-

Posts

5,457 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

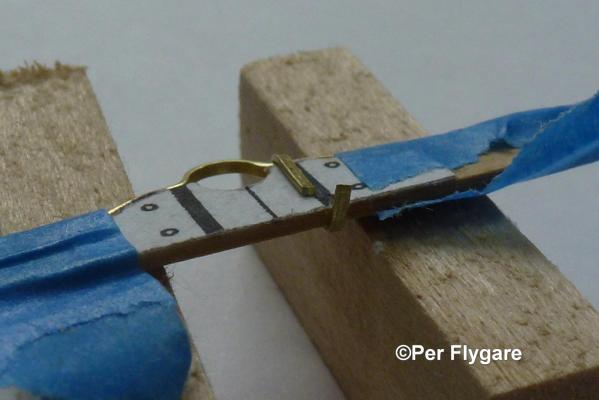

The band strap that "secures" the mast ring to the thwart is not cut equal see the bottom side. Will not be visible once in place.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

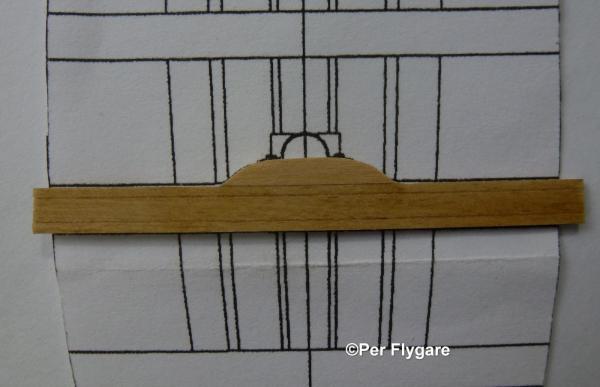

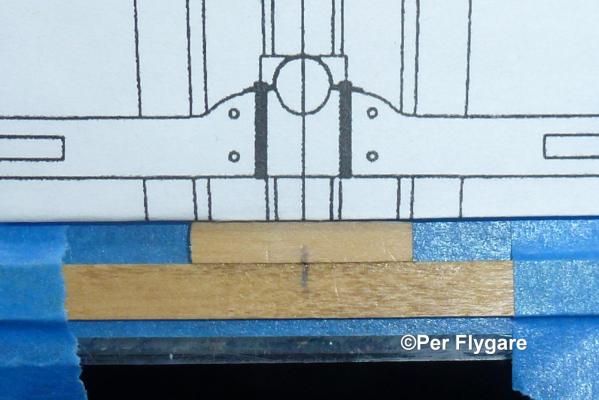

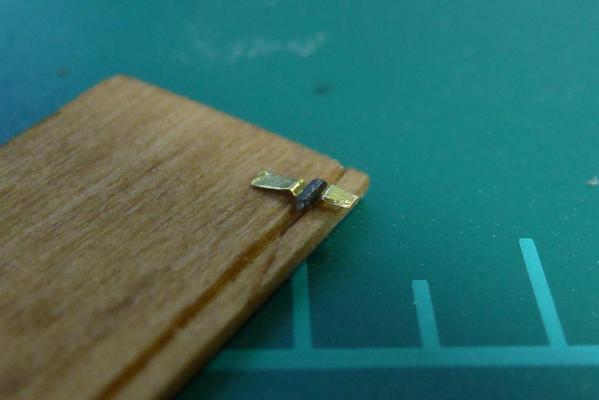

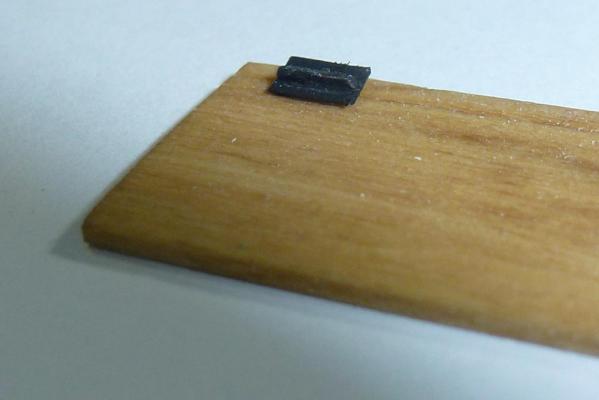

Progress with the mast thwart, I did cut a small piece from the mast material to get the right diameter. Thereafter the half circle in the thwart was made along with other side of the "iron ring" (brass).

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Found this product thanks to a friend in FB. Glowforge is US company based in Seattle WA! What it seems to me, the machines are made in the USA. Check the machines out, there are three versions of them, starting at USD 1995

-

Wow Erik, Seems like we are at the same point in our builds. Very inspiring. Your longboat looks very nice.

- 222 replies

-

- 18th century longboat

- model shipways

-

(and 2 more)

Tagged with:

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

I have the MS Bluenose awaiting as next project. During the time I have gattered a library of various books and practicums related to her. I have extra wood for her as well from Jeff (HobbyMill), blocks and rigging line from Chuck - Syren Ship Model Company. One book I can recommend, which can be to help is Frank Mastini's book Ship Modeling Simplified. A book very much based around the Bluenose. Good luck which ever you choose.

-

Okay, Here is a link to the newspaper (in Swedish) along with pictures and video from the found. Solen It has also been confirmed from The Swedish Maritime Museum this is the ship.

- 10 replies

-

- 17th century

- 66 cannons

-

(and 1 more)

Tagged with:

-

Yesterday (Wednesday), another Swedish ship from 17th century was found. This time at a depth of 6m (about 18t). She is slightly bigger than Wasa with 66 cannons. Her name is Solen (the Sun), built in Lubeck 1669, sunk 1694. Armament: 16x24 pounder 8x18 pounder 24x12 pounder 2x8 pounder 14x6 pounder 2x4 pounder 4x3 pounder Length: 45meter Width:12 meter

- 10 replies

-

- 17th century

- 66 cannons

-

(and 1 more)

Tagged with:

-

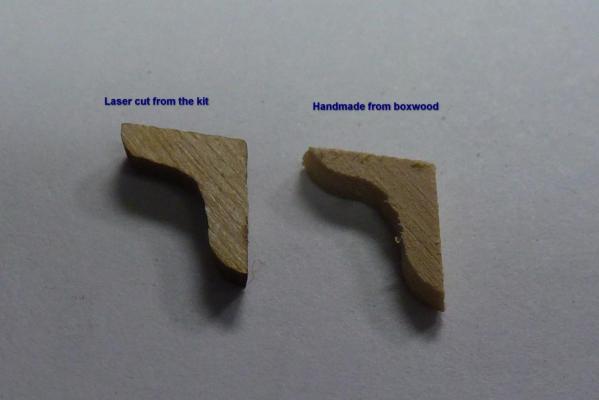

Again, I am trying to figure out whether to go painted or au natural. As above the piece from the kit but painted and 50/50 varnish on the boxwood. Leaning towards the painted in order to get some contrast, but the natural looks good too........ HELP! Maybe doing two sets and then take it from there......hmmmm

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

I broke a knee today....... Well at least it wasn't my own knee, but one for the longboat. This resulted I made one more before realizing Chuck already had made sure of two extra from the laser cut board. However, take a look at this I am more than pleased how the boxwood knee turned out. Now I am wondering if I should do all six of them in boxwood. On the other hand if they are to be painted then it won't matter but if I leave them natural then I should do it?!

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

The hinges are made and in place. They turned out the way I wanted them. Working with the 110gram paper was quite an easy approach. I have decided not to paint the seats. Looking at the picture it looks like I could have put simulated "going through bolts" in place.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Mike, I would hang it on the wall in the workshop, as decoration. Our workshops should have a nautical theme.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I still don't know whether to go with natural or painted cockpit. After some experimenting the hinge in the last picture is a 110gram papercard with the 28 gauge black wire from the kit. I did a trial with brass but I didn't like it. I like this version better.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Mark, I don't what to say..... but Thank You. As for the photos I am using a 5 year old 8mb pixel Panasonic Lumix camera. No macro lense is being used. No photoshop or editing has been taking place either. I feel that the details of mine should be better.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

With some trimming I feel the seats are in my comfort zone. I am not to do the locker parts as per instructions. It will all be one and a solid part, hopefully I will pull this off.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

The cockpit is under construction. Again I am using boxwood instead of the provided material from the kit. The seats are wider, as per instructions from Chuck and will be slightly trimmed. Using the locker part as guide I have an idea how much to trim. Gee, photos are more revealing than you think....

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.