-

Posts

1,673 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

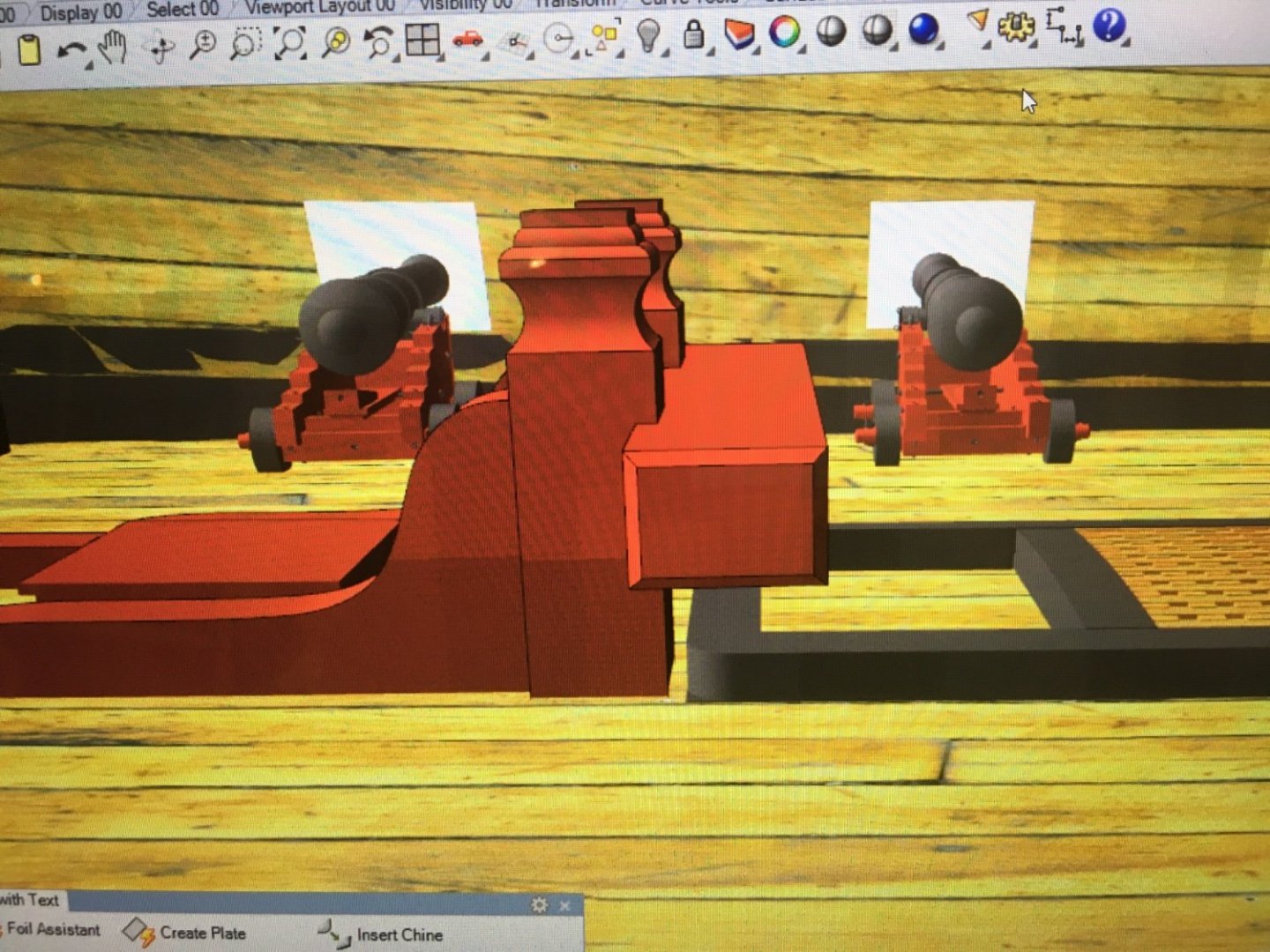

That clearance looks close to what I have, about 18-20” at 1/48 scale. I also like the guns arranged as you have them in the second photo, but I’m also curious as to how they were actually set on the real ship. Looks really good though. JJ

-

Hi Siggi, very interesting to see that so prevalent in so many designs. Wonder why they intended to obstruct a decent portion of the opening? Weird. I’ll just leave it as is then! JJ

-

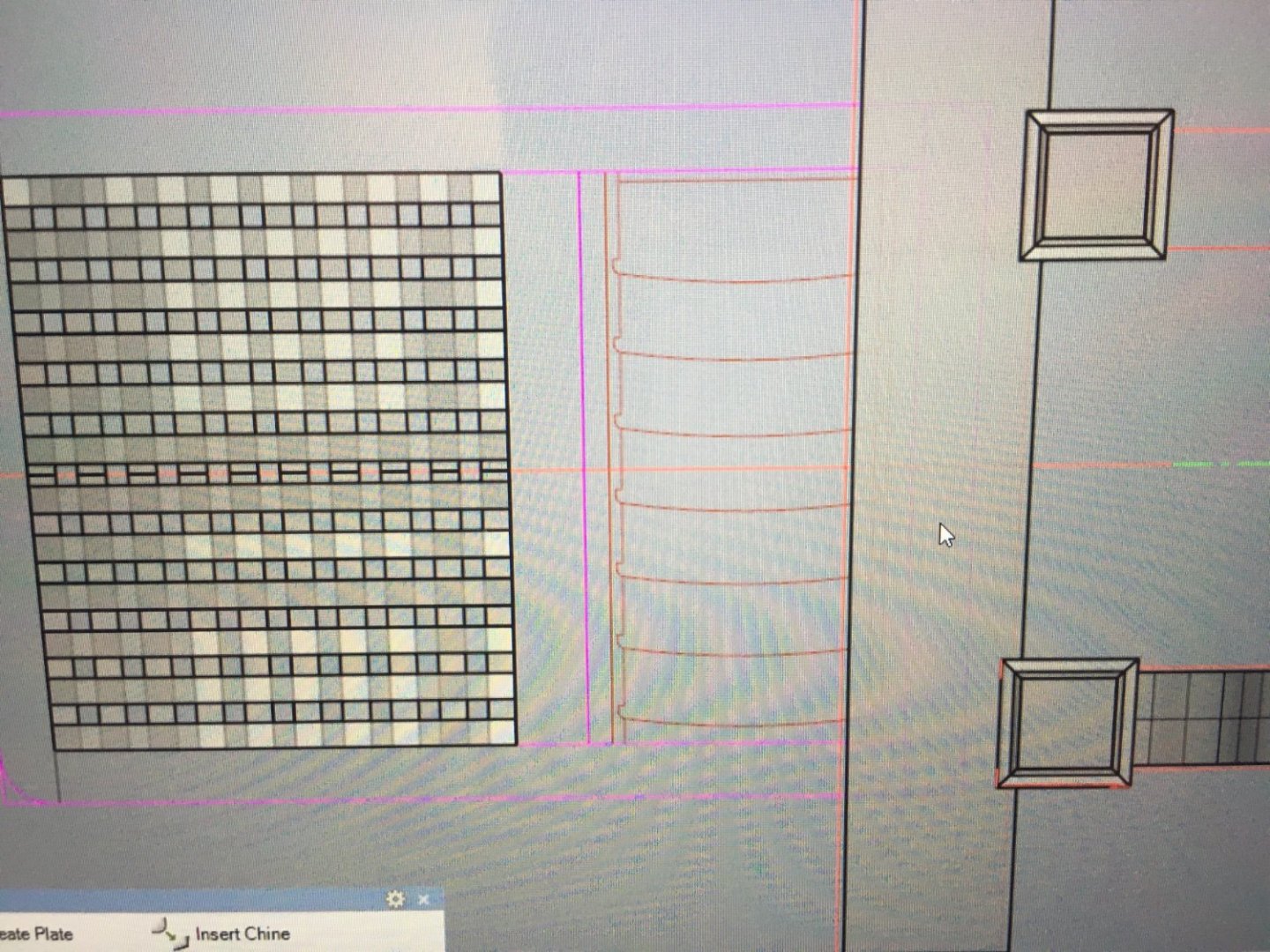

Hi Siggi, again wonderful work, I’m just in awe over this model. I just noticed in your last post that your aft FWD riding bit appears to potentially cover a portion of your FWD companionway. They reason why I ask is that I’m drafting Portland 1770 and I ran into this issues while utilizing the original drawings, I’m curious to know if you encounter this on Tiger and if so, do you move the bit or leave as designed? below is your model and the bitt appears to cover the companionway below you can see my 3D model of the bitt in question on Portland as well as the original draft also showing the error: JJ

-

That looks really good! Well on your way. Happy New Years! JJ

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very nice Chuck! What an achievement to produce a model of such extraordinary detail and quality and share it with us! I can’t wait to resume mine.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Lookin great Chuck! Merry Christmas

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Excellent! Looking forward to this step!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

scrubbyj427 replied to cafmodel's topic in Wood ship model kits

Awesome carvings Tom! What software are you sculpting with? -

See post 525 on chucks build log, he explains it. If you’re not there yet it will also be covered in the instructions:

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Remember all the laser etched moulding Chuck provided along the rails? They were intended to match the scrolls... there was plenty of extra... I didn’t even think about using them for the columns, clearly nobody else did either except Ben.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That went right over my head when I was doing mine. I’m seriously contemplating going back and redoing those. That’s just the bees knees!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

It looks like you used laser etched moulding to cap your columns? Looks wonderful, what a great idea!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

HMS VICTORY 1765 by albert - 1/48

scrubbyj427 replied to albert's topic in - Build logs for subjects built 1751 - 1800

Beautiful work! -

I’m also onboard with the 1/4 scale, with the Winnie being my first 1/4 scale I’ve been converted. Will probably never go smaller than that ever again. A big 1/2” scale frigate or something along those lines sure looks tempting sometimes though. But Winnie has proved beyond a doubt that an amazing model can be produced at 1/4.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks great Rusty! That’s such a rewarding part of the chapter to complete and complete well. I still just love how your Winnie looks with your choices of wood!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.