-

Posts

5,677 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jack12477

-

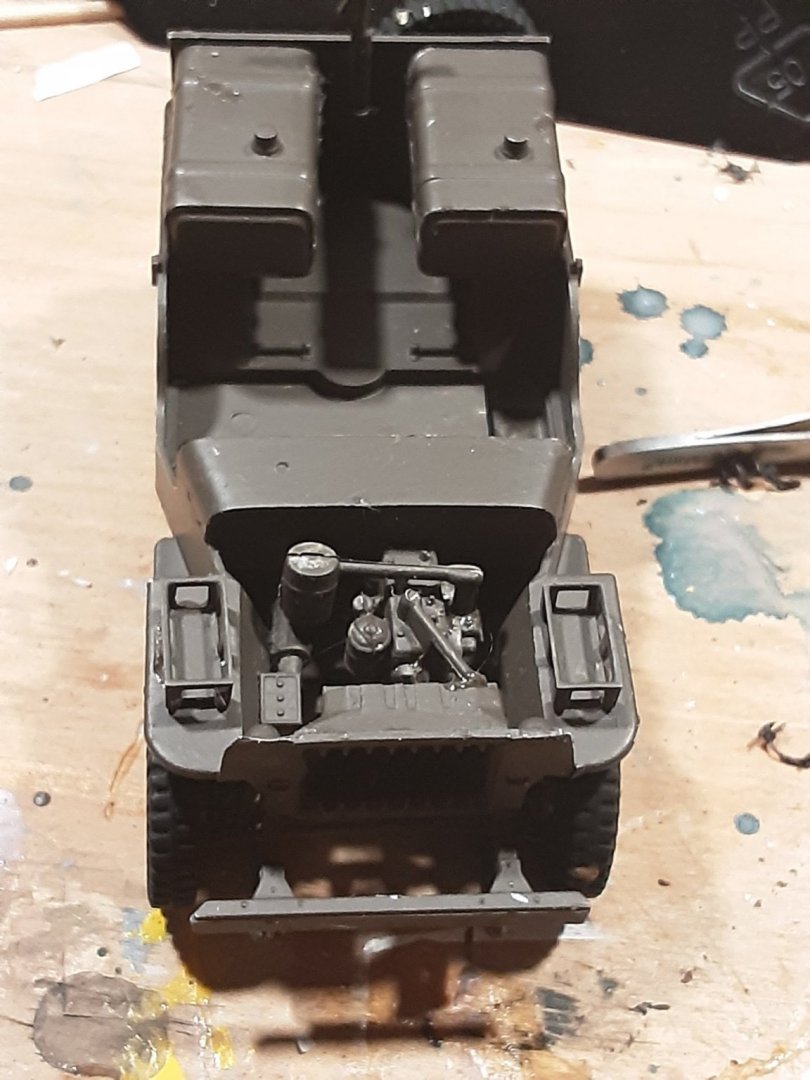

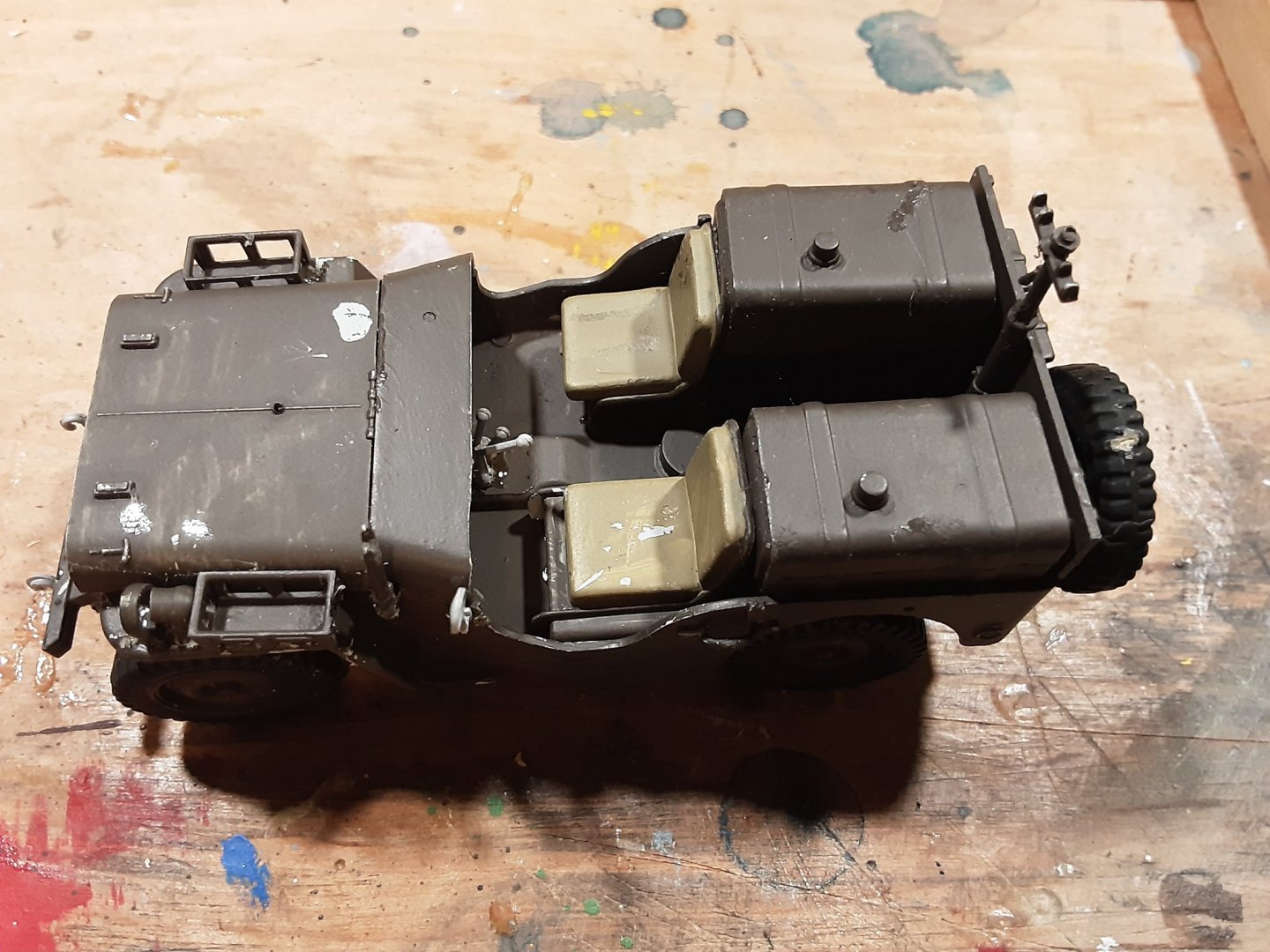

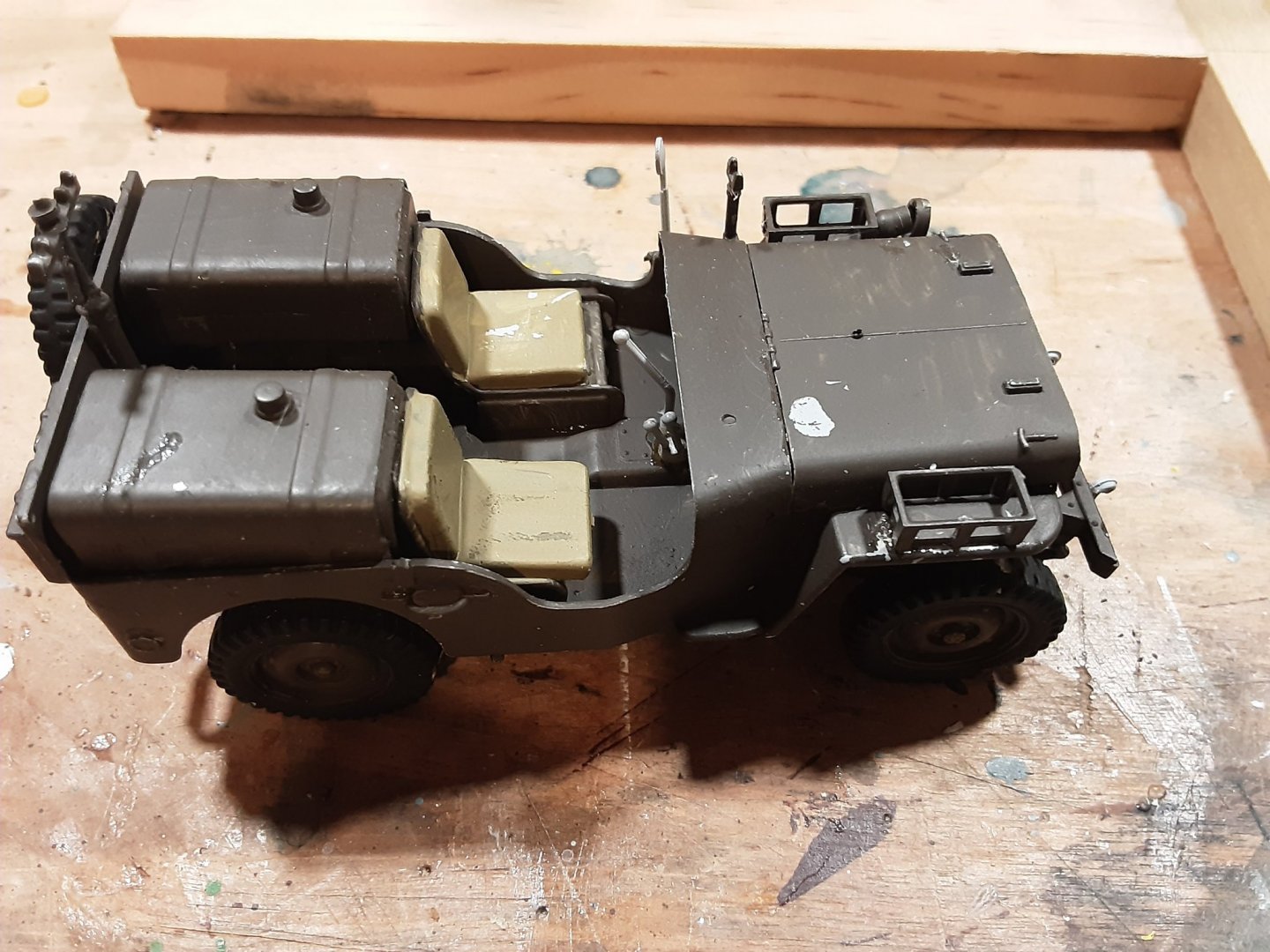

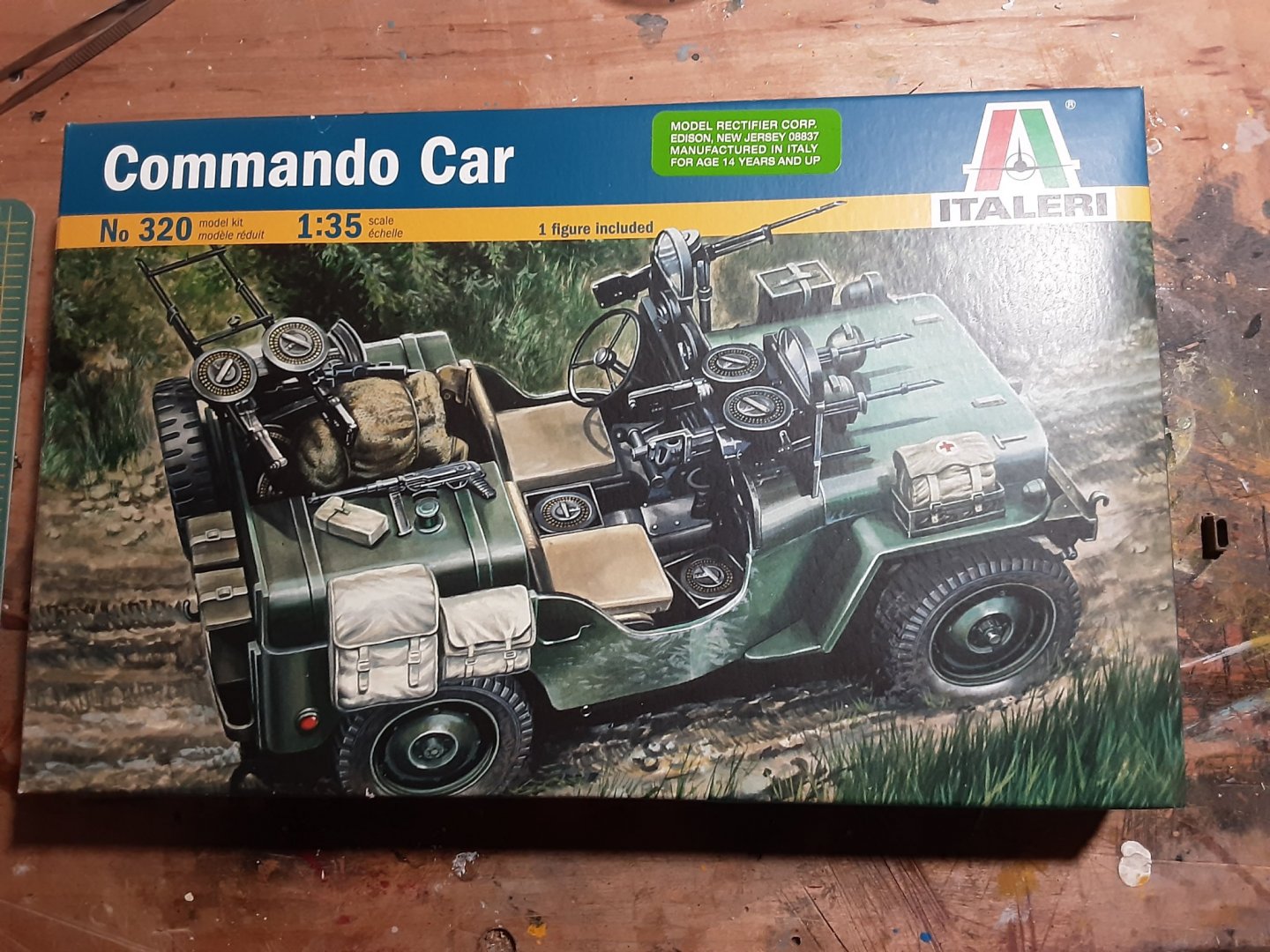

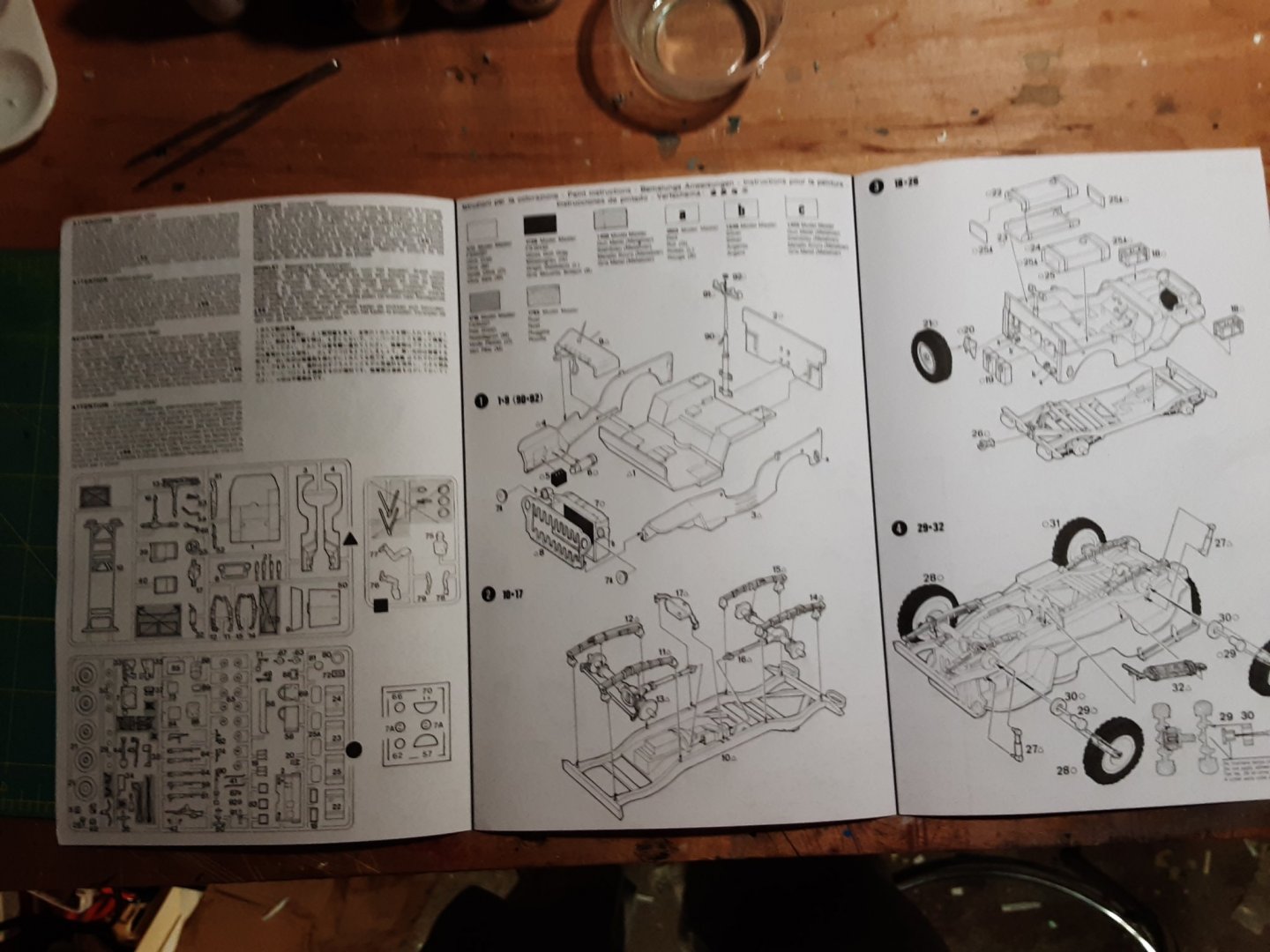

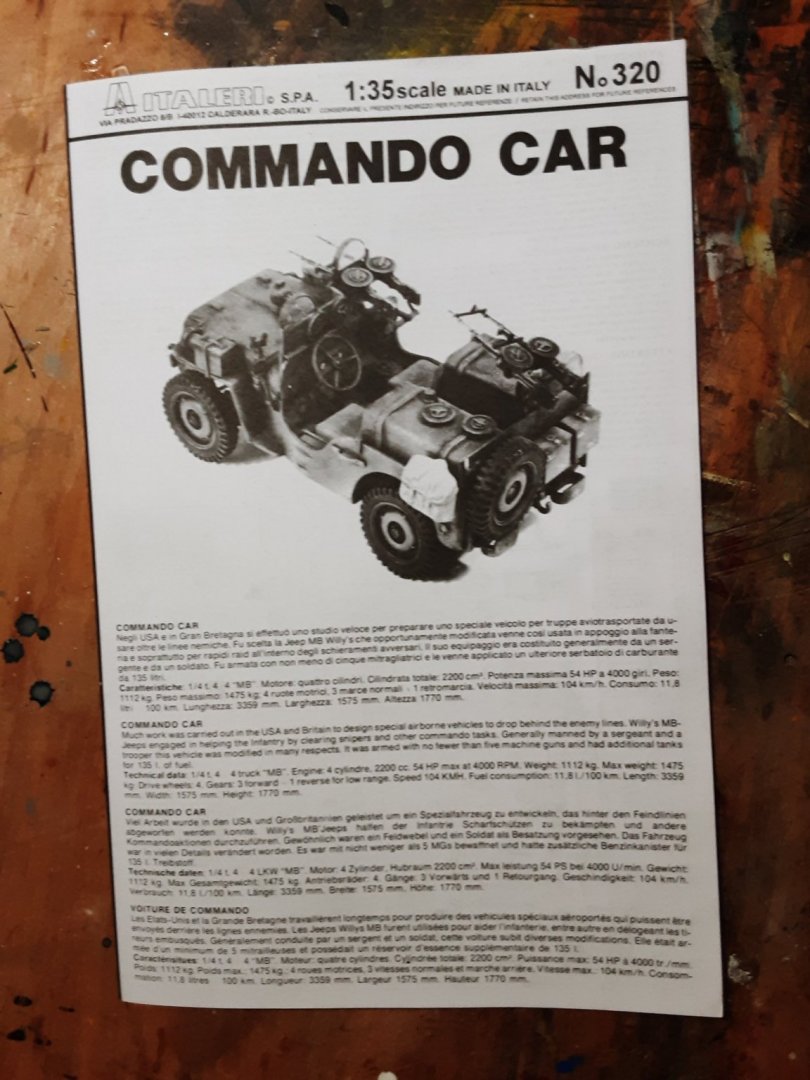

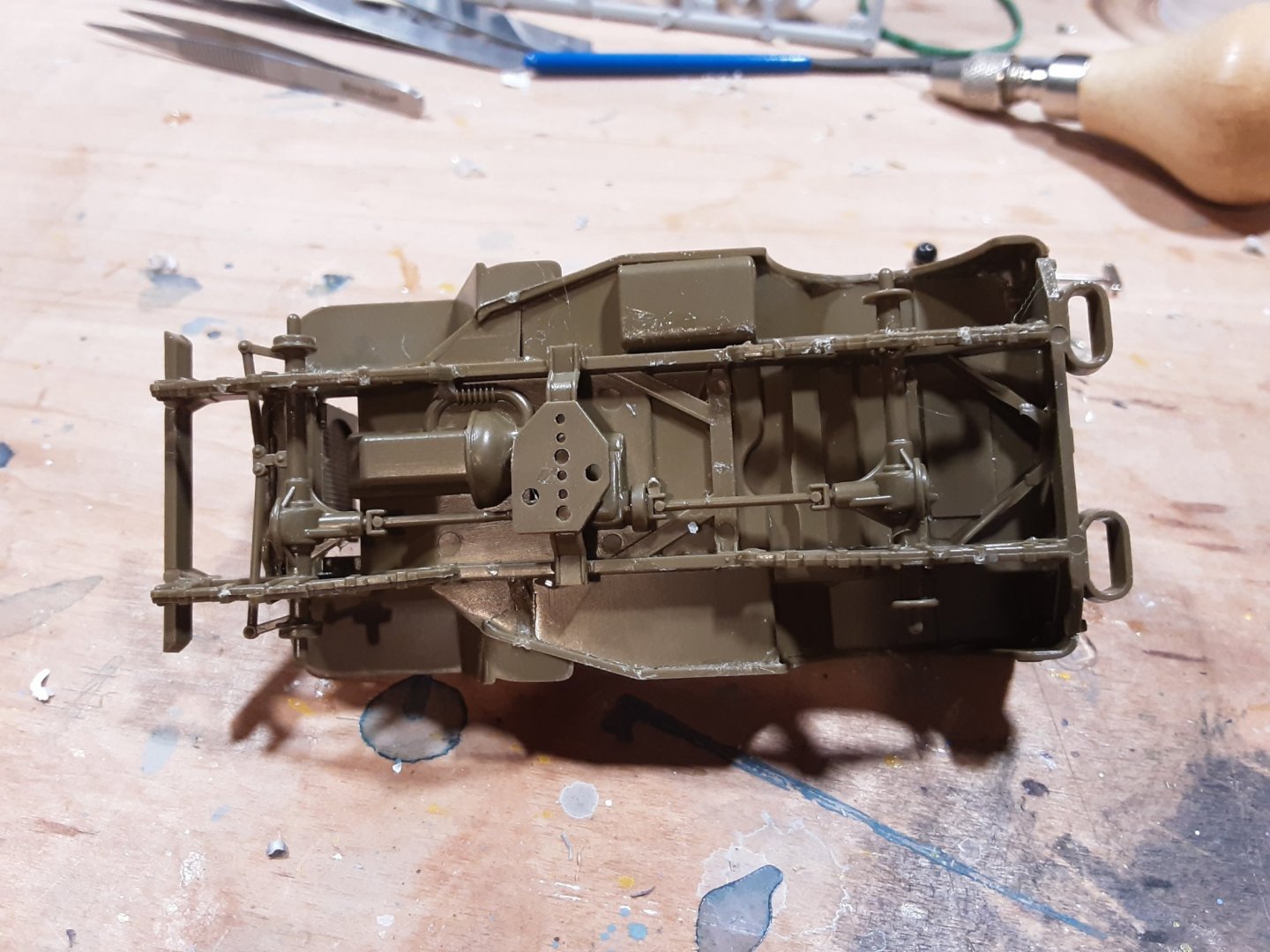

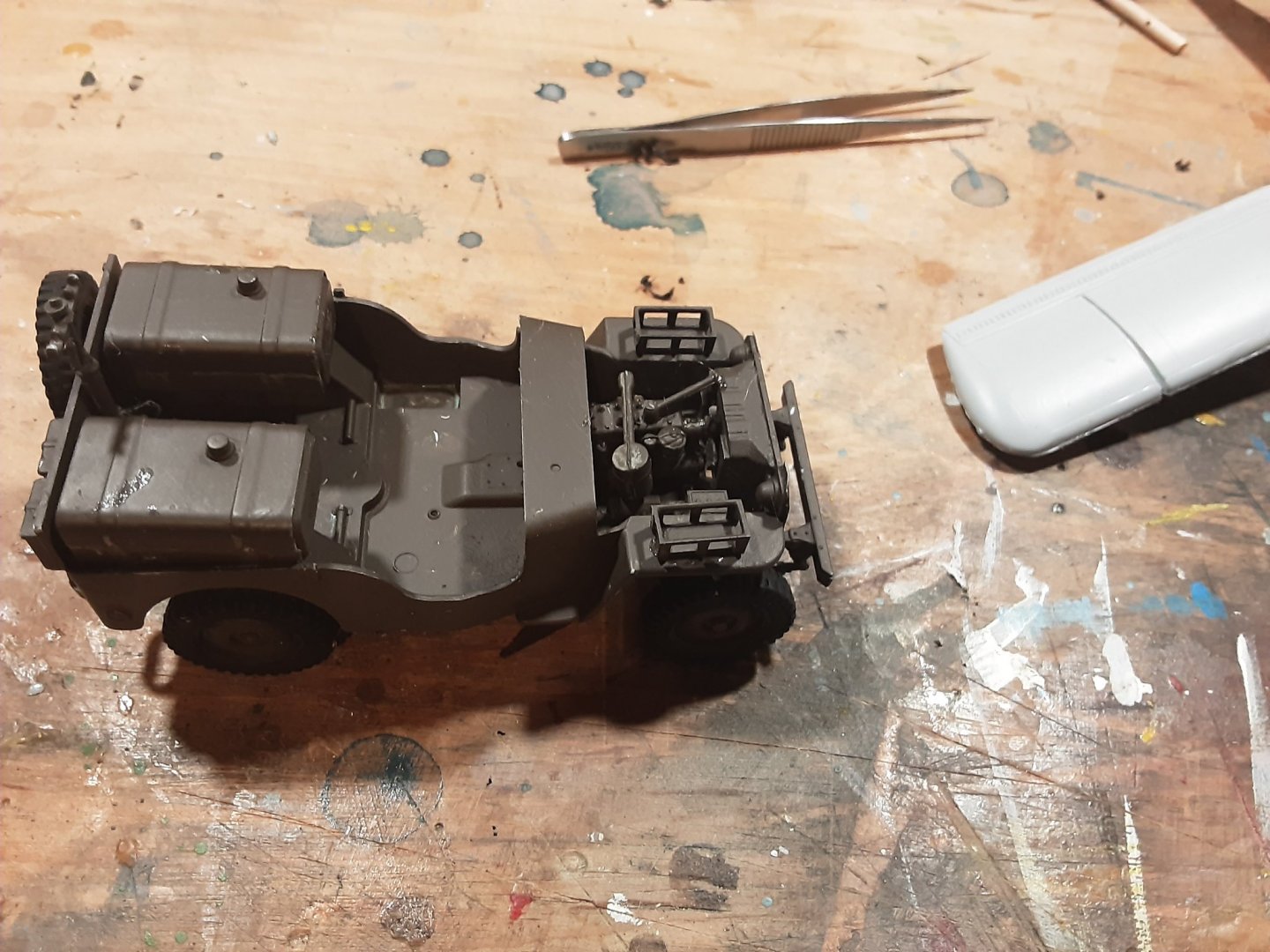

While I've been struggling with the Twin Otter kit, I decided to build this kit in parallel. Box says it is for 14 year old and up. The instruction are simple enough but don't show sequence within the individual steps which lead to some contortions when I went to install the driver. I literally had to install him one leg at a time, glue them together in situ, then glue the upper torso to the legs. But otherwise a fun and easy kit, altho there are no decals. Pictures follow:

-

What's wrong with Artesania Latina Constellation?

Jack12477 replied to Antti's topic in Wood ship model kits

Or you can do as I am doing and ignore the historical inaccuracies and everyone's opinion on it and build it as shown on the box art and have a nice looking model, because 99.99999 % of the people who come to your house and see the model can't tell you what a frigate, corvette or dingy is and will just comment "Oh that's a beautiful model ! How long did it take you to build it ?" My kit was a birthday gift from a friend about a decade ago. It's a hobby, so enjoy the kit ! You're not building it for a museum or hysterical (sic) society; you're building it for yourself. It is still a nice looking (fictional maybe) model of an old warship under sail. -

Happy New Year, all ! Got really bored with the build, so I decided to take a break and do some plastic models for a change of pace. Of course the Covid isolationism is not helping the boredom either. Been taking a lot of walks through the neighborhood with the Admiral, but that only goes so far. Will get back to this in a bit. Stay safe and healthy everyone.

-

You know "close" only counts in horseshoes or hand grenades 😇 {chuckle} Looking good so far EG !

-

I got tired of all 3 delivery services dropping packages on the uncovered front patio and NEVER ringing the door bell and leaving. Found 1 package by accident soaking wet in downpour. So I got a cheap battery powered motion sensor for $20 at Lowes and installed it by front door so now I get a chime if someone comes to door.

-

Yea, I sent 2 boxes of Christmas presents to my daughter/granddaughter in Maryland on Dec 12th via USPS Priority Mail 2 day delivery. Both boxes got to Merrifield VA USPS Distribution Center at 1519 hrs on Dec 13th. Last update on tracking was Dec 17th status "in transit to next facility arriving late". As of today Dec 31st, no delivery, no new status, lost in Merrifield VA . Did a Google Maps, it is 56 miles from Merrifield to ltheir local post office 1 hr 2 min by car, 4 hr 55 min by bicycle or 15 hrs 15 min walking. It might arrive by next Christmas 🤫🤔🤐🤨😐😑😒 Oh, she sent me a box via UPS on Dec 21st, arrived here Dec 23rd. United Parcel Spacers beat the USPS Pony Express. 😀😀😁

-

So I started assembling the model. Only 4 sprue! Not a lot of parts per sprue. Assembled the cockpit interior which cannot be seen once the 2 halves are glued together, installed all the tiny glass windows, glued the hull halves together. Simple ! Added the engine nacelles to the wings, selected the nose cone for the variant. Nose needs 20 g of weight to keep the nose wheel on ground (tail sitter), so I added a bunch of copper clad steel BBs. And now senility sets in, to keep the BBs in place I squeezed some Testors plastic cement over the BBs and attached the nose cone to the hull. (You all know where this is going! Right ! ?) 🤔☹ Yep a few hours later I notice that the port side of the nose is slowly melting....... 😒 Left it overnight to see what would happen after the glue had fully cured. Photos below show the disaster. Guess this is what happens to "ole coots" when they spend too much time underground.. 😷 The ole grey matter turns to mush. So today I took out the Tamiya White Putty and a small spatula and started filling in and reshaping the nose cone. Stay tuned !

-

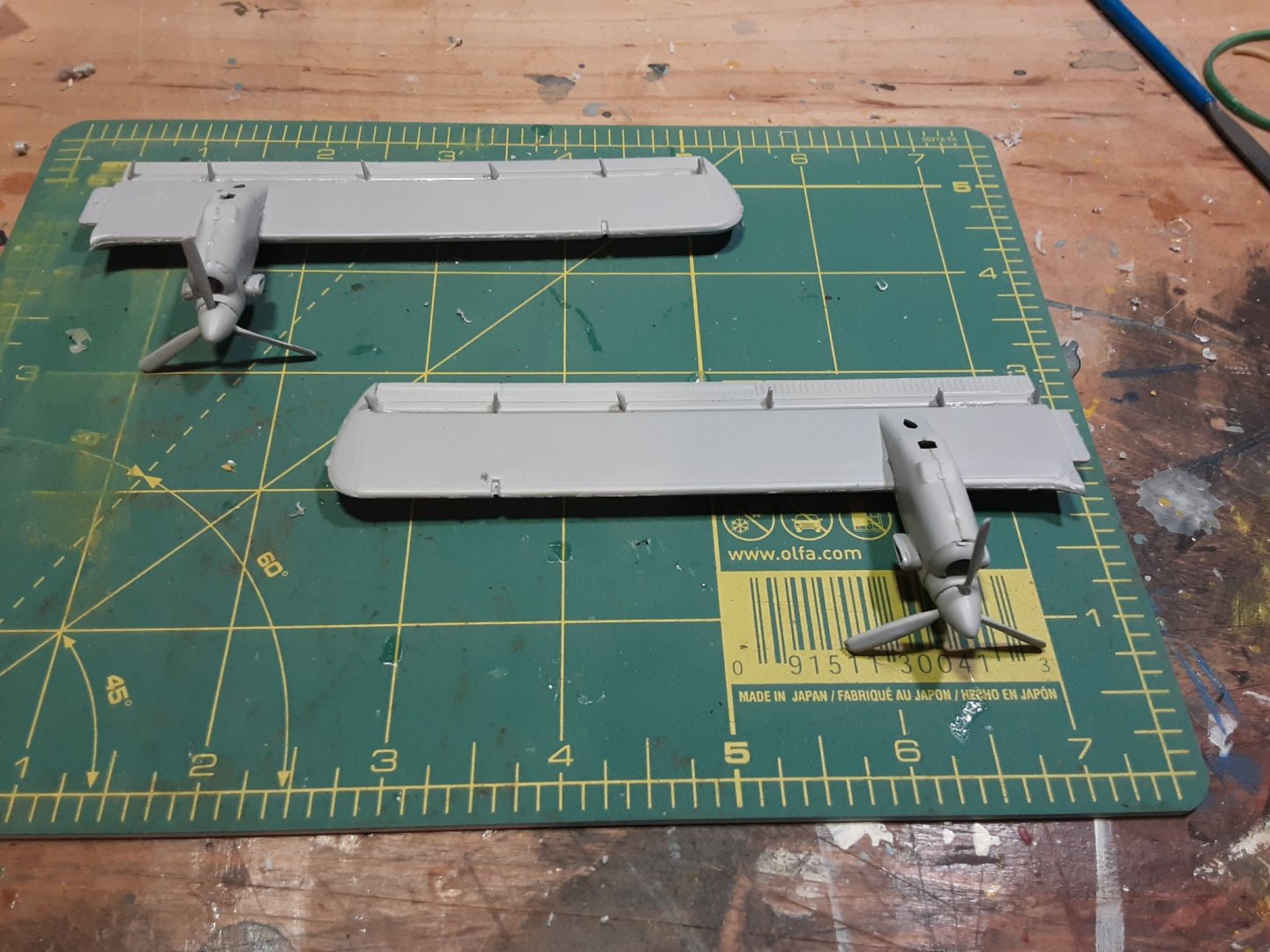

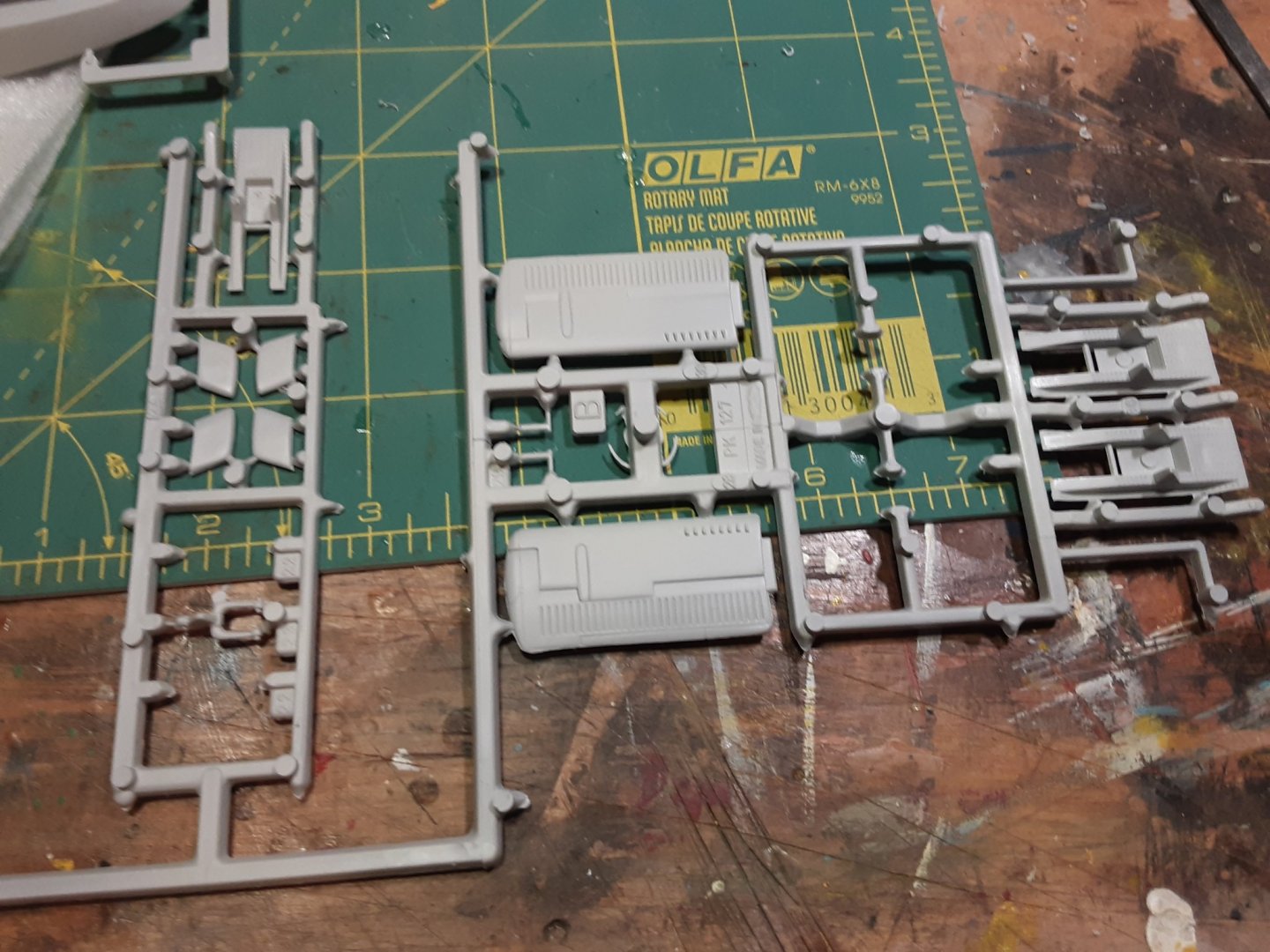

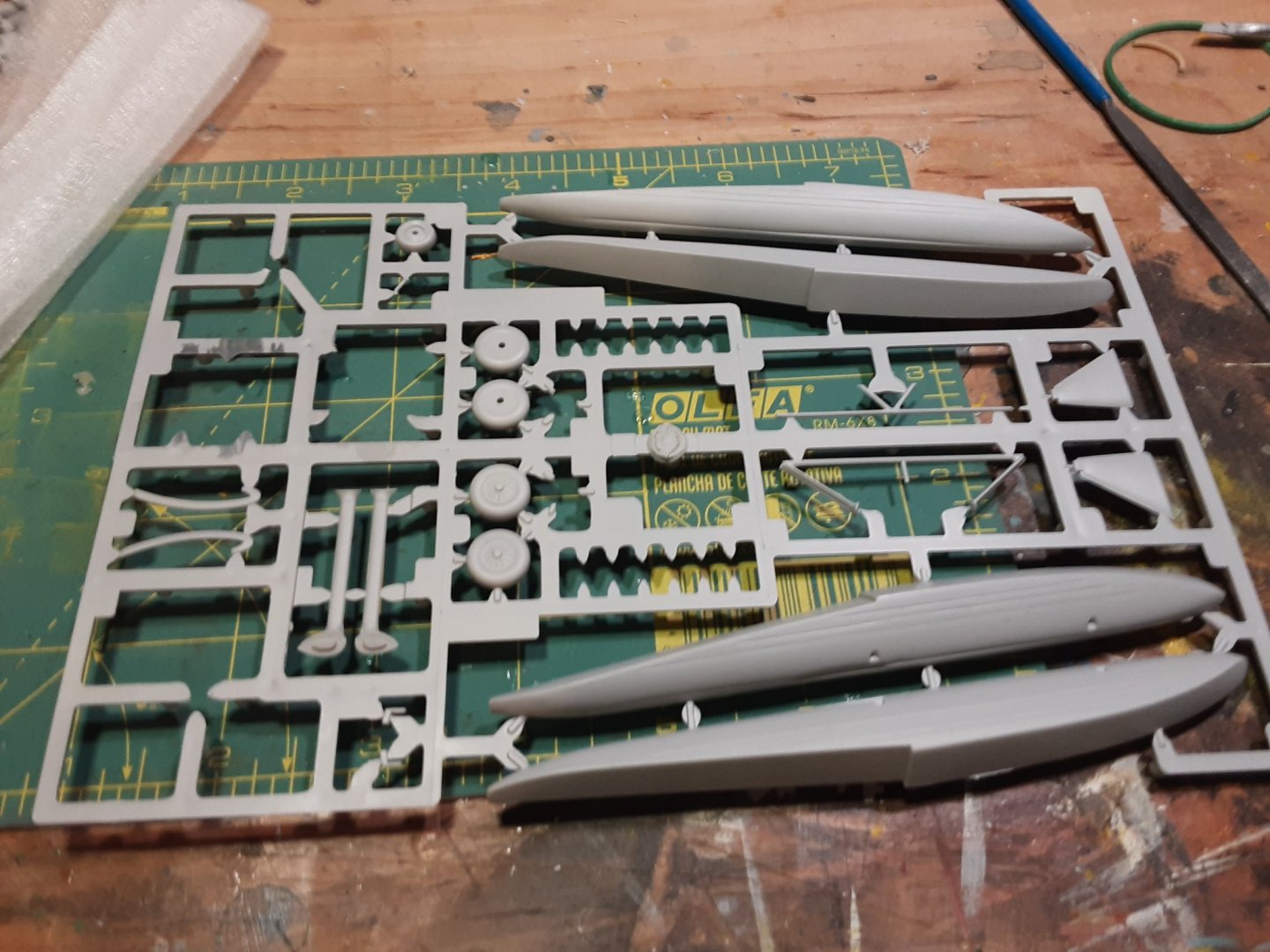

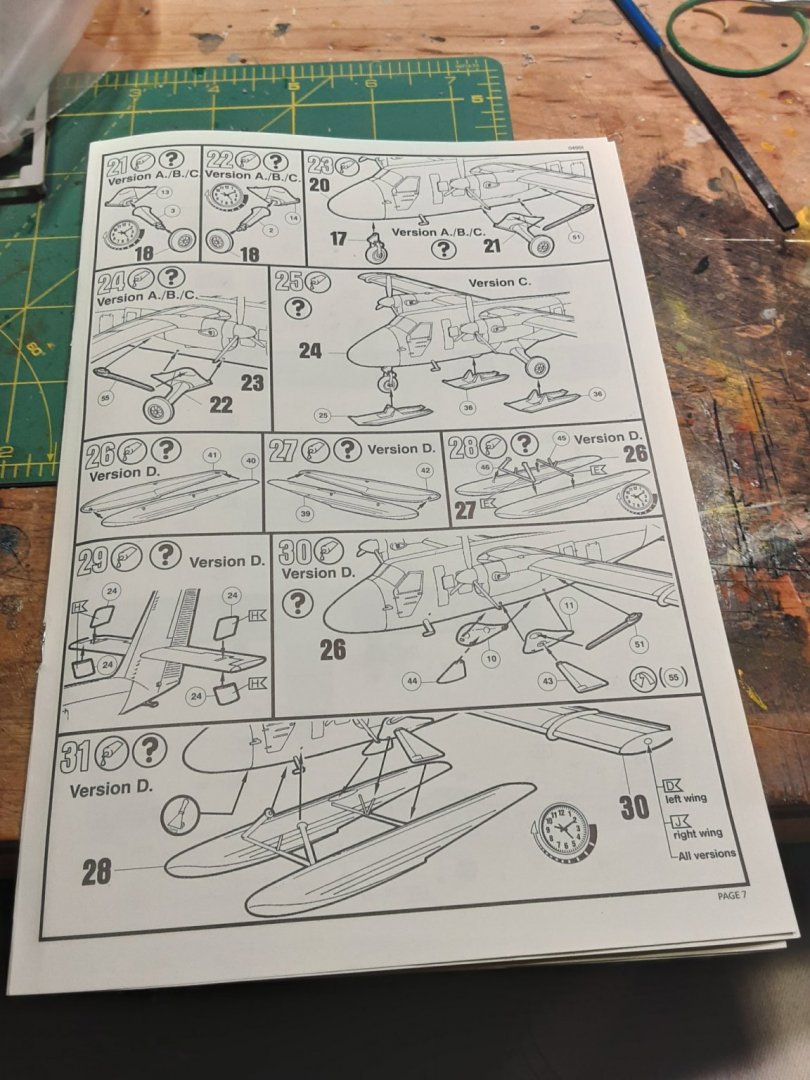

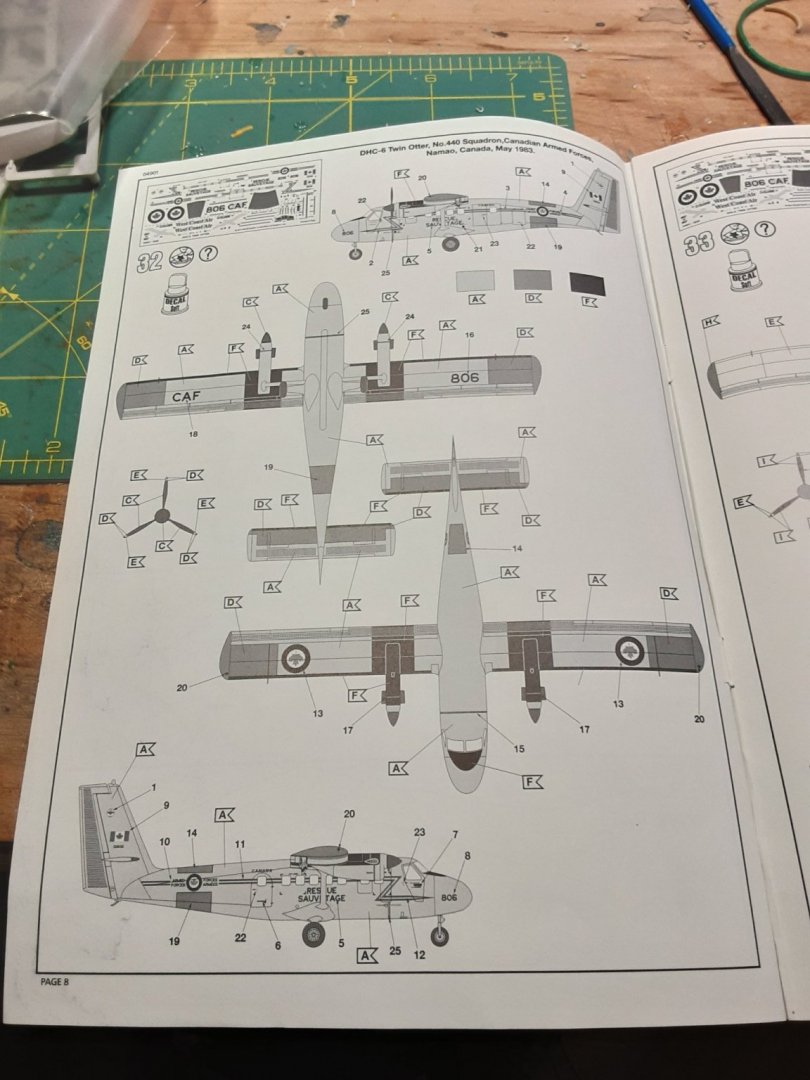

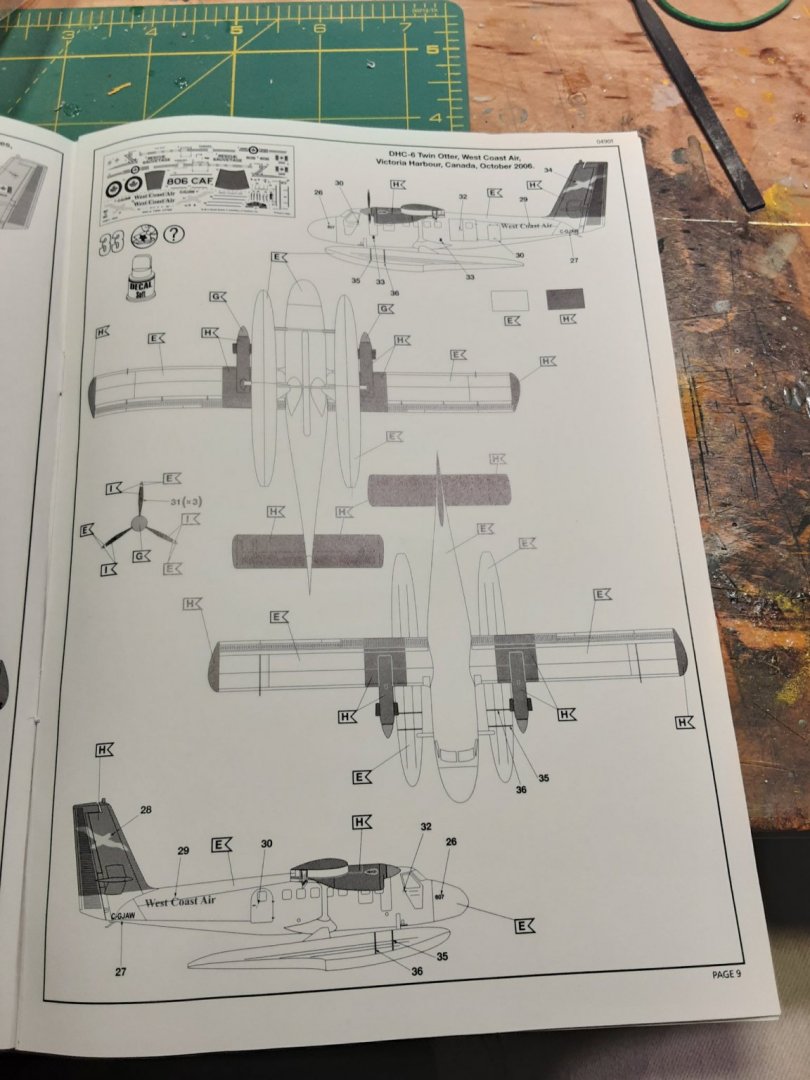

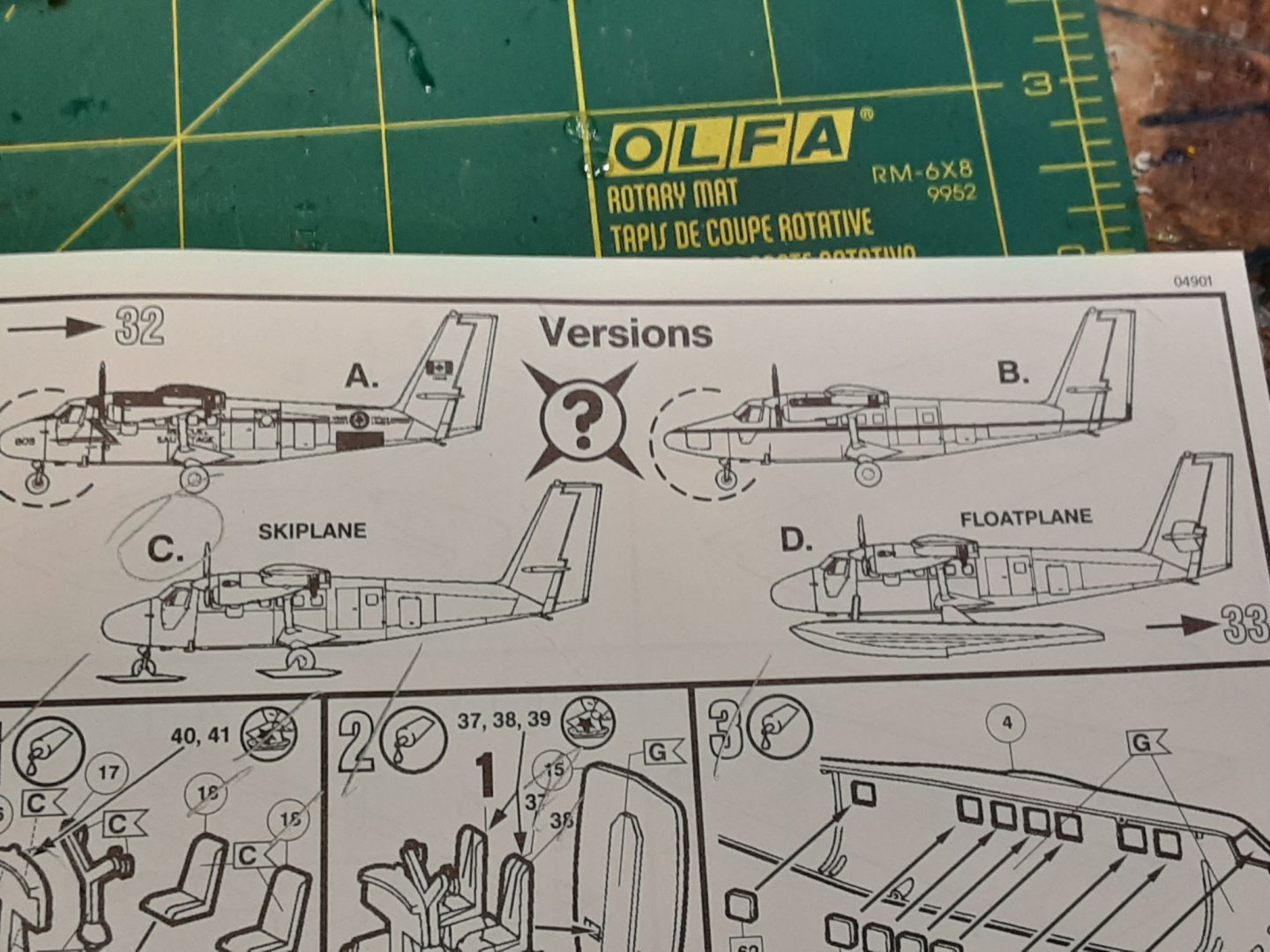

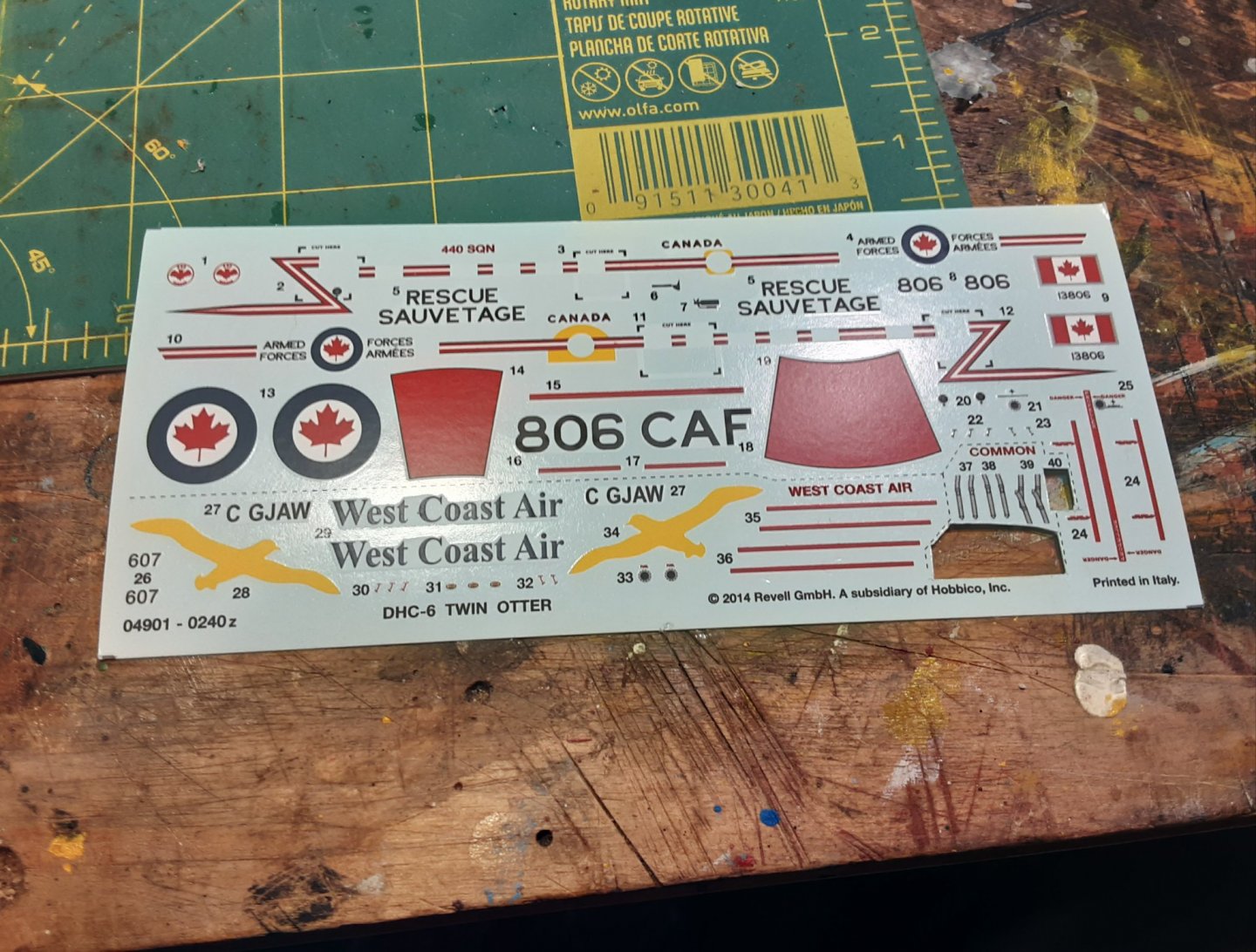

Now for build number 2 in the anti-boredom project, the DHC -6 Twin Otter done in the colors of the Canadian Rescue service. First the box art and sprue contents, sorry I started building before I dragged out the camera, EG. 😉 The model can be built in one of 4 variants, including a float and ski plane. I prefer the ski plane variant and will build it as such Decals provided

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.