-

Posts

1,398 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DelF

-

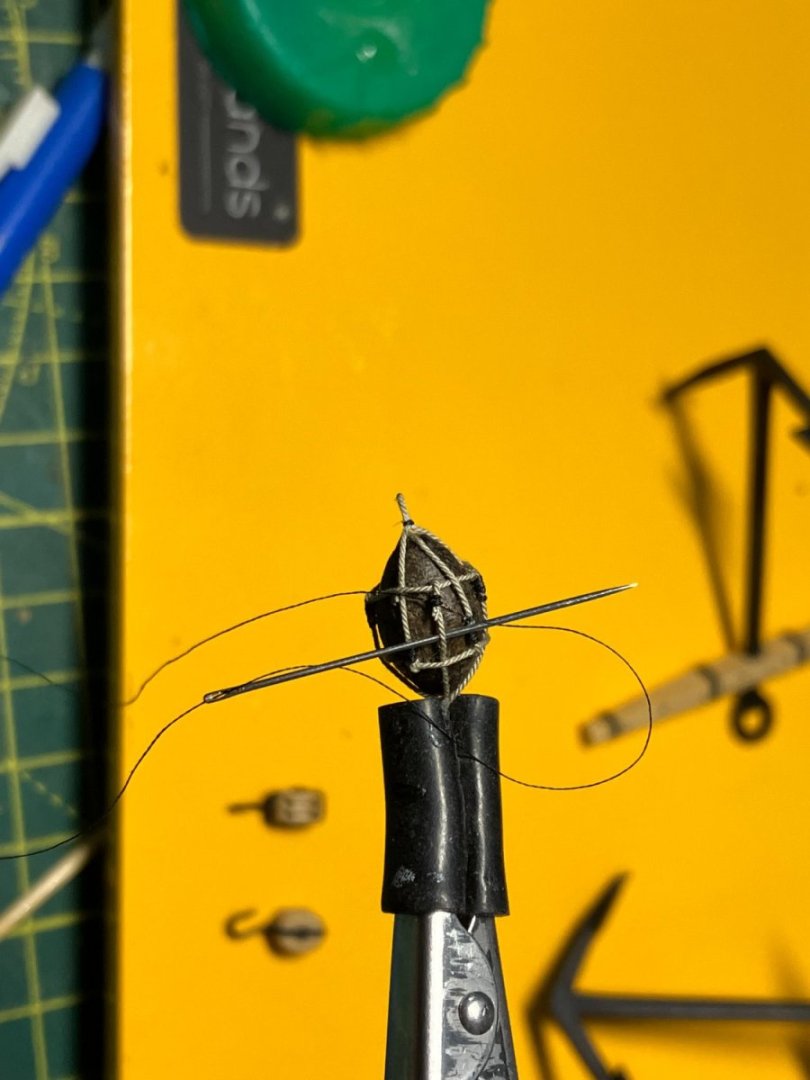

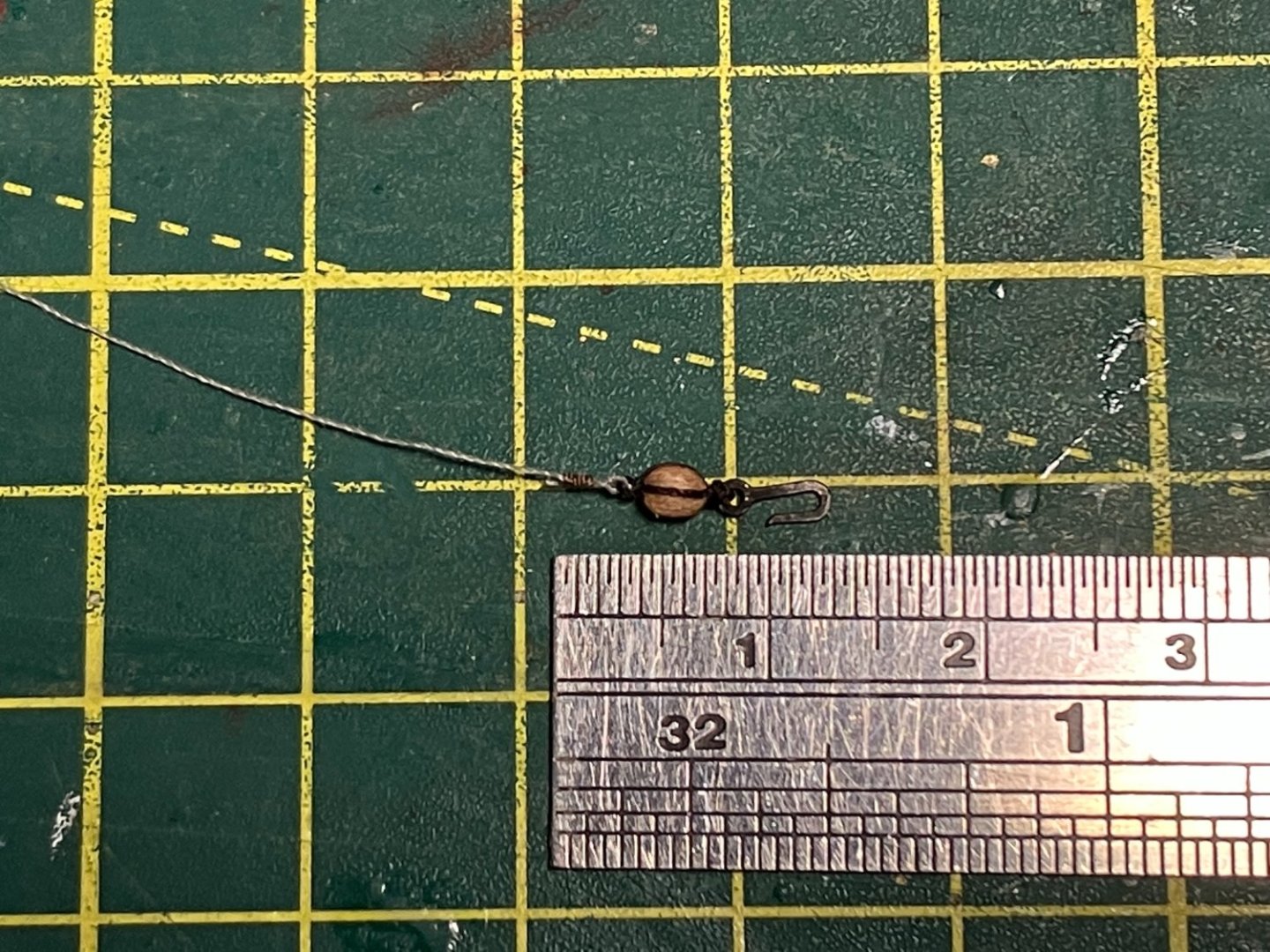

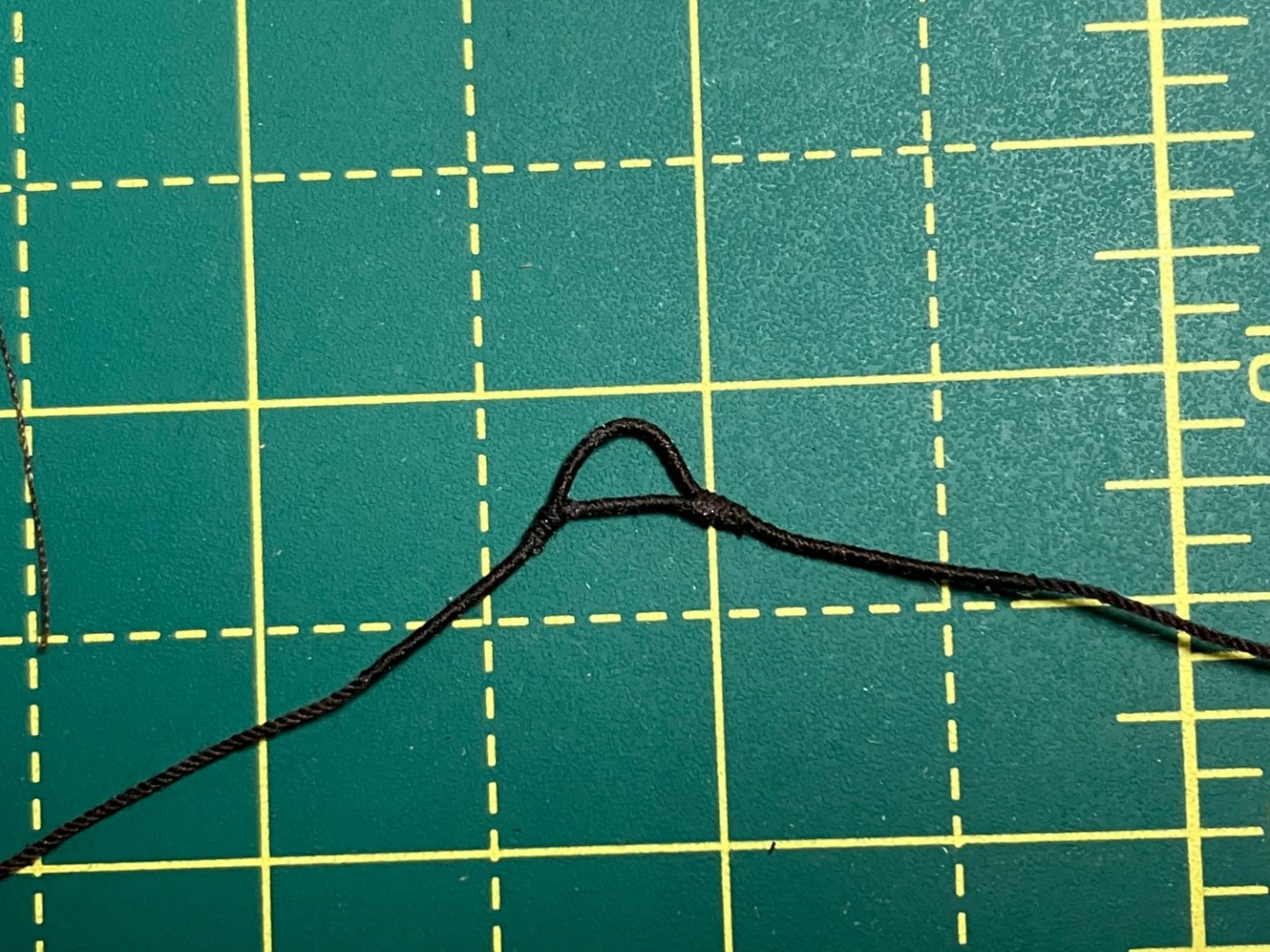

Anchors Not much time in the workshop recently. I've been working on the anchors for a while and eventually got round to finishing them. Much of the work was the same as for Speedy, except this time the whole of each anchor is made from MDF. The shanks in particular needed a good session with a file to chamfer the edges, probably best shown in the close-up photos below. I used Admiralty ironwork black as a base then lightly brushed on some iron metal powder. The stock came in two halves that clamped neatly round the shank. However as they were laser cut from a sheet they were only tapered in one dimension rather than two. To cut the second taper as neatly as possible I worked out the angle needed then cut a small wooden wedge the top edge of which sloped at said angle. With the wedge sitting in a vice on the Proxxon mill, the required angle was shaved off the anchor stock, one half at a time: Double-sided tape was sufficient to hold the stock on the wedge. The bands on the stocks were the usual shrink tubing, the puddening from dark line and the bolts are made from bristles stolen from a hair brush (Shhh!!!). I made the anchor buoys using mostly the same method I employed for Speedy and other ships (link here), but this time I tried to make the end result neater. I made the wooden body of each buoy on the lathe as before, but instead of making eyes in the rope slings before fitting them to the buoy, this time I did all the fitting on the buoy. This enabled me to make each eye as tight as possible around the two rope bands circling the buoy. As before, I drilled two 0.9mm holes right through the buoy to accommodate the rope bands and put a touch of thin CA in each hole. Once the glue had set I started attaching the rope slings. I had to use a needle to get round the bands, and everything was so tight and awkward I ended up using light rope so I could see what I was doing: Obviously I dyed it once I was happy with the end result. Here's one of the buoys attached to an anchor ready for fitting to the model. Also shown are the two cat blocks. Here's how I made the blocks last time. The only difference this time was I discovered I had some 1/4" triple boxwood blocks I got years ago from Syren and never used. Rather than make my own as I did before I cheated by milling off one side of each triple block to create a double . Here's the starboard anchor rigged, then a closer shot showing the cat block: Apologies for the focus. The finish line is rapidly approaching. I'll update the log shortly to show progress on the remaining rigging tasks. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I used this car lacquer on Speedy. I was worried it might be too glossy, but it dried with a nice sheen, and has kept the copper tarnish free:

- 473 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

K&E Mark.I Proportional divider

DelF replied to modeller_masa's topic in Modeling tools and Workshop Equipment

I got an old Staedtler set years ago but only used them for the first time on my current build. They were a revelation - like you I found them more accurate than tick strips - and much faster. They'll be my goto planking measuring tool from now on. Very true. You can't beat the genuine tools. I think I paid about £30 for mine on ebay. Here's a link to how I used them. Derek -

Great idea Glenn! HMS Sphindefatigable? 🙄

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks guys! Much appreciated. I must confess I'm finding it hard to concentrate on the Duchess just now, with HMS Indefatigable on order from Vanguard and HMS Sphinx sitting on a shelf for the last year shouting "build me!". I'm looking forward to seeing her complete though. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I can only echo what everyone else has said Ron - simply magnificent, the most realistic representation of the sea I've ever seen (and the ship ain't 'alf bad either!). Derek

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Running rigging - mizzen lifts and lower yard braces Happy New Year everyone, and many thanks for the likes and kind comments. The various lifts on the mizzen mast were mostly straightforward. The peak halliard required some in situ seizing of lines to the lateen yard, but nothing too difficult: I used three strands of Mara #150 to make the ropes. The lifts on the crossjack and mizzen topsail yards were somewhat lighter - I used Mara #70 and Mara #100 respectively: The photo above hides a real problem I had with the crossjack lifts. The falls are seized to the strops on a pair of 3mm blocks on a span clove hitched around the topmast, just above the cap. The falls then rove through the 3mm blocks on the yard arms, back through the first blocks then through the top to belay on the mizzen bitts. Unfortunately I'd fitted the blocks without the falls attached. The only solution was to use the finest needle I could find to thread the fall line through the strop on the end of each block, tie it off with a simple overhand knot, apply CA and trim. Needless to say the air was blue as I struggled to do this through a forest of existing lines. The result was not to a standard I would normally be happy with but in reality it's hard to spot the bodge: Btw, I didn't follow the kit plans and fit footropes on the crossjack. Sails weren't fitted to this yard, and as a result my understanding is that footropes were seldom fitted either. Braces I started at the bow and worked aft, although I have decided to leave the main brace off at this stage as I felt it would get in the way too much. The standing ends of the spritsail yard braces are hitched to the forestay, just below the crowsfeet tackle. Rather than two lines, I used one long length of Mara #70 (roughly 2.5" rope) clove hitched round the stay, which is easier and neater than tying and trimming separate knots. The falls then run forward through the brace pendants then back aft to the foretop: Each brace then reeves through the pair of blocks under its side of the top, then down to belay on the pinrail attached to the belfry. Threading the line through these blocks was easier than I had found on previous builds, although in this shot I'd managed to push the first block out of position: I used the same technique with the foreyard brace, clove hitching a long line round the main stay. The braces then lead forward through the brace pendants on the yard, back to the 5mm blocks fitted to the main stay then down to belay on the main bitts: The crossjack is different in that it is braced forward, and the braces cross. The standing part of each brace is seized to the aftermost lower shroud on the main mast, at roughly the height of the crossjack. It then crosses to the brace pendant on the opposite side of the ship, and across again to reeve through a 3mm block seized lower down on the same shroud, then belays to a cleat on the deck. NB Because the lines cross it's a good idea to stagger the seizings on the two shrouds to avoid the lines fouling. Not far to go now - I need to get my finger out and start making up some rope coils and finish the anchors. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks for your kind words. Boxwood is so beautiful I'm always reluctant to paint over it and I'm glad I eventually decided not to in this case, especially as I learned how to apply wipe-on poly properly. Having said that, the bare timber also contrasts well with painted areas such as the wales, and with coppering such as on Speedy. When stuck for a decision on these matters I must confess aesthetic considerations usually trump historic accuracy, for me at least.

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Merry Christmas to you and yours Glenn!

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

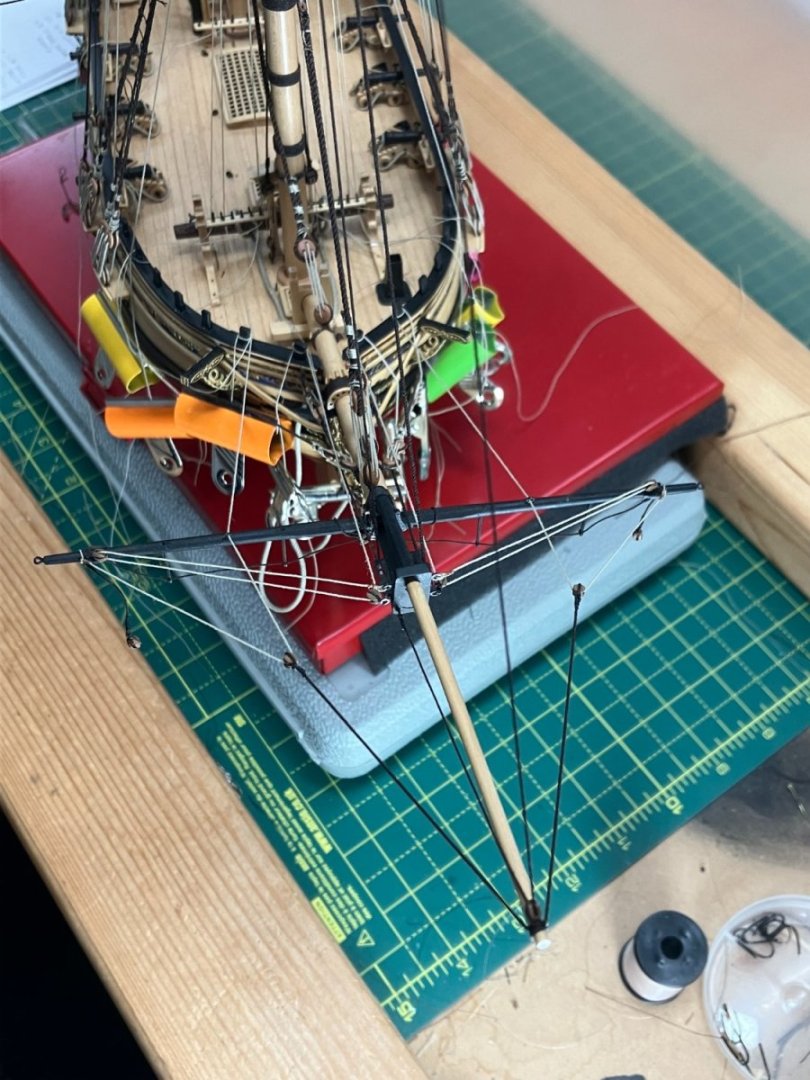

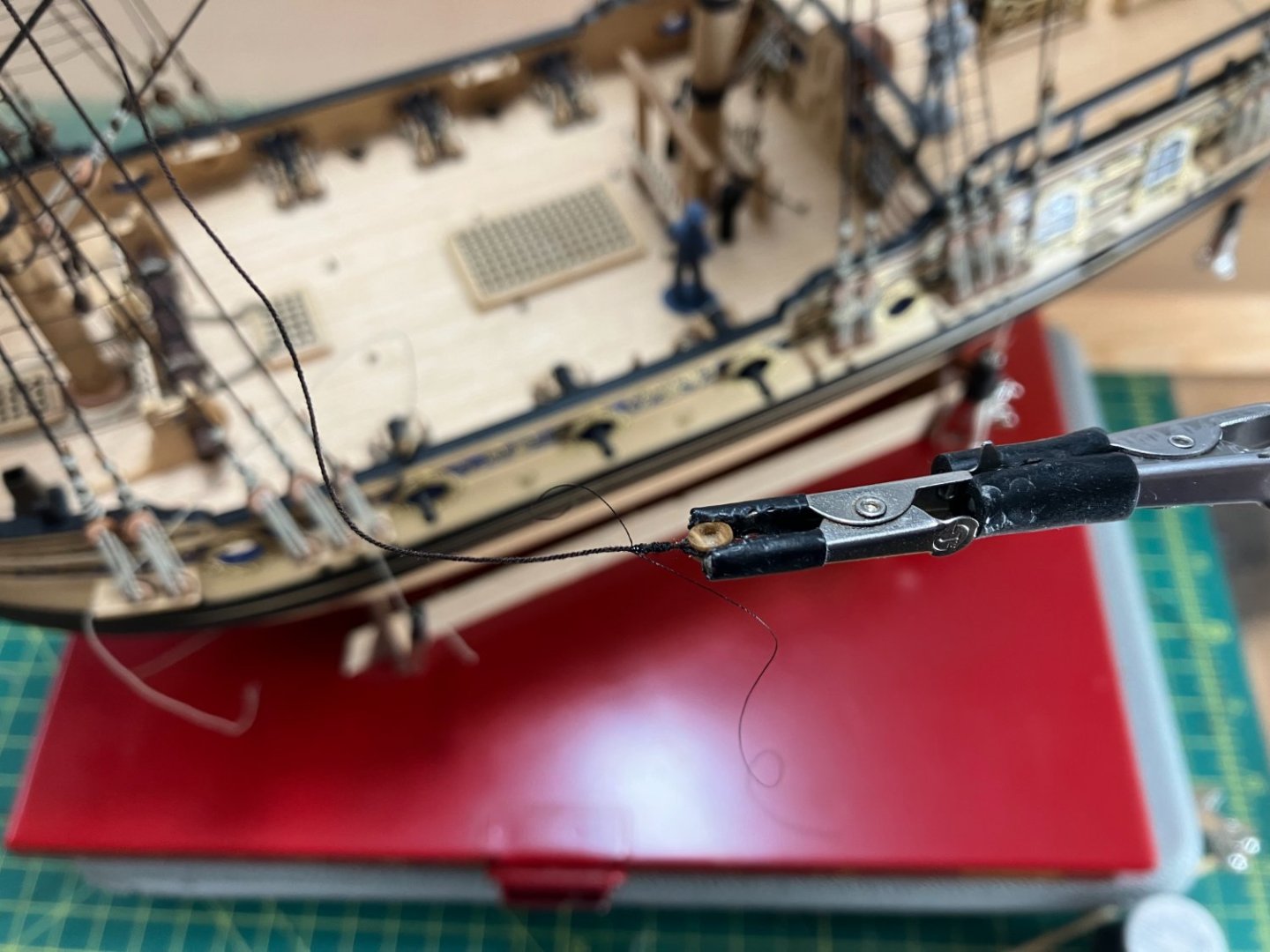

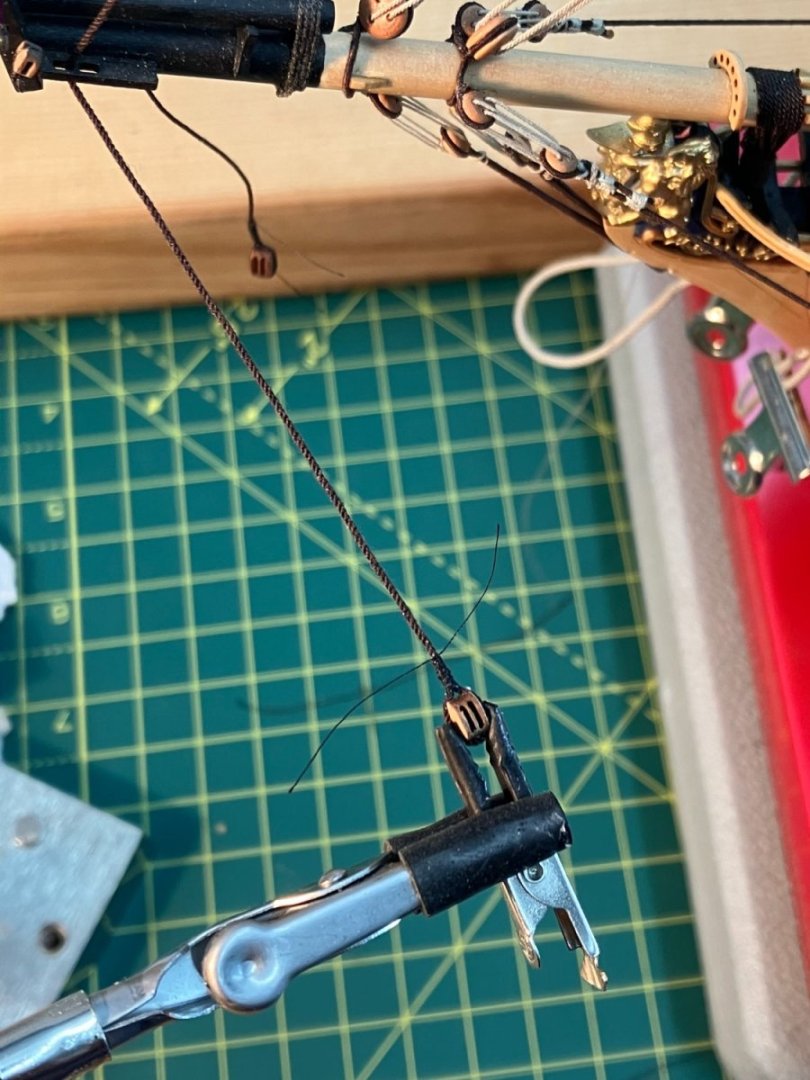

Running Rigging - brief update I've not kept the log up as conscientiously as I should, partly because it is difficult to photograph the model properly in the dust cabinet, but mainly because this stage of the build is an almost identical repeat of the same stage in HMS Speedy's construction. I confess I baulked at the idea of simply mirroring my entries in the earlier log. I hope anyone wanting more details will check the latter. Here's the current state of play: I've completed most of the rigging to the bowsprit, along with the ties and lifts on the main and fore masts, the ties on the mizzen and the vangs on the mizzen yard. As usual I haven't secured most of the lines yet, preferring to wait until a final squaring up. I found the bowsprit a little challenging, and had to have a couple of attempts to get the various lines to run cleanly without fouling: The first of these shots reminds me of another lesson I keep forgetting, despite keeping logs, which is that it is much easier to rig lines to eyebolts off the model. In my enthusiasm to complete the hull in line with the drawings I glued all such fittings in place long before I started thinking about the rigging, and of course I then had the pleasure of trying to seize lines on the model, usually through a cats cradle of existing ropes and spars. The one exception on the Duchess was the pair of cleats on the transom. I forgot these until I came to rig the vangs, at which point I had great fun drilling holes without destroying deck fittings and shrouds. Hey ho. Similarly, I usually regret not fitting more lines to spars before attaching them to the model. Quadhands is often my saviour, although I had to develop other solutions for higher parts of the ship. Here's me rigging the main topgallant yard tie: On a more positive note, I found that the beige 6/0 fly tying thread I rejected as an option for the crowsfeet works well as a seizing. I normally use the thinner 18/0 thread but the 6/0 version looks good on heavier lines: Anyway, my new year's resolution will be to work harder at keeping my log up. I'll also have to work harder in the dockyard - I've got Sphinx waiting on the stocks and I've ordered Indefatigable 😁. In the meantime, I'd like to wish everyone a merry Christmas and a happy and peaceful New Year. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

She's looking great Glenn. I don't think I'd appreciated how big she is until I saw your shot with the metal rules on the deck, and the one on the cutting mat. As always, I admire your attention to detail and your refusal to accept second best. I would probably have been happy with a couple of coats of paint, but you show what can be achieved by going the extra mile and applying seven coats - inspirational! Derek

-

What they all said. Simply stunning. Derek

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks guys! Boxwood is certainly my favourite timber for ship models, although I'd love to get hold of some Alaskan yellow cedar to try it out having seen how beautiful it looks, for example on Glenn's Winchelsea. Unfortunately it's not readily available in the UK, and as Glenn knows, I wasn't able to smuggle any out on my recent trip to Alaska Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

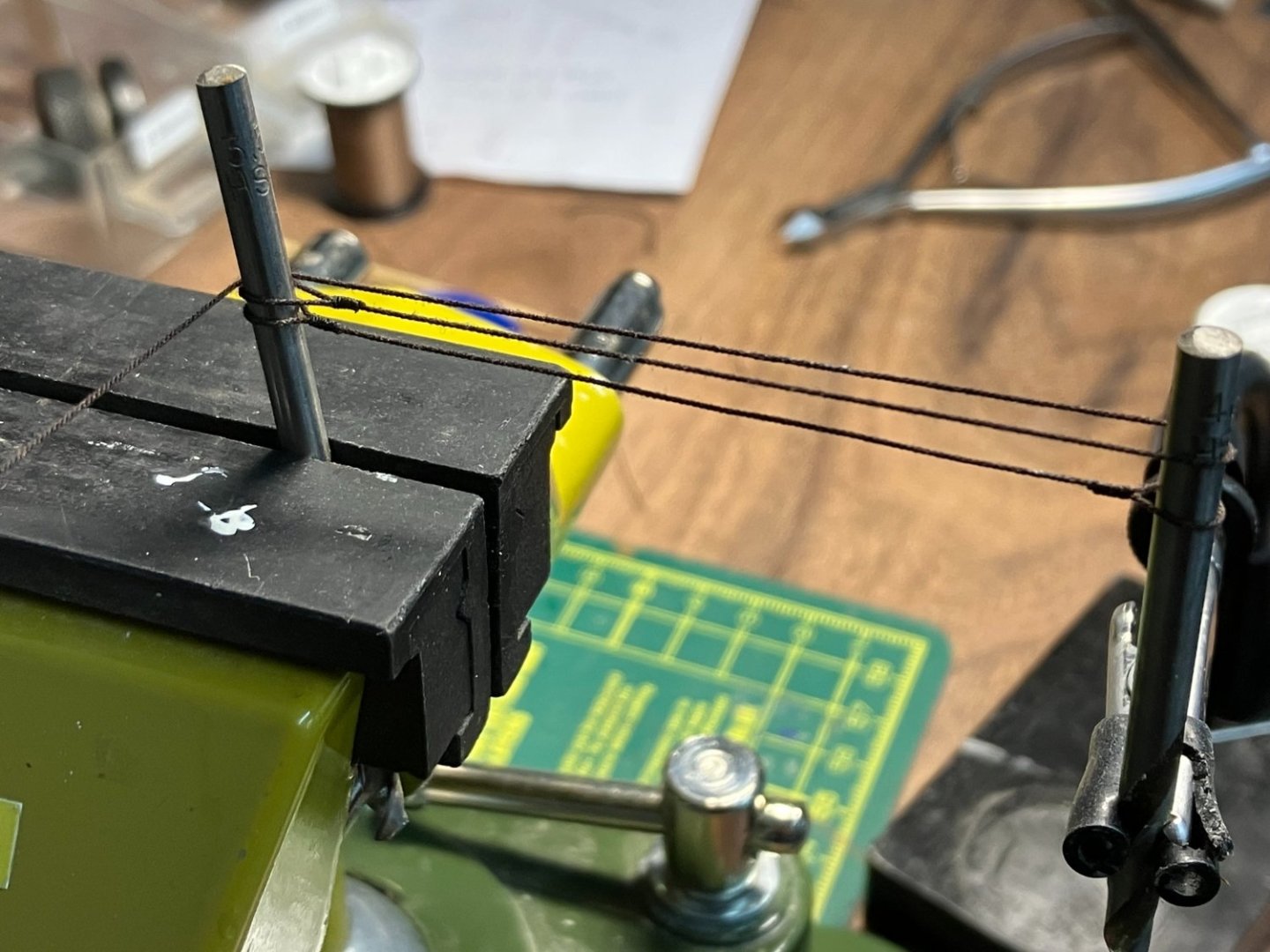

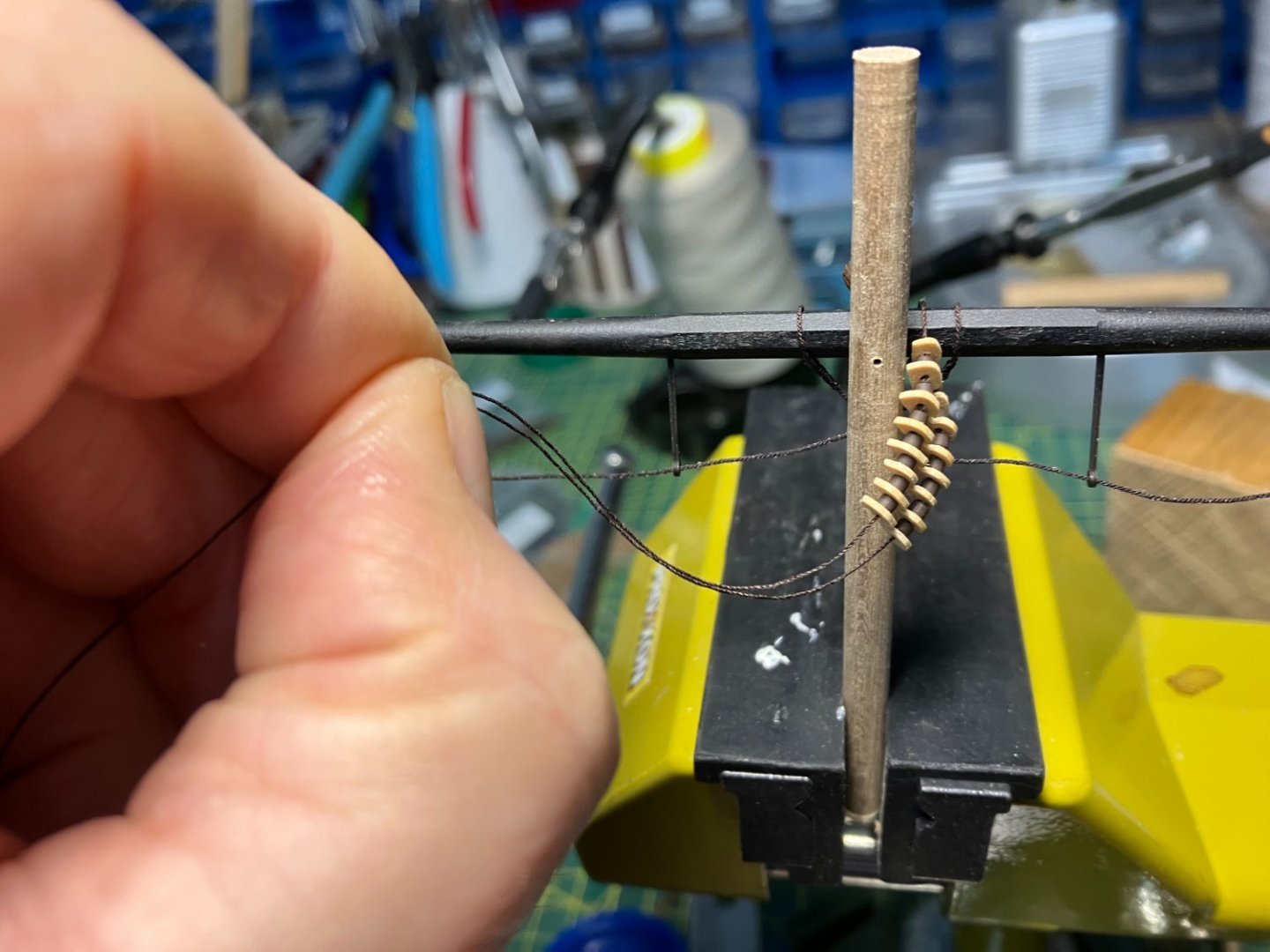

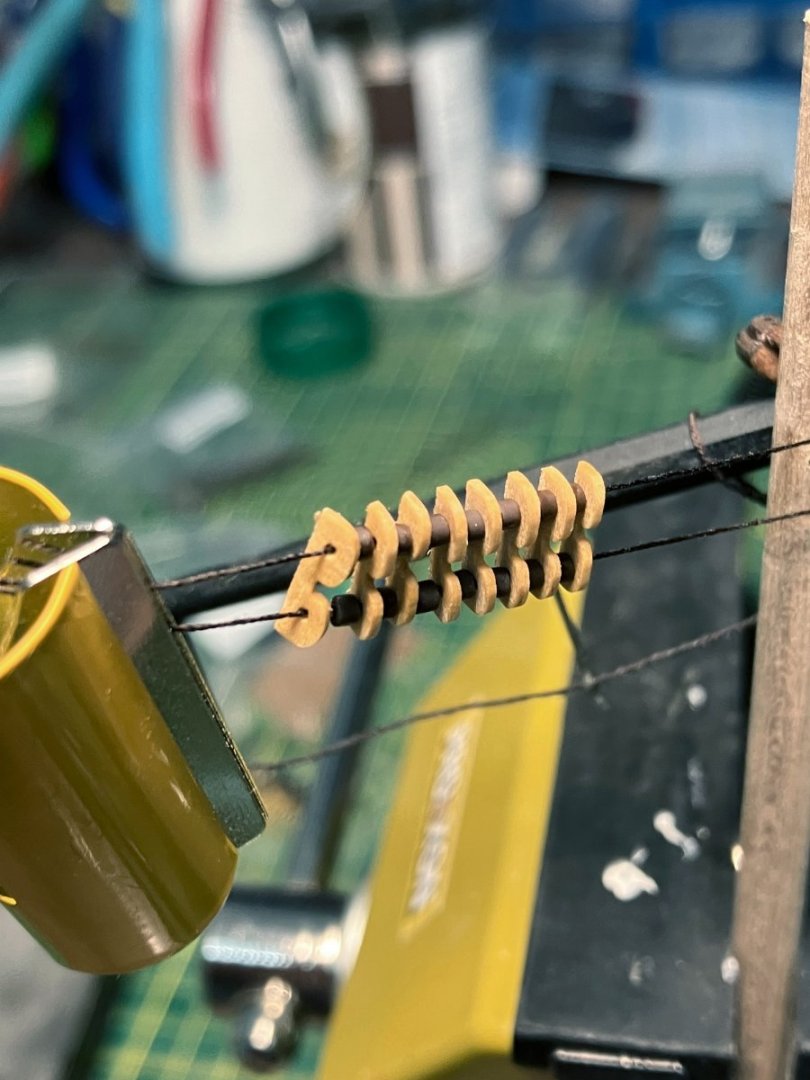

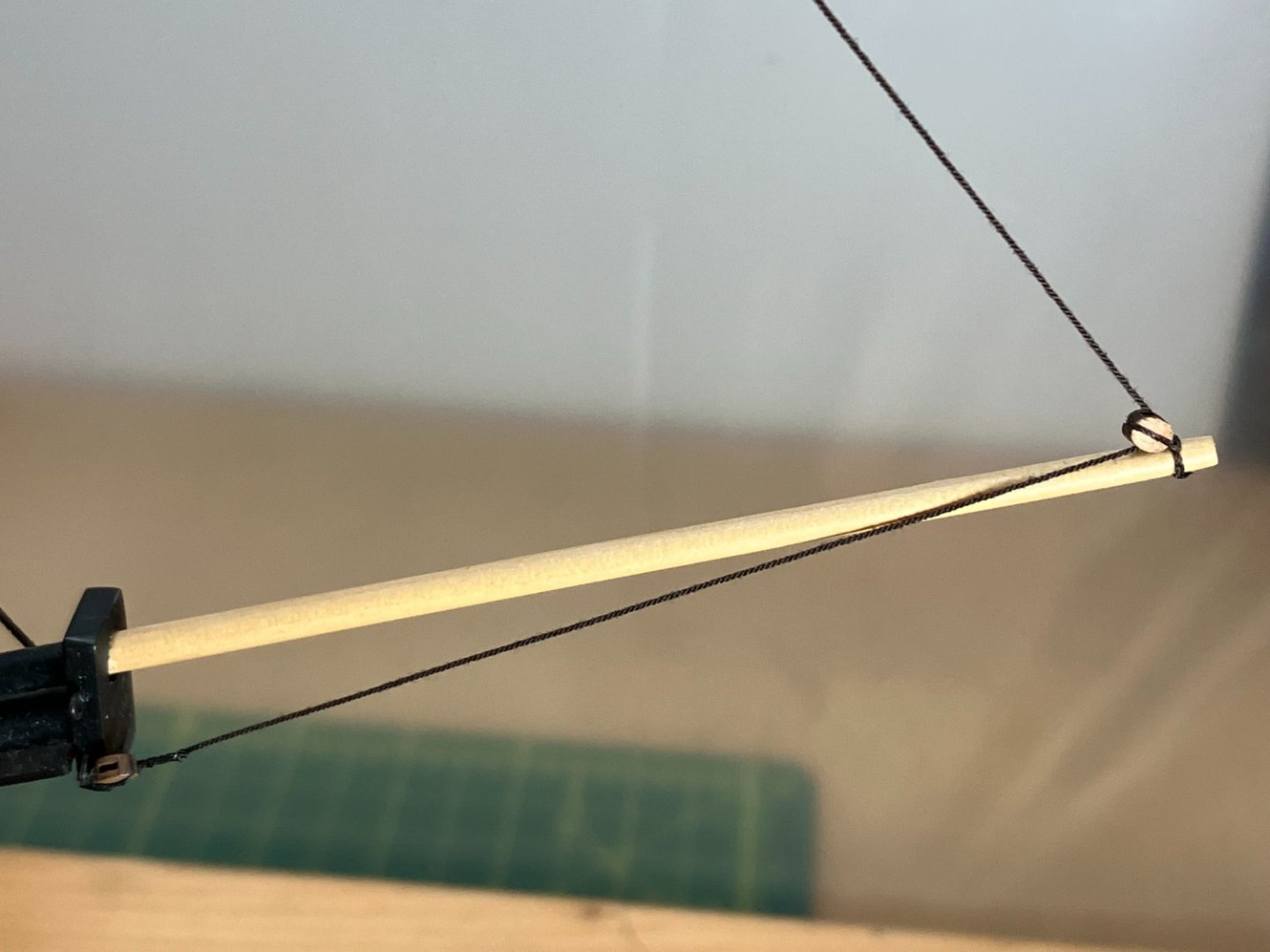

Crossing the Yards I crossed all the yards today. I'd already completed most of the work on them in advance so it didn't take too long. Here she is in the dust cabinet: Most of the work was fairly routine, so I'll just mention a couple of items. Getting the footropes to hang properly is always a challenge. I use dilute acrylic matte medium to wet the rope, with small pieces of bent wire hanging on it while it dries to try to get the right shape. However I did this before crossing the yards, and unfortunately the act of fitting them to the model undid a lot of the work so I'm having to re-shape the footropes in situ, starting with the topgallant yards: The topgallant footropes are the easiest to get right. I seized the first footrope on the yard and then, as there are no stirrups, I was able to slip this rope off the yard and use it as a template for the other side. The first rope is on the bottom in this shot, stretched between two drill bits, with the rope above being seized round the bits to create an exact copy. The left hand side has been completed, and the rope pulled tight and ready to be seized round the right hand bit. As usual I used fly tying thread for the seizings: As with previous builds I made my own parrel ribs for the topsail yards, preferring bare wood to painted brass. I originally found the method in The Fully Framed Model by David Antscherl and it is useful for other tasks where multiple copies of flat objects are required. For example I've used the same method for gun carriage sides. I think of it as the sandwich method, as you start by gluing strips of wood together to form a block that you then shape before separating the individual pieces. The individual ribs need to be 8.0 x 2.5mm. I cut 20 pieces from 0.6mm boxwood, slightly oversize to allow for trimming, and glued them into two blocks of 10 strips each. I needed 16, but wanted to allow for waste. I glued a kit rib to the front and back of each block as templates then drilled 0.75mm holes: Shaping with Swiss files was easy using the templates, after which I separated the strips by soaking the blocks in IPA: Rather than use the shiny black parrel beads from the kit I sourced some from the Spellbound Bead Co in the UK. They are closer to the size and barrel shape of parrel beads, and I found two colours that seemed close: In the end I decided the lighter beads were too shiny and metallic so I went for the dark matt ones. I started rigging them off the model. In this shot I've passed a single length of line round the yard between the sling cleats and started threading the ribs and beads: With eight ribs and seven pairs of beads threaded I held the parrels away from the yard so I could brush on some shellac: Here's the result on the model: And a final close up of the current state of play: I plan to do some work on the anchors next, as a bit of a break from rigging. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

A superb addition to your fleet Glenn. I’m not usually keen on sails, but yours help to make her a very attractive model. Derek

- 106 replies

-

- Erycina

- Plymouth Trawler

-

(and 3 more)

Tagged with:

-

Looking very smart Glenn. Your rigging has come on leaps and bounds. Derek

- 106 replies

-

- Erycina

- Plymouth Trawler

-

(and 3 more)

Tagged with:

-

Topgallant stays Thanks everyone - much appreciated. The fore and main topgallant stays were straightforward. Both start with simple eyes slipped over the topgallant masts and brought down to rest on the backstays and shrouds. The main then roves through a 3mm block lashed to the head of the fore topmast, shown in the photo below: The stay terminates in a thimble tackle hooked to the foretop (apologies for the focus): Note the Quadhands in the background. Being able to take 'hands' off the baseplate and mount them on spare bits of iron is invaluable in the confined space of the dust cabinet. The fore topgallant stay roves through a 3mm block rigged round the groove in the end of the jibboom, passing fore to aft through the block, then belaying to a hook in the fore face of the bowsprit cap: That's the bulk of the standing rigging finished. Next I'll concentrate on crossing the yards. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Topgallant shrouds & Backstays Thanks guys - much appreciated! These are straightforward shrouds, not needing any ratlines. Although there is an odd number of shrouds - three - on both sides of both masts, the shrouds are still set up in pairs - two each side. That's because the aftmost leg of each pair becomes the topgallant backstay. You just have to remember that this leg needs to be considerably longer than its companion. I'm not sure this practice is recognised in the kit instructions where the topgallant backstays seem to feature as separate items, but my understanding is that this was the way it was done at the time. In theory the central portion of each pair should be served as per the lower masts, but I don't like serving such light line (I used 0.40mm), partly because it's difficult but also the result looks too heavy. On Speedy I experimented with using fly tying thread to serve the line which avoided the bulkiness, but it was so hard to tell the difference between served and unserved line I concluded it wasn't worth the effort. The shrouds rove through the holes in the cross trees and are then led round the futtock staves and the ends seized to the topmast shrouds. An innovation that came in towards the end of the eighteenth century (and is suggested in the kit instructions) was to lead the topgallant shrouds down to the tops where they were tied off to the lower deadeyes, presumably for ease of access when they needed adjustment. I thought that might look a bit messy so I stuck to the older method. On both masts, the backstays ended in a thimble lashed to another thimble hooked close to the main and fore channels: As usual, I haven't tightened any of the stays yet, preferring to wait until they're all rigged and I can make sure everything is balanced. Here's the current state of play: Topgallant stays next. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Topmast stays Thanks as always for the likes and kind comments. I rigged the stays from aft to fore, starting with 0.40mm line for the mizzen (3 X Mara100) . One end of the stay is seized round the head of the mizzen topmast, this end being served for about six (scale) feet beyond the eye. The other end was reeved through a block seized round the main mast, just below the hounds. This end has a thimble seized into it, which in turn is lashed to another thimble hooked to an eyebolt just abaft the main bitts. I used Mara150 for the lashing (about 0.20mm): (Just notice some ratline knots I'll need to fix!) I've previously always made my own thimbles from copper tubing (eg Speedy log here). However I was impressed by the quality of the wooden thimbles in this kit and so was happy to use them. The main topmast has both a stay and a preventer stay, each fitted with a mouse in imitation of their big brothers at the main top. I used 0.65mm and 0.50mm line for these two stays (9 X Mara150 and 3 X Mara70 respectively), serving each to about six scale feet below the mouse. I made the eye in the end of each stay and the mouse in the same way as I described for the main stay (here), with one minor variation. Previously when making a mouse I'd used my metal working lathe with a drill bit in the tailstock to make the hole through wooden dowel prior to shaping it. This time I decided that it would be easier, given the small workpiece and low powered machine involved, to perform this operation on the Proxxon lathe, simply by holding a drill bit by hand and pushing it against the dowel. I'd marked the centre of the dowel with a pointy tool and this was sufficient to keep the drill in place as it made the initial cut: I used a 0.90mm bit to give clearance for the served line. Then it was on with the turning tools to create the shape and size (aiming for the mouse to be about 3X the diameter of the stay): Here's the stained result - I will darken these further to match the stays: The stays then rove through blocks seized to the fore mast before having 4mm double blocks seized into their ends. With eyes and mice on the other ends, it is not possible to do this operation off the model. As usual, Quadhands proves invaluable (this is the fore topmast stay, but the idea is the same): As usual, I used 18/0 fly tying line for the seizings (or more accurately, to fake the look of a splice). The tackle for the main topmast stays consists of the double block and a single 3mm block seized to a hook. Opposite the hook I created a loop (becket?) in the strop using a 0.90mm drill bit and CA, as previously described. For the tackle line I used 0.25mm Mara100 seized to the becket: The tackle is then hooked to eyebolts, one either side and just abaft of the foremast: Here, I've temporarily jammed the spare line into the pinrack. The fore topmast stay and preventer stay are made of the same size line and are also seized and fitted with eyes and mice. They rove through the bees then end in similar tackles to the main topmast stays, hooked to eyebolts either side of the bowsprit. This time the spare line is temporarily hitched around a timberhead: Here's the current state of play: Photography inside the dust cabinet isn't great, but at least the rigging is starting to take shape. On to the topgallants next. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Crowsfeet & Topmast Backstays Thanks guys. I decided to stick with the 6/0 fly tying line for the crowsfeet. Here's the current state of play, with the crowsfeet on all three masts (now that I've started the rigging in earnest I've put the model in my dust cabinet, which makes photography a bit trickier): I've also rigged the topmast backstays, seen above with the small clips holding the laniards in place prior to final adjustment. Each backstay is made from a single line (I used 0.50mm for the mizzen and 0.65mm for the main and fore masts) fitted with a horseshoe splice in the middle to fit over the masthead: I served the central 40mm of each line, and created the horseshoe by splicing in a short 6mm length of line to form the straight piece. Here's a description of the method I used. I seized a 3mm deadeye into the end of each backstay and used 0.30mm for the laniards connecting them to the deadeyes already fitted to the channels: Topmast stays next. Derek

- 341 replies

-

- Duchess Of Kingston

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I use a similar routine. I have a couple of ships in cases, but in a perverse way I quite enjoy getting reacquainted with my other models when I have to dust them. That, and the fact that I simply haven't got round to casing them yet 😁. Your Vanguard figures look great. I've got a set but have yet to paint them - not something I've done before, so I'll be resorting to Youtube to hopefully find some lessons. Derek

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

-

Thanks Ron. I'll try and lay the blame on you but I'm not sure it'll wash. Too late I'm afraid. This is our entrance hall - Speedy was only meant to be there temporarily but somehow temporary has turned into over a year: Most of the pictures in the house are of ships and other maritime themes, which doesn't help. My last-ditch tactic will be to remind Karen that she bought me Sphinx as a present so ultimately it's her fault. But that's not a line I'll take unless I'm desperate (and preferably outside throwing distance!). Derek

- 542 replies

-

- Sphinx

- Vanguard Models

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.