-

Posts

5,457 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Nirvana

-

But your longboat is coming just beautifully!

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

I know the Gremlins are still around....... wreaking havoc when it comes to parts...... Ne er finding the i ems you are looking for. Hey, they are ev n taking away letters. Mike, I bought deadeyes from Chuck, very nice once that I am to use. So I have extra, just in case of the Gremlins.

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Mike, Many thanks for the looping plier idea, I have looked them up and seems to be a Very good investment. Thanks again

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Bluenose2, I think it will be much much cheaper to dispose the drill and get another one than having it re-shaped. Think I could some 20+ drills for some the shop price, or even more...

-

I thought in order to bend a bit like this you need some heat..... maybe a carpet is good enough... The length: oh sorry, total length only 2 3/4 inches ( about 6.2 cm) long. Could have been stepped on, never felt it though......

-

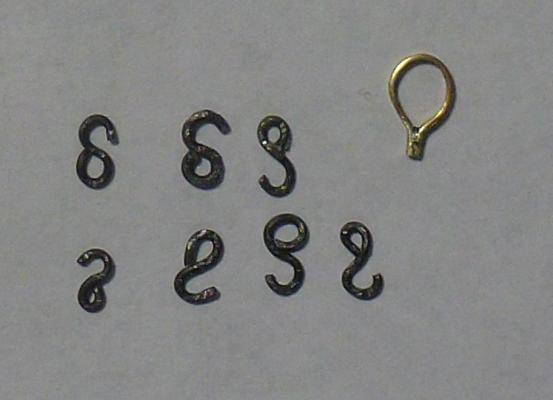

Well, my home made hooks didn't come out uniformed. Funny though they are all the same length. Seven hooks and the mast ring. It was a long time since I did some soldering, but the butan powered soldering pistol it worked out fine. Think the heat was greater than with an electric. The ring has been drilled for the boom-hook.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

So I had done drilling and lost a one of the HSS drill bits in carpet, when I found it it looked like this. Most of my bits going of like this has been broken. Take a look and ponder about it.

-

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

The "lift rings" were hard to get round, so I settled with the second best. Now both of them are in place and not glued to the boat. They are movable.

- 335 replies

-

- 18th century longboat

- Finished

-

(and 1 more)

Tagged with:

-

Found a casket, seems to be filled with some liquid..... Smells good from it though..... well better sit down on it instead of trying to open it. Looking forward to next step.

- 203 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

Jack, I just finalized reading through your build log, and got goose-bumps when seeing your transom part. It was like deja-vu. Back in the 70's when I built Marie-Jeanne, I was all alone on the project, And no support but that part gave me a lot of thinking. I probably re-did that part 4 - 5 times. Still it didn't turn out perfect. Besides today with internet it is so much easier to get help if stuck. Good job.

- 203 replies

-

- artesania latina

- marie jeanne

-

(and 1 more)

Tagged with:

-

Hamilton, I looked at Amazon and found the Proxxon was a little higher rated in reviews than the Makita. However, it was based on very few reviews as well. Try to find local hardware stores carrying them to compare. Also, check out this website for more info. http://scrollsawreviews.com/ Don't know if it will help but at least something more to go on.

-

Echo by Maury S - FINISHED - Cross-Section

Nirvana replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Phwee, Lot's of reading and lot's of ideas. Maury, thank you very much for this part of the cross section. I am very very tempted, but have so many other on the hold. One of your build logs will truly be a great help for one of my next build. And that is your Emma C. Berry.- 324 replies

-

Geez, can't you get a better picture? lol, Dirk, don't get me wrong..... but that picture is amazing, the detailing and depth of field. Very Nice! Can be used in other builds as well. Thank you.

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

New mini-mill... CNC and impressive

Nirvana replied to mtaylor's topic in Modeling tools and Workshop Equipment

Oh my, And only 4000 dollars, maybe a trip to Bozeman to pay this little company a visit. Well, it's out of my pocket as well. But thank you posting this. This is what I call enterprising. -

Tony, The Sherbourne is beautiful. I like the way you are describing by words and picture the detailing that's put in.

- 269 replies

-

- Caldercraft

- First build

-

(and 3 more)

Tagged with:

-

Very nice Mike, Hmm, using the wire instead of the rope? Great idea!

- 100 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

Burnside63, or what your name is.... I am glad to hear you have an Admiral requesting for something different than a ship. You have great support! To bad this is not the right forum that build, but please provide us all for a link to that tram or two, I am certainly looking forward to a build log.

- 50 replies

-

- mariefred

- nordic class boats

-

(and 1 more)

Tagged with:

-

Erik, What size of hooks did you use? I think I bought to small hooks from Chuck, the 3mm. Very nice and clean job you have done.

- 222 replies

-

- 18th century longboat

- model shipways

-

(and 2 more)

Tagged with:

-

The Admiral and I are in the process of moving. Due to that I have to store my kits in another location for time being. Yes, sealing them up with plastic wrapping is to be done, but is that good enough? They have all been stored in my office closet so far. For a while the kits will be stored in a non-heated garage. Inputs would be appreciated.

-

Burnside63, That very nice. I like the warm glow. How about a christmas tree on the foredeck. All this types of ships had a tree during christmas time.

- 50 replies

-

- mariefred

- nordic class boats

-

(and 1 more)

Tagged with:

-

Mobbsie, nice start as I stood up for the first part. lol, now I am sitting with my own cup of joe. Since this is a fairly small hull kit,I would have replaced the stubborn walnut planking with basswood or boxwood. I guess it is a double planked hull?! Looking forward to next episode. Hmm, so it wasn't doubleplanked. I found several builts on youtube, some shorter other longer.

- 129 replies

-

- armed launch

- panart

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.