-

Posts

1,217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Gahm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Hello Richard,

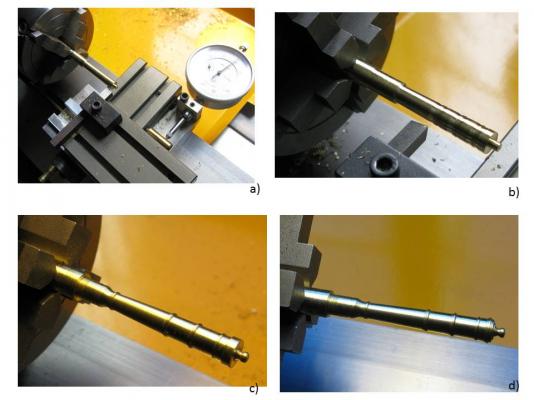

Image 1a in the last sequence of images shows just one brass piece. I hope the images below make things a bit clearer. I selected a round brass dowel with diameter slightly larger than the largest diameter of the cannon barrel (image 1a). This dowel was then mounted on the lathe in a 4-jaw-chuck with individual jaw alignment (it allows for more precise centering than self-centering chucks) with a piece of the dowel about 1.3 times the cannon barrel length protruding out of the chuck. This piece was first turned to the largest cannon diameter (image 1b). By means of a cross sled I then tapered the piece by about 1.5˚ to give it its rough "cannon" shape (image 1c). This corresponds to what you have seen in my last image sequence as image 1a). After a lot of additional processing steps the major part of the barrel was finished but still part of the original brass dowel (image 2). As a final step it was cut off the dowel, turned around and mounted again in the lathe in order to finish the work on the front end of the cannon.

Please don't hesitate to ask questions if the process is not clear. In any case it is a lot of fun to make your own cannon barrels

Thomas

Image 1

Image 2

-

-

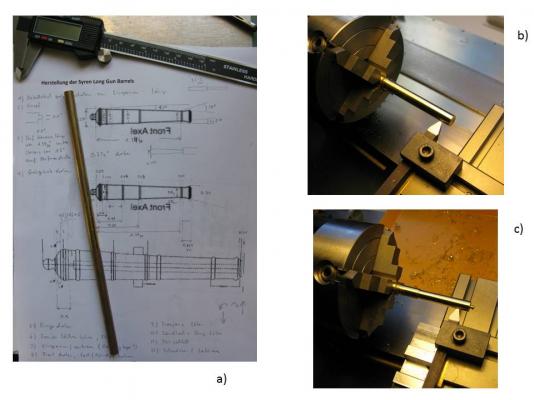

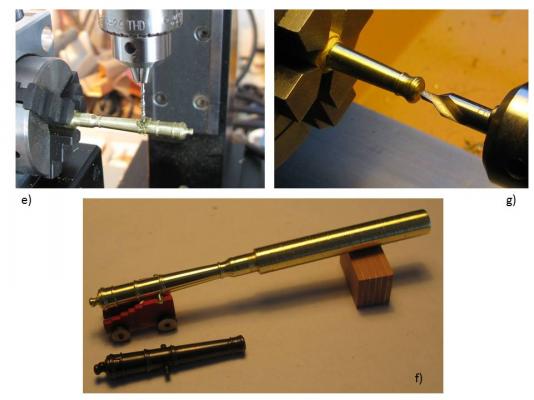

After getting distracted by a lot of other (mostly business related) projects I finally found some time to resume work on my Syren. Now the long gun prototypes, which I have shown on my model during the last 2 years, need to be replaced with the final versions. As there are only 2 guns I decided to make the gun barrels myself based on Chuck’s Syren plans. Images 1a – 1d show the different steps of turning one of the gun barrels. In image 2e the trunnion holes are drilled. After a “sanity check” with one of the gun carriages from the Syren kit the barrel is separated from the raw metal piece and the gun muzzle finished (img 2g). Img 3a shows the barrel with trunnions in place, the locations for the breech ring and touch-hole parts milled out, and the parts lying beside the barrel. The assembled gun barrel and Chuck’s plans are depicted in images 3b and 3c. The final result after blackening can be seen in image 4.

Thomas

Image 1

Image 2

Image 3

Image 4

- _SalD_, Stuntflyer, Ryland Craze and 14 others

-

17

17

-

-

-

-

-

-

-

-

-

Cutter Cheerful 1806 by rafine - FINISHED

in - Build logs for subjects built 1801 - 1850

Posted

Your rigging looks great! As you say after Essex the ratlines must have been just a little "warm up" exercise for you

Thomas