-

Posts

836 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mark Pearse

-

Hi Jim, Keith This photo is a good one, a displacement hull trying to exceed her hull speed. I was out on the day, motoring our boat with my heavily pregnant wife & watching the start of a race. It was 5-10 knots 5 minutes before this photo was taken. Best reminder ever to always check the weather forecast. This is the boat I'm doing a model of, & the benefits of her higher ballast ratio are showing - the hull is lighter because in strip planking the hull is lighter as timber never soaks up any water, so the boat needs more lead to pull her down to the waterline.

-

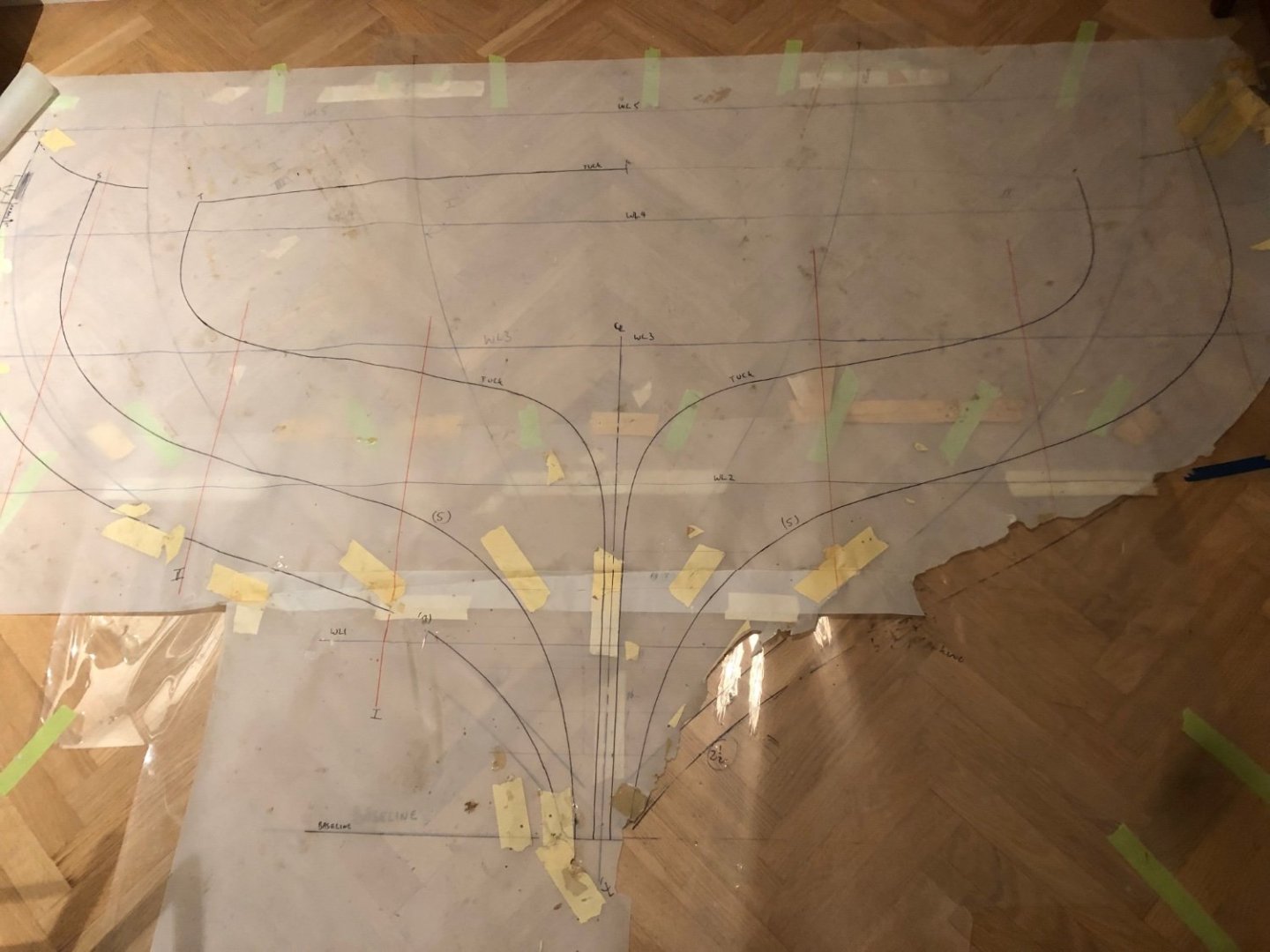

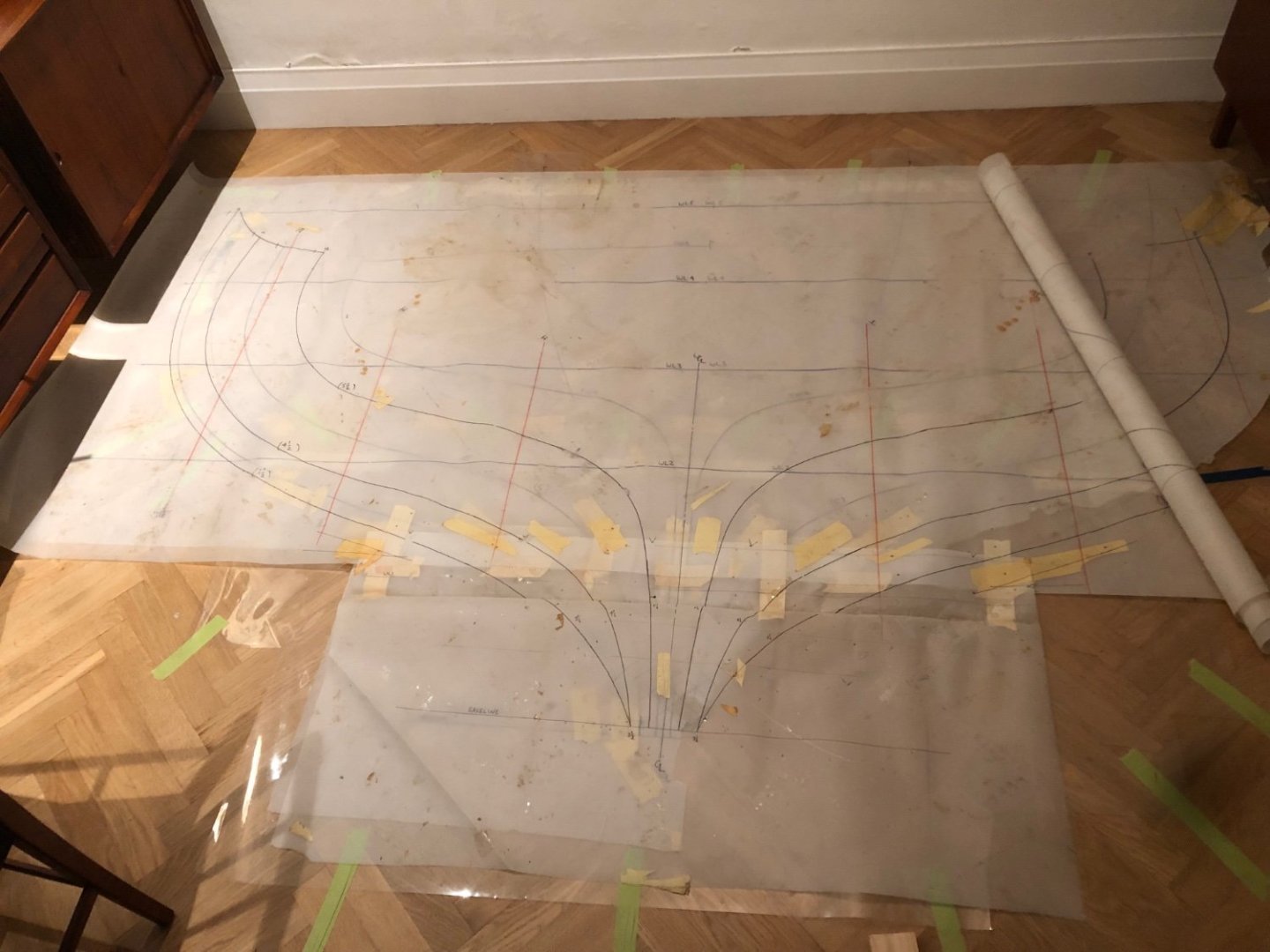

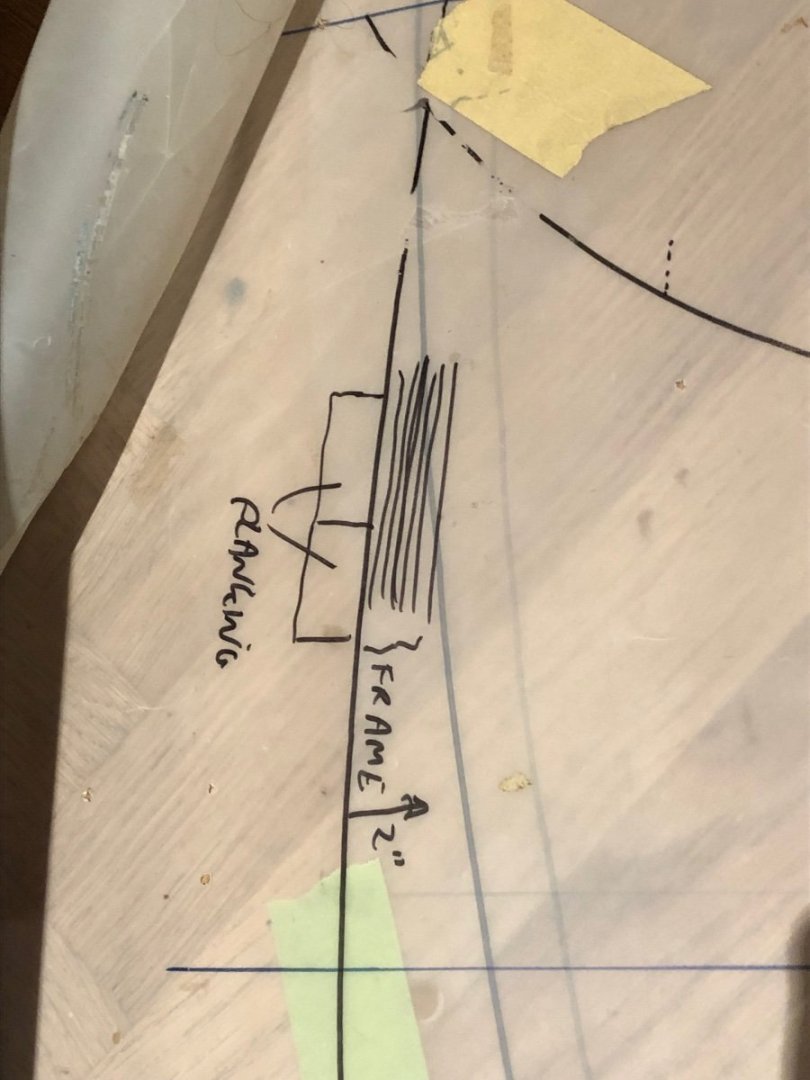

I have been asked to make a model of a specific yacht, the yacht is a recent build of a 1930s Sydney design. My previous build logs are both of designs by Cliff Gale, & somewhat inevitably, this is a Cliff Gale design also. Actually, I'm thrilled, & it is a version of his most famous design, or at least his best known design. The yacht herself was built around 2000, & built strip-planked. The original yacht built to this design was called Ranger, & Cliff had her built for himself & his family. They are 24' (7.3m) long & 9'6" (2.9m) beam, so very beamy for a short boat. But they are excellent for their purpose: day sailing in Sydney Harbour, overnighting & near coastal sailing. This one has sailed as far as Tasmania, but with good preparation & picking the suitable weather windows. Since 1933, when the original was launched, around 9 or 10 have been built, some not especially close to the original design. But there's one completed a couple of years ago & another nearing completion, being built by retired shipwright & general legend Ian Smith. I'll let the photos do the talking, & if I think of more things to say I'll add them in following posts. I'll also try to find a couple more good photos of the yacht herself. Launch day, or close to it, I think around 2002. They are great day boats, & sail well with all that sail area. Quite a lot of usable room, for a small boat. Happily, I have the original lines drawings from the build. That's something you don't see very often in this forum....1:1 lines drawings from the actual build. These yachts vary a bit, the original one - Ranger - was adjusted during her build, to increase her load carrying capacity. This yacht, built 65 odd years later, is actually closer to the original designed lines than the first yacht built to the design. There's 3 main lines drawings, here's the first, taped to the dining room floor: The second, sitting on that: And the third: The lines are to the outside of the ribs / inside of planking. Fortunately, there is this doodle on one corner, in the top left side of the 2nd lines drawing: I have traced over these in a series of A1 tracing paper sheets, & they are getting scanned & I will assemble a digital compilation of the lines. Thanks,

-

Wow, thank you everyone for the assistance. This is a huge help. John, good to hear from you as well. Thanks that's great idea & turns out I have a mate who's an upholsterer. Keith, thank you, & yes I tried Ropes of Scale (after searching this forum, the name came up quickly). They don't seem to have white of the same weave. Their 'cable laid rope' is exquisite, but more complex in the weave. This is actually 3 strand, so visually quite simple. The hull might have been ballasted inside the hull or perhaps screwed onto the underside of the keel. The hull is screwed to the stand & I haven't removed it to look. The shape of the hull is 19C in yachting design, a real 'lead mine', or that's what I've heard them called: narrow beam with very deep hulls. It's quite hard to photograph her without distortion but I'll attach a bow shot lower down. Another option is that she was only sailed in light conditions, the 'lead mine' boats are known to heel quite a bit as the hull shape doesn't have much volume to support a lot of ballast nor much buoyancy righting moment from hull shape. Hi Mark, good to meet you. Thanks for the link to Ropes Galore, that's also a very close match, & I can't resist the cheesy business name. Yes I've read a lot on the Balmain Bugs, which raced in the harbour for prize money, but I think (going from memory here, Steve Crewe's book on them is the one to read) that they started in that type from maybe the 30s. This model is (my estimate) 1900-1914. I believe that she would not be capable of sailing in the harbour without risking losing her. And I thin she was sailed for pleasure rather than races - why? There is no evidence that she could be tacked quickly. The Balmain Bugs were tacked in split second as they were self tacking, they just rowed up behind & pushed the boom across. This one has 2 jibs & a staysail - & only the one traveller bar for the headsails. I think that they had only one sheet, & the boat was set up for one tack across a pond (like Centennial Park, which was a popular place for it). The 2 foot Bugs also had a mast 8 or 10' tall, much larger than this. Hi Roger, thank you as well. I looked up Cuttyhunk line & it is beautiful stuff. A bit thin, but a great idea. The one on the model is probably cotton, it is probably softer than linen. And I looked up the company you mentioned, they have one quite good, just a bit thin in diameter. Jaager, thank you as well, & I agree with your comments on the model & the rigging. Make do, but she was well made. I did find a couple of alternatives that are quite close, apart from the Ropes Galore option from Mark. This one is close: This is the bow view of the model. The side photo doesn't really show how dramatically slim she is. Again, thank you everyone for your assistance, advice , comments.

-

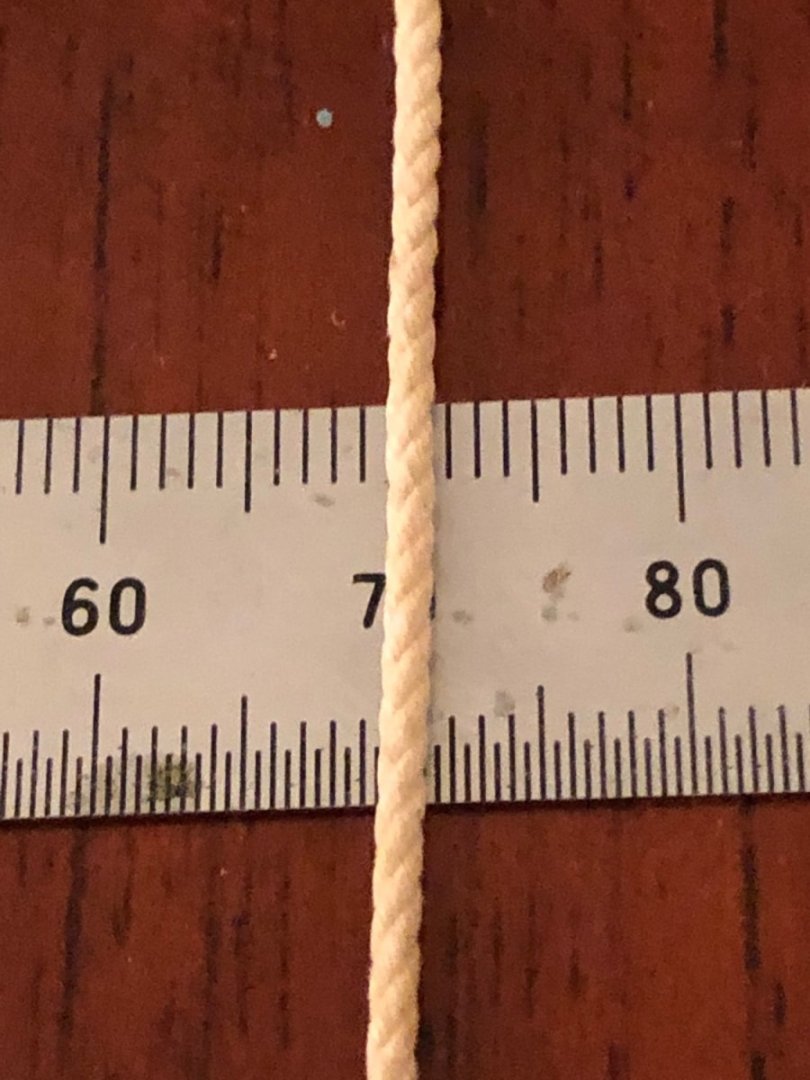

Hi everyone I am doing some repair work on an antique pond yacht. It's a full sized small yacht rather than a scale model, this is important because I'm trying to find thread similar to some that's on the model, as opposed to a scale version of something. She's a great model, my estimate is 1900-1914, the hull is about 107cm, & the bowsprit adds about 50cm. In fact she's difficult to take a reasonable photo with a phone, but there's one below to whet your appetite. Unfortunately the original finish was removed, it would have been almost black. I can see that it looks good like this, & I am not doing a restoration, just repairs. One of the lines that is incomplete is the mainsheet. It's about 1.5-1.6mm diameter & quite white. It's like a classic 3-strand rope. It's soft & is probably cotton. Another one is what has been used for standing rigging, definitely not the original, but perhaps 30-50 years old anyway. I'm not replacing it, just matching it for rigging. In its weave, it looks like vb cord (ie: Venetian blind cord). I did some hunting on the forum in general & found some ok leads...but not quite the same thing. This is 3 strand, not a more complex weave, & it's quite white. If anyone has seen something very close, & they recall where it was from, I would greatly appreciate any tips. much appreciated, Mark

-

Hi Steven, looking forwards to it, & the history that comes with it.

- 508 replies

-

Bravo Keith, & thank you for explaining the process so carefully throughout. What is a pig stick....?

-

Hi Keith Germania is looking just beautiful. Just a practical question: will you be adding glue to stabilise the rope coils?

-

Hi Steven This looks very interesting. Do you have an idea of how large the actual vessel would have been? It's difficult from the images, with the way they have multiple scales operating at once.

- 508 replies

-

Hi Keith Possibly the large bilge keels are to reduce wallowing. For this launch, drying on a mud or sand bank doesn't seem as likely. Thanks for the ongoing detailed posts on how you make things.

-

Hi Steven Just catching up on models - & wow, what an extraordinary craft. I'll read your introduction, I'm sure there's some information on her there.

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

Hello Håkån I've enjoyed this journey very much, it's a beautiful model. I'm sure it would be a lovely boat to sail on.

-

Hi Druxey I came across this lovely image of women's rowing teams in Sydney approx 1900-20, with the steering yoke pretty much as your craft, & showing how they worked. Amazing how close the designs are.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Hi Keith The foremast one is curious. However, it does look like (from the initial photos) that the foremain might be loose footed & the main main laced. Moving the gooseneck pivot point aft would mean the sail foot automatically loosens when the boom is eased out (good), but wouldn't make a difference if the foot was laced. So that's a possibility. The only thing I know for sure is that a gaff main puts a huge load on the gooseneck fitting, having broken two 7/8" solid bronze gooseneck pins, with a comparatively small 24' hull, see results below...

-

You've done a wonderful job. An interesting boat, a couple of things are especially interesting: With the person in the model for scale you realise just how big the boat is, especially the rudder & tiller arm are huge; also it's interesting how high the freeboard is. I'd love to go for a sail on that!

-

It's hard to see on the photo, but does the mast have thumb cleats, or something like that, that the shrouds pull up against. thanks, Mark

-

Hi Pat Ha! Yes the submarine 'Platypus Trophy' is a curious one for a sailing club. I don't recall what the connection is.... A couple of the grander sailing clubs have some very nice models - if you're in town, The Squadron (Royal Sydney Yacht Squadron) & CYC (Cruising Yacht Club of Australia), up in Pittwater the Royal Motor Yacht Club - they all have great collections. Notable is the CYC's half model of every handicap winner of the Hobart.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.