-

Posts

1,790 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ulises Victoria

-

Jim Byrnes Model Machines

Ulises Victoria replied to Mahuna's topic in Modeling tools and Workshop Equipment

Update: I ran out of ropes to finish the shrouds on my Vasa, so there was no option: I HAD to make some more rope. So I took my regular dark brown thread and partially loaded 3 spools with 2 strands each of thread. This time I put more attention on the tension at which I loaded the threads in the spools. Then I started the machine at 0 speed and crank it up just a bit. The rope came out very nice and even. I was very pleasantly surprised! With this successful attempt, next day I went to make the light tan thread I tried to make a few days ago with no success.(Post # 129 above) I did the same things about the tension and the speed, and this time I got a more than acceptable 6 strands light beige rope. I'm posting this only because I think is the right thing to do to give Jim's machine it's credit back. My guess is that the number one problem was speed. I have not changed belts or put belt dressing... yet. FWIW. Best regards. -

Hello Matti. As always, a pleasure to look at your work. Those pictures of the real Vasa show something that wasn't in my plans and I just noticed: The way the main stay goes around the foremast and attach below the bowsprit. If I start modifying every detail I see that's wrong in my kit, I will never finish Cheers!!!

-

Hello Vivian: Wow... you are doing a terrific job. Your model is coming a little big masterpiece. Your attention to detail is what makes it so well done. Please keep posting photos of your advances. Tu amigo: Ulises

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

Well Amazon has one (and I mean "one unit") of a Vasa Documentary selling used at 127 dlls, and filmed in 1996. I don't think is the one linked here.

-

Thank you all. Your words are very encouraging. I'm almost done with the standing rigging. Working on shrouds and ratlines with about 80% of advance. Will load some more photos soon Mike: No clews in my sails this time. But after seeing your post on how you do your sails I will surely include them in my next build.

-

Can you post a picture of your product? Is it something like in post #19 above? I bought about a 1mt. of this material and have enough for a lifetime.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Landlubber Mike's technique for furled sails

Ulises Victoria replied to Landlubber Mike's topic in Masting, rigging and sails

Excellent post, Mike. Too late for my Vasa, but certainly will check it out again in my next build. Furled sails is my favorite method of doing my ships. Thank you!!! -

Christmas elves doing a late prank on you??? Glad you found them!!!

-

I wish you had started your Vasa before I did mine, so I could learn from your build. Seriously. Respectfully.

-

Try here. http://www.bestrc.com/constructo/contact.html A search in Google for "constructo ships" took me there in less than 5 seconds!

-

Very likely. I made emphasis on that step! Great idea that of the gun carriages. Why didn't I think of that??? Best wishes!!!

-

Excellent! Fond memories of my start of this kit!!! I was going to tell you to rig the violin shaped block before closing your decks, but saw you already did!!! Good work. I will follow with interest. Best regards

-

Jim Byrnes Model Machines

Ulises Victoria replied to Mahuna's topic in Modeling tools and Workshop Equipment

Thank you Jim. Sorry I have another question. Can some type of "dressing" be used to prevent slipping of the O rings? Something like described in post #121 above? Your last answer makes me think the problem may be in the inner belts. -

Oh my! I always thought I have too many tools... and I was right.

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

Jim Byrnes Model Machines

Ulises Victoria replied to Mahuna's topic in Modeling tools and Workshop Equipment

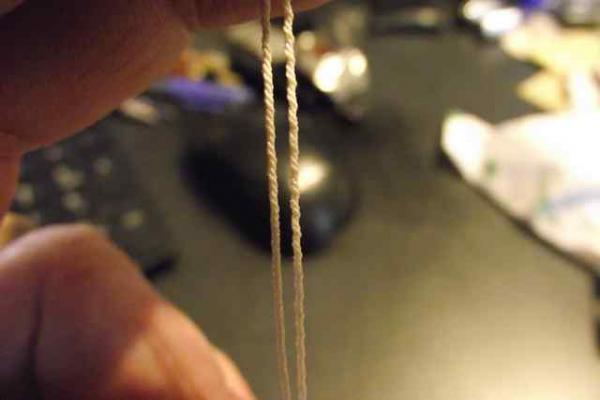

Jim. First of all, I wish you a very Happy New Year and thanks for your answer. I did not know that DC motors turned in steps. So then the motor is OK. Lesson learned. Jim: The way I make heavier rope is by using 2, 3, 4, strands per spool. I have made up to 7 strands in your machine with very satisfactory results. I am uncertain then why now I can't have good rope out of 2 stranded spools. May it be the cracked belt? Are your belts "belts" or very large O'Rings? A friend of mine told me of a place where I could get O'Rings of very large sizes. I'm wondering if they may work? Edit: Last two photos show the 2 stranded rope I made before, and lately. -

Vivian. It's coming along really nice. The weathered-dirty look on your hull is just right. Congrats! Keep on it, girl !!!

- 188 replies

-

- latin caravel

- artesania latina

-

(and 1 more)

Tagged with:

-

Jim Byrnes Model Machines

Ulises Victoria replied to Mahuna's topic in Modeling tools and Workshop Equipment

Update I tried to make some rope these last few days. I needed 2 strand rope, (two threads in each spool) which I have made before without problems. This time, I made about half spool of rope and I don't think any part of it is usable. There is un-even portions everywhere. When I turn the big wheel by hand very slowly, it feels it moves in steps, with a little continuous bump every second. I took off the main belt and turned by hand the rod that comes out of the motor and drives the wheel. It felt exactly the same way, so that unevenness comes from the motor. The motor does not spins smoothly. I even disassembled the motor and lubricated the bearings with DW40. Nothing changed. So my conclusion is: I need a new motor. Lets see what Jim has to say about this. I know he is a very reasonable man.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.