-

Posts

836 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mark Pearse

-

Since my lost post I have been preparing for planking & adding a keel. I have made the front inner part of the stem; put solid blocking between the moulds (mainly to give the keel something solid to be fixed to); some solid blocking around the propellor cutaway (the final shape is best made from solid timber, so again the blocking gives something good to fix to); plus some timber next to the transom, just so the glueing surface is greater. I did some fairing of the moulds, it's not yet 100% completed but the lower parts of the hull, towards the gunwales, are pretty accurate now. The hull is a raised decker, so the topmost full length plank is from the top of the transom, which is lower than the main deck line. I decided to do this plank first then plank up & down from it. The process was influenced by the fact that it won't be traditionally planked, because this actual yacht was built strip planked (ie: wood epoxy composite). I've realised it does give more flexibility on planking. Anyway, the do the first plank without pinholes in it, I pinned a temporary plank on each side, but 2 planks distant....2 planks so that I didn't glue the pinned plank to the moulds. Subsequent planks can be clamped to the ones already installed. You can see it below, the glued plank is not pinned. Spacers offset so they didn't glue to the hull. First plank done, some slight imperfections, but within 0.5mm sanding depth. Planks are 2mm thick, replicating the actual strip planks of 25 x 50mm approx. I used epoxy for these two planks. I hoping that I can use it for all the planking, including the edges (ie: plank/plank). I'm hoping that it will give a more monocoque hull so the planking lines won't be visible. Strip planks don't run in the natural way, so seeing the trace of them will be off-putting, & given the hull colour is black detail issues will probably be more visible. all the best

-

Hi there Håkån That's an interesting way to plank it - it looks like you have two mirror-image jigs. You do a bit of planking one side then flip the model into the other cradle, clamp the keel & do some planking on the other side...? I like the way it means you can clamp the keel straight each time. I haven't seen that before, could you explain why you are doing it this way?

-

Hi Silverman, as you raised the question, I looked & I do think that you are right - the lower part of the two centre knees are a bit heavy. Remembering that their job isn't to support or strengthen the beam itself, but to brace & strengthen their connection to other members. The part of the knees sitting on the top of the central beam probably need to be more slender than the beam. Perhaps also the aft knees a bit as well. best wishes, looking superb

-

Hi Steven, A subject close to my heart, they are wonderful boats & I race against them quite a lot. For once I have a bit of knowledge - the fish they went after is Barracouta, & not related to Barracuda. The bowsprit question I had to look up in the wonderful book "First Home, The Couta Boat & Victoria's Couta Coast". I had assumed it was to get a larger jib, as sailing performance was important - the first boat home got the best prices for their catch. This is partly correct...on the curved bowsprit (on Coutas called the jibboom) the book says "The early boats ... had little or not bend in the jib boom. Later, the larger boats ... had higher bows & more sheer. Extra bend was put in the jib boom to get more length in the jib & to improve the appearance of the boat." The book has a lot of details, if you want anything you could post or PM me. The model is looking lovely, & I shall follow with great interest.

-

Hi Steven Have you come across the photos of Alan Villiers? In the 1930s he spent some time on lateen rigged dhows. No doubt many differences, however it's just possible some the the technical questions might be helped by some details that are visible. His photos, if you haven't seen them, are very good quality images.

- 508 replies

-

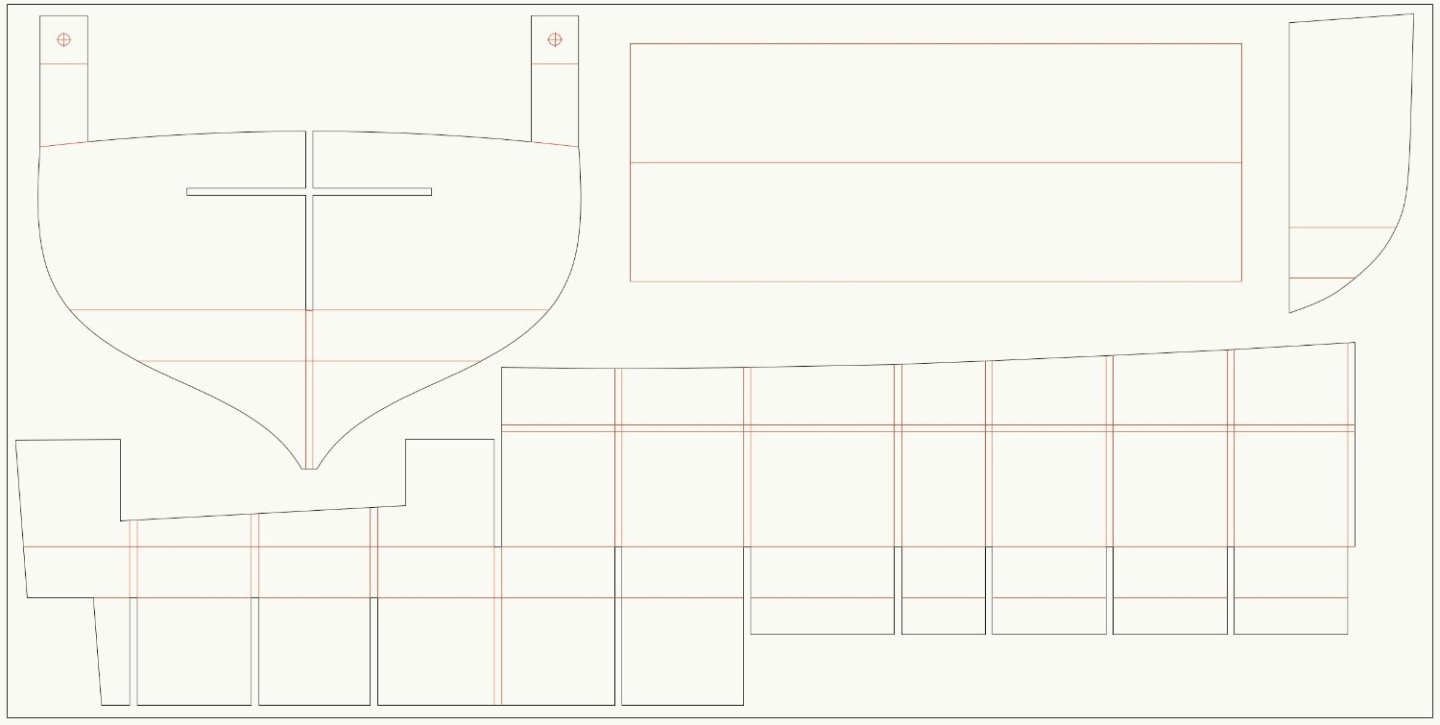

Good progress, I've cut the moulds & have started assembling them. It's always exciting when the model starts to go from 2D to 3D... But first I have to make some comments that may assist others who choose to cut their own moulds from laser cut drawings they do themselves: the assembly was more difficult because when I worked out the shapes to have cut, I didn't include the building frame in my thinking. Assembling them was more complex then it needed to be. Anyway, it worked out ok. I originally planned to screw the moulds to timber strips to hold them, but it's now quite obvious that if the moulds interlock in the way that these do, then screwing them together wasn't possible. So they were all glued to the main building frame beams with PVA. The photo below includes a detail of the bow extension - the laser cutting bed was only 600mm long, so there were some extra pieces at the bow. This gave an opportunity to make the bow thick enough for the inner stem to land on & sit against. you can see how the front moulds include a cutout for the 8 x 8mm inner stem. You can also see the lateral pieces to give rigidity in the planking stage. The inner stem will be glue laminated by the jigs I cut, also by laser. 3 thicknesses of 3mm plywood. The pale lines will help to position the final piece. The transom piece has just been temporarily tacked on with hot-melt glue. The plywood is still loose, although I pinned it with dogs of hot-melt glue to stabilise it. In the next few days I'll glue them with epoxy glue.....once I've had a good long look at the frames to see if I need to tweak anything. The uneven spacing of the moulds has a reason - the lines drawings I got were the actual moulds from the boat's build. The moulds were used to shape a series of glue laminated frames that were not evenly spaced. The hull was strip-planked (timber/epoxy composite construction) & there are only 10 or 11 frames (or ribs) instead of the 60 or 70 needed for traditional construction. So, because they were the only lines drawings I had to use that same spacing, which was to locate the frames in relation to hatches, mast etc. thanks,

-

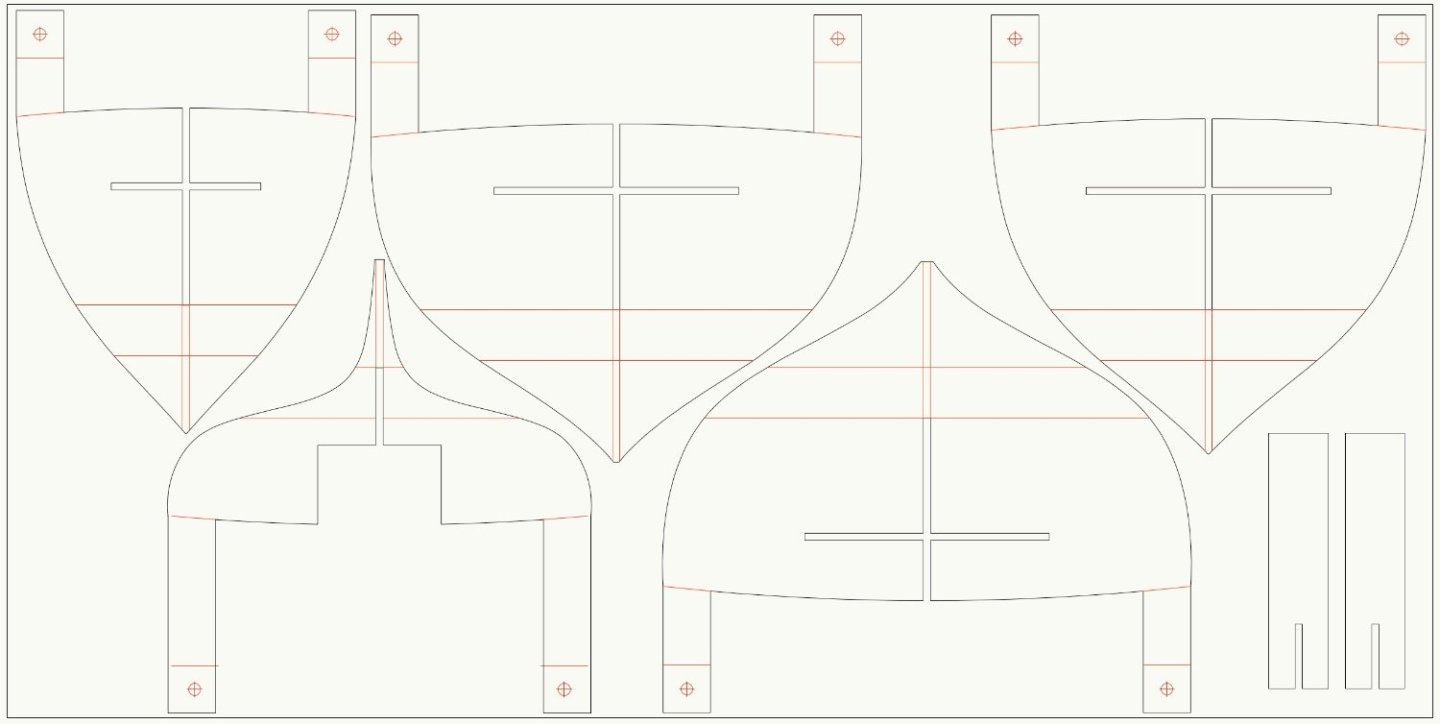

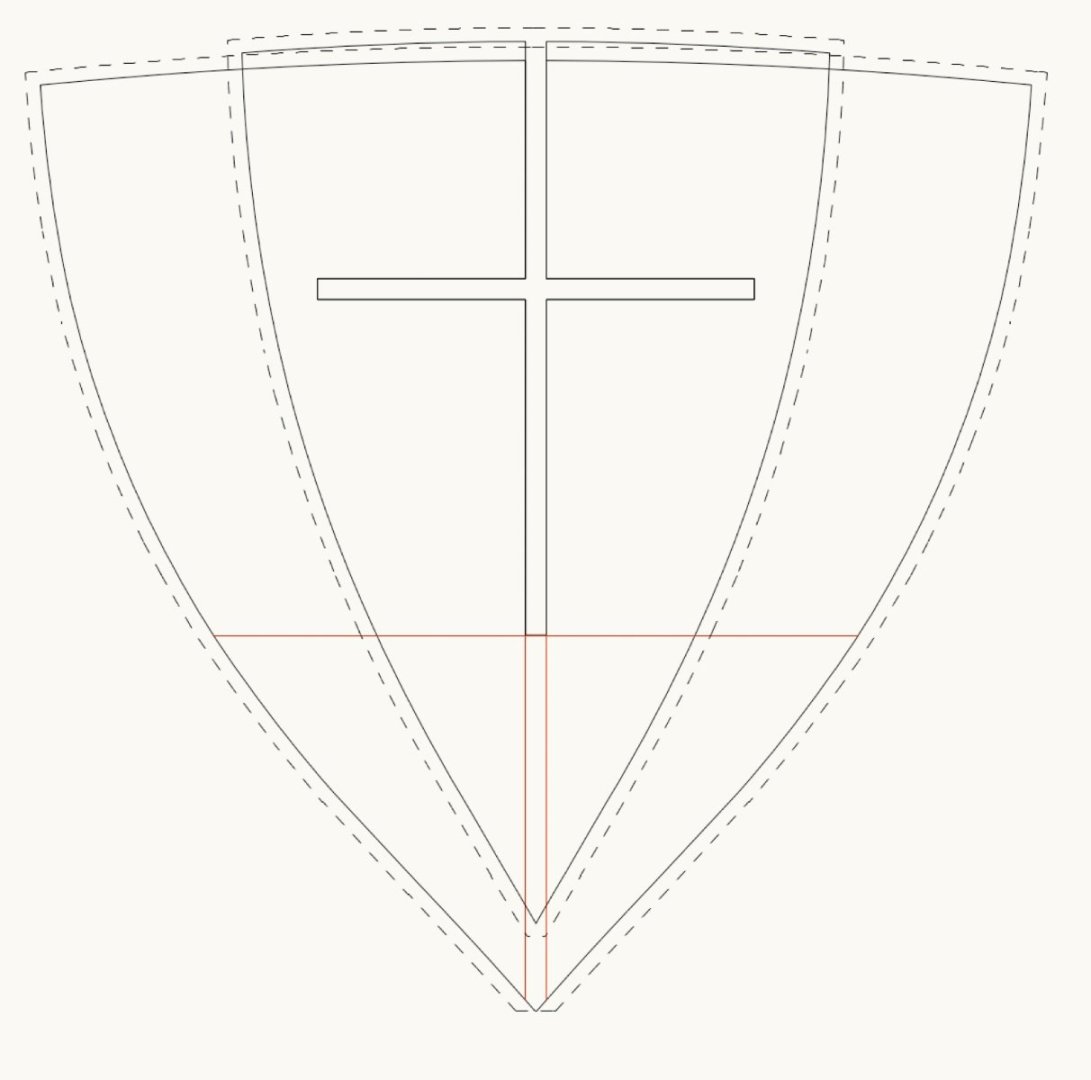

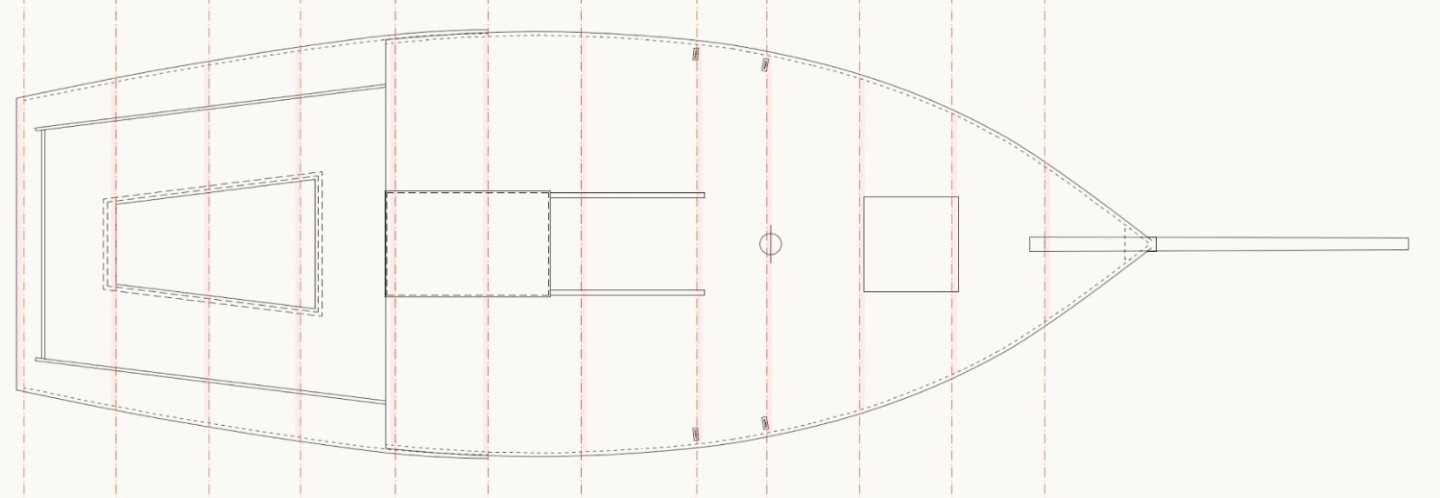

Thank you, I should be able to cut next week, below are the cutting plans. There's something I need to check on the weekend. Black lines are cuts & red are scored lines. The perimeter boxes are the bed size of the cutter. The glued up moulds should be quite rigid, but I think there's still going to be good reasons to build it on a frame, so I put legs on the moulds & more setout lines.

-

There looks to be an optical illusion, I think it's the tapering of the hull against the squareness, & the rectangle appears wider towards the stern. If there is no evidence the structures were not tapered, would it be wrong to try a version that has a very slight taper towards the stern?

- 508 replies

-

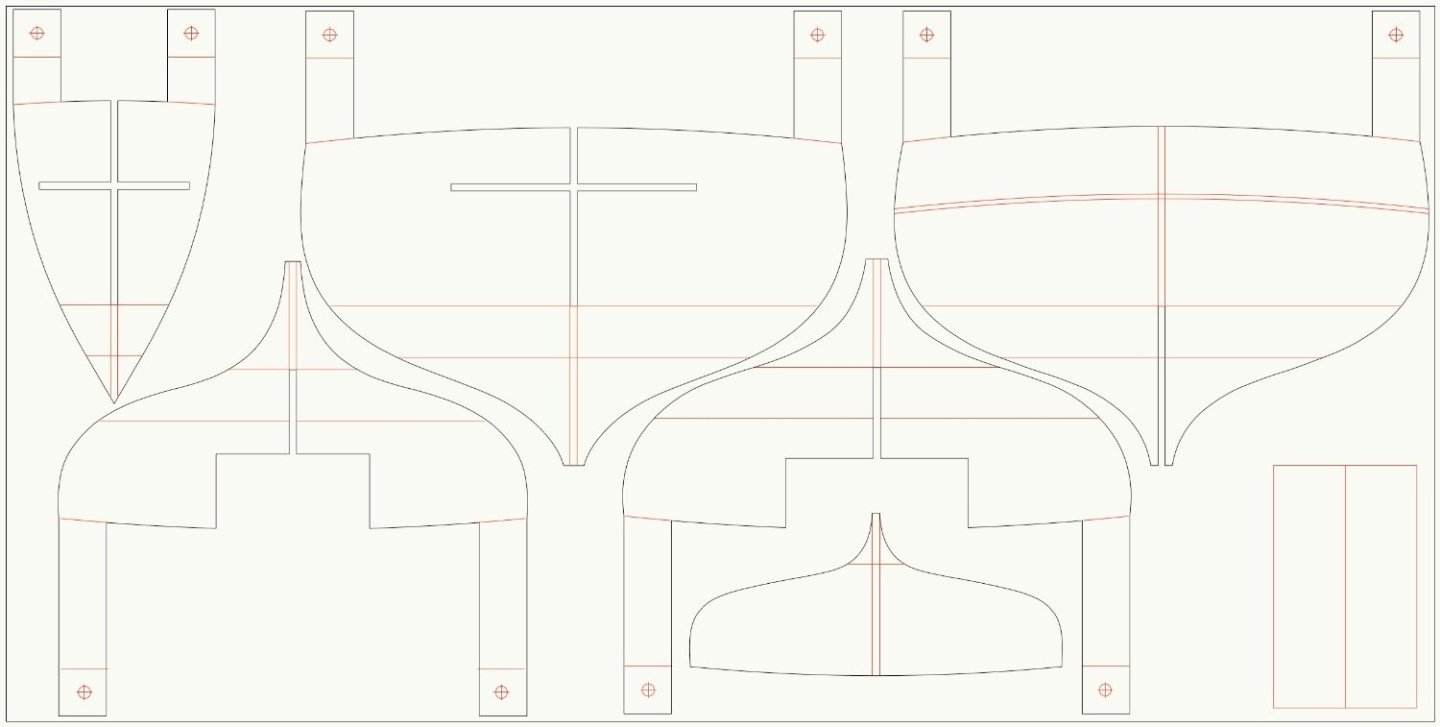

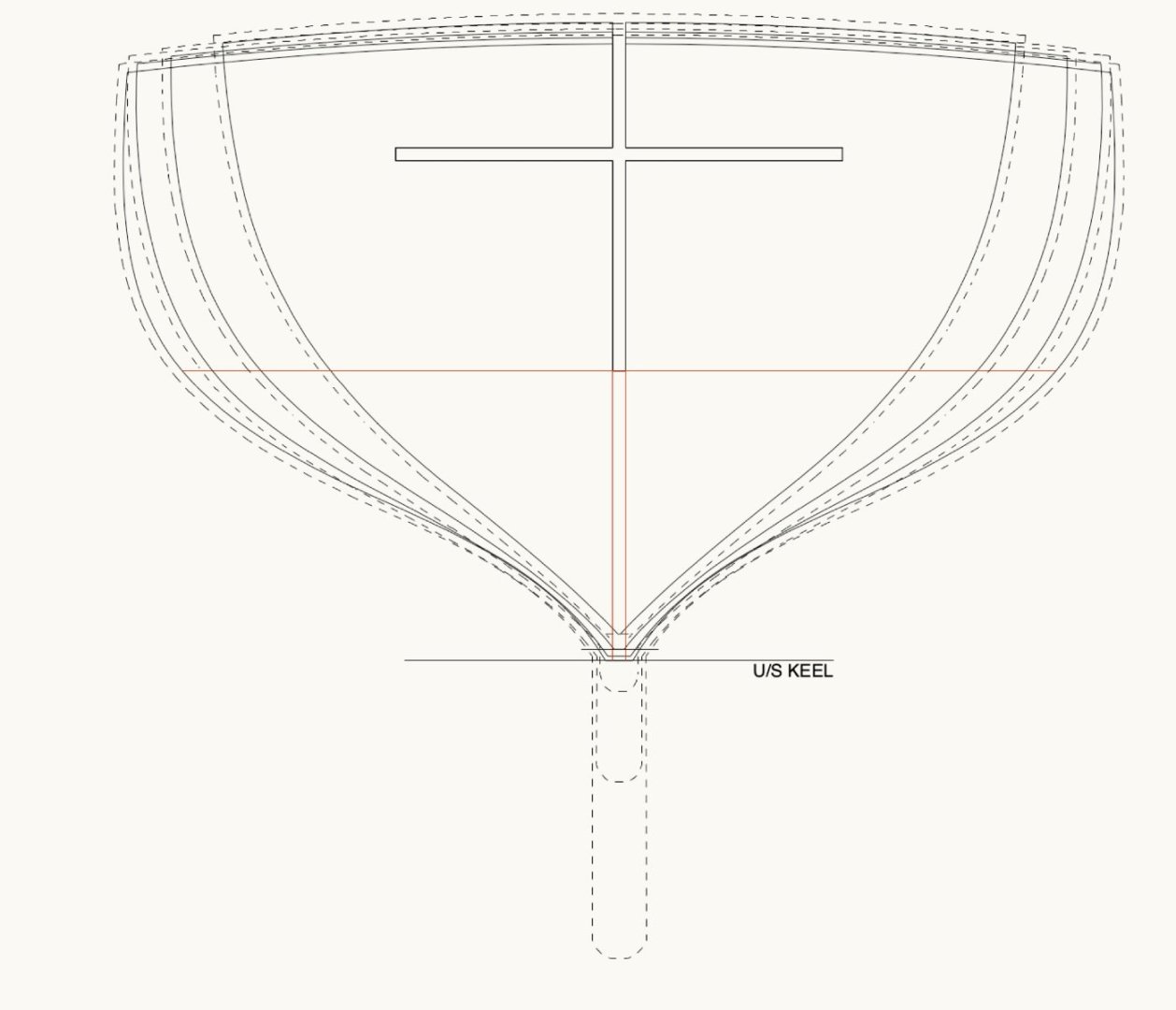

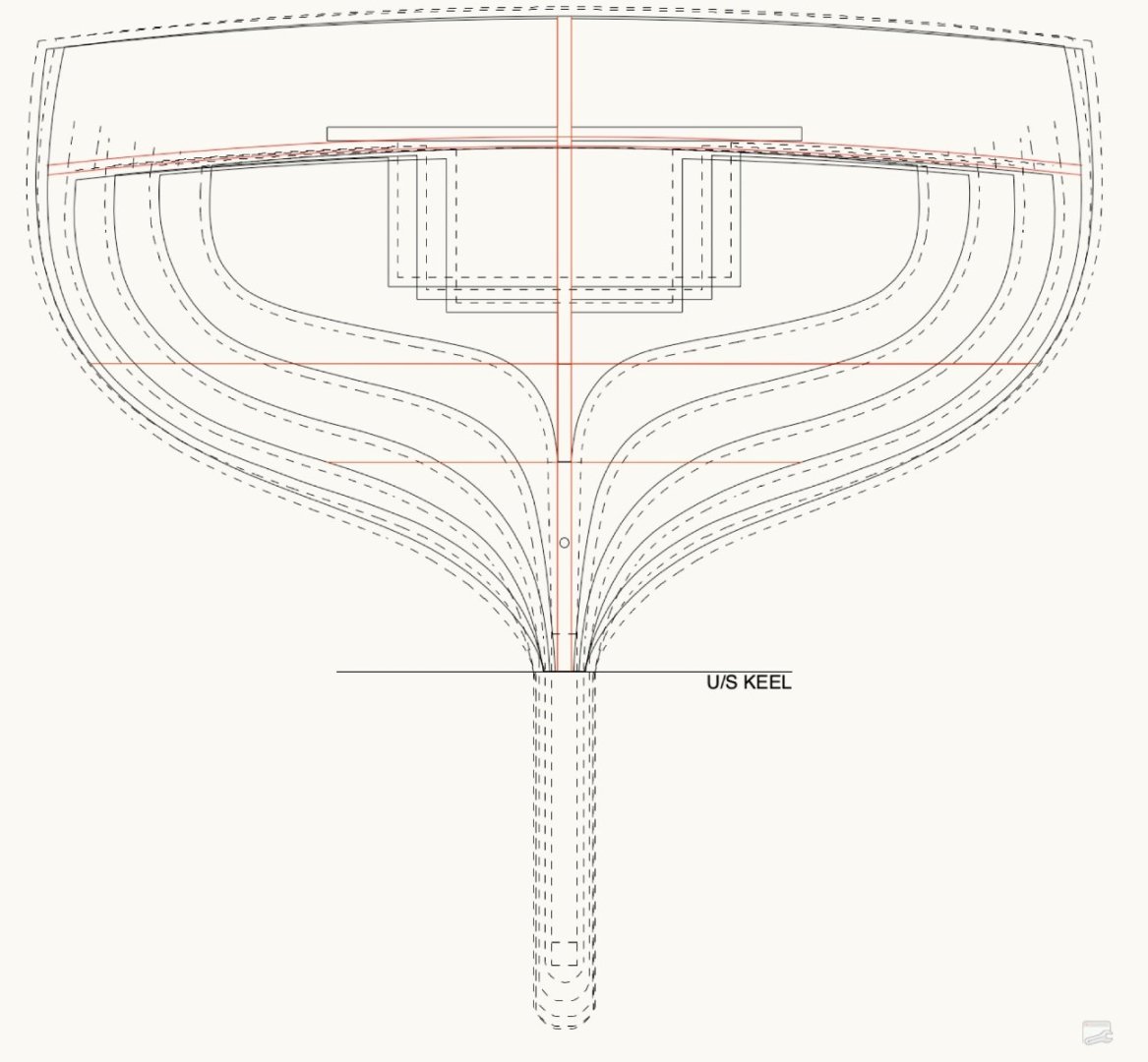

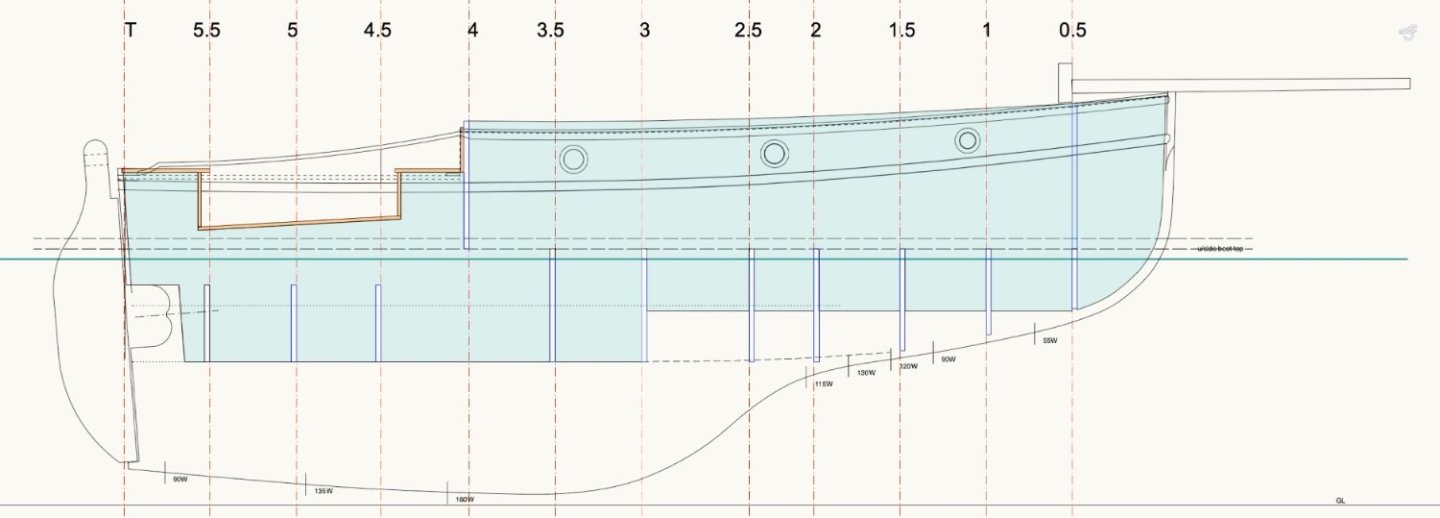

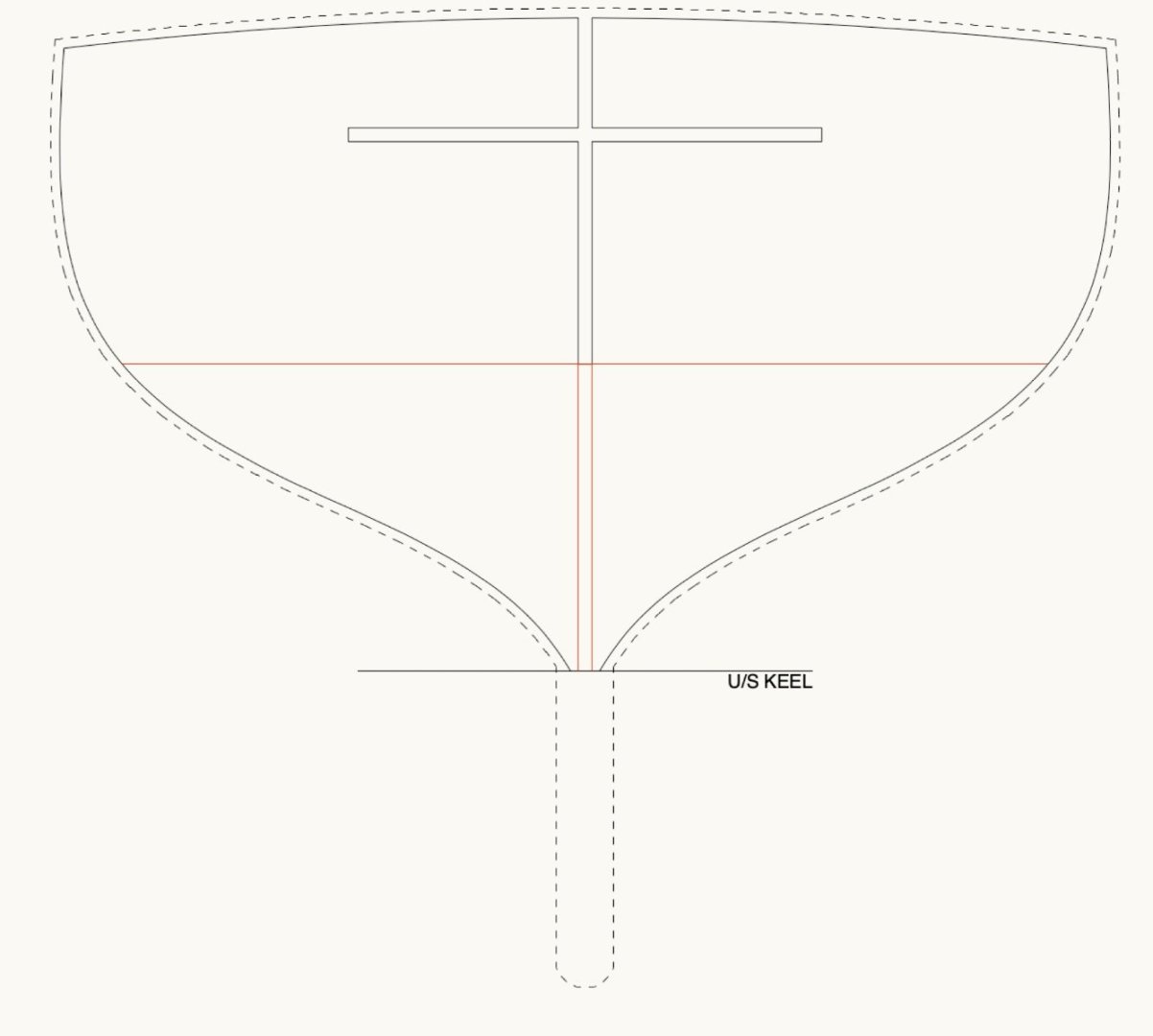

Hi everyone It's been a while, but it's been quite difficult to pin down some of the details & shapes. The builders never recorded the keel profile or the shape of the stem. But she was on the hard last week & I took some measurements & I'm now close to the next step. Just to recap, I'm going to cut an egg-cate style frame in plywood. My brother has a laser cutter so I can do them from 3mm plywood. The shape is the boat is done, or nearly done: I'll sort out spars etc later, for now it's just the hull. The pale blue shape in the drawing below is the lengthwise ply piece, which will also help support the stem. The drawing is assuming the stem is 10mm. You can see that mould #4 slides in from the top, the others slide in from the bottom. The ochre coloured lines are really reminders on how I will fabricate the cockpit area, using 2mm ply for that. The cockpit well is surprisingly steeply sloped, but the duckboard is packed up more at the stern end. There will be some lateral strips inserted in the forwards sections, narrower at the bow & then a wider one. Moulds half & 1 below. The red lines are not cut lines, they are burn lines to help an accurate setup: Moulds 1.5, 2, 2.5, 3: 3.5, 4, 4.5, 5, 5.5 & transom: There is a 28' version of the design, modified for ocean sailing, that just completed the Fastnet race. Below is the difficult conditions of the first day; the happy team approaching the rock. You can see the deeper keel & fuller shape in the first shot.

-

Hi Steven, bearing in mind I know very little about these particular craft....I think your idea is good but somehow it doesn't look quite right, it's a lot of structure above the deck line.

- 508 replies

-

or ceramic beads to weight the pieces of rope, or so the ropes can spin (like parrel beads)..... I was taken by the suggestion they were for putting the oars through & rowing. That would explain the apparent randomness, as loops for this purpose would not need to be fixed to the hull & might b moved around. The white dots as weights might then make sense, they would tend to not fall off.

- 508 replies

-

Hi Steven Yes, I agree - but not because I have any insight into what they could be. I wish I could help on that. I agree that they just don't look like rope. And there's a randomness...two loops here, none there, etc. I favour something along the lines of rosaries, or charms, decorations..... A mosaic depiction of a ship can't go into too much detail, so it is probably be something either visually obvious or else something meaningful, & relatively minor loop of rigging rope doesn't fit well into either. I'm putting my money on meaningful.

- 508 replies

-

Hi Steven The model is showing a boat with a very pleasing shape.

- 508 replies

-

Yes, even a slight curve in the keel would make the hull much more resistant to hogging, or just generally changing its shape. The curved hull planking meeting a curved keel is a 3D curved surface rather than an 'extruded' curved shape.

- 508 replies

-

it's interesting with boats how a straight line can look curved (the wrong way), & a curved line...just looks right.

- 508 replies

-

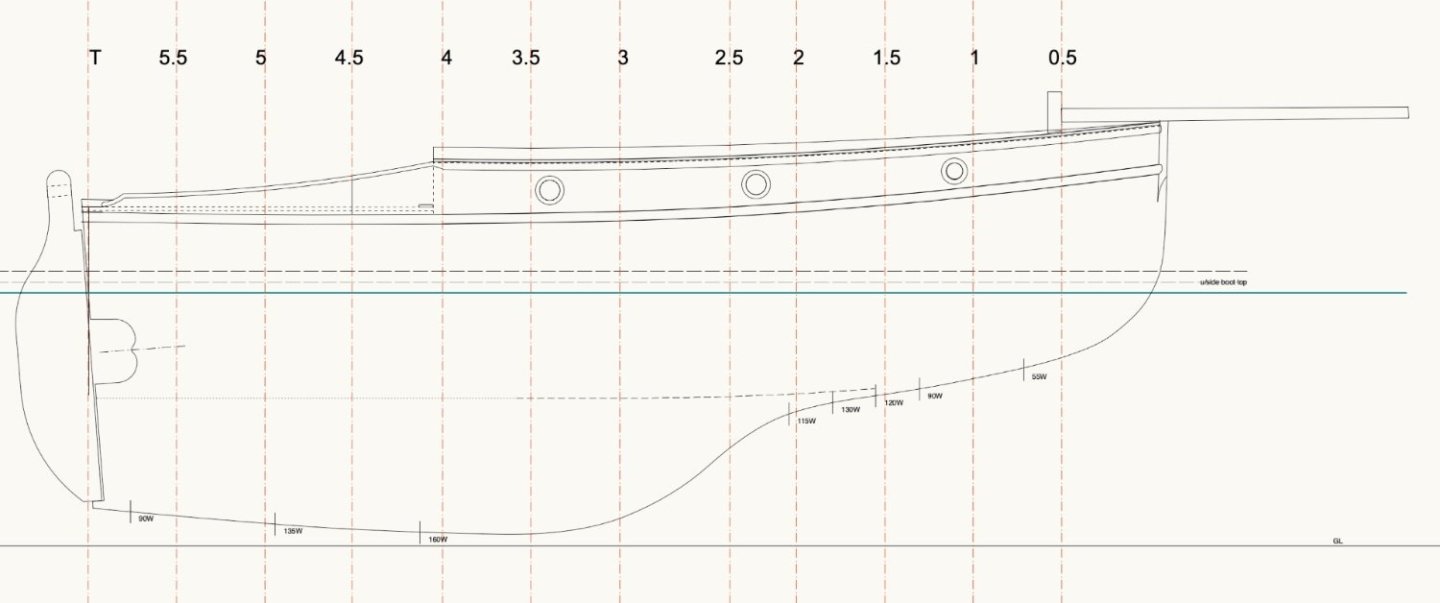

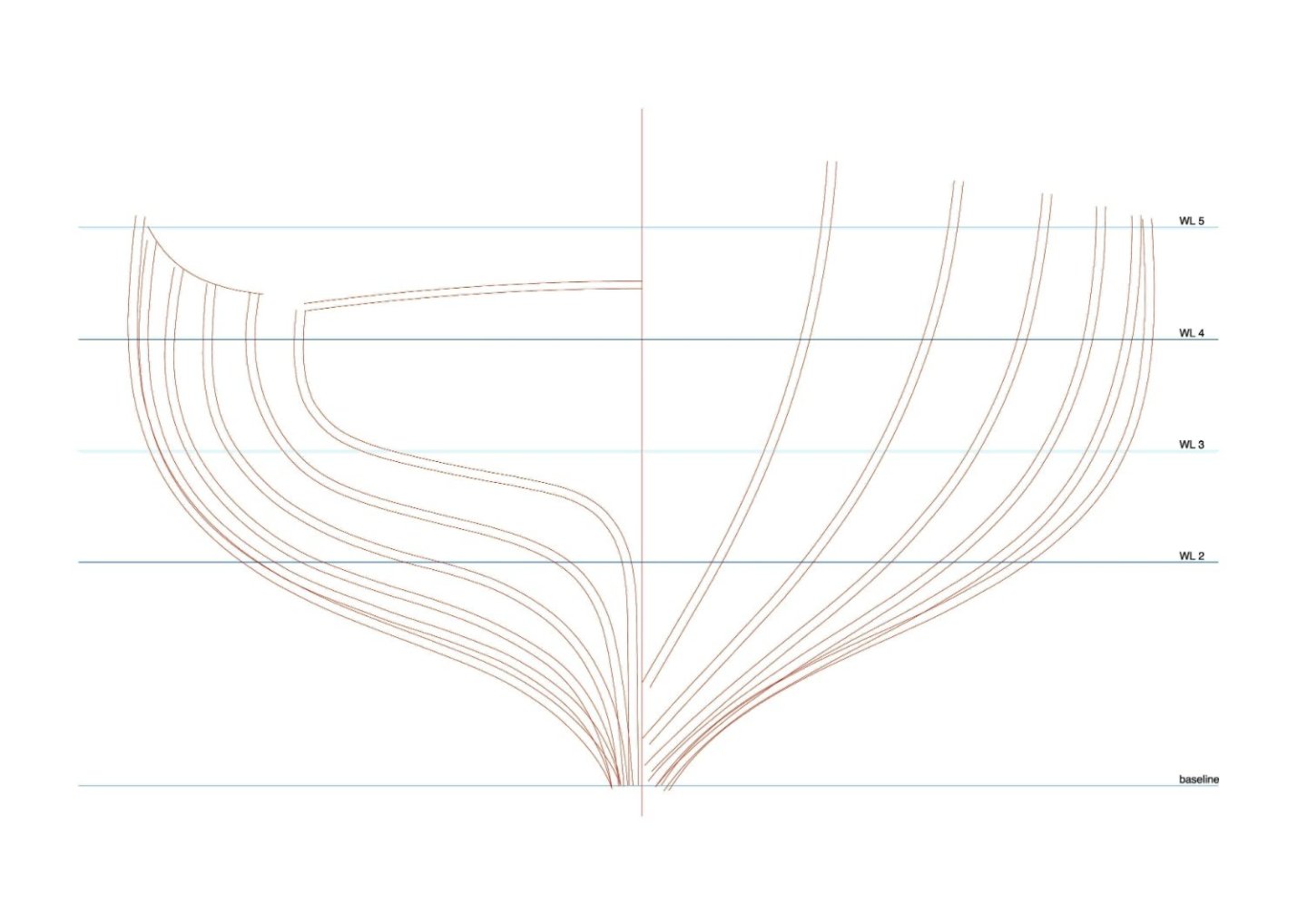

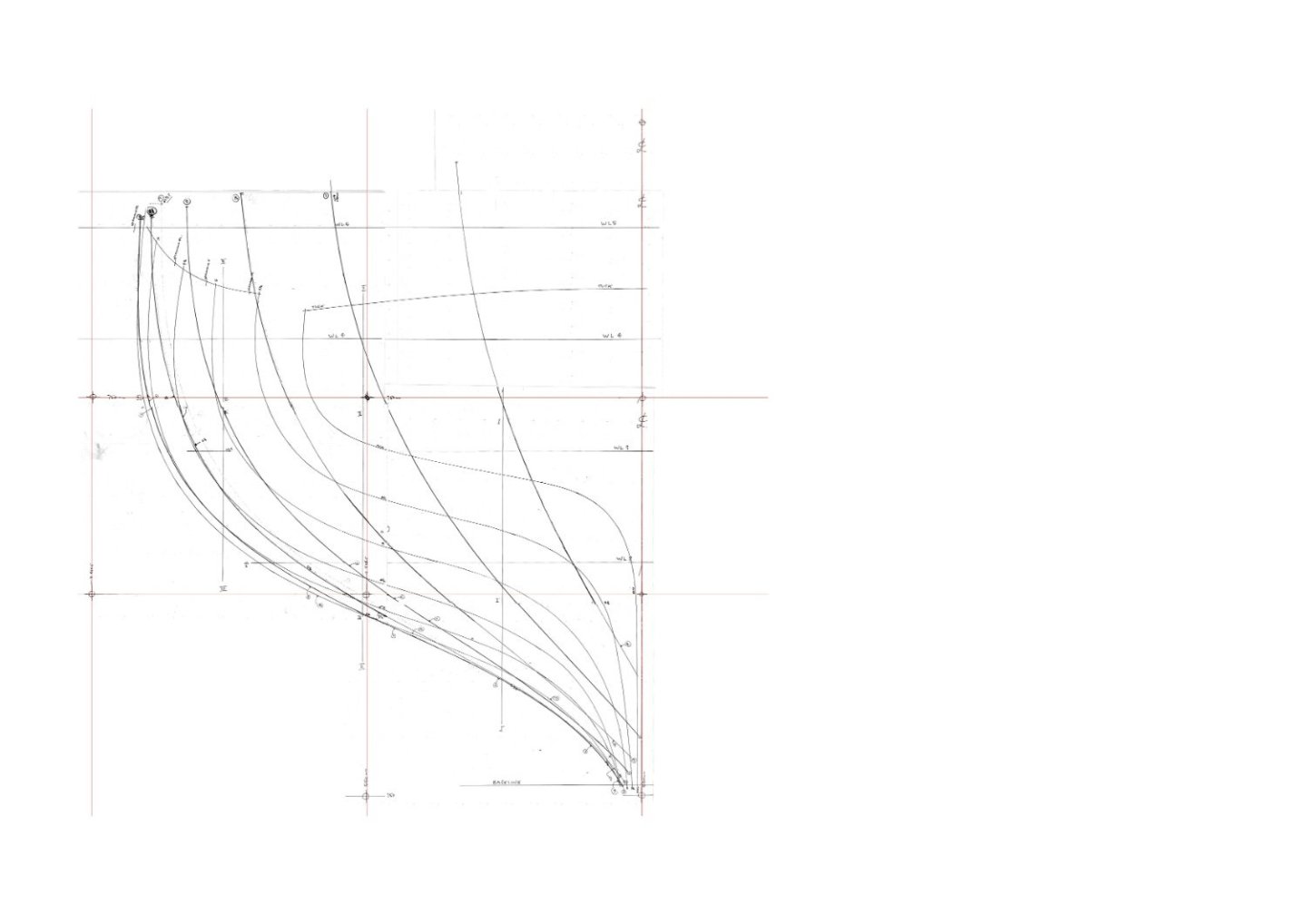

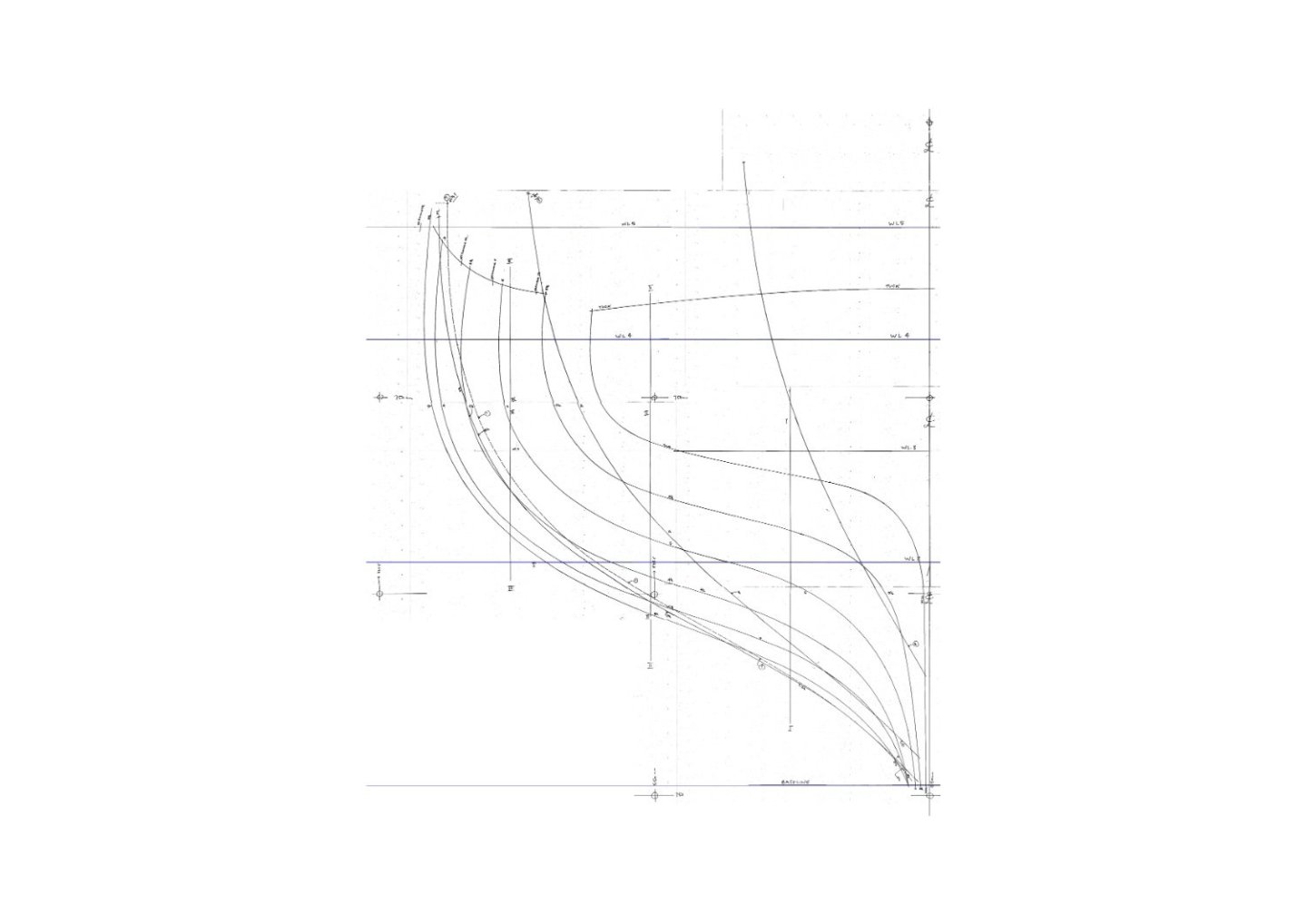

I found the missing lines on one of the drawings, & will attach below the scans of my full size tracings, so 6x A1 sized sheets. Then my first go at the lines off them. I will next have a go at putting these lines with keel profiles, stem details, gunwale line, etc. The double lines on the lower drawing is because the original drawings I had to work off were to the inside of planking. The double lines therefore are the inside & outside of the planking.

-

Below are the traced lines. The A1 sized tracings were scanned & loaded them into a draughting programme, then scaled & assembled. There doesn't seem to be enough lines though. The photo looks to show 11 frames plus tuck (transom - but it's called tuck on the drawings, so I'm following that, I believe it's what the older shipwrights in Sydney used), & the drawings shows 9 frames plus transom. I'll start by checking the lines drawings again, see if I missed anything.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.