-

Posts

1,729 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

It looks like you used laser etched moulding to cap your columns? Looks wonderful, what a great idea!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS VICTORY 1765 by albert - 1/48

scrubbyj427 replied to albert's topic in - Build logs for subjects built 1751 - 1800

Beautiful work! -

I’m also onboard with the 1/4 scale, with the Winnie being my first 1/4 scale I’ve been converted. Will probably never go smaller than that ever again. A big 1/2” scale frigate or something along those lines sure looks tempting sometimes though. But Winnie has proved beyond a doubt that an amazing model can be produced at 1/4.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great Rusty! That’s such a rewarding part of the chapter to complete and complete well. I still just love how your Winnie looks with your choices of wood!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This will make a great post Winnie subject! Looking forward to seeing this develop further!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Well I’m sure whatever project comes out next whether it’s Hornet or the sloop, it will build into another wonderful model.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I can’t decide if I want to do Amazon or Minerva next as I’ve fallen in love with both of them through the course of the Winnie project, it’s like they all belong together now.😂

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Ok thanks, that’s kinda what I was thinking but I don’t have my drawings nearby for reference. Looking good!

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Excellent work Mike...as always! Is it me or is there a small section of your moulding missing along the waist? JJ

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Amazing work as usual. Not much more to go it looks.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking really nice rusty!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

MONTAÑES by Amalio

scrubbyj427 replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

Amazing work! Just wonderful to look at! -

Magnificent! What an achievement!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Steve, I used medium zap on all my planks, it made the job a million times easier, I also used PVA on all the edges, which was messy but worked great. When I finished the planking I mixed some epoxy and coated the inside of the hull to prevent any planks from coming loose and expansion/contraction. JJ

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Chuck! This just keeps getting better

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

scrubbyj427 replied to cafmodel's topic in Wood ship model kits

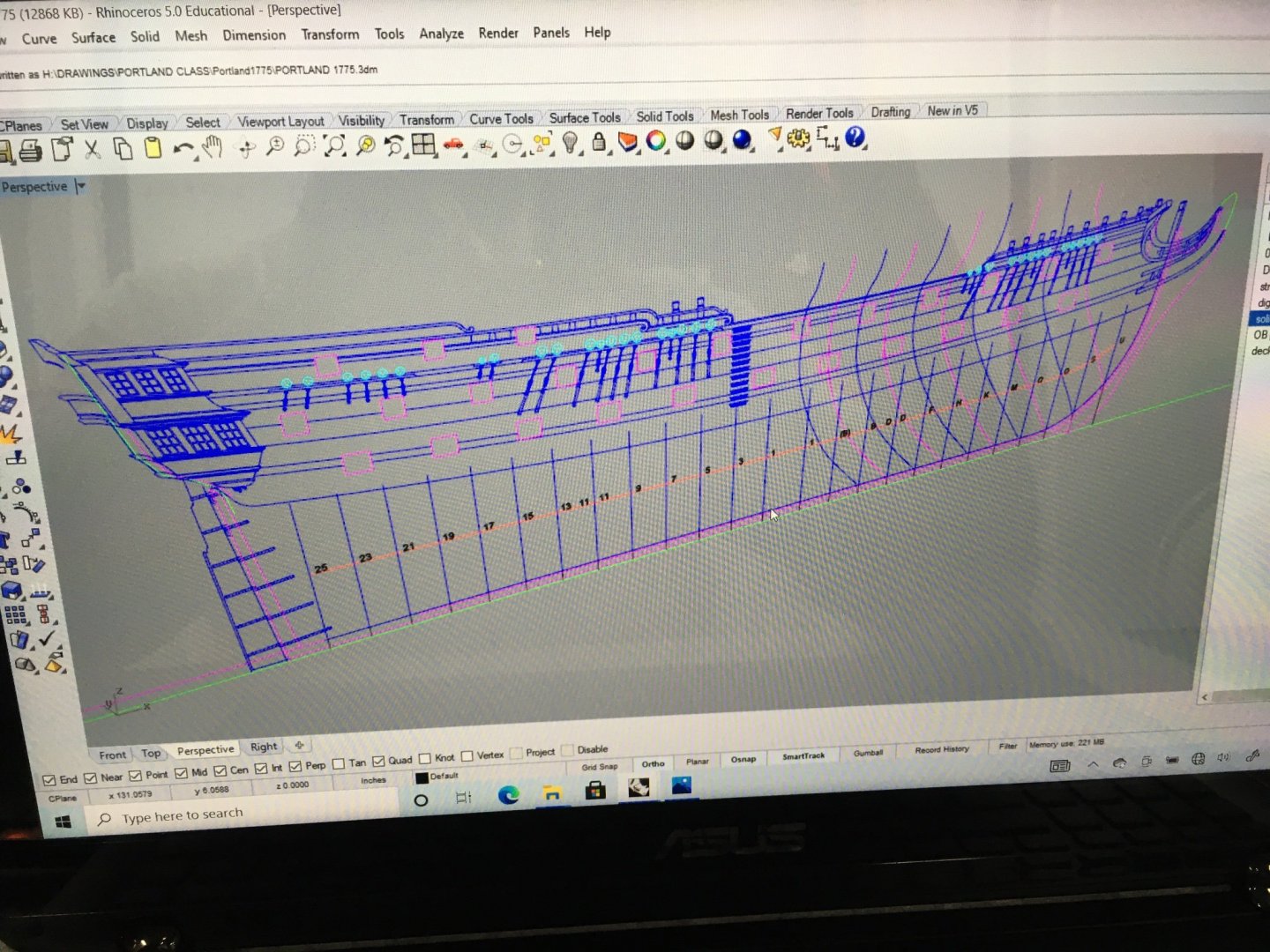

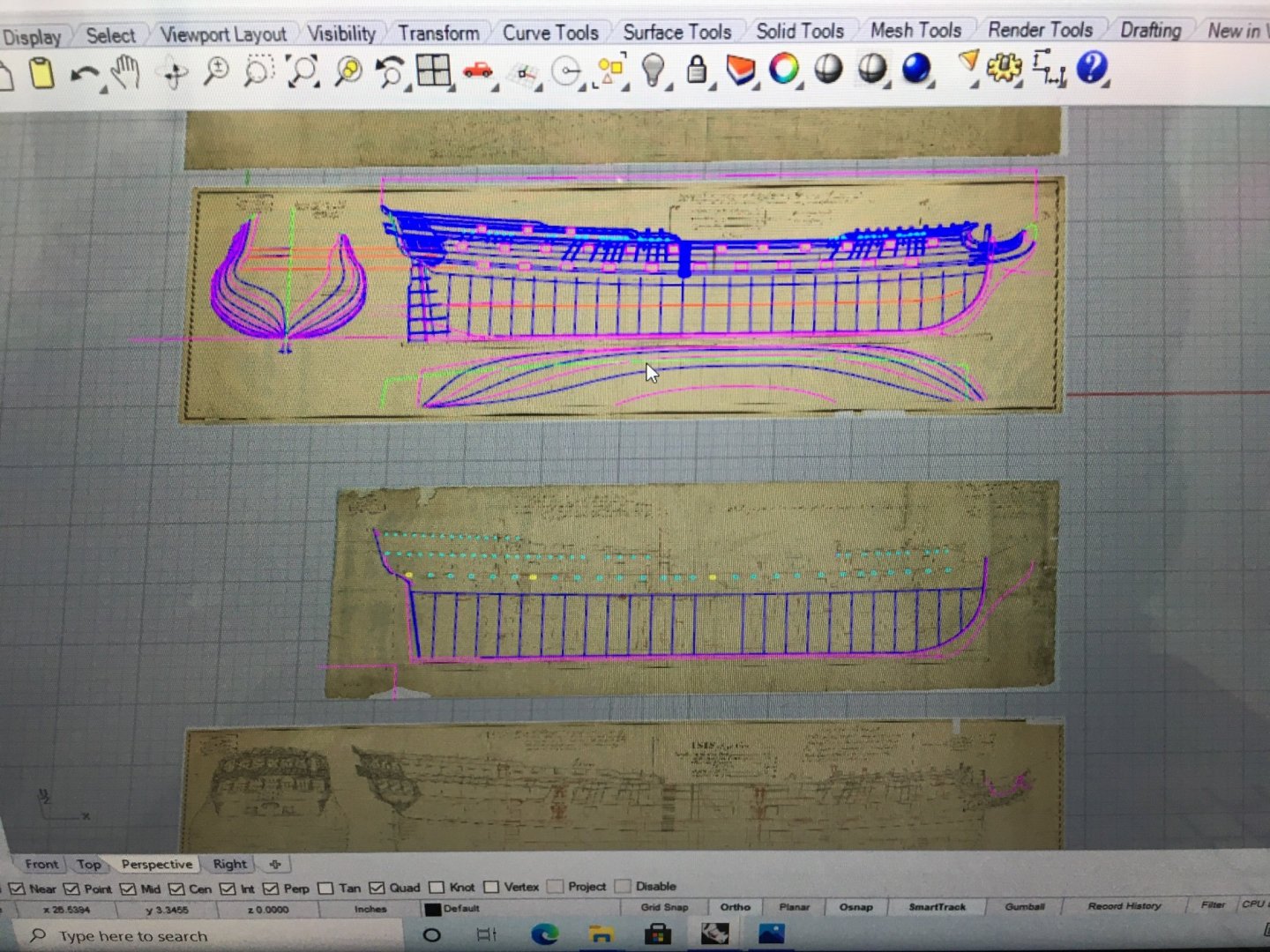

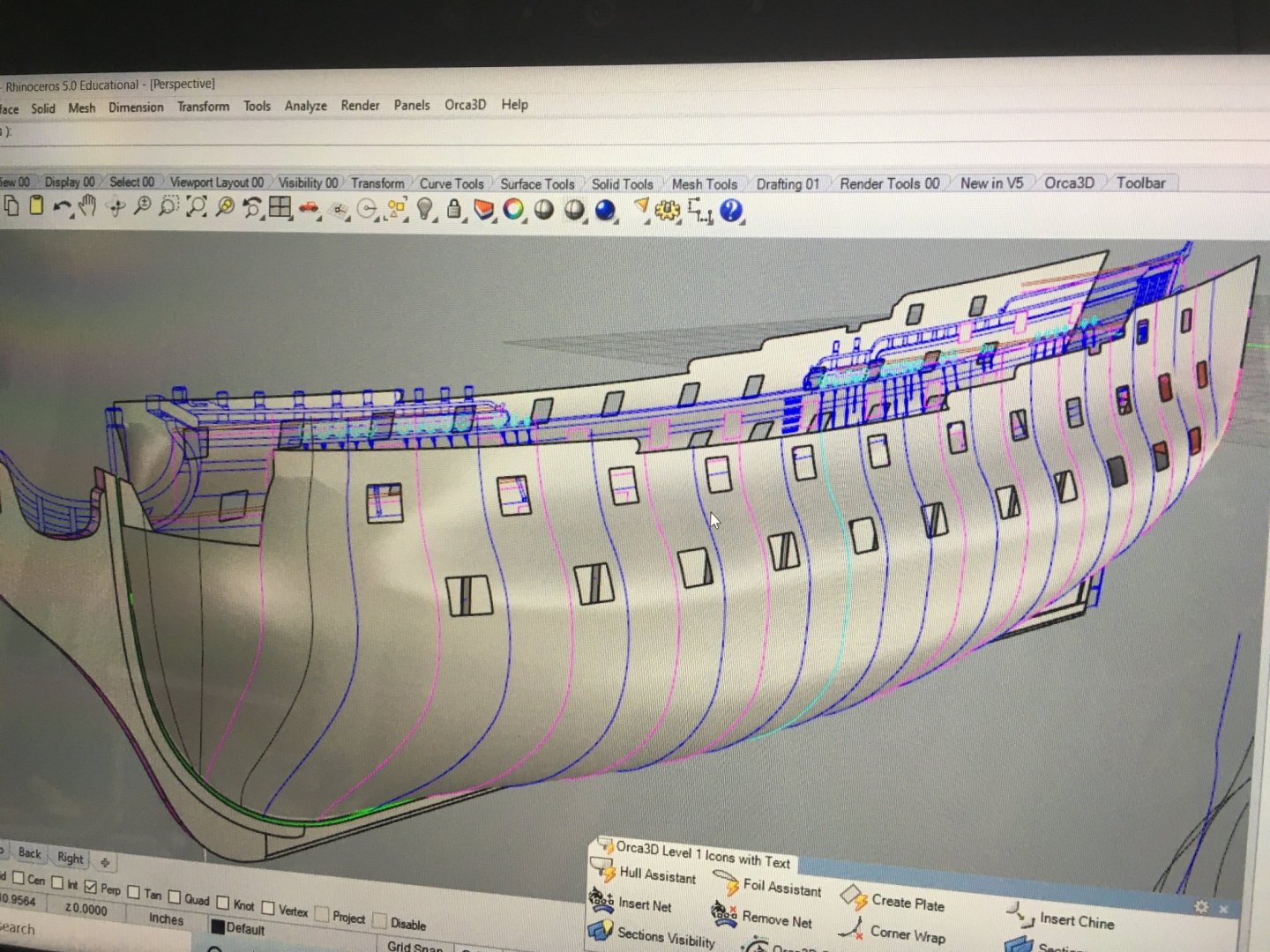

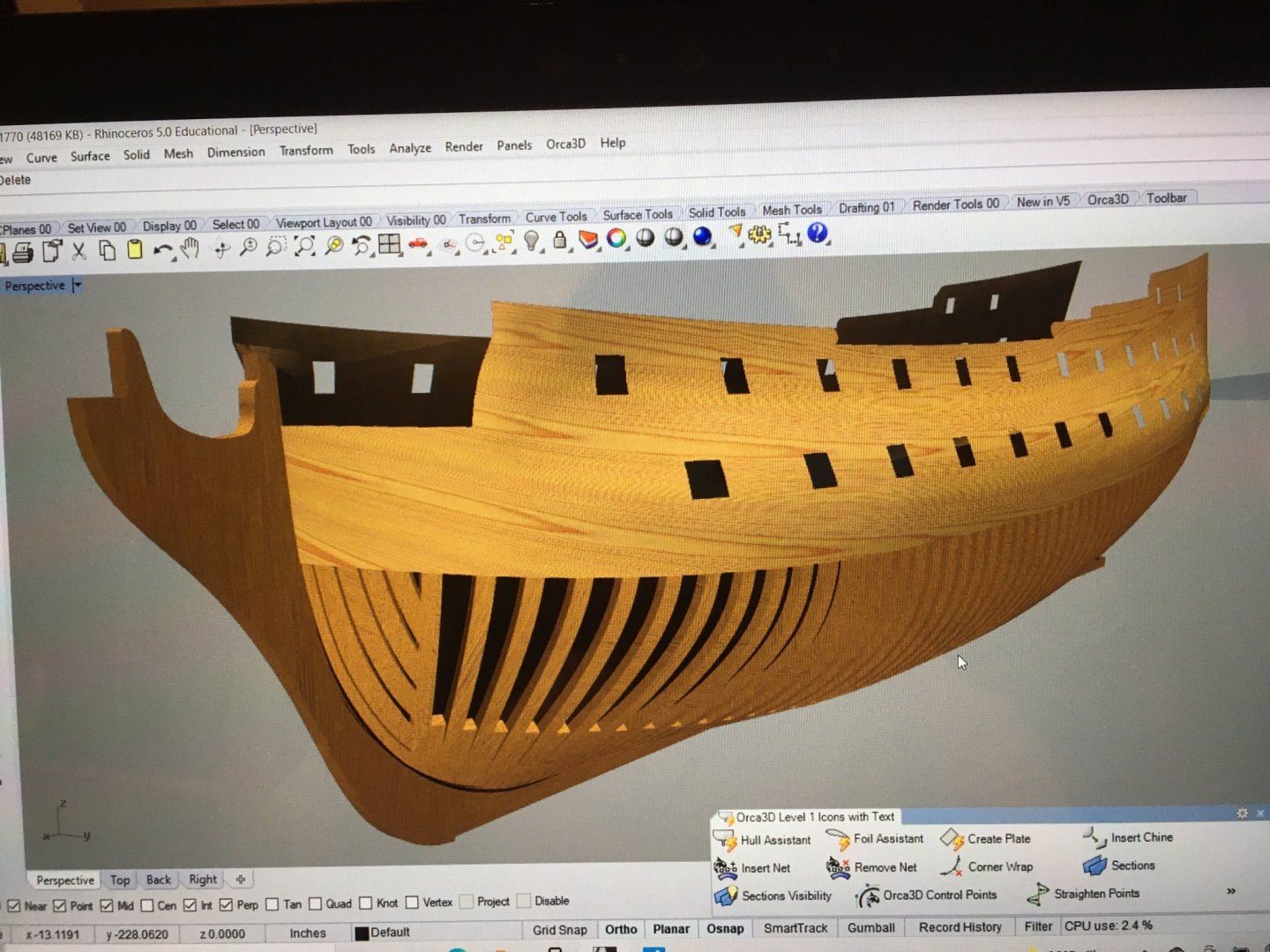

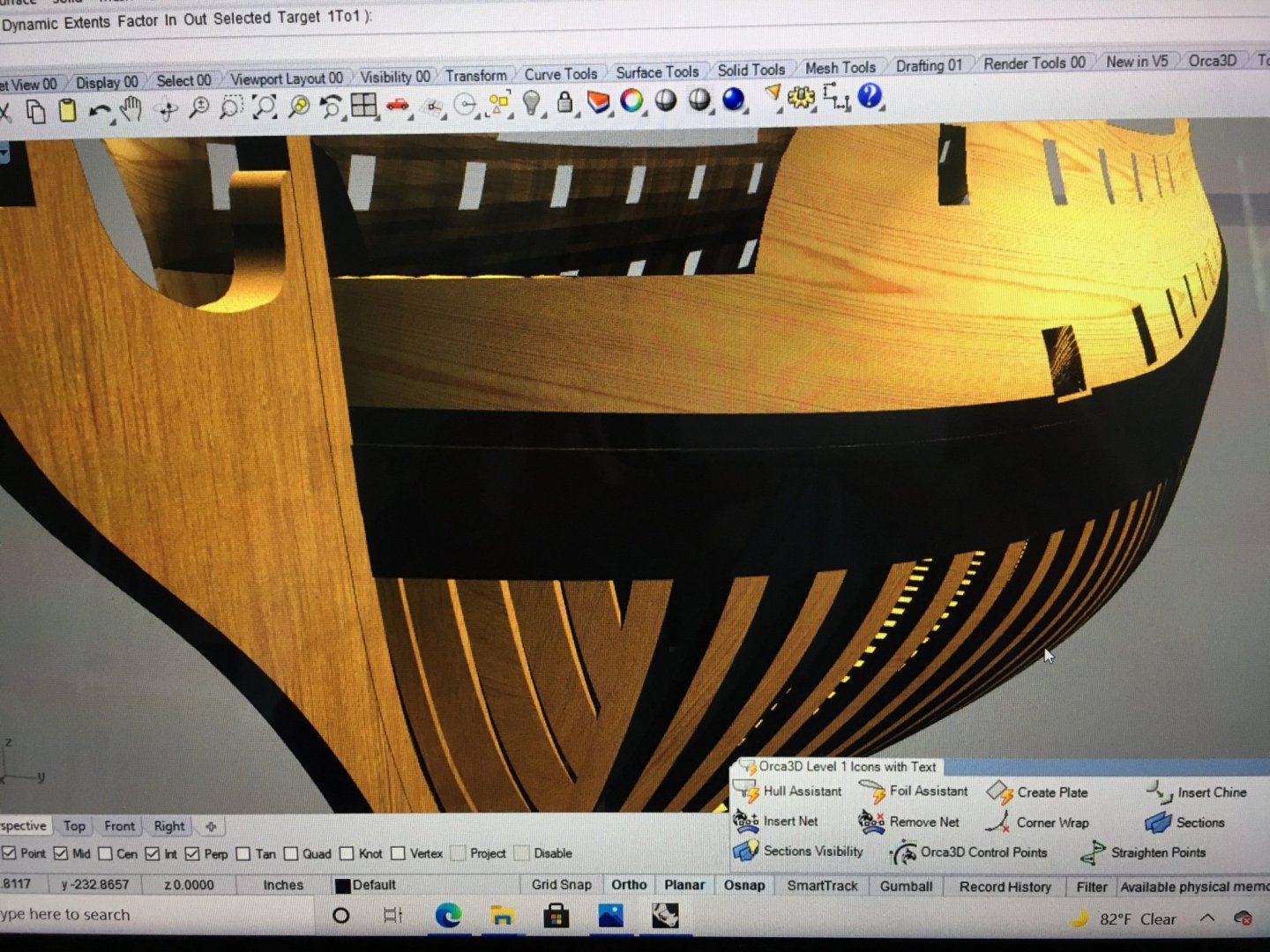

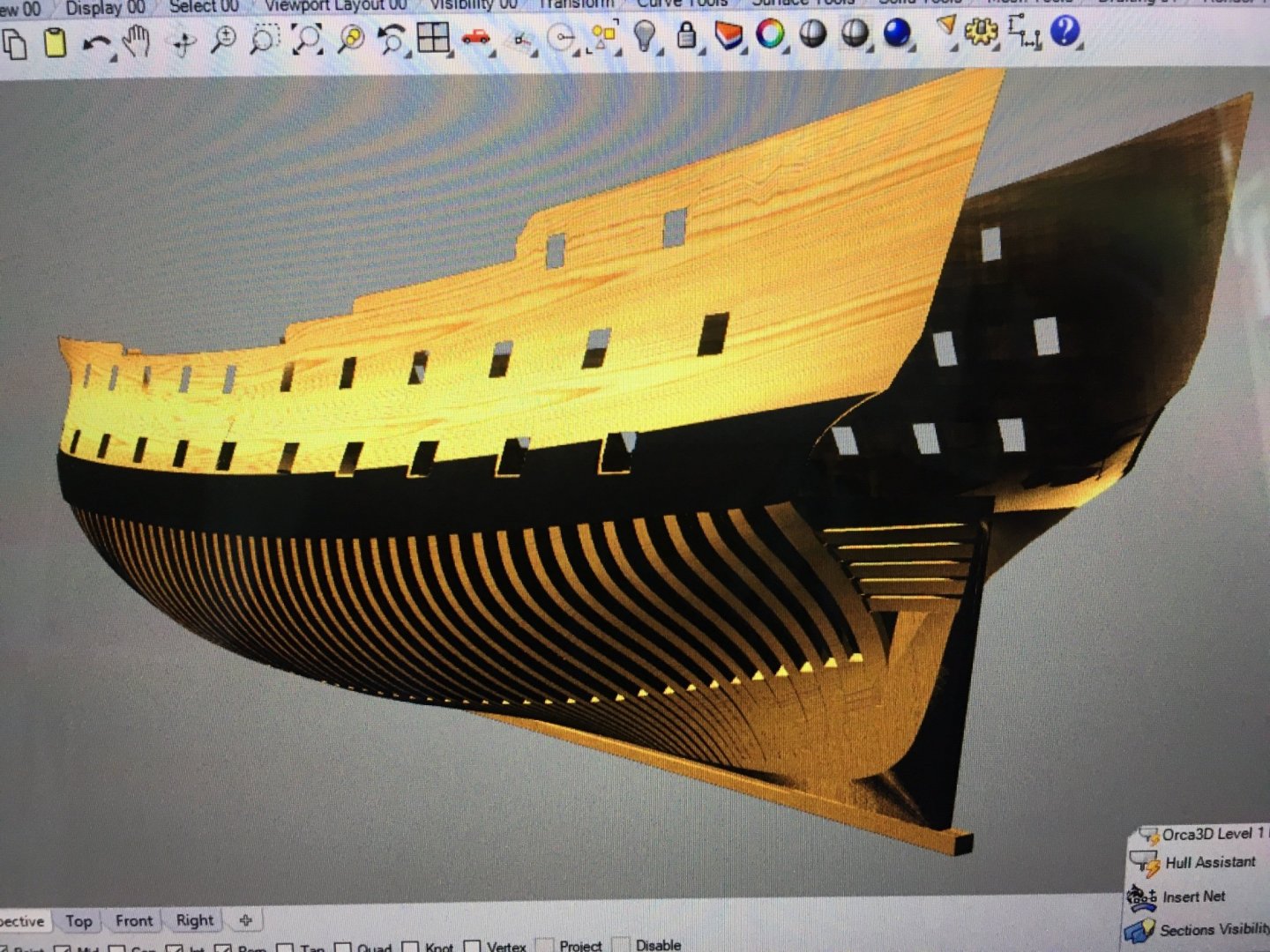

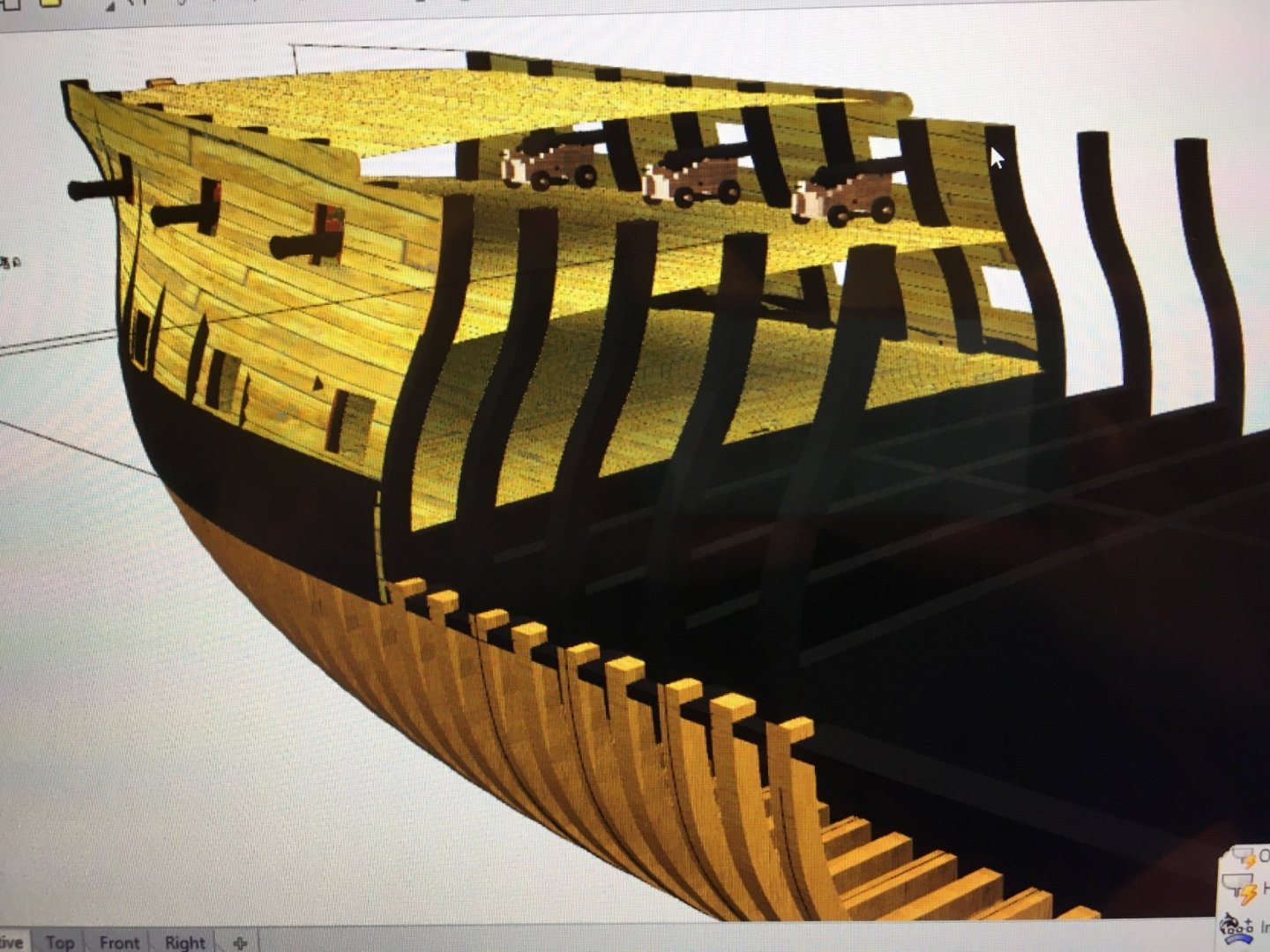

I'm not sure which is more impressive, your rhino model or your real one.... very nice!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.