-

Posts

6,036 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by James H

-

Ranger is now completed. It's taken me well over 2 weeks longer than I expected due to illness, hospital etc! This has been a beautiful model to build and very, very easy. Nothing here is at all taxing and she's perfect for anyone who's never built a model before, as are all the fisher kits. I do very much like this one though. I do find them easy after doing six of the fishers though! Anyway, here we go. These photos are very self-explanatory. Here she is, now finished. The little boat on deck does come with the kit too.

- 16 replies

-

- Ranger

- Vanguard Models

-

(and 2 more)

Tagged with:

-

I use thinned PVA for mine. Just a drop of water in a little squeeze bottle filled with PVA.

-

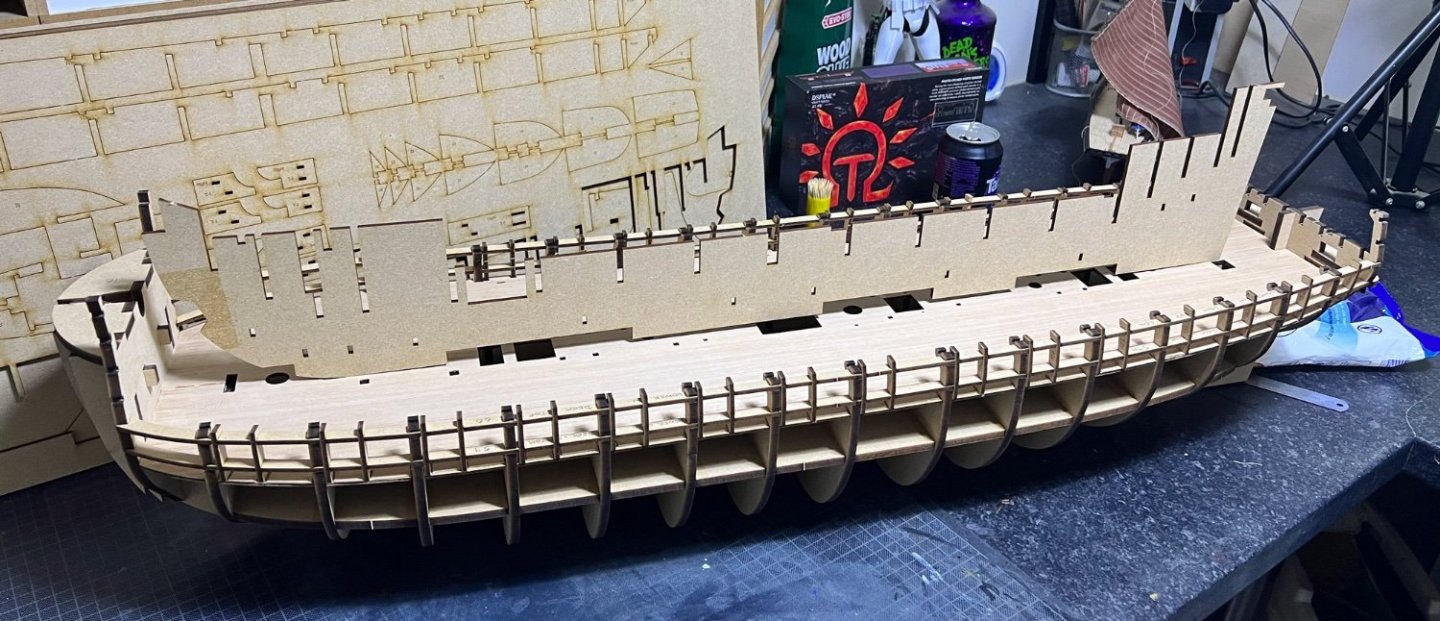

Hull length is around 880mm, I'm told. (minus bowsprit)

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

In all fairness, can that engraving be trusted as evidence? After all, it shows round gun ports on the quarter too. Also all main gun deck ports seems to be lidded on that illustration.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

That really is a very pretty little model.

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

That is a certainty! The manual for Sphinx is 152 pages with about 1000 photos and 27500 words. Over 900 construction stages. I think Indy will easily top that with another 50+ pages. It remains to be seen yet, but there are no corners being cut whatsoever.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

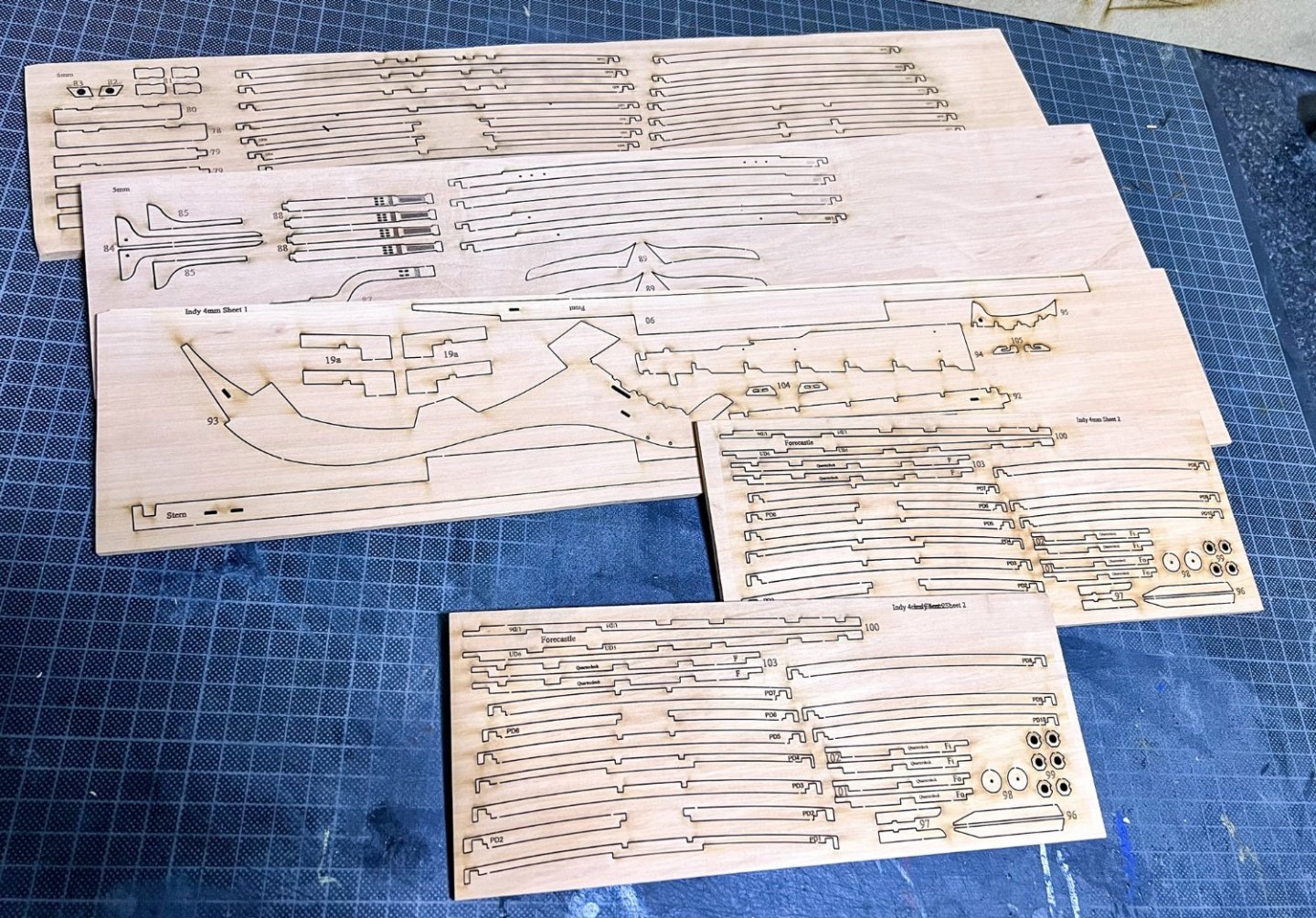

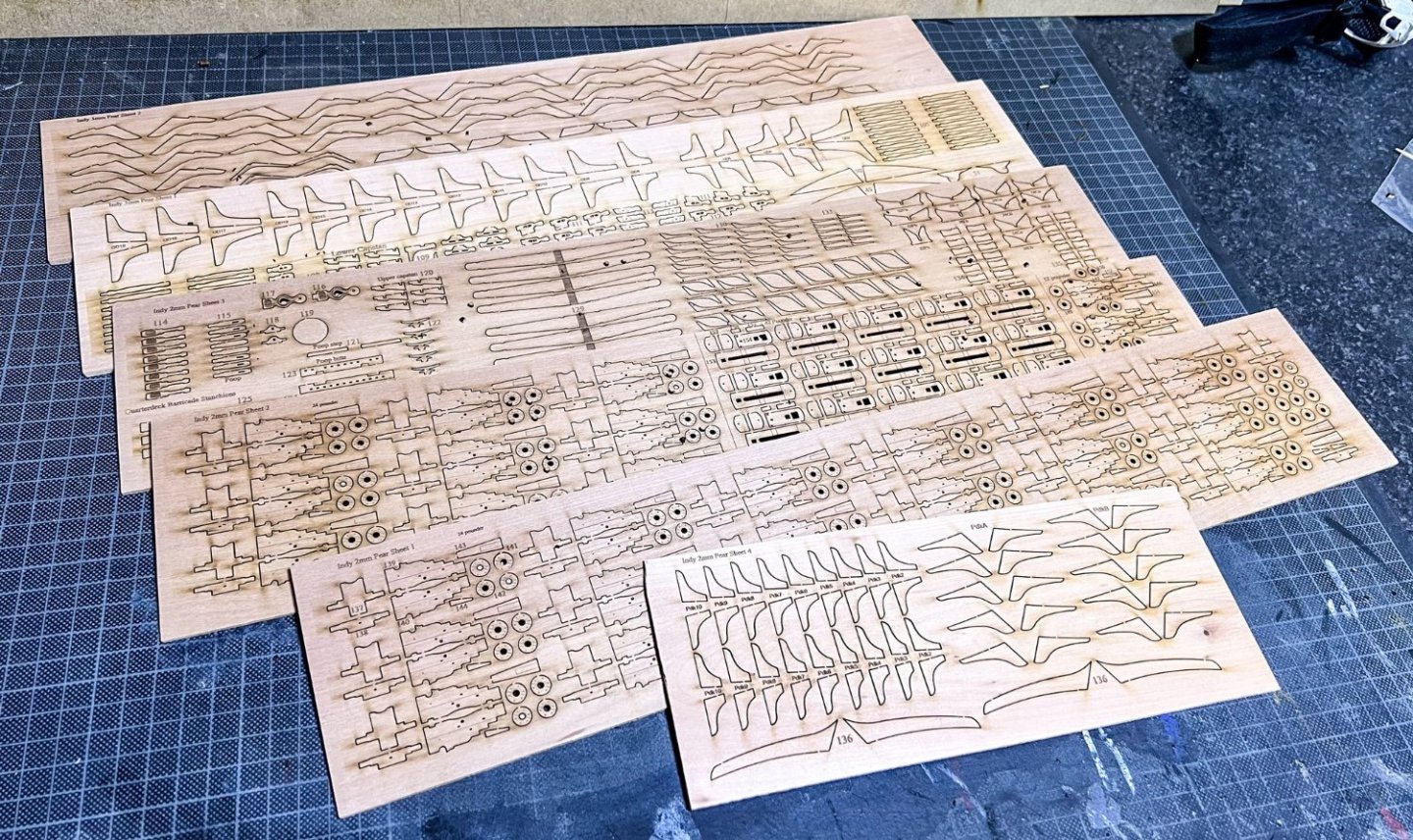

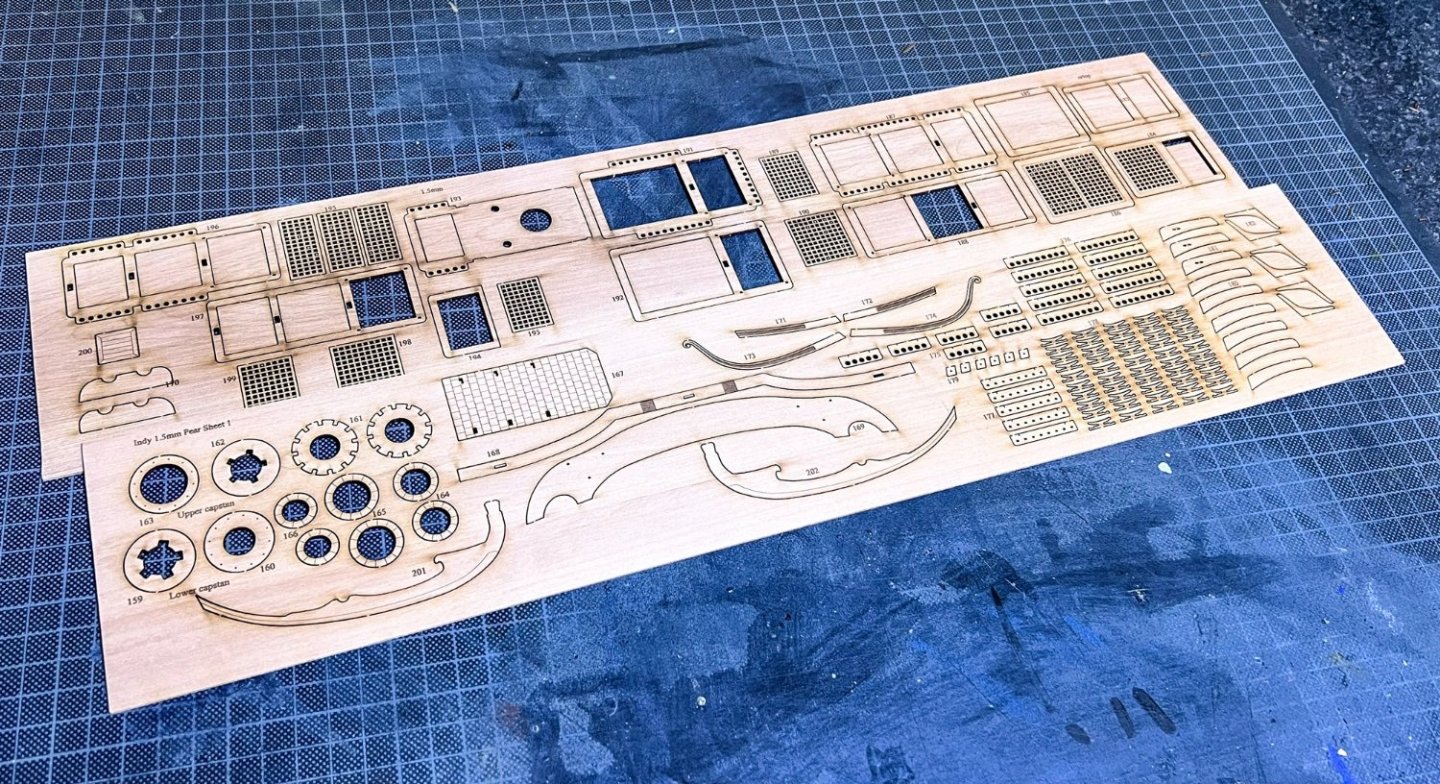

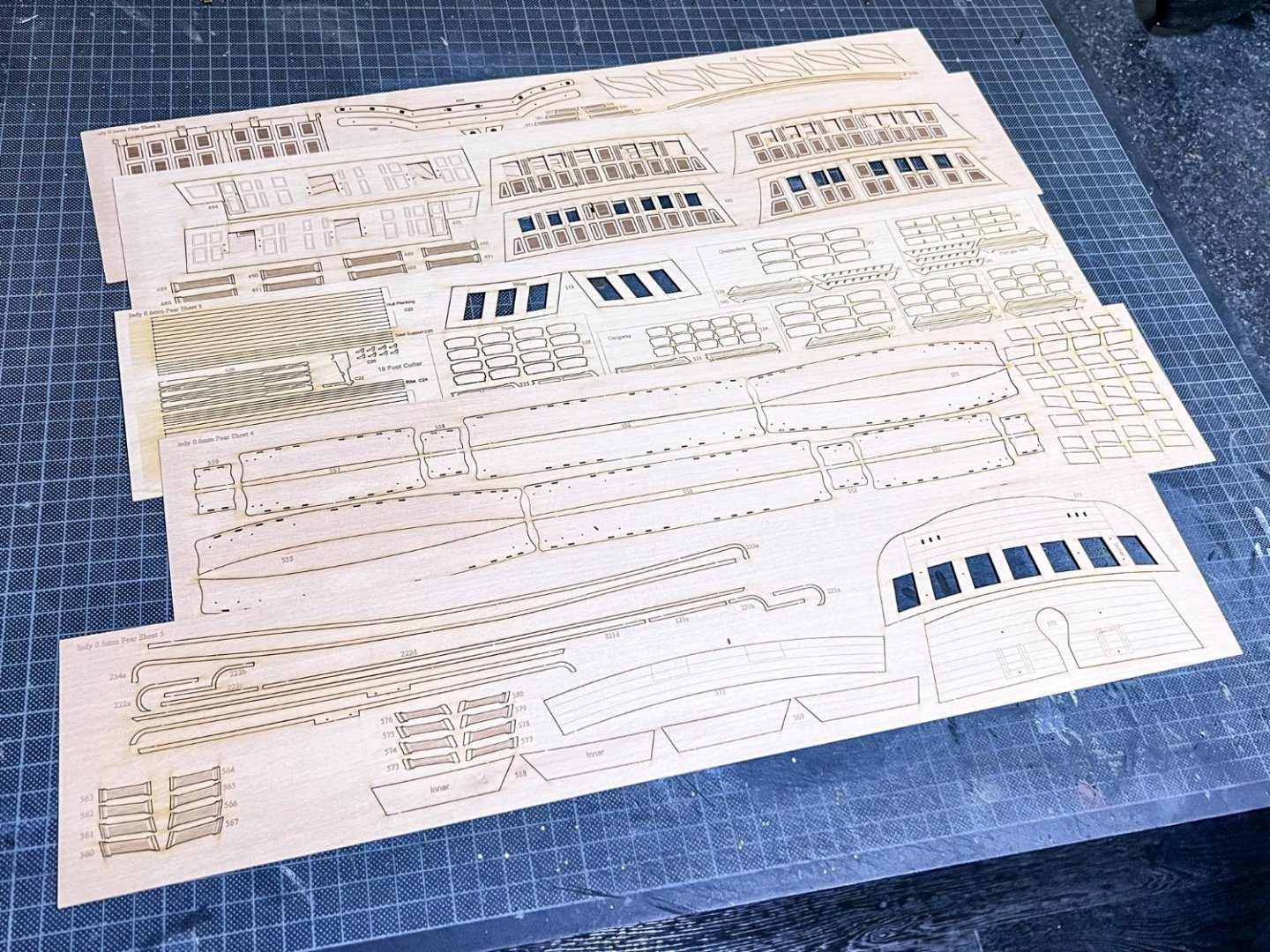

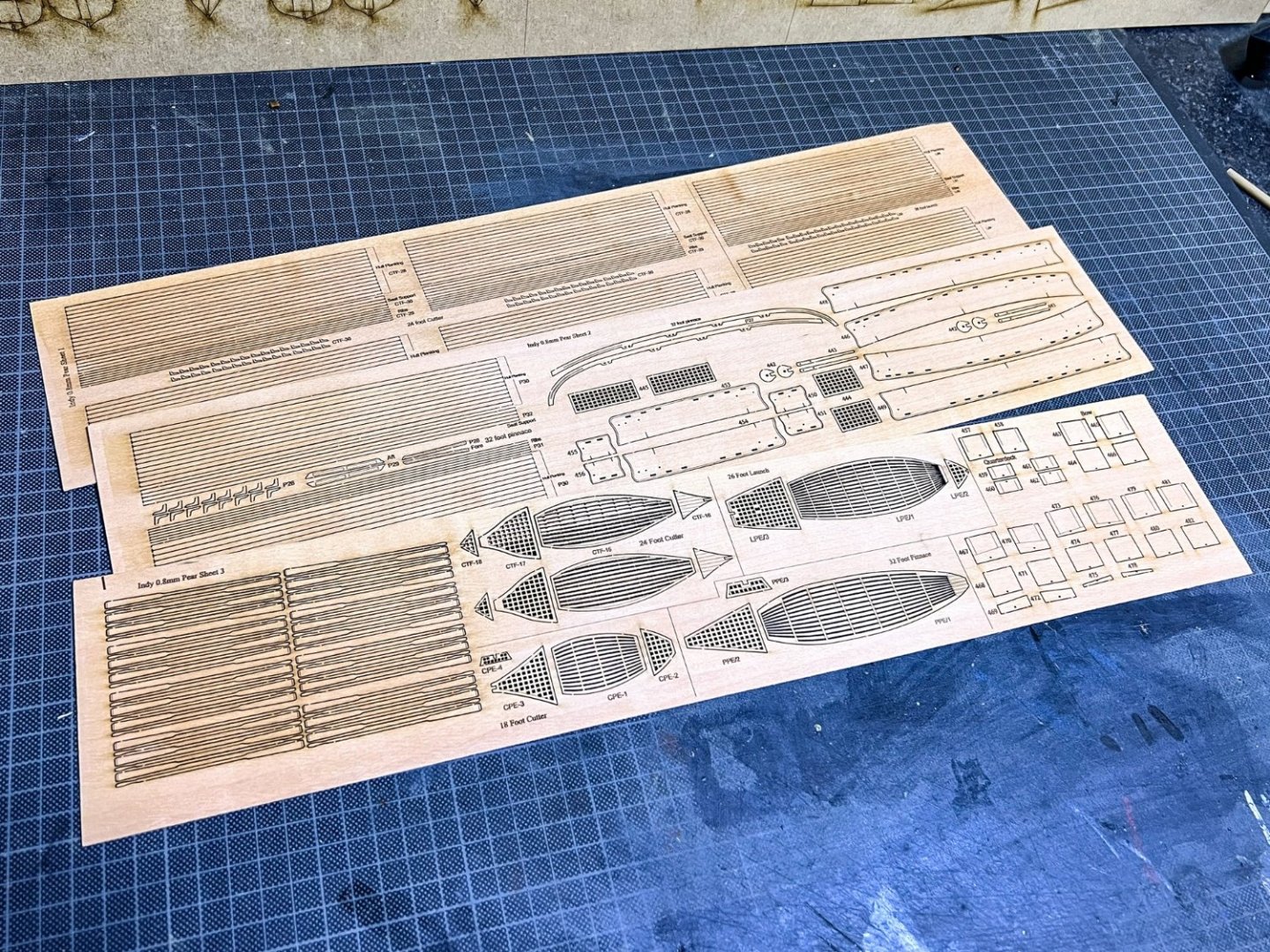

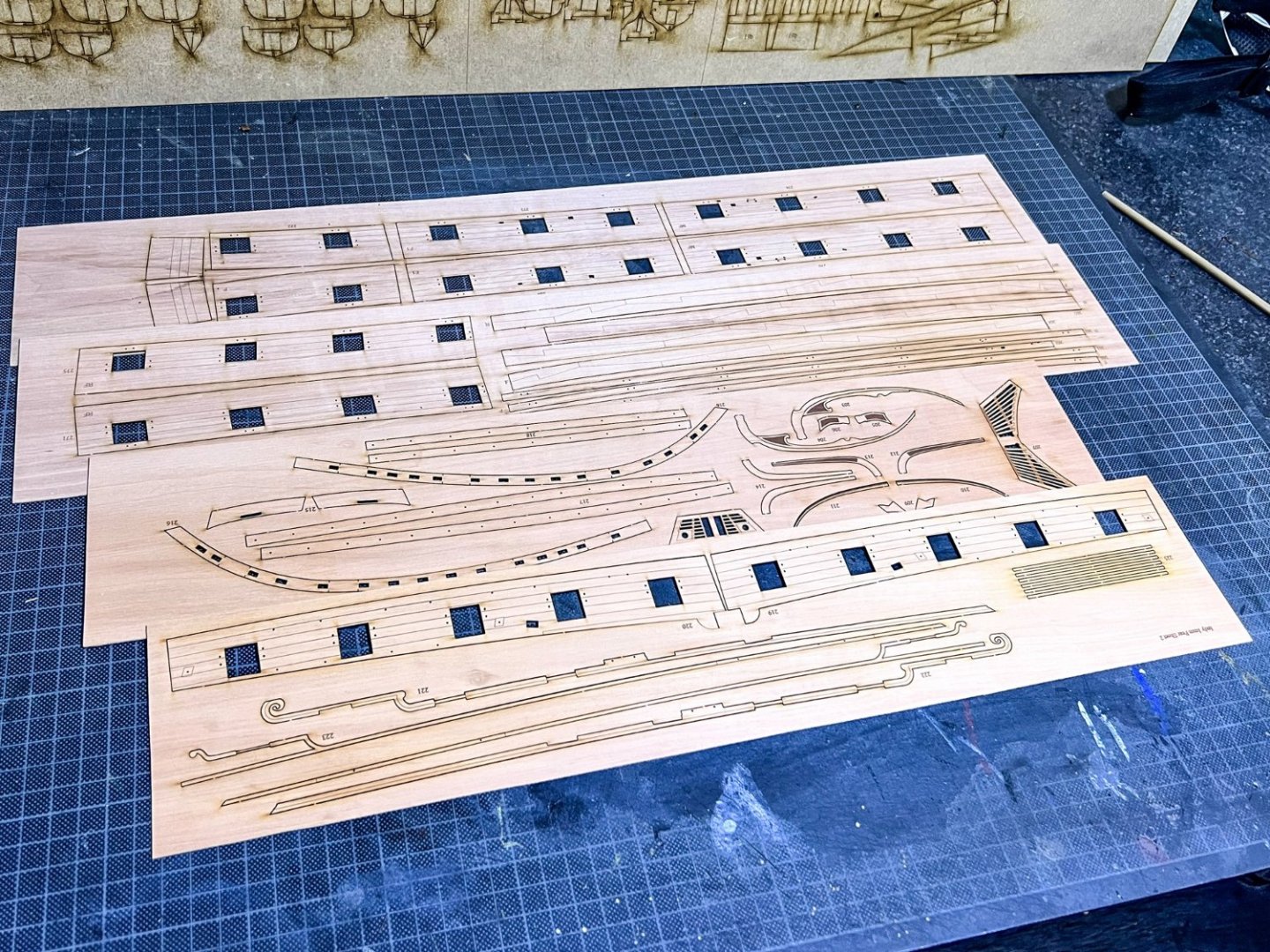

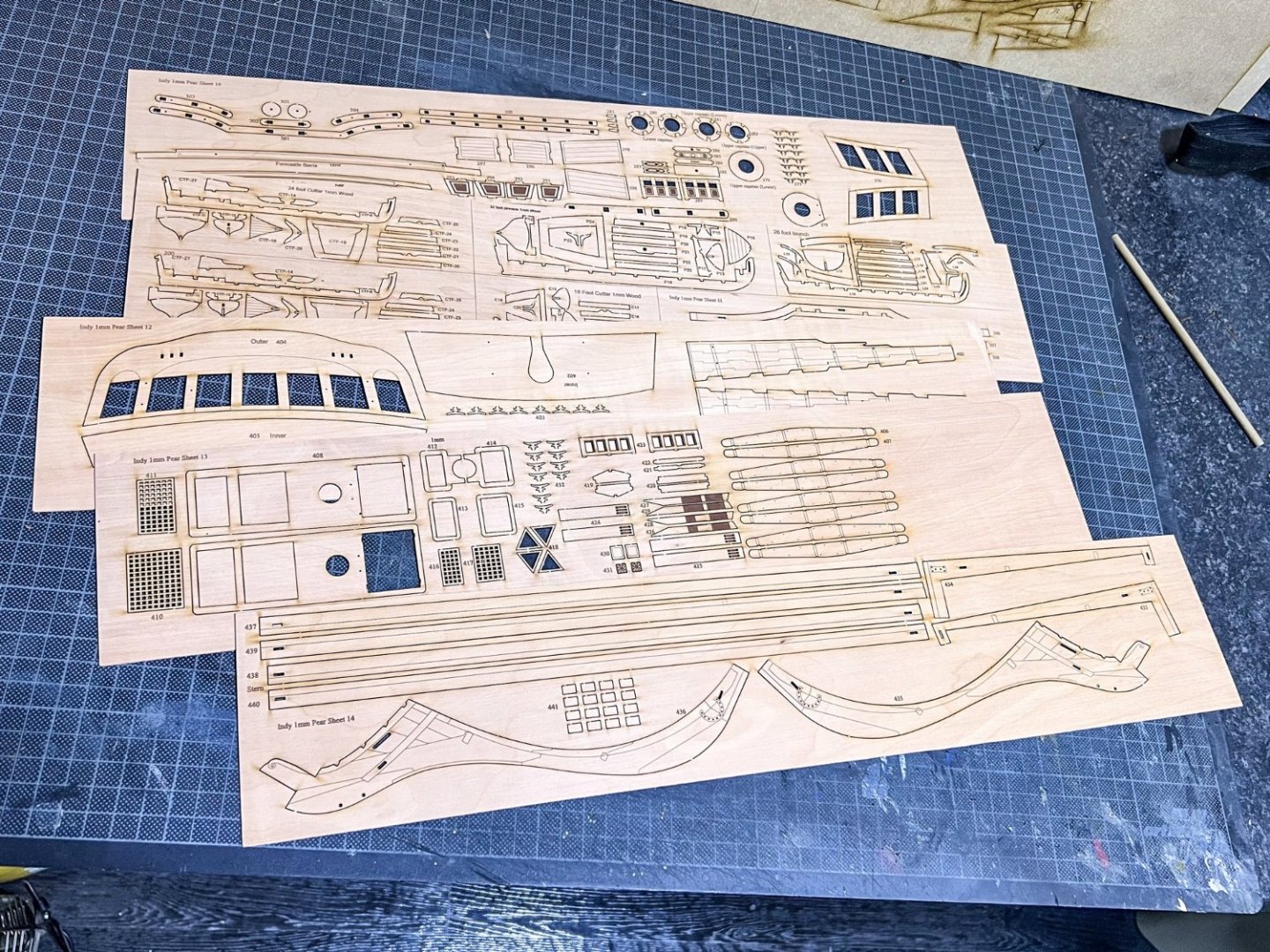

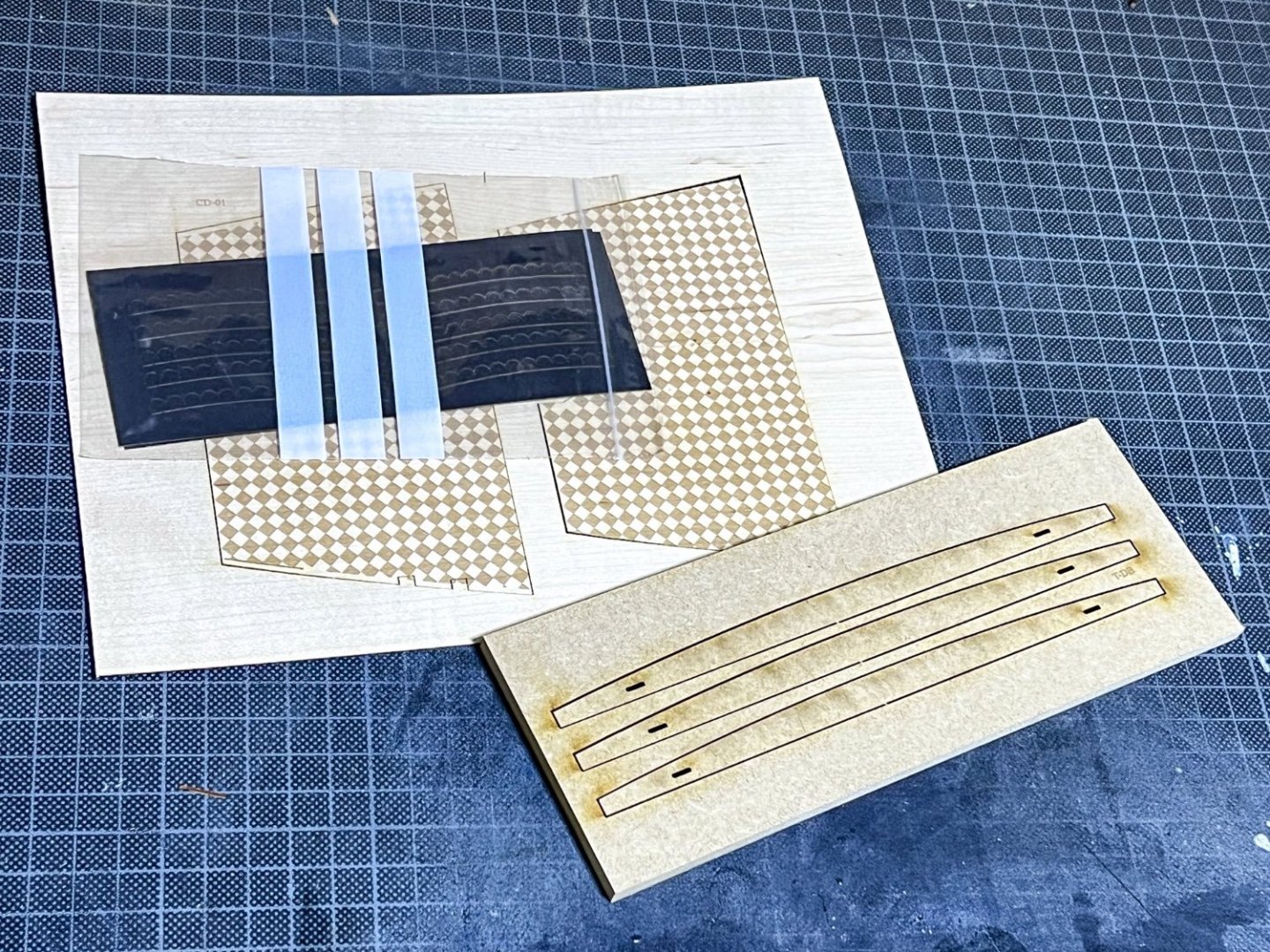

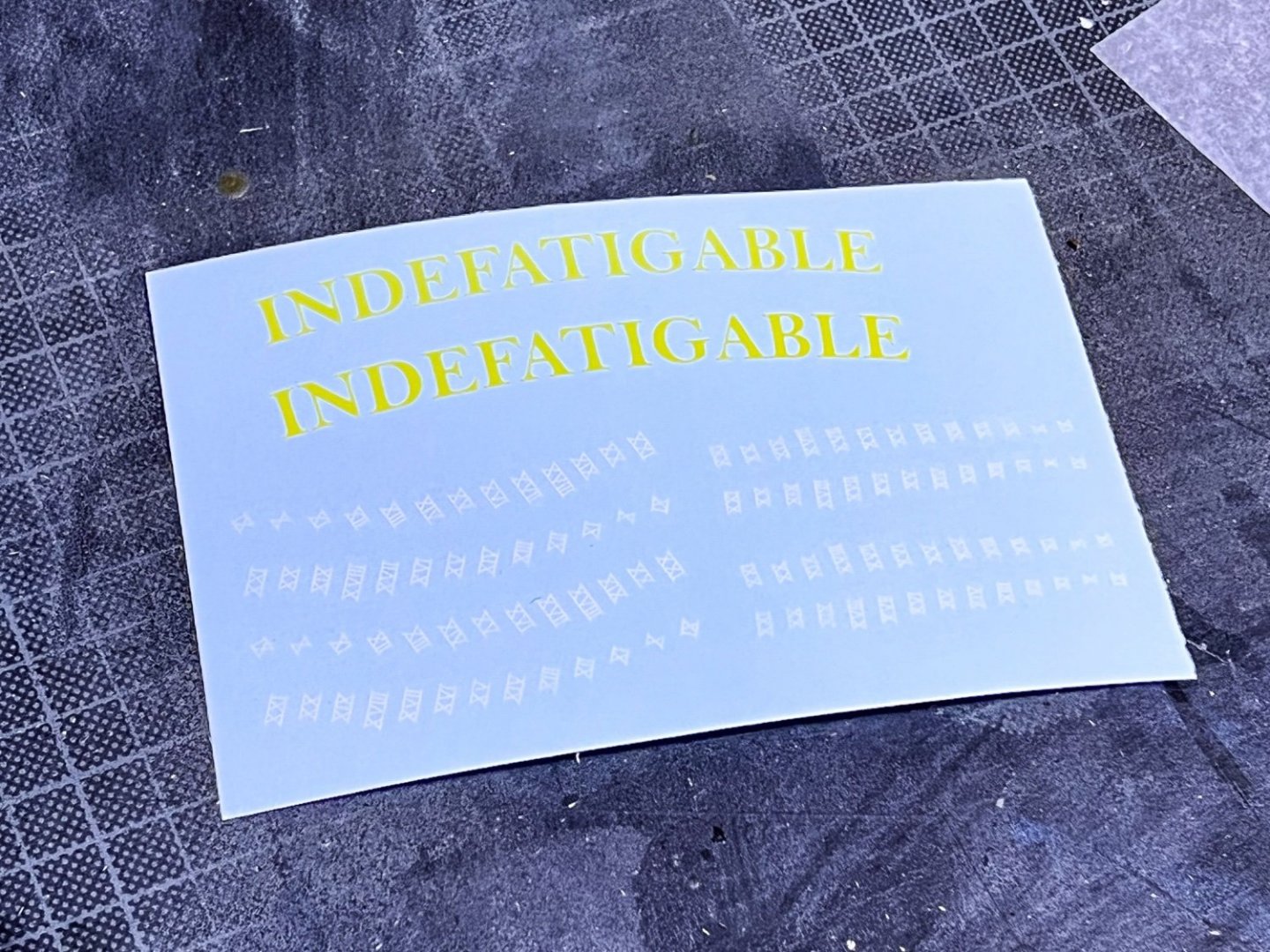

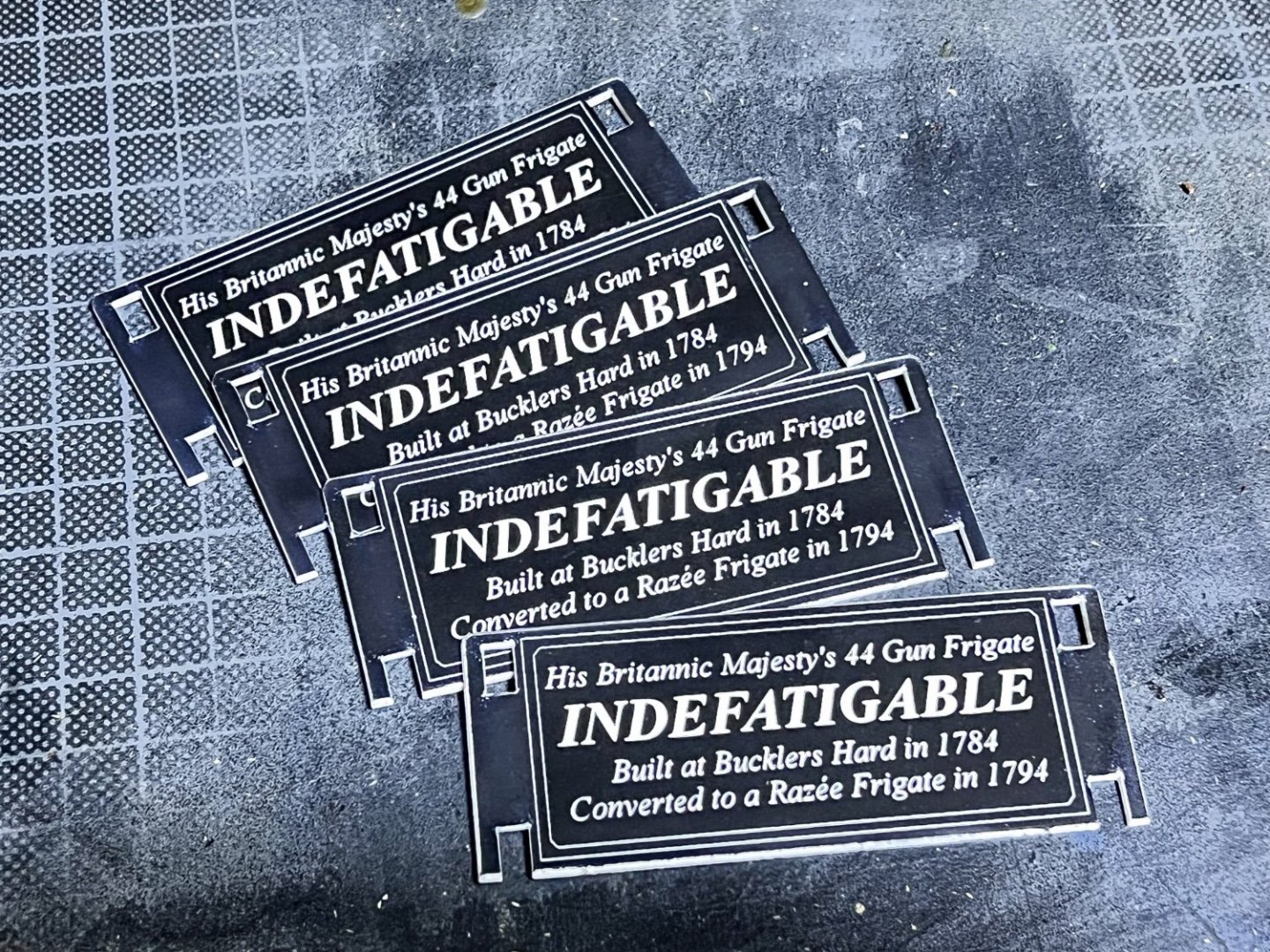

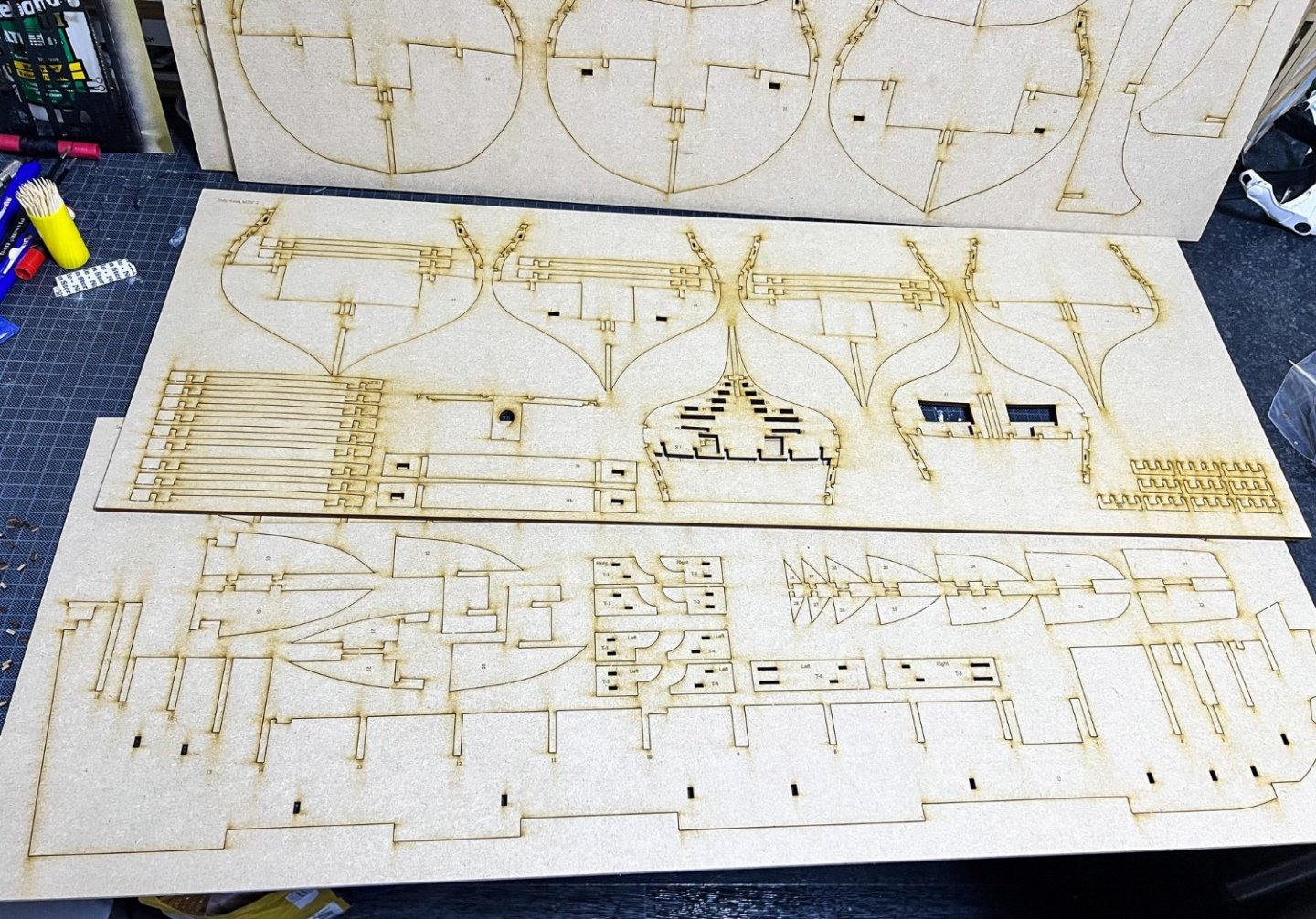

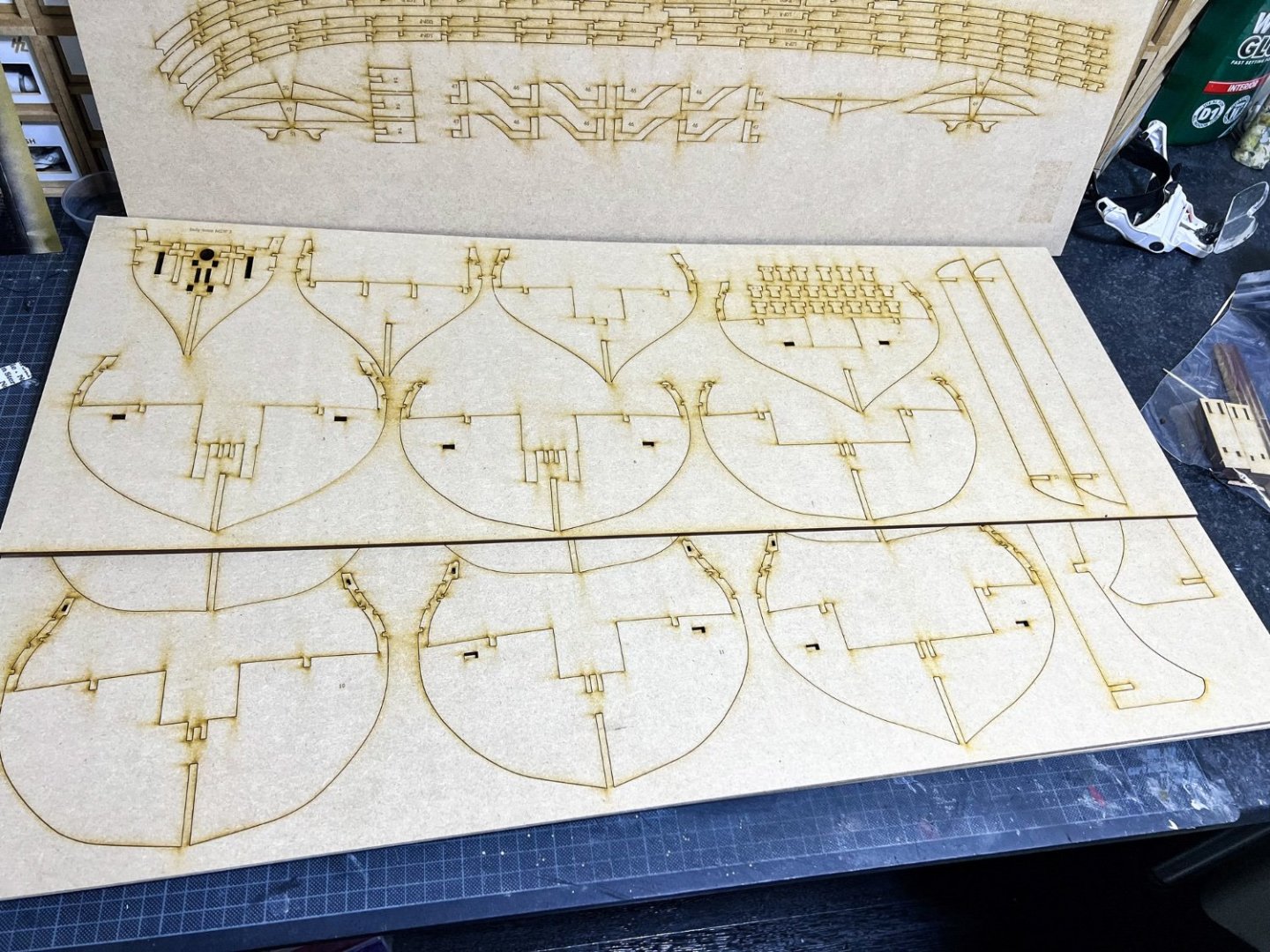

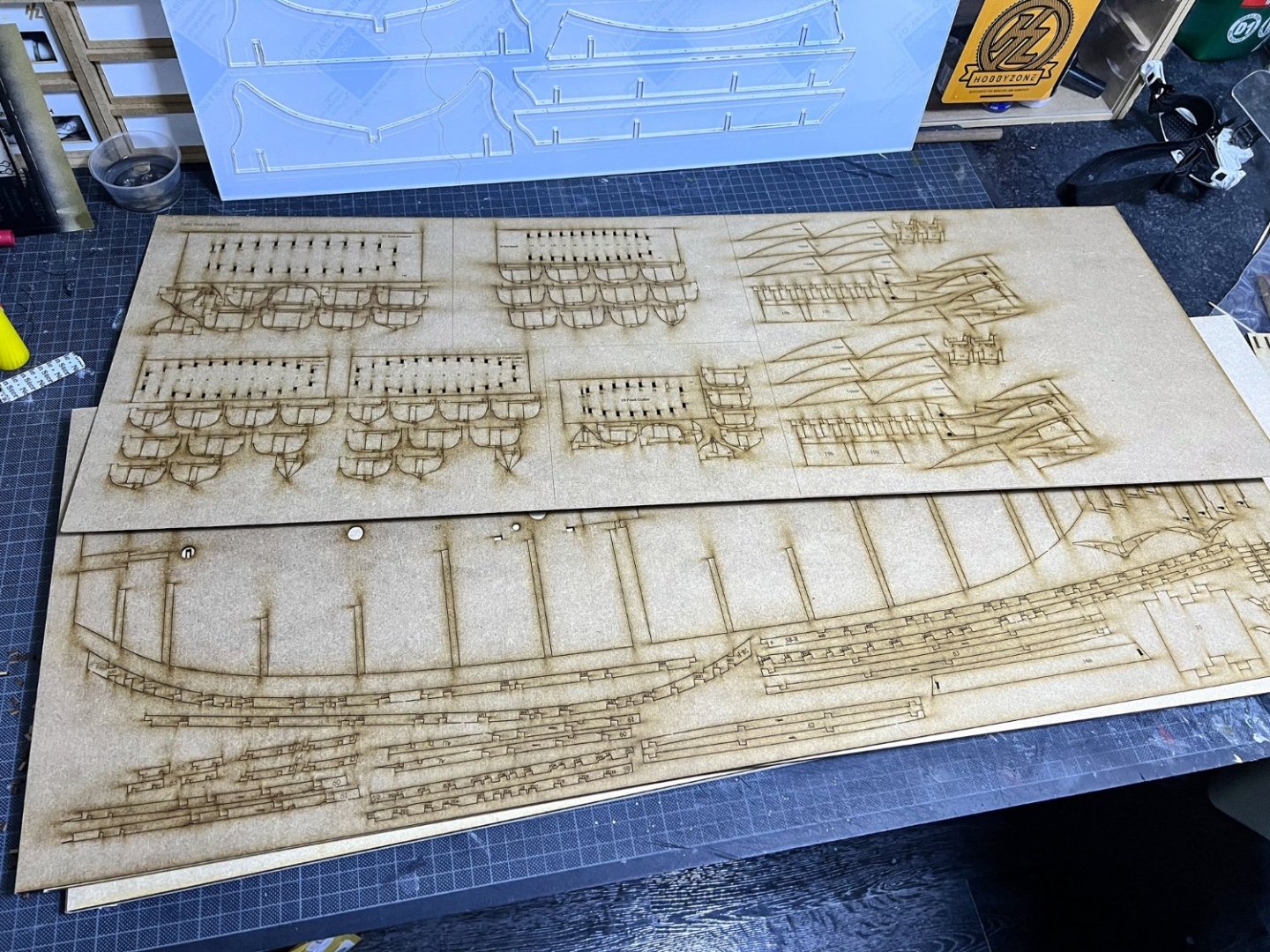

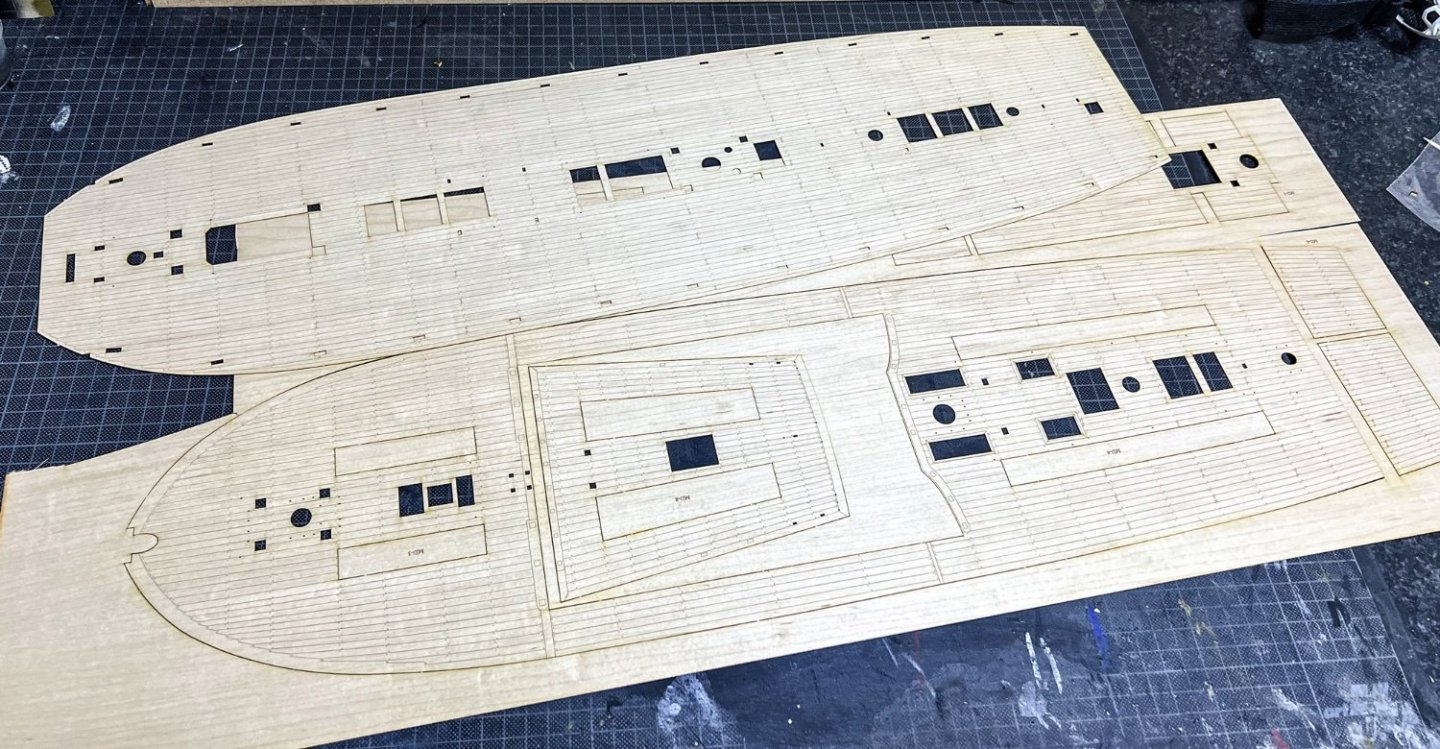

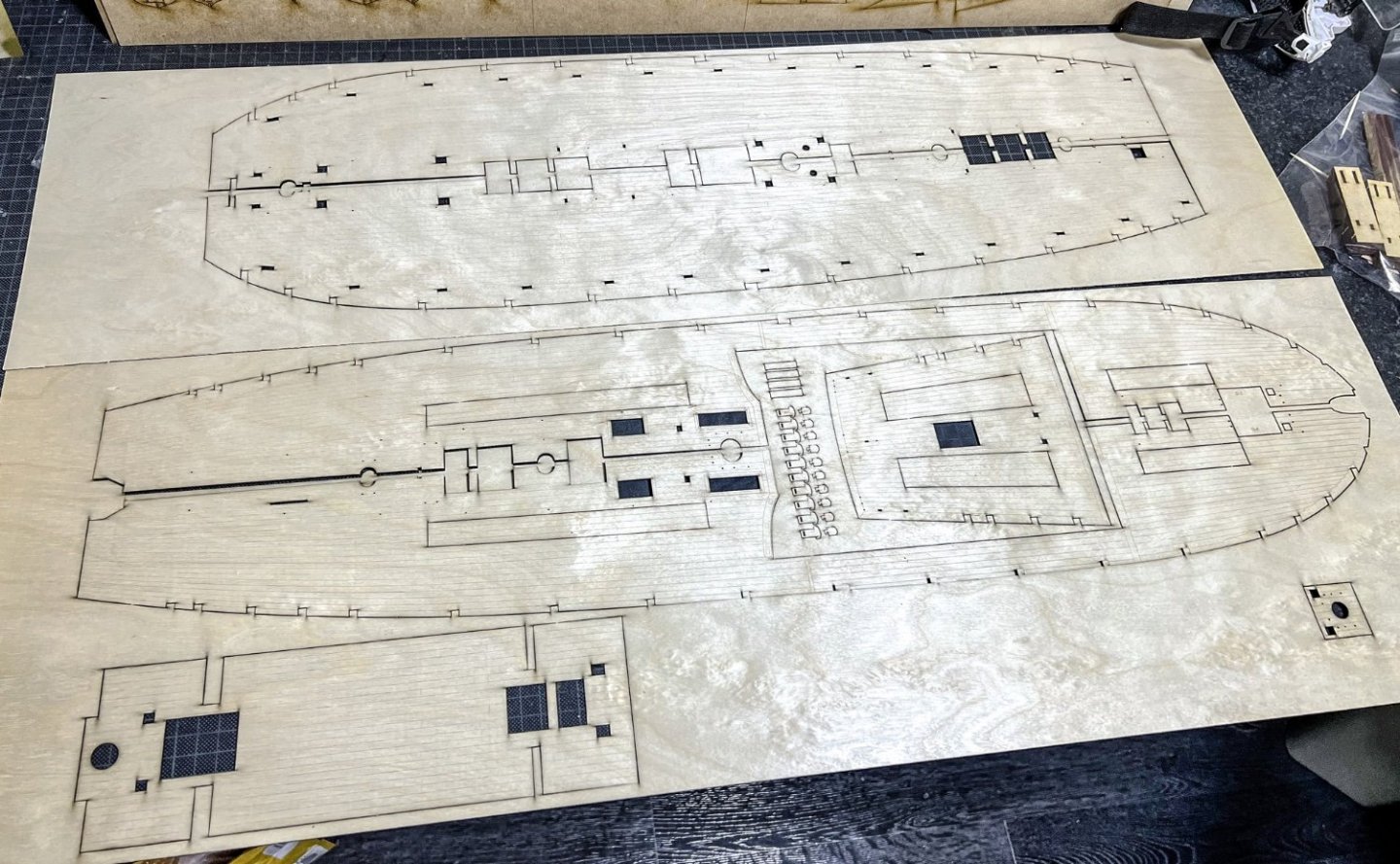

Continued. I've grouped most of these photos into thickness of sheet, and there are a lot of various thicknesses with multiple sheets for them. You can see the tabbed gun carts here too. Those tabs are on the forward 'bulkhead', closest to the inner bulwarks. You're going to have to make FIVE ship's boats for this one! Inner bulwarks are split into three sections to cover the entire length. There will also be doorways from the cabin into the quarter galleries. 3D printed stuff, like belfry, anchors etc. and I do see some copper tape there too. Quirks of prototyping. Various cabin floor sections. LOTS of strip too. Decals for name and depth markings. Also, there is no white edge on that text. It's merely the light catching the ink edging! I have checked.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

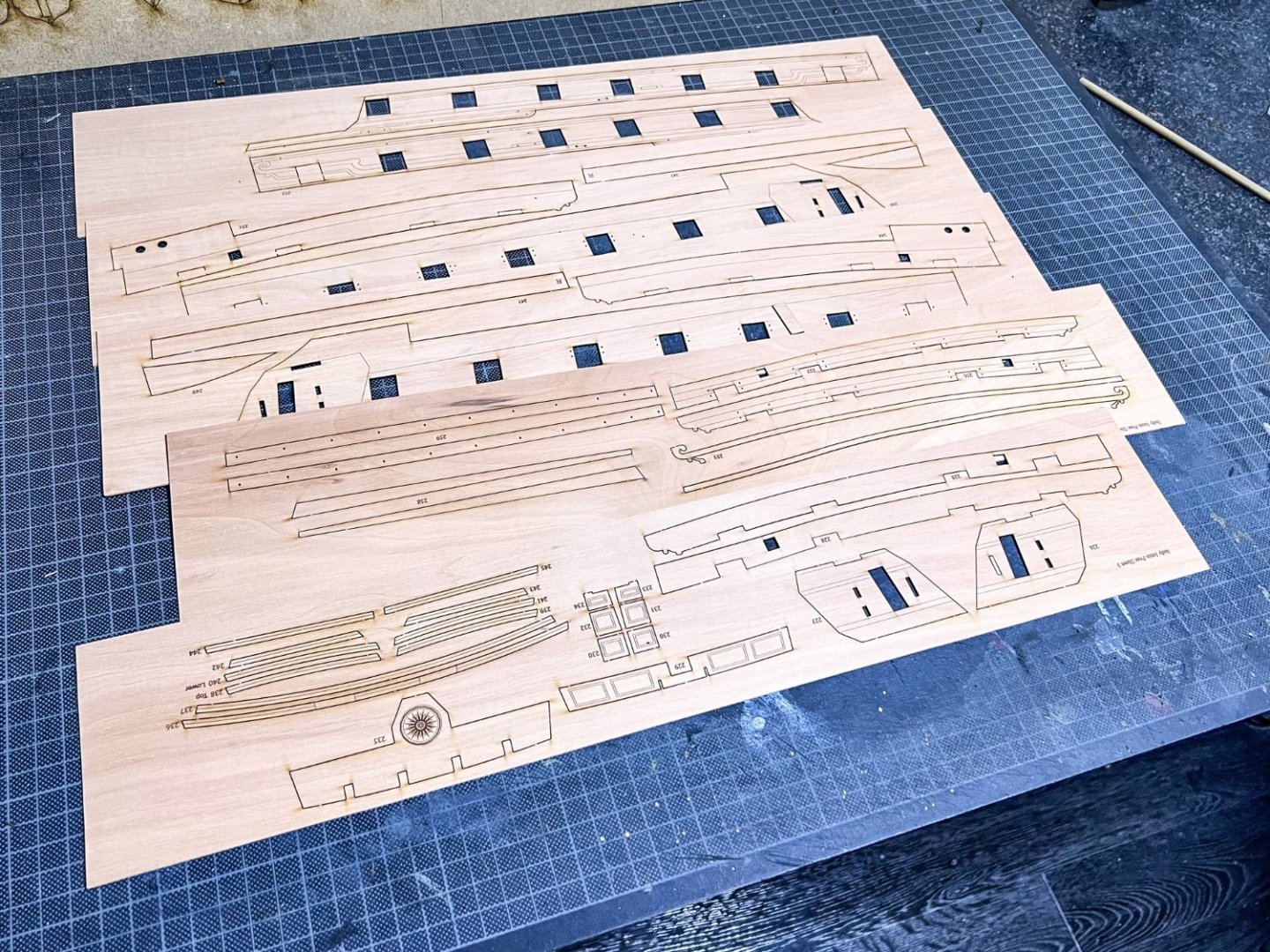

Time for a quick update. This will be the last one before work starts very shortly. I'm making this update over TWO posts due to number of pics. These are just camera photos and won't represent anything you see in the manual. Indy turned up with UPS this morning, and the box is large and heavy. In fact, the box isn't large enough yet as the masting, rigging, manual and plans also need to be included, as well as PE etc. The box was packed out as it was. This one took up two seats on my sofa. Take a look through and you'll notice some little things here and there. One of those is that the main gun deck carriages are tabbed so they slot into the deck and can't be knocked free later in the build. This is only an optional feature as the modeller can, if they wish, plank over the tab slots and remove the tab from the carriage. That would be up to the individual but this is a perfectly good solution that will be invisible when implemented. If also means the guns will be perfectly spaced too and the barrels therefore evenly protrude from the hull. Those barrels will also be fitted after the hull is painted, so attaching them later won't dislodge a gun cart. This is the engraved maple deck which won't be included as standard, unlike the other kits. This kit will have traditional planks for the deck, but it is quite likely that this option will be provided on release. If that happens, then the gun carriage location slots aren't likely to be there, and you'll simply open them up if you want use that kit feature. Oh, these parts are BIG!! My cutting mat is in 1cm squares, as a guide. Not fantastically clear here, but the ply sub decks are engraved with planks. This isn't the finish. It's designed to give you a template onto which to lay the kit planks. That will save the modeller having to mark up stuff themselves.

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Questions Before I Buy My First Ship

James H replied to Magarkus's topic in New member Introductions

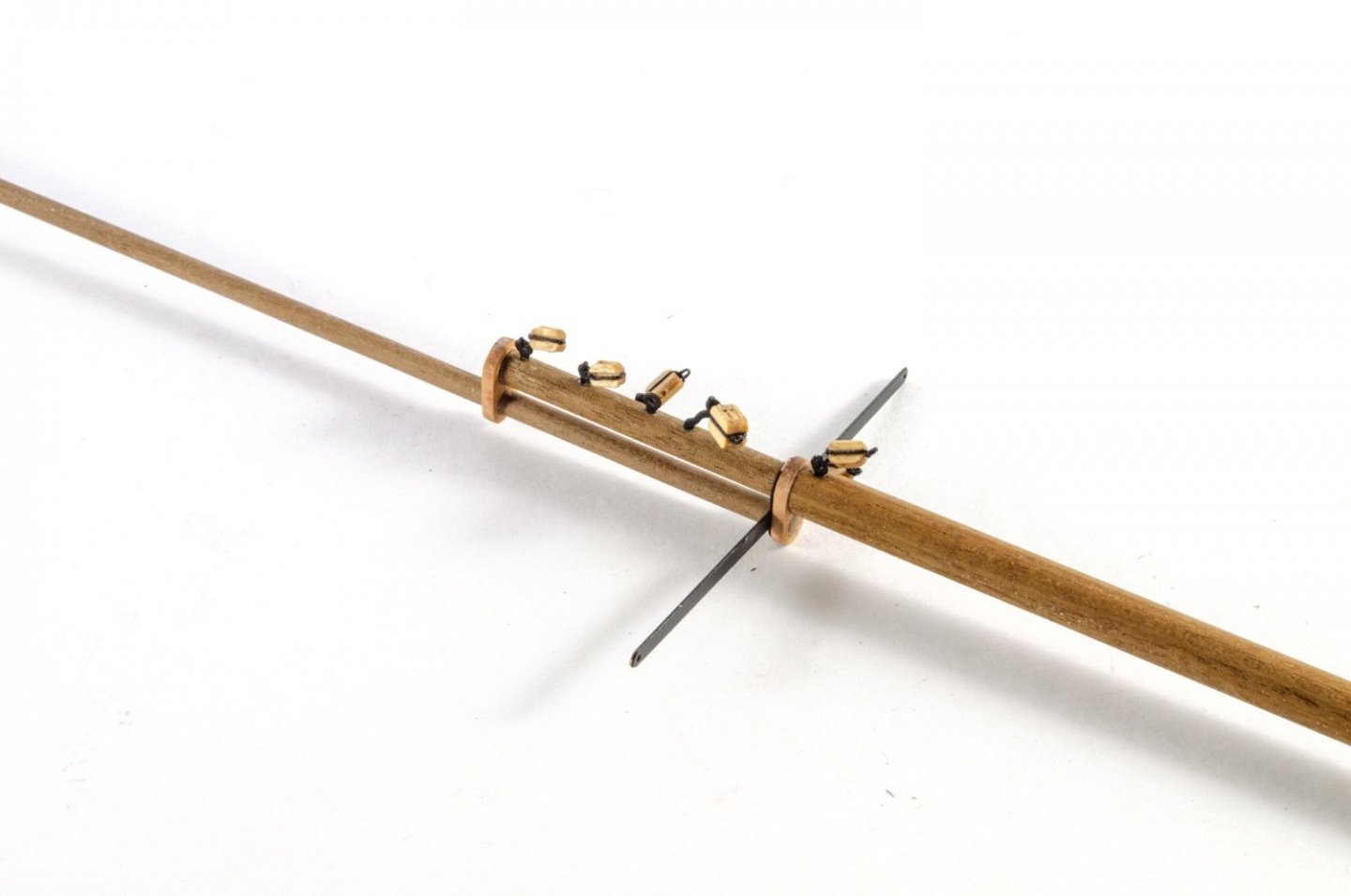

I don't really use much in the way of tools for what I do. To build VM prototype kits, I use: Scalpel knife sanding block and sandpaper tweezers steel rule clamps - 2inch and 4inch nail pusher pin vice with selection of drills long nose pliers needle files waterline marker I do have a plank nipper for occasional stuff, but really use it. They are cheap enough though. Most of what you see there is very basic and quite inexpensive. -

lol! I really don't think that's the remit of any kit! I've certainly never, ever seen that from any manufacturer.

- 476 replies

-

- sphinx

- vanguard models

-

(and 1 more)

Tagged with:

-

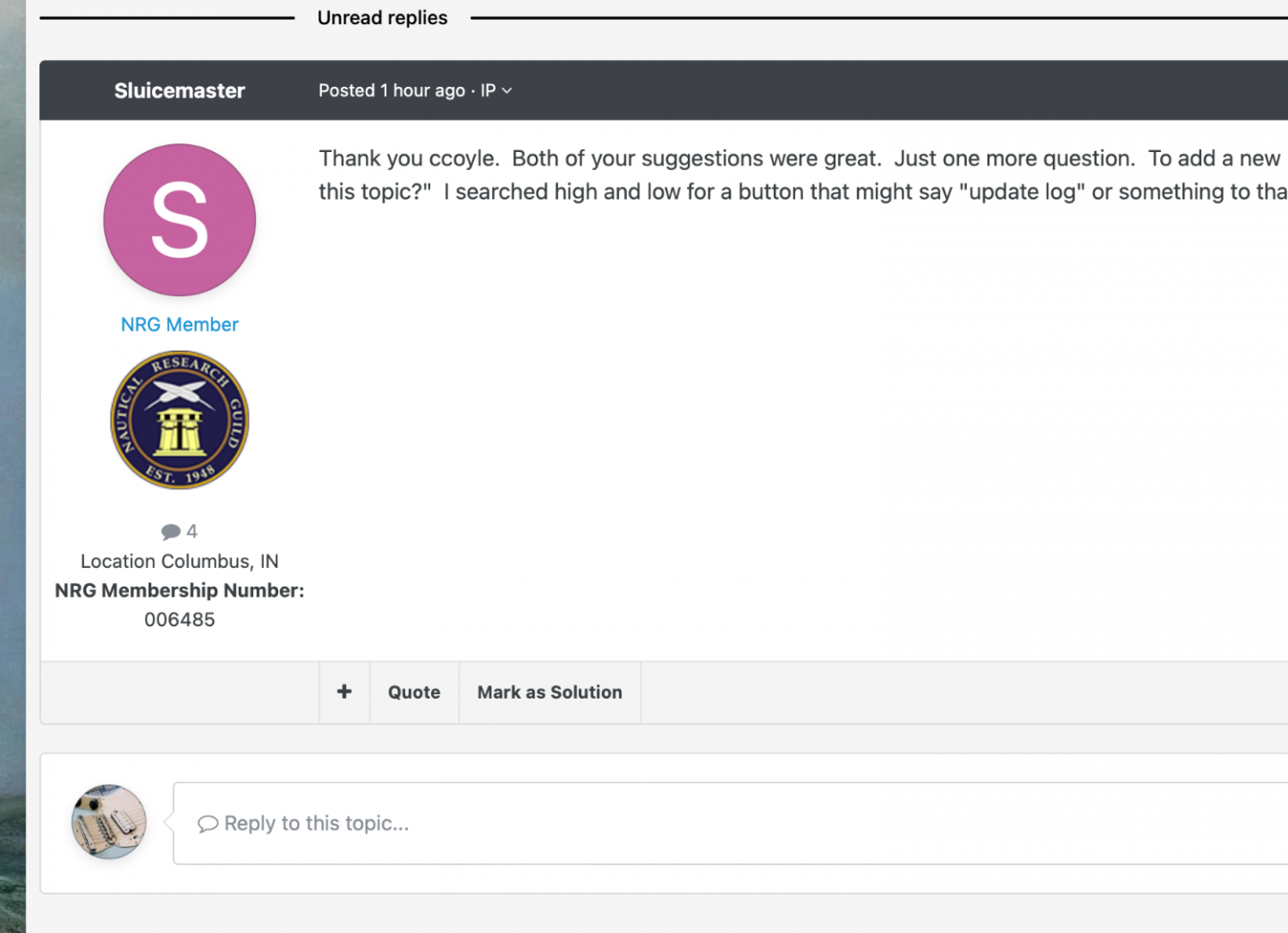

Updating Build Log

James H replied to Sluicemaster's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Just click the 'Reply to this topic' you see in this screenshot in the same way you replied to this topic you created. That applies throughout the site. -

HMS Granado 1742 Kit - CAF Model - 1:48 Scale

James H replied to cafmodel's topic in Wood ship model kits

That looks real good Tom. I hope your supply issues are sorted very soon. -

Eugen, that looks superb and beautifully clean work. When do you think this one will be finished?

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

I'm pleased that I did my bit with the instructions build and that it's easy enough to follow. God help me when I have to do the pics for Indefatigable! 😂

- 32 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.