-

Posts

1,733 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by scrubbyj427

-

Wow that looks very promising. I think I’ve seen this before somewhere. May have to take a crack at it.

-

I’ve been chewing my nails in anticipation for the last four hours, Chuck... what’s the secret?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I think you could go any direction with this. You would really have to start adding tons of crap to spoil this model. I think Amazon looks great and not too busy. But I wouldn’t go past that point. Maybe settle somewhere between Amazon and Winnie contemporary.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

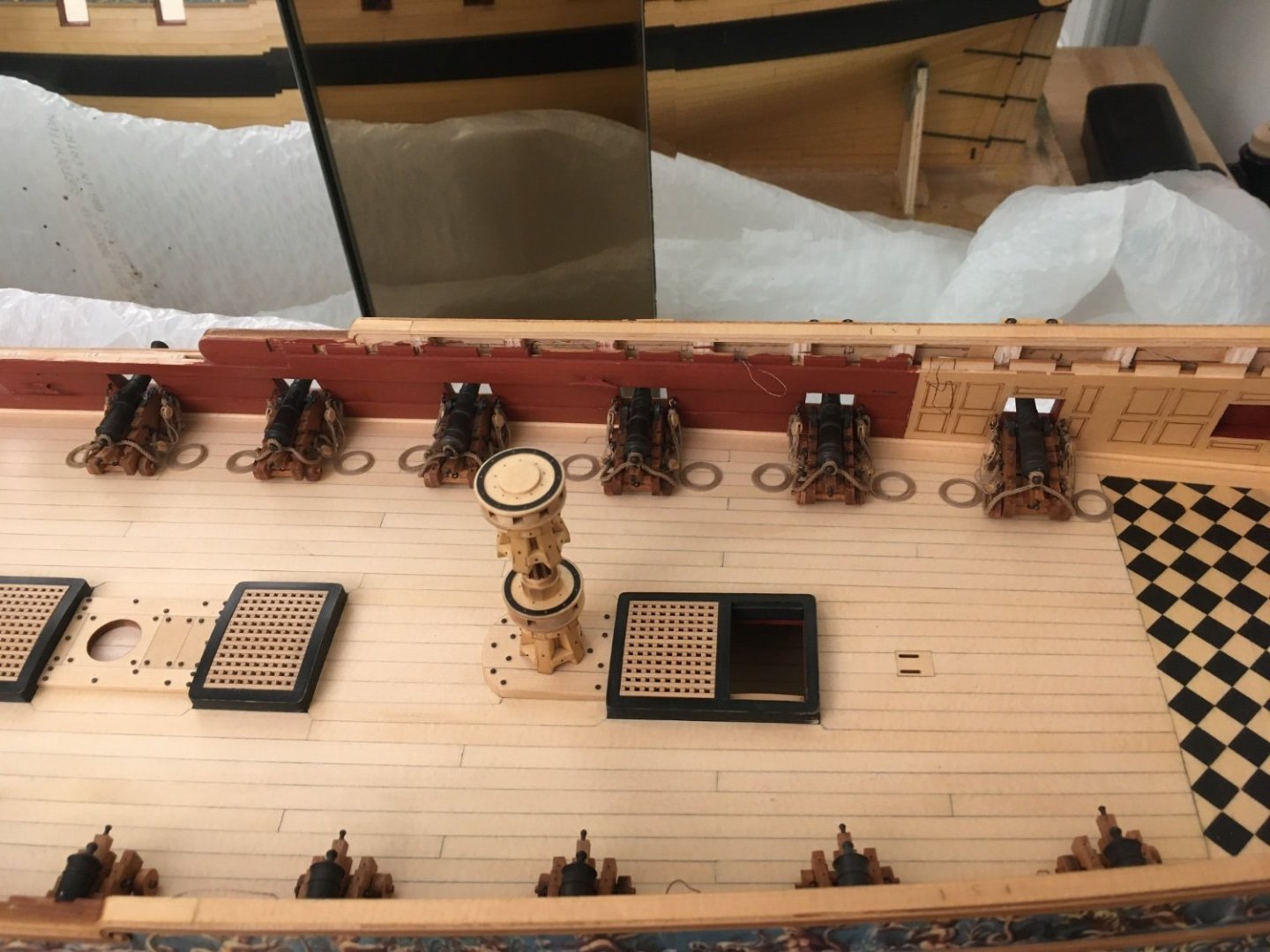

Remarkable work Chuck! What an incredible project the Winnie has become!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work Marsalv! Your work continues to inspire.

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

Glenn your planking looks great! Very impressive work. I never thought I’d say it but I’m looking forward to my next model to up my planking game to your level.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I’ll try the resin ones then, I’m just worried I won’t be able to match the finish of my other guns. But I’m also a long ways off from these little swivels.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Those look great Chuck, but I’m assuming they won’t be available in turned brass?

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I think the head rails are going to be the icing on the cake at this point. Very excited to see this part develop.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

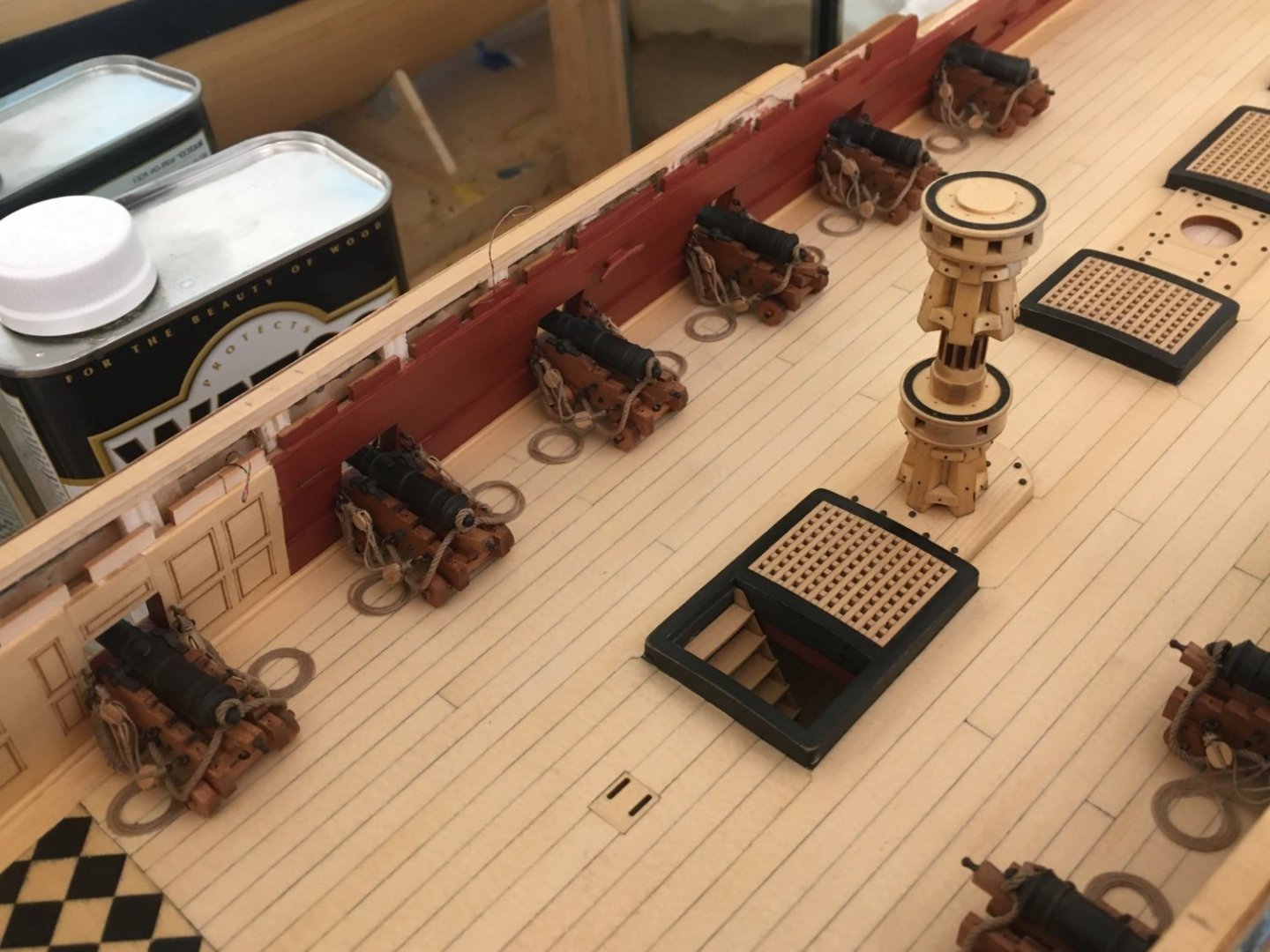

Don’t worry Glenn... I’ll still probably be rigging guns by the time you get to this point.😁

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Wonderful work Chuck! This just looks awesome!

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

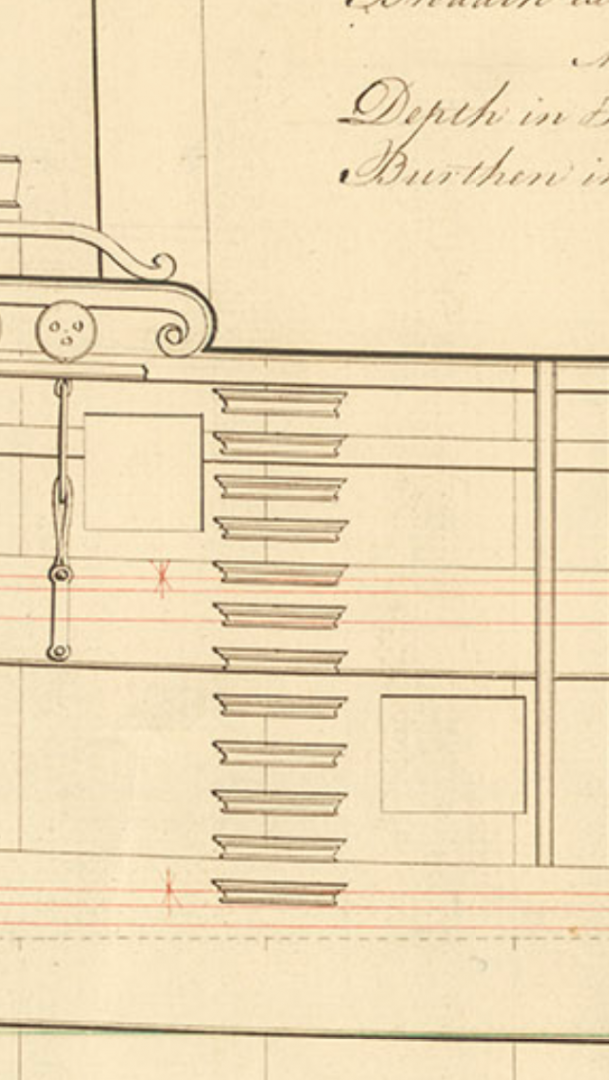

Looks like you could run both ways with it. But I agree with you, perhaps the modeler didn’t want to cut a nice run of moulding. And since it’s not actually functional I think aesthetics take priority. Also the molding and the steps seem to have similar profiles. I checked my drafts for Portland class and it shows the same thing.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Those look really good. Often represented just as a slab of wood just glued on the side. I’m curious to see how the steps unfold.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Excellent work Ben! Everything looks great!

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Your figurehead looks excellent Marsalv! In your cnc did you have to carve one side at a time and flip the figure over each time or did the machine cut at all angles in one pass? JJ

- 589 replies

-

- le gros ventre

- cargo

-

(and 1 more)

Tagged with:

-

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

scrubbyj427 replied to cafmodel's topic in Wood ship model kits

Granado Looks very good Tom, well done on splitting the hull.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.