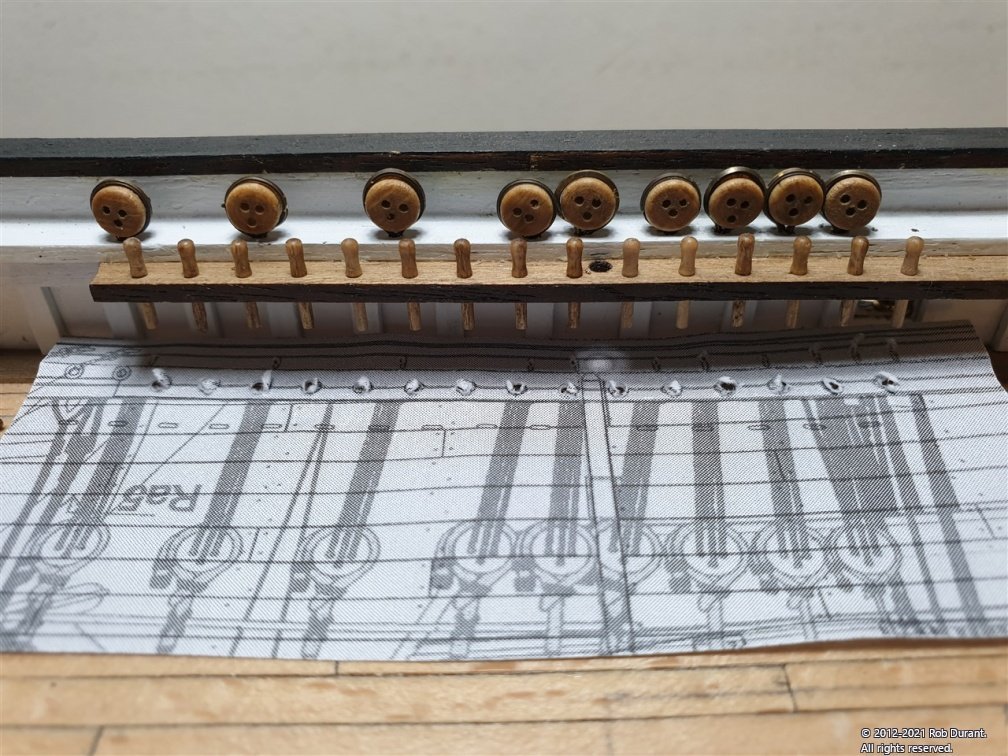

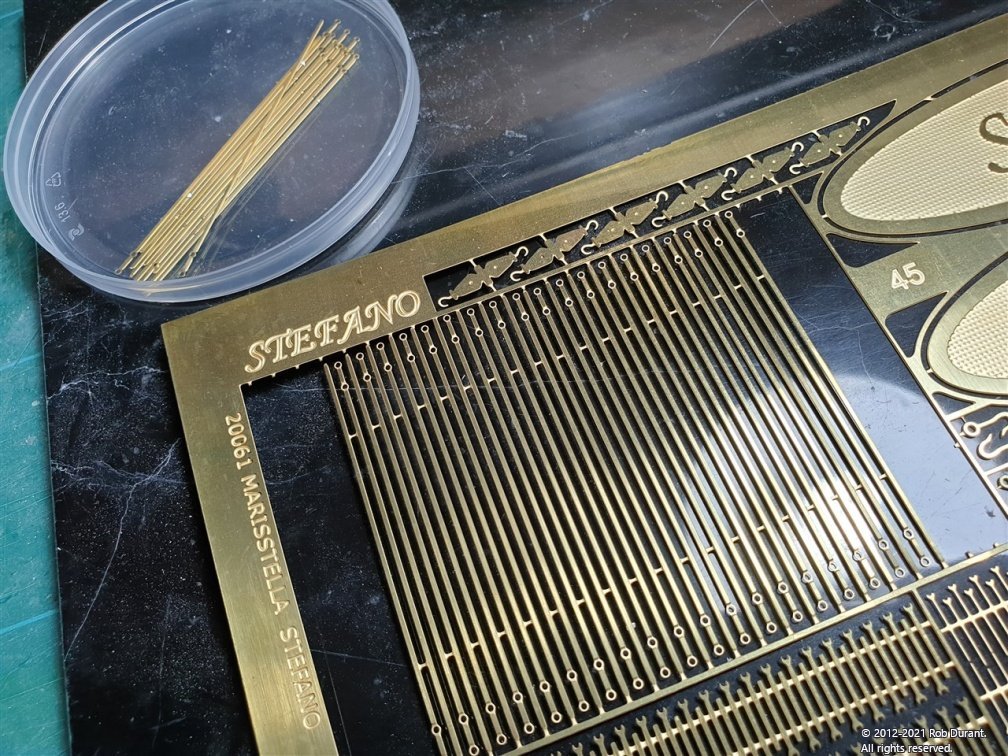

Hi all, A small update. I've added the eyelets on the deck, drilling the holes using the template I made for the deck. This kind of worked, although in retrospect I would have gone back and neatened up the marks a little before I actually drilled them. I've also completed the (faux) chain plates on the starboard side. These are attached like chain plates, but actually stop where they enter the underside of the rail. The deadeyes themselves will be glued into the rail on the top side. Careful comparison of the top down and side elevations were necessary to ensure these match up, and will look right compared to the mast position / pin rails, etc... This was done by overlaying the two elevations on the computer and printing out the resulting overlay to cut out and place on the model. The chainplates themselves are photoetch, and look very flimsy, but I was surprised by how sturdy they actually proved to be. They were blackened before fitting with brass pins (a 0.8mm hole was drilled to accommodate the lower pin for fitting, and then once fitted the position of the upper hole was marked and drilled. This ensured the two holes lined up as hoped. Small sewing snips proved to be the best tool for removing the chain plates from the photo-etch sheet. You'll notice that the remained of the belaying pins also arrived from Cornwall Model Boats, so those have been put into position. It blows my mind that I'd pre-drilled the holes for these wooden components before they arrived (to 0.6mm), and they were a gentle push fit when they arrived... every single one of them! I wish I could work with that kind of precision and consistency! Happy building, all! Rob

- 286 replies

-

Very nice Looks like you're making great progress! I made my own window frames too. Plenty of work, but I'm really glad I did. It is a real feature of the vessel. As far as the gratings go, I made up all of mine in one go, and only once they were done did I notice that the gratings on the quarter deck and fore deck have much narrower coamings than those on the gun deck. I didn't want to remake them all, and wasn't confident I could do a good job of cutting them down, so they're all a bit overscale on my quarter deck which makes things a little crowded. Oh well... next time!

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

As a note, do be careful with these, as they're very easy to put on too high or too low. Photocopying the plans and sticking them to the side of the hull will help you here. Also, if in doubt, make card templates of the ply parts and try it out as a mockup (they're easier to bend and manipulate before you bend the parts!). It took me a good while to be satisfied it would all fit together, and I ended up pinning parts so I knew when I glued them they'd go where I'd intended them to go. The line where the top of the stern lights finishes will determine the intersection between the bulwark rail and the capping rail over the transom. And it will also determine how the lights look as they transition between the quarter galleries and the stern... which for me is a line that the eye picks up on (one of those "you'll never notice it if it's right" things?) and makes a big difference. Anyway - I wish you all the best as you set out into perhaps the most challenging, but also the most rewarding section of the build!

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

What a fantastic coppering job! The transition between the stem and the bow is particularly neat. Looking at those photos I realise just how much the copper has toned down on mine already... a much more mellow shine. Without the comparison I hadn't really noticed it happening. The black line at the top of the copper really works well. Whenever people visit my house they're always slightly shocked that we glue these tiles on one by one... I guess you have to love the hobby to understand why we would. But it sure feels good to glue on the last one! Looking forward to the next update. Rob

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Hi Jason, It is refreshing - no gun ports, no gun carriages, no breeching ropes or gun tackle... No elevation quoins... And no worries about catching the barrel and sending it into the hull out of reach, either! I decided to glue it in, and with the 90degree angle between the strake and the underside of the rail it seems pretty solid. Given how narrow they are, I don't think the force on them should cause too much trouble. It'll be pulling them into the rail above. I'm in awe of the guys who could find the right belaying pin in a gale in the middle of the night with the deck pitching and waves washing over them. Especially when you realise these great machines were being operated by a handful of skilled crew! Brave stuff. If my model were going to go through that, I'd definitely want the rails pinned! Rob

- 286 replies

-

Great work Jason. I'm sure you'll be really pleased you tapered the planks. My approach was a little less precise but still it makes a nice contrast to the straight planking runs on the gun deck. As a thought you may want to put some of the planks down then reassess the widths to make fine adjustments in case laying the planks introduced some drift? But your planking is so precise I'm sure you'll be fine. My digital calipers are the tool I never put away on my build desk. Especially useful when you need to work put which drill bit you need (and what order they go back in the box when you accidentally drop them!). Looking forward to seeing this deck come together. Rob

-

Thanks Bob. Yes it's a great kit, and a bit out of the ordinary which was part of the appeal

- 286 replies

-

Thanks for the likes. Okay - I took the plunge. The holes for the belaying pins turned out to be a little tight, so i redrilled them out to 1.3mm, and then glued the pin rails onto the strake and the underside of the rail. Now I'll leave it overnight and we'll see just how strongly the carpenter's glue has stuck the rails on. The contact area for the glue is pretty big compared to the pieces themselves, so I'm reasonably confident they'll be okay. If this has worked, then next up will be the eyelets on the rails, deadeyes (which also mount on the rails, and the chainplates.

- 286 replies

-

A little update. I realised that once I stuck the pin rails (parts 43) in place, I would restrict access to the deck to put in all the eyelets. So I printed out a scan of the deck plan on plan 3, stuck the parts together, and used it as a template for the holes. The plan was located using the mast holes to ensure the eyelets holes went in the right place. Some 100 holes later, I began gluing in the eyelets (which are blackened rather than painted) with superglue. This was time-consuming, but after a good few hours, it's done. There are eyelets included in the kit, but I used some which I already had blackened, and left over from a previous Caldercraft kit. They needed 0.60mm hole. I'm going to replace the belaying pins that are provided with caldercraft ones. Namely, the 9x1.5mm ones, which are longer and thinner, and to my eye somewhat more to scale - I swapped out the HMS Diana ones for these, and was glad I did. These 9x1.5mm pins need a 1.2mm [edit: actually, I opened this up to 1.3mm later] hole, so the pin rails have been drilled out in readiness. In the instructions this is done after the pin rails are glued in place, but I didn't trust myself not to scuff the deck. Now, I'm just wondering whether to strengthen the bond between the pin rails and the bulwark? I'm just not confident I won't knock it and end with a massive tangle of rigging and no way to get it back in place. I might try and put some pins in to help adhesion. Hmm... have to think about it. Hopefully I'll be able to get some more done today.

- 286 replies

-

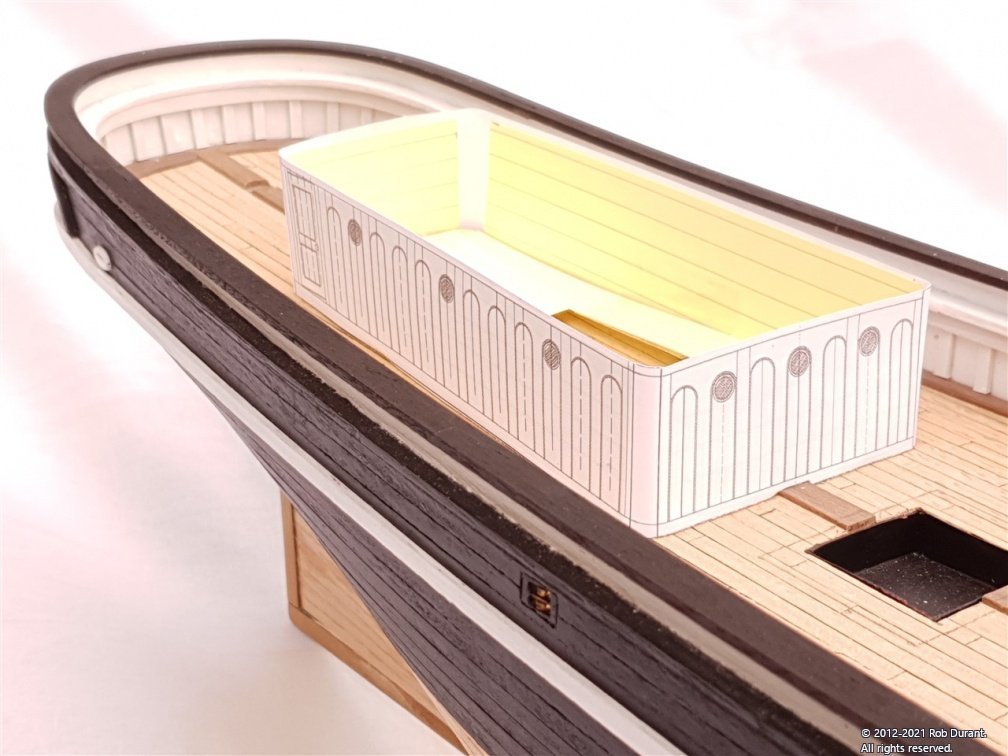

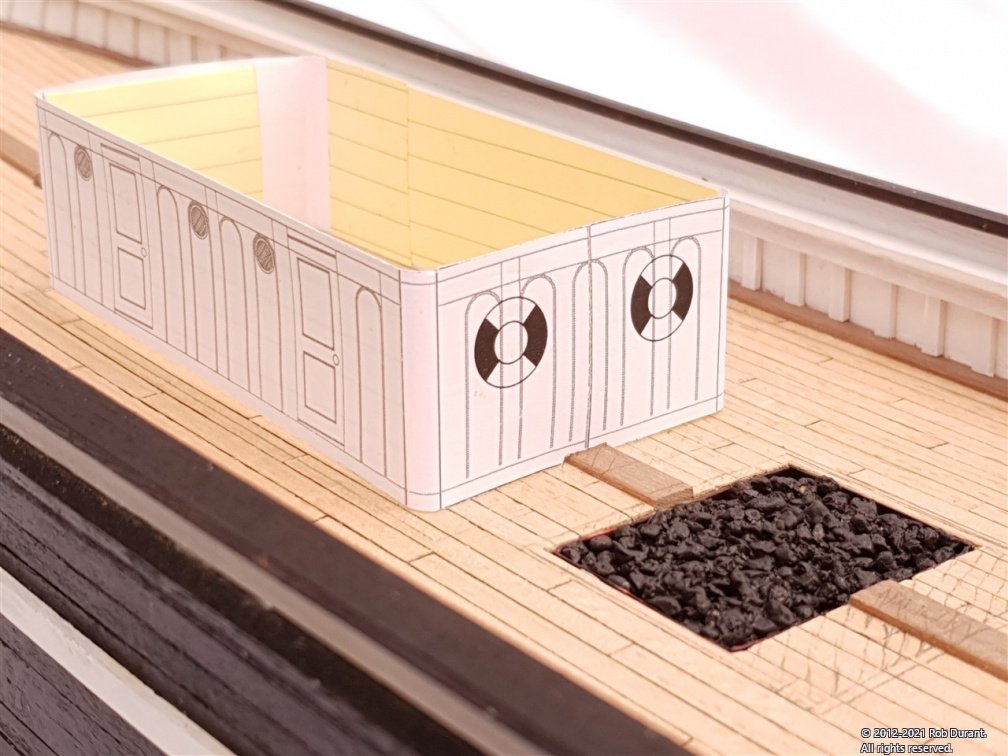

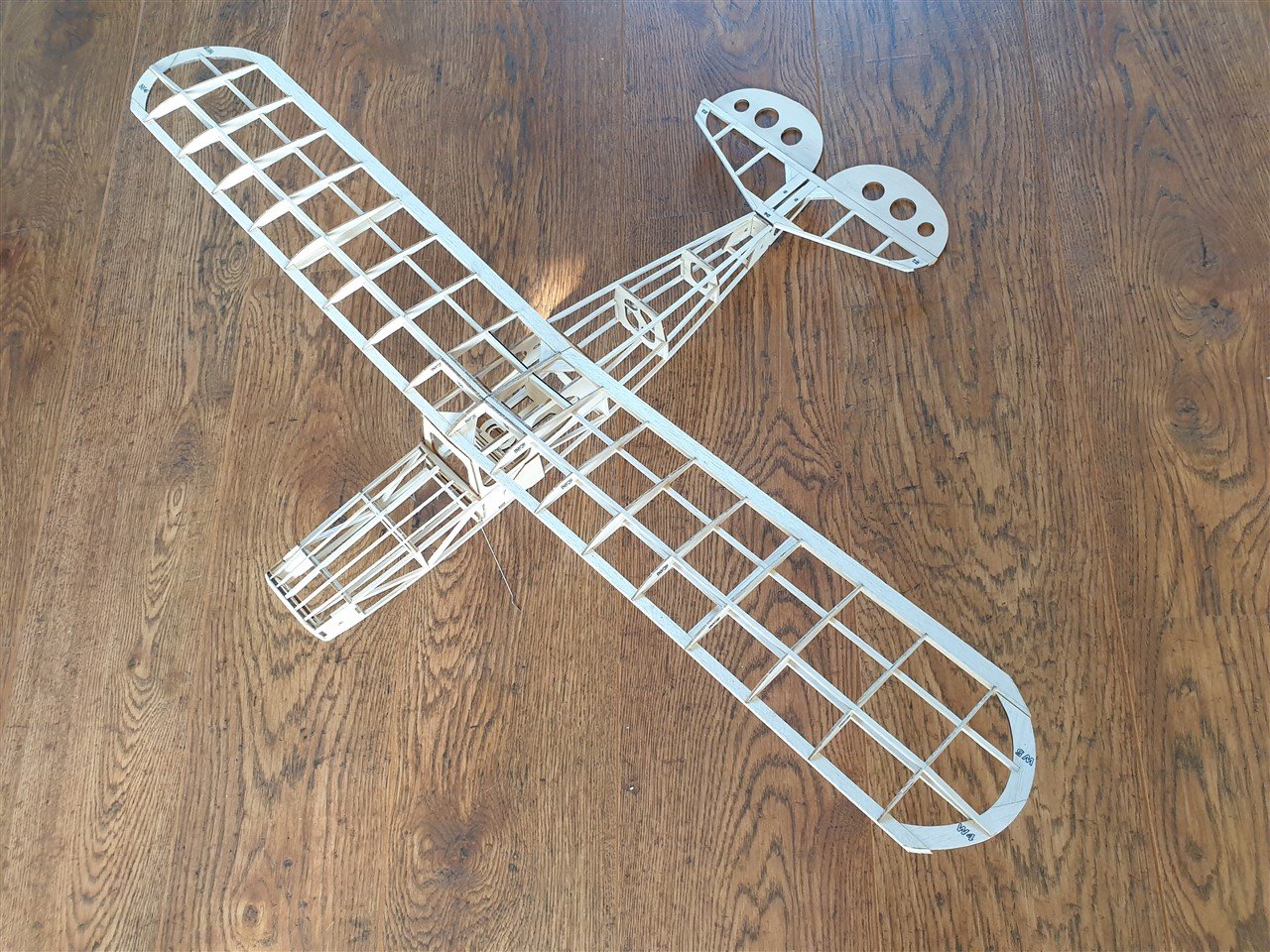

Okay. The plane is all skinned and radio-controlled and ready to go. I'm just waiting for the battery charger So... time to go back to the bigger project. I've ummed and aahed and wondered how to best go about the topgallant bulwarks, and eventually I just had to bite the bullet and get on with it. And it turned out to be not so bad. I used styrene square section as shims on either side, and pre-bent the parts using my rib-bending iron. They were glued in place with carpenter's glue (Alphatic resin), and left overnight to set really solid. Once in place I painted the inside of the rail white, and tidied up a bit before the topgallant bulwark rail was stuck on. This is made up of laser-cut parts from the 2mm walnut, and as with the main rail, it was the perfect size and shape. So that was a relief. I glued it all together using masking tape to hold the parts together while they stuck, on the desk, and then glued the whole thing in place in one go. This allowed me to get a nice sweeping curve from front to back. Then I gave myself a big pat on the back, and THEN I realised it was glued too far inboard. So I've just unglued the sides, and restuck them further outboard, so the top rail ends at the same point as the main rail, as per the plans. The thing that made me see my mistake was looking at the plans and seeing that the deadeyes are going to go on the main rail, and if the top gallant rail is too far inboard it leaves no room for them. I suspect they're going to be somewhat challenging to rig anyway, so I'm leaving myself as much room as possible to ease the process. It's only a matter of 2 - 3mm but something tells me I would have been rueing the day I chose not to bother moving it. Anyway - here's a photo I took before I realised the rail was too far inboard. Also in some of these photos are the mockups for the photo-etch cabins I want to put onto this model. Currently they're a bit heath-robinson, but they prove the concept, I think. Happy building

- 286 replies

-

Okay - so updates here have been a little less frequent, as I got distracted helping my son get stuck into warhammer and with those flying things - a refreshing change for a little, and a work in progress... I'll be back onto Stefano soon

- 286 replies

-

That's a very neat looking repair that looks like a great foundation for the copper tiling. Unicorn's a fascinating vessel... I hadn't realised the roof was so old... I hope, Dunnock, you won't mind me linking to this article recently put on the BBC news website that gives a little more information from the team involved in her care... https://www.bbc.co.uk/news/uk-scotland-tayside-central-56818539 If anyone has some nice oak they don't need, they'd be interested Hopefully they'll manage to get her into a dry dock sooner rather than later. Rob

- 310 replies

-

- Diana

- Caldercraft

-

(and 1 more)

Tagged with:

-

Hi Rob (@rwiederrich), Not too late at all... I discovered this wood filler, which I find a massive improvement over normal DIY filler. It's much more sturdy once it dries, almost odourless, doesn't seem to shrink at all, and easy to sand to a nice finish. It's also available in much larger quantities than most hobby fillers, so it's much more cost effective for smoothing a whole hull. This (fairly small) pot was more than enough for the whole hull (and a few diy jobs around the house, too!)... I'd recommend it over the tube of the same product, which I found dried out very quickly, and got to the point where I couldn't get any more out of the tube. Hope that's helpful.

- 286 replies

-

Meanwhile, in another thread.... (no personal connection... just happened to be reading both.)

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.