-

Posts

1,673 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

Kits sure have come a long way from when I started building. This is amazing design work.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Thank you for the likes and comments fellas! So the process for painting the black squares was very simple. All I did was, first I sealed up the checker floor with a generous amount of WOP and let it dry over night. The next day I began painting the darker squares in with black acrylic paint with little regard for staying in the lines as the acrylic won’t stick to the WOP very well. Once dry I lightly sanded the whole floor and since the lighter squares are higher up than the darker ones it cleaned up nice. You can see a small spot on the port side where I didn’t seal the wood well enough and some of the black bled through, so make sure your WOP gets everywhere before you paint! Then after you clean it up just WOP the whole thing again to seal up the bare wood as well as lock in the black paint. JJ

-

Small update: I got the checkered floor glued down tonight, I wanted to go with a black pattern but keep it a little more subtle so I kept the light squares just plain AYC with WOP. , I am almost finished with the margin planks, a little bit of clean up some sanding and then off to the hatch coamings! JJ

-

Ok that makes sense. These will be exciting to put in!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Would the real Winnie have had the knees in the cabin?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

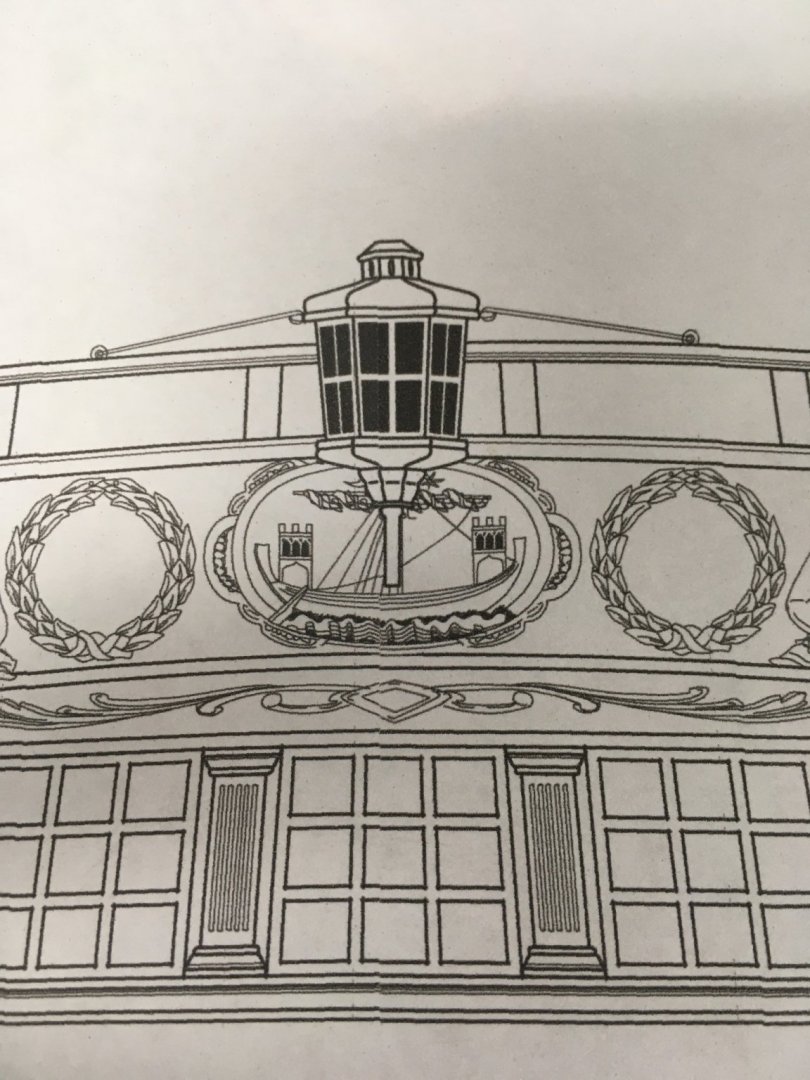

Chuck, I’m looking at the drawing in the profile and stern view for the stern lantern and I’m trying to determine exactly how the lantern post will attach, it appears it will land right on the middle of the carving. I am just trying to run my small light before I close up the inner counter. Are you planning on drilling a small hole into the carving to attach the post? JJ

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

These columns will be fun to make, are you going to take a similar approach to What was done with the bollard timbers?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Oh this will be exciting! Will we be installing Turned columns to support the beams?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking great Chuck! Are you going to add all the tackle to the guns or leave them bare? JJ

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks really good Mike! thanks for the tape tip, I will definitely be using that. JJ

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks good Fred, moving right along. I couldn’t even tell your panels were painted by the shade of light on them, I was going to ask if you carved your own. I’m still on the fence with painting mine... did you consider some weathering powder in the groves to help define the panels more? This is what I was thinking about doing. They look very nice. I cant give advice on the rudder box or benches, I’d see if you can find any photos of the real thing. JJ

-

Thanks Rusty and Diver for the comments. Diver, to answer your question, yes I am building in an engine room. Winchelsea will be my 4th boat built... on a boat and she comes in second For overall nautical miles under her keel! I started Adding the panels to the stbd side tonight, making sure they are as close to the port as possible. A little trick I used to insure that the panels are square and lined up perfectly to the ports, I used a flat piece of wood that sits parallel to the gunport frame, glued it to the deck and wedged it in the frame, from there I can keep test fitting the panel until it fits perfectly between the two ports. When It comes time to glue it in place I can just put it up against the port with the wooden block and set the elevation and it will fit just as it’s supposed to without worrying about it moving side to side. I also used this on all the spirketting between the gunports as well. Hope Someone finds this is helpful. JJ

-

Wow! I wasn’t so sure of those resin cannons at first but that looks very convincing. Will these and the carriages all be available in the Winnie section of the store?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Have you ever had issues with any rust appearing with steel wire?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.