-

Posts

7,568 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Louie da fly

-

Ships at Trafalgar - what kits are available?

Louie da fly replied to bruce d's topic in Wood ship model kits

And what about the Fighting Temeraire? -

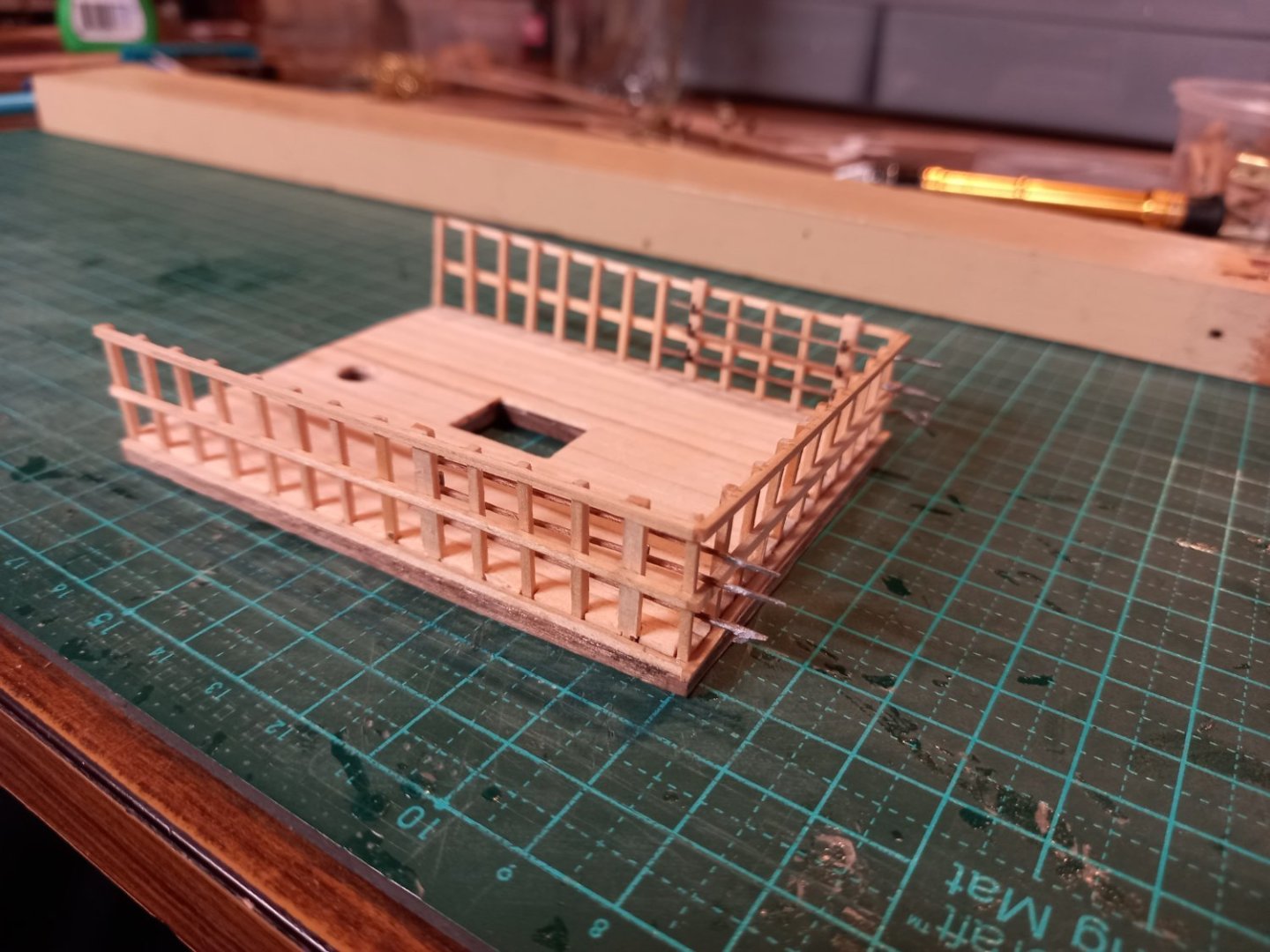

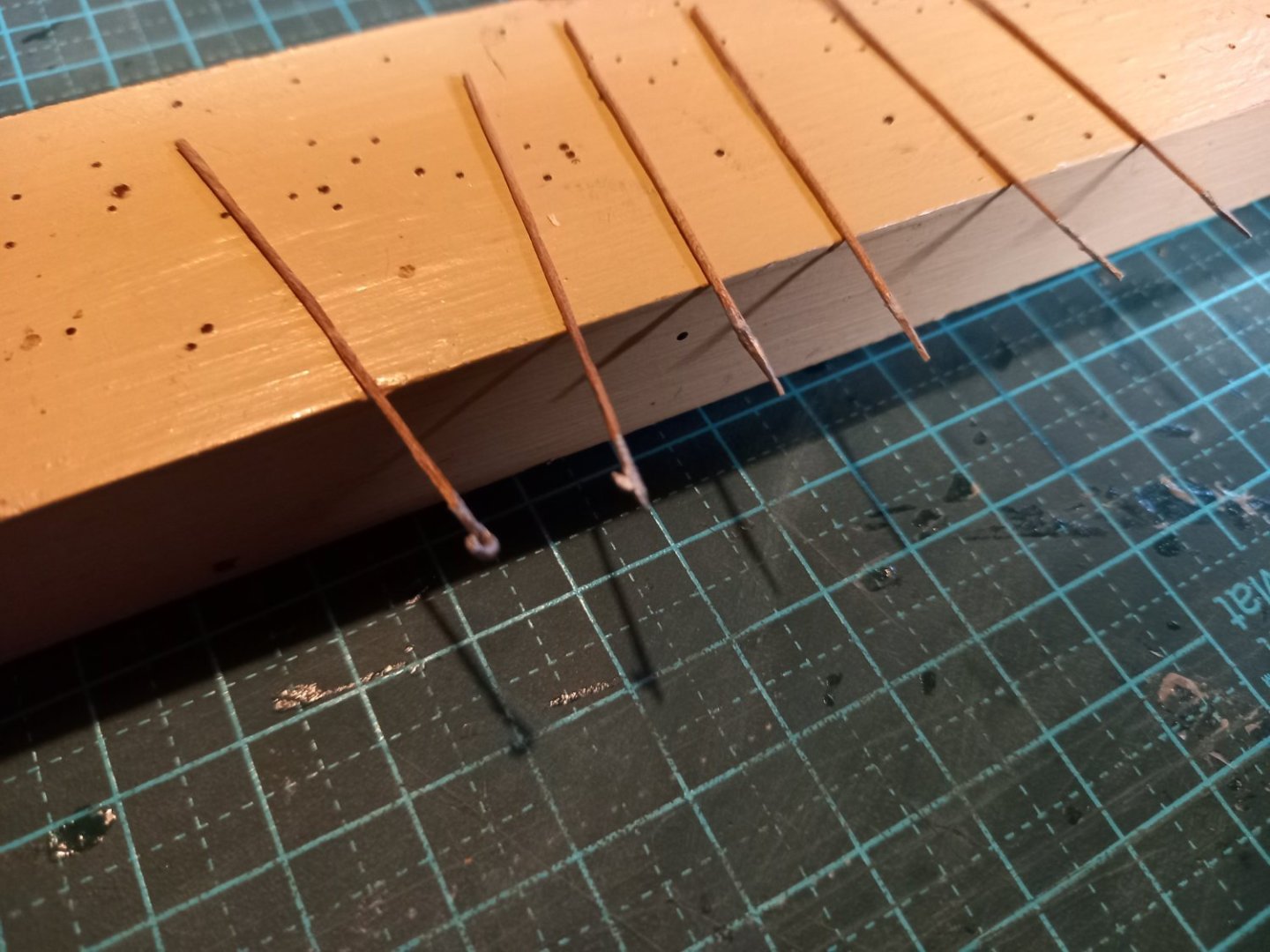

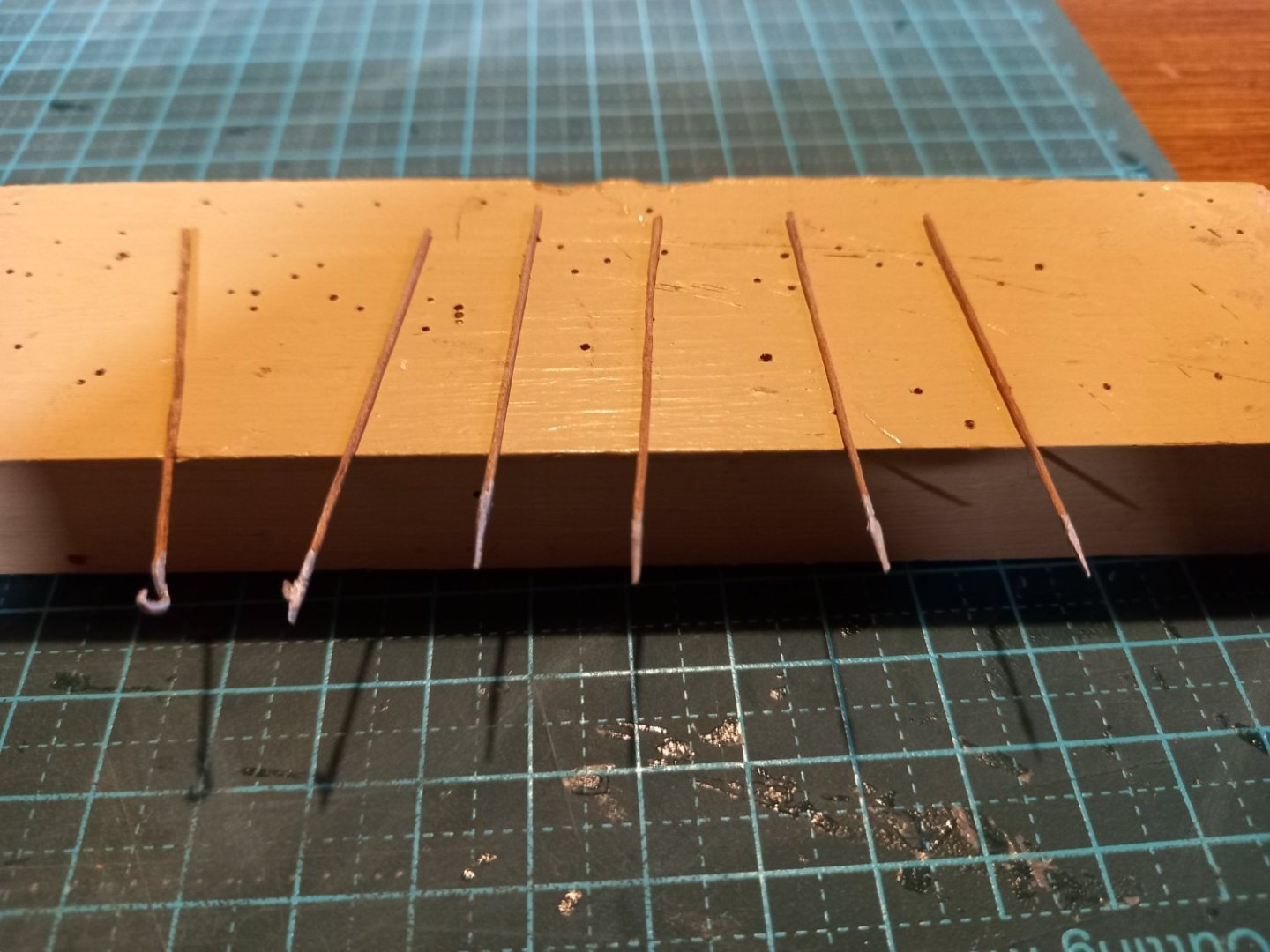

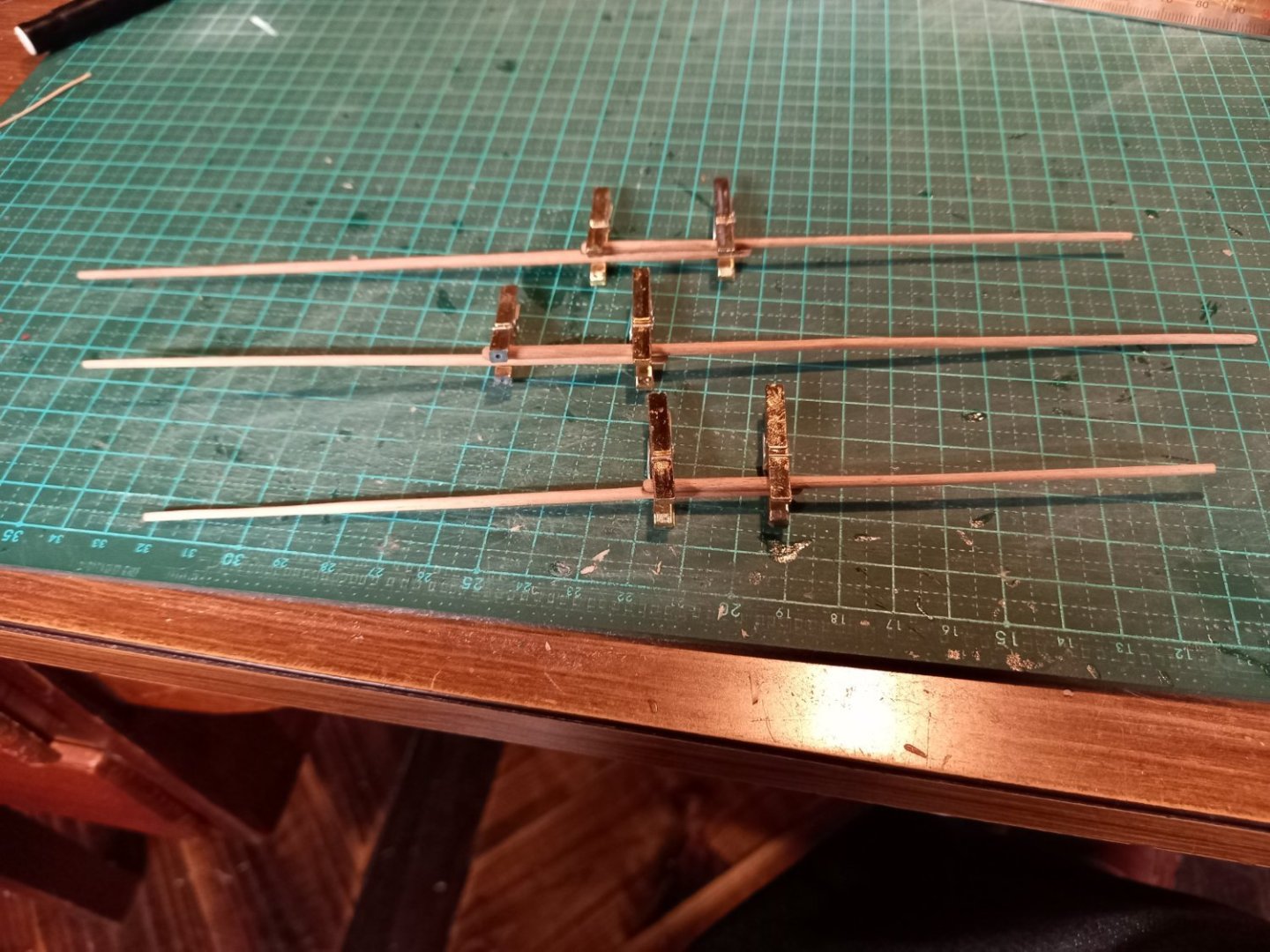

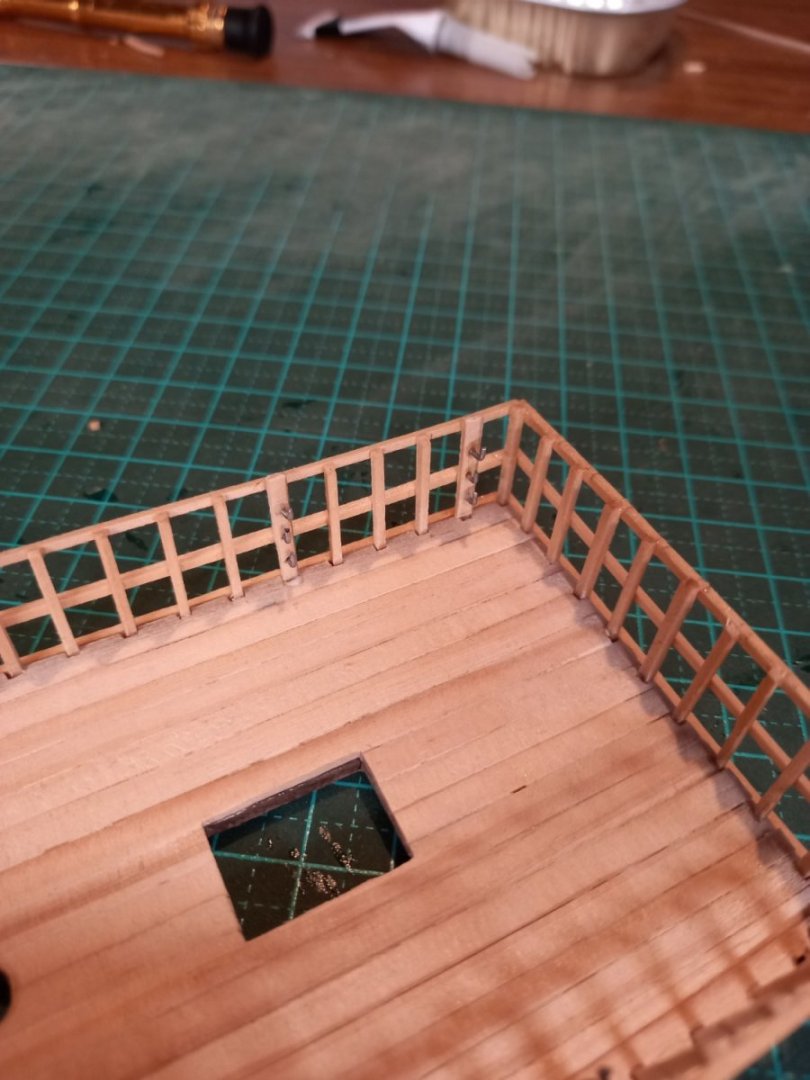

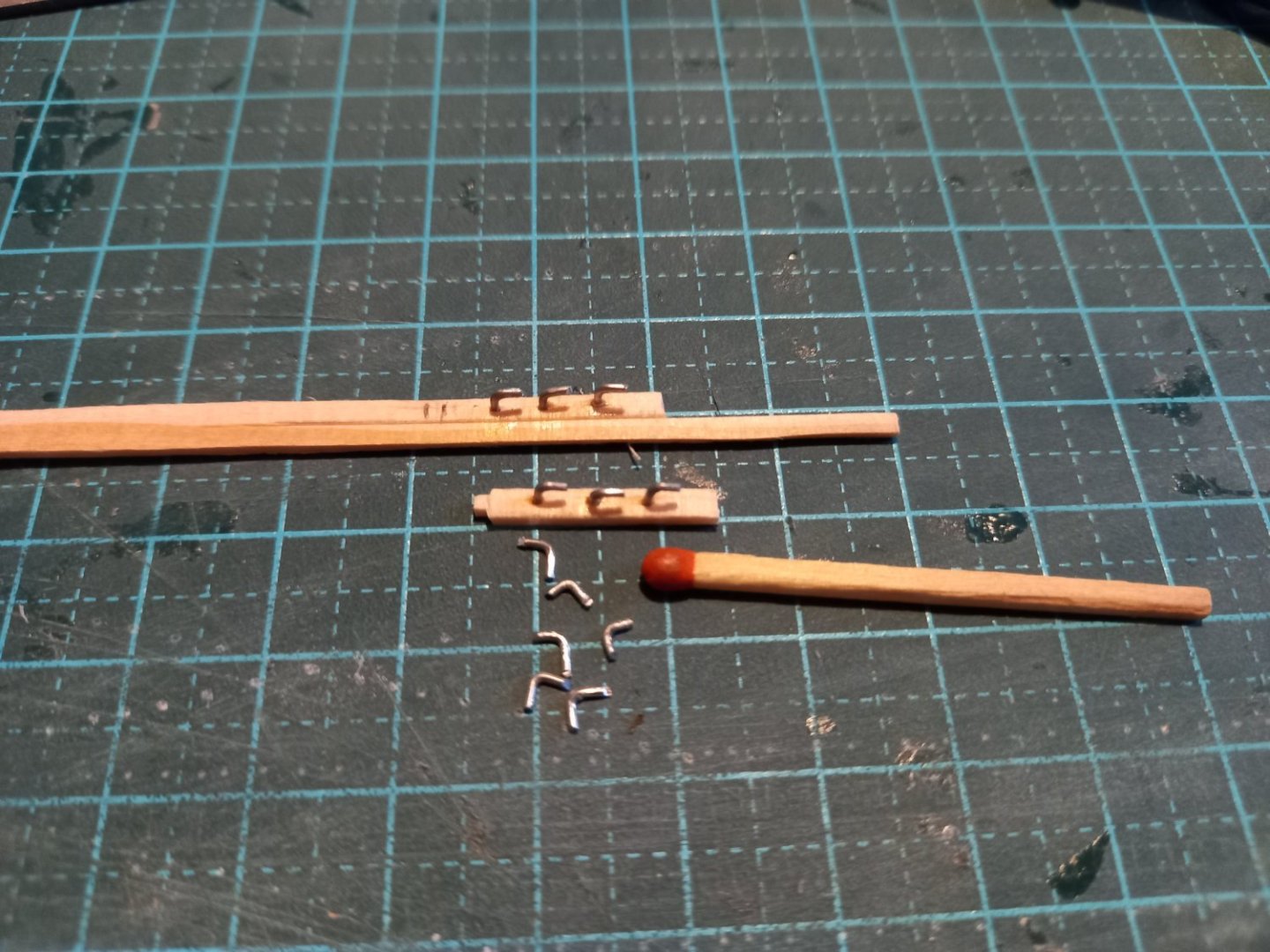

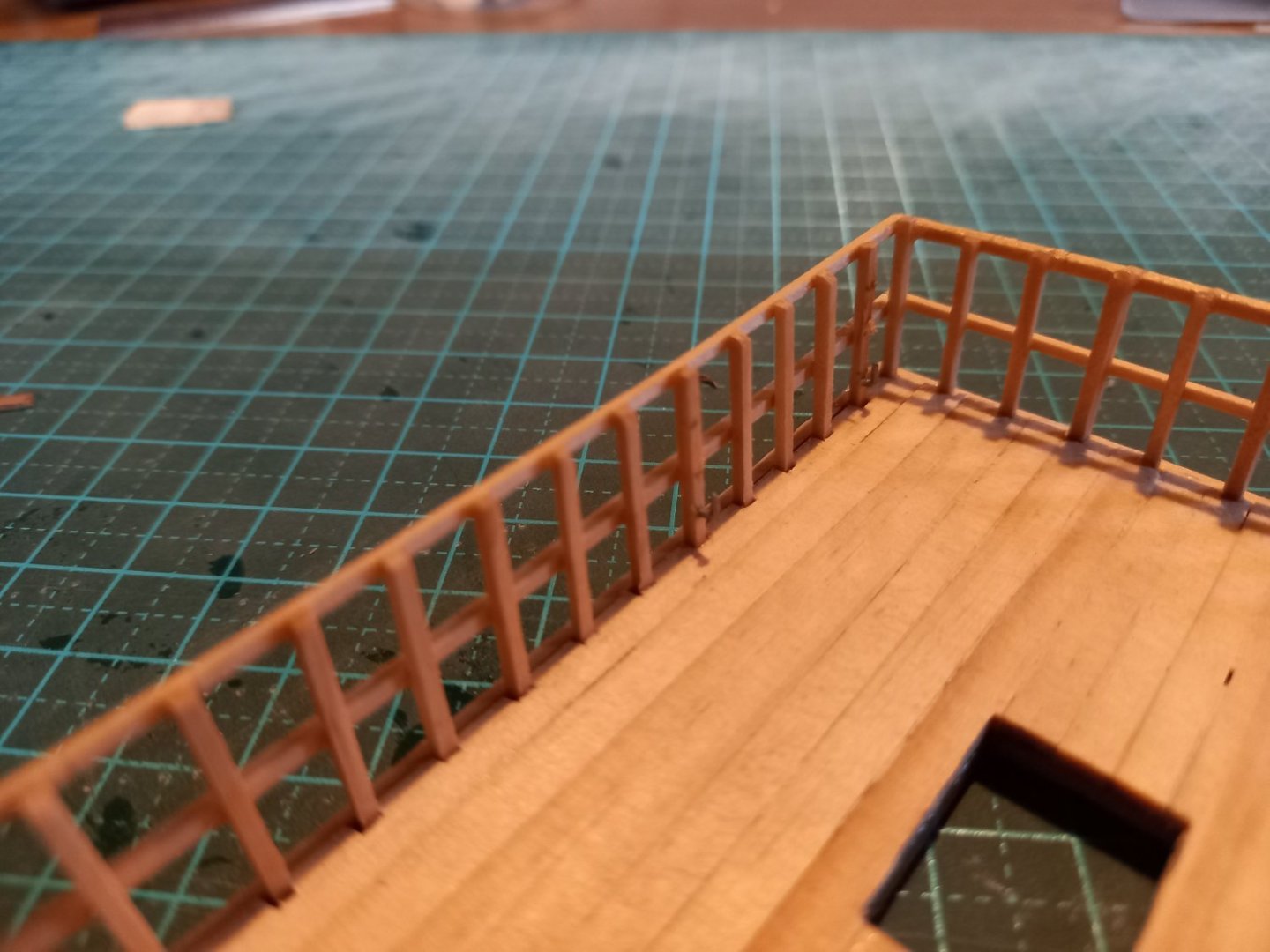

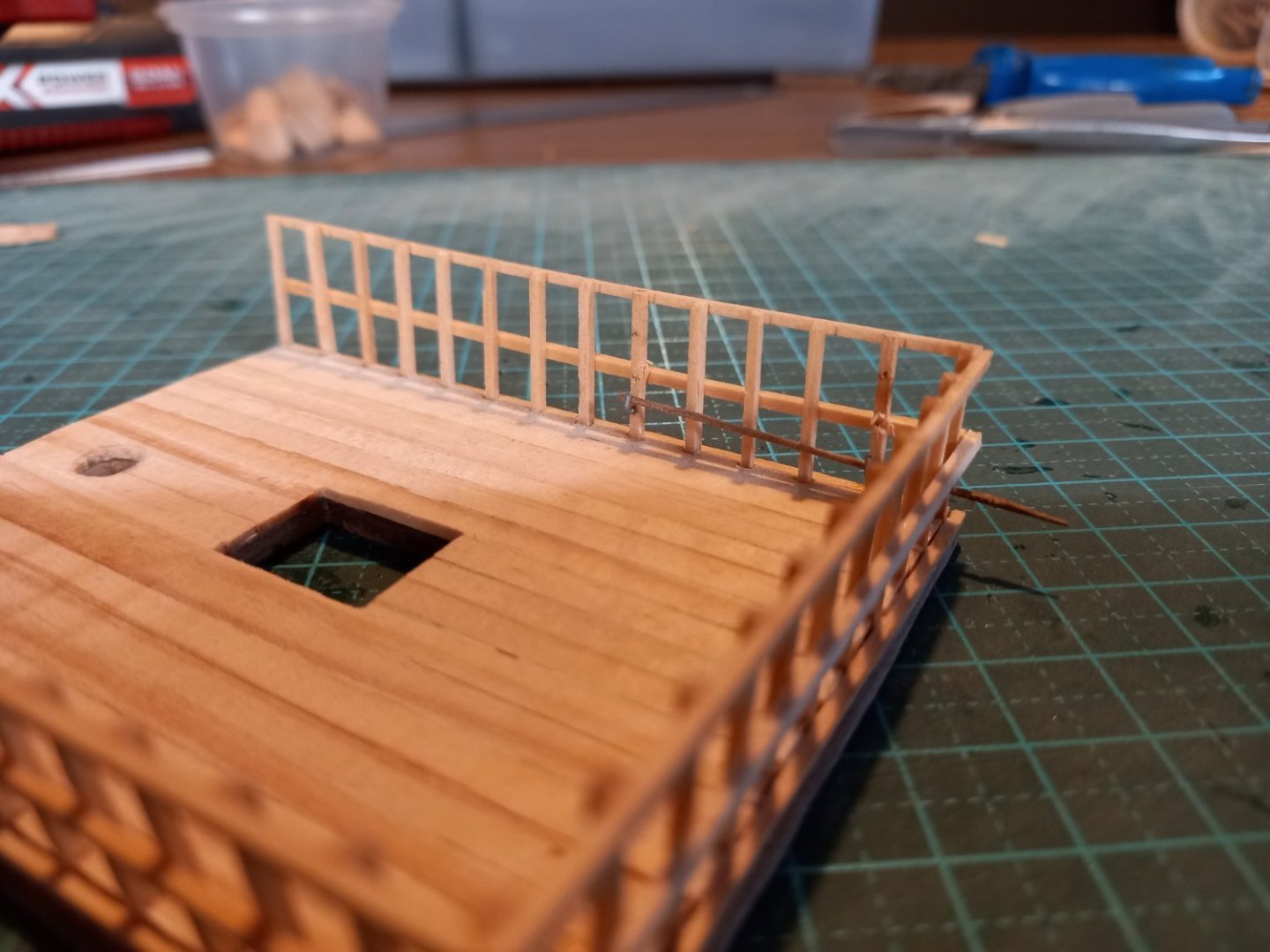

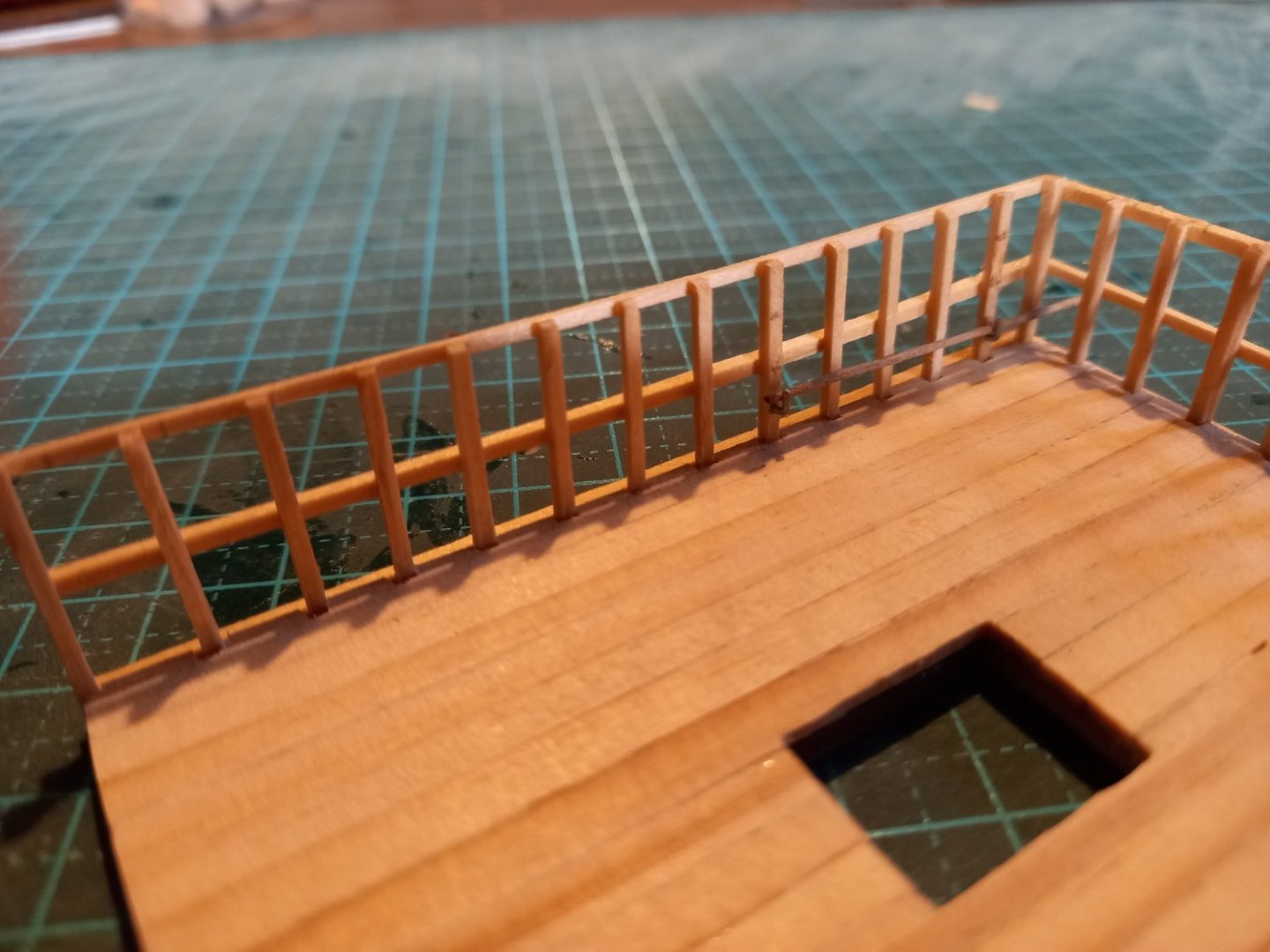

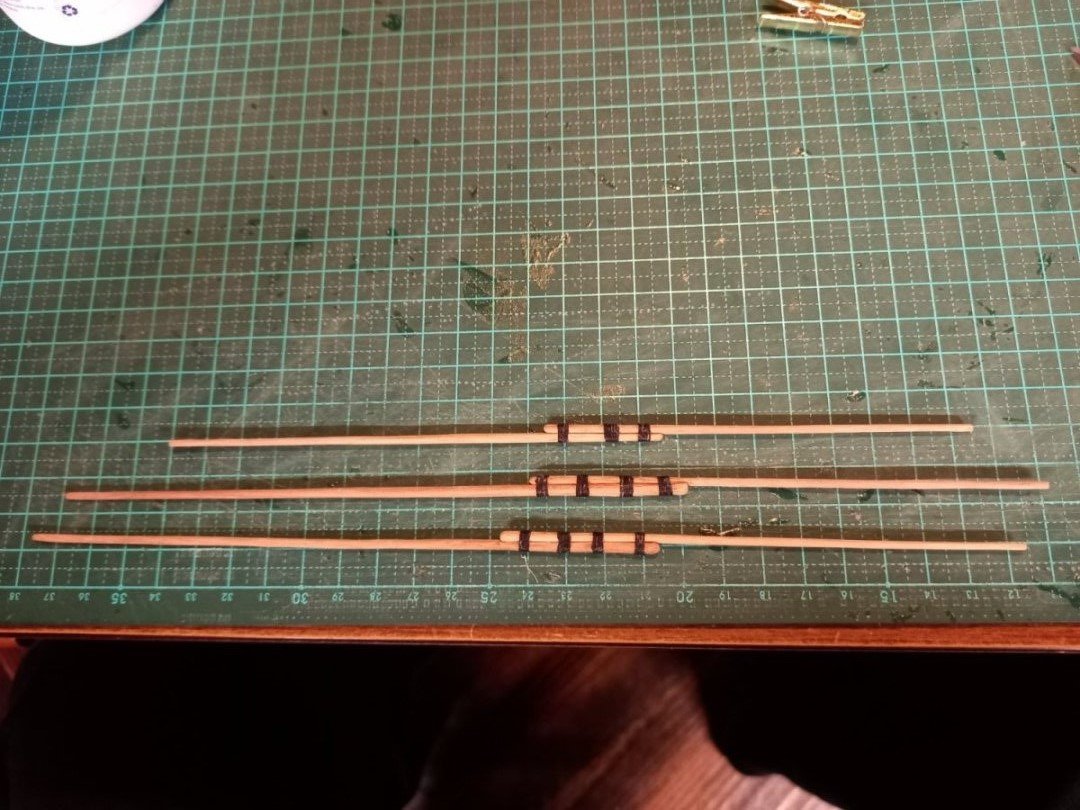

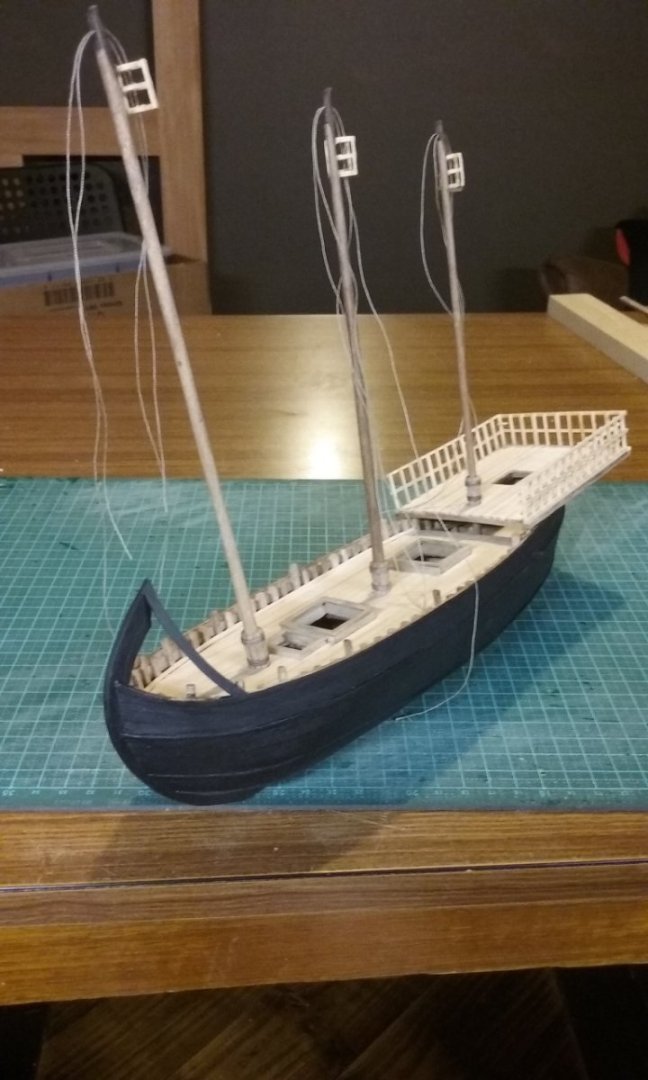

Thanks everybody for the likes and comments. I'm afraid I'm not very systematic in building. I often make things as the mood takes me rather than follow a logical sequence. Sometimes I end up painting myself into a corner, but so far I've mostly managed to avoid that on this build (touch wood). I've puzzled for some time over how to support the spears and other pole-arms sticking out at the stern shown in several of the mosaics. I came up with several ideas but none really seemed likely or workable, until I thought of two metal hooky things, (made of bent wire) attached to the uprights of the side railings, to support each shaft. First I tried adding them to the existing uprights. But there was too little space to make the holes to take the hooks and the uprights were too narrow - the holes were almost the width of the uprights. So I removed the existing uprights and made new ones rather wider but still looking like they belonged, made the holes and inserted the hooks before putting the new uprights in place. Here are the pole-arms. Mostly simple spears but one was more like a harpoon and another had a head in the shape of a shepherd's crook - which I believe was intended to cut the rigging of an enemy ship. Took a fair bit of work - they're pretty small - but finally got them done. Painted the heads silver, and the hooks on the railings black to resemble forged iron. And here they are dry fitted in place. You can see the pole-arms sticking out the back railing. I've also been working on the lateen yards, for the fore, "middle" and mizzen masts. Each yard is made of two spars lashed together; the upper one longer and with a "hollow" cut into it to take the lower one. (Thanks to Woodrat for the information on how these were configured). Here they are glued together: And with the lashings in place. Steven

- 409 replies

-

Titanic by Tsm209 - 1/100

Louie da fly replied to Tsm209's topic in - Build logs for subjects built 1901 - Present Day

Nice work. I'm following with interest. I finished my solid hull model of the same ship, but was not terribly satisfied with it - particularly whether I'd got the details right. So I'll be very interested to see what you do with yours (no pressure, of course!) Steven -

Some updates: Making a stand for the ship out of walnut wood. I'm also re-making the stand for my Winchelsea nef - I've never been happy with the old one. The supports are made but need smoothing off. The joining beam is re-used from the old stand. Once finished I'll post it on the nef build log. And here are the yards for the three masts. Steven

- 409 replies

-

Just a bit of context - your gob is your mouth, your cakehole, your north-and-south. So it means being smacked in the gob - pollaxed, blown away . . . Steven (Better than a poke in the eye with a burnt stick). Steven

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

Glen, I'm gobsmacked. That's amazing work. Steven

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

AAaaand - finished! I've simplified the rig and I'm not totally happy with the sails - my fault. I should have consulted with my wife before I cut, folded and ironed them. She did what she could to correct my mistakes, but there's only so much you can do, even when you've been trained as a seamstress. Ah well, all part of the learning process. Steven

-

Thanks everybody for the help and suggestions, and in particular thanks Woodrat for the photos of vessels with weathered pitch. I think I removed just the amount of paint I needed to on my first run-through. I really don't want to do any more. But I'm thinking seriously of adding greenish below the waterline for weed, and discoloration where water would run down the hull fairly often - such as where the anchors sit, scuppers etc. And weather the anchors when I get to that stage. I suppose I'll also have to weather the aftercastle (I think the mosaic shows it as bare wood, probably pine) with light greys etc as well to continue the theme. Interesting times ahead! No - it's not shown that way in the mosaic so I won't be doing it. Steven

- 409 replies

-

Turned out all right after all, and it actually looks as if it was always supposed to be like that.

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

Well, I dry fitted the stuff that's already made but not ready to be fitted, just to get an idea of how it's going to look.. And I tried a bit of mild weathering by sanding lightly with fine grade sandpaper in places where I think there'd be a bit of wear. Didn't turn out too badly at all. Encourages me to go a little further (without pushing it too hard - I don't want to mess it up). Mark, that's two coats of standard cheapo acrylic from a school-style set for doing pictures with. Steven

- 409 replies

-

The client took delivery of the model yesterday. Very happy with it. I didn't think to take a photo of him holding it, unfortunately. Steven

-

And painted black to represent waterproofing with pitch. It's all a bit monotone now - I'm thinking of perhaps doing a bit of weathering down the track to add a bit of interest. I haven't weathered a model before, so I'll have to do some research before I start. Steven

- 409 replies

-

A very interesting project. It's very different from the kits we get nowadays but I think you could make a very worthwhile model from it. Is it to be planked, or is that the finished hull configuration? Though they're not built the same way, I'd recommend you check out the other Viking model build logs in this section to pick up some ideas. And ask questions if there's anything you don't understand. They're a very helpful bunch here on MSW. Steven

-

Yes it was, rather. They were way cool. But I still have the warm fuzzy feeling of having made them successfully, plus the satisfaction of making something more appropriate - and making it just as successfully, and the evidence that my skills have improved to such a degree that I can take something like that on with the confidence that I'd get it right.

- 409 replies

-

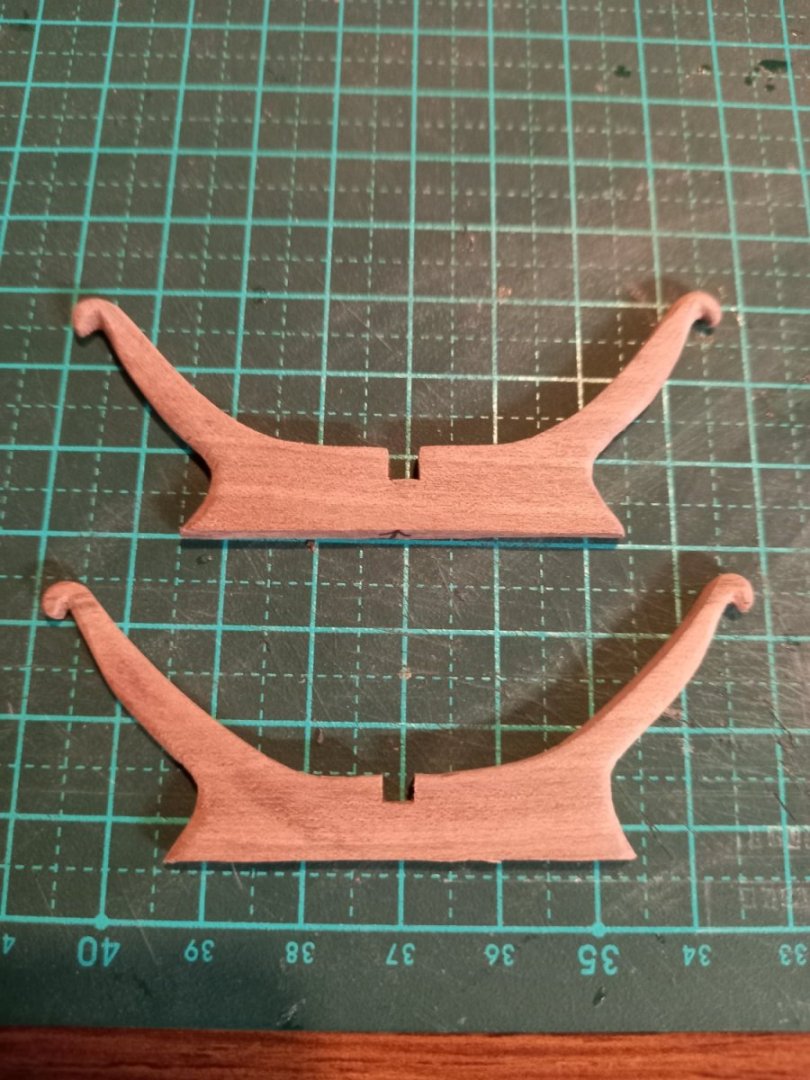

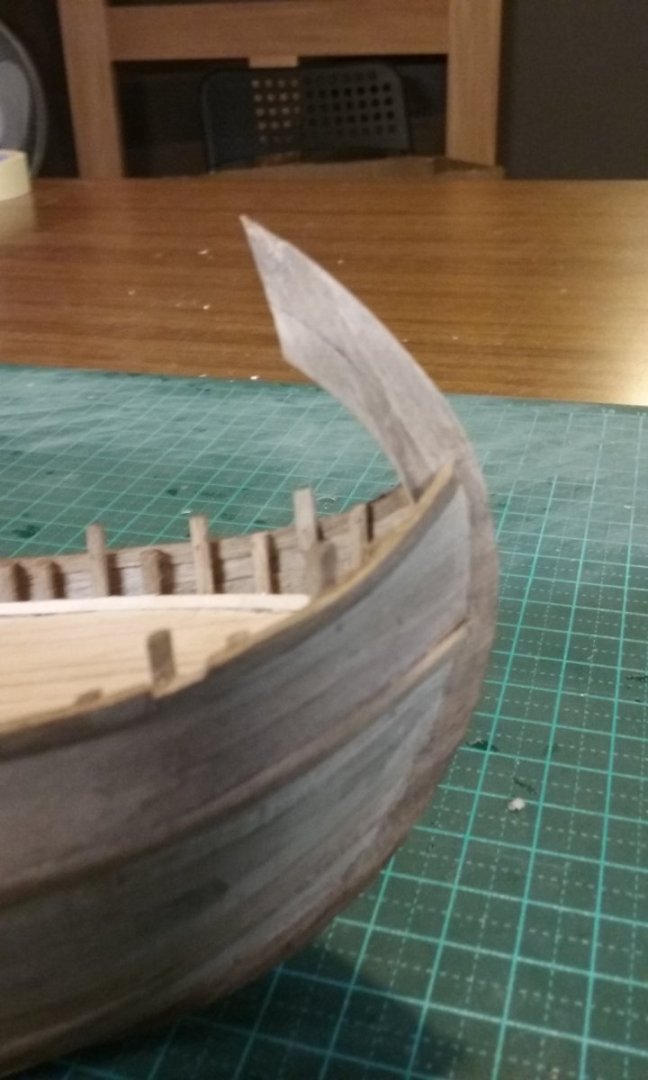

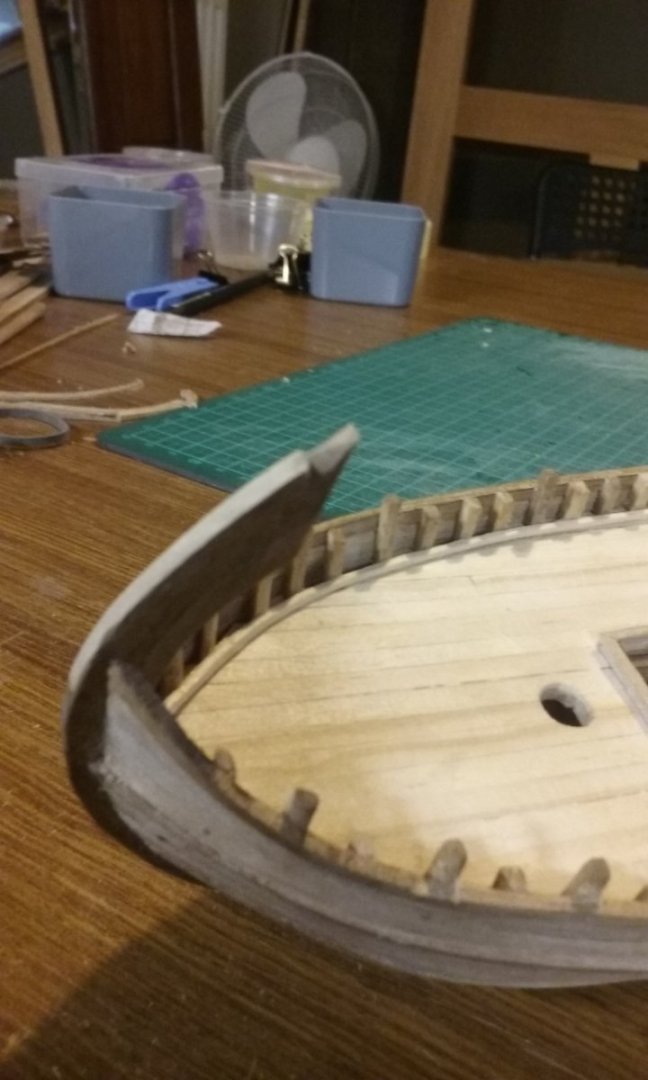

Thanks, Pat. I'm pretty chuffed with how they came out, but . . . see below. Dick, I haven't seen hawse holes in any representations earlier than the 14th century. They may just not have been invented yet. But certainly the bitt in that opening would probably be doing the same job, even if not quite so efficiently. I agree about rabbeting the joints. Much better. And though the joint was probably nailed, my idea was to fix each join with a treenail. Regarding the possibility of an anti-splash cover, well, could be. But I'll go with the way it's presented in the mosaic. I'm doing enough speculation as it is without adding more. Now for the bad news - after a period of existential angst, soul-searching and questioning the meaning of existence I came to the conclusion that those braces just didn't look right. I can't see what purpose those exaggeratedly complex curves would serve, why any shipwright in his right mind would go to all the trouble of making them and why any skipper in his right mind would ask for them. Yes, they are a possible interpretation of the mosaic, but not a likely one. I think Occam's razor - the idea that the simplest solution to a problem is probably the correct one - applies here. After some discussions with and suggestions from Woodrat (thanks, mate!) I've re-considered the braces and made them simpler. Still a 3-dimensional curve, but more logical. But first I revisited the mosaic and decided the stempost was much more curved, and wider, than the original picture shows. So I decided to trim it down to be closer to the one in the picture. Note the pencil line in the photo above. Even that wasn't quite right, so I didn't follow it exactly. Then I put in the rabbets in the gunwales to take the braces. And corresponding rabbets in the top of the stempost to take the other end of the braces. (I later changed the angle of the rabbets so everything fitted as smoothly as possible - a bit of trial and error involved in getting it quite right.) Here are the new braces. Much simpler, and they carry the curve of the gunwale up smoothly to the stempost. A tiny bit of tidying to do, but I'm much happier with this version. Steven

- 409 replies

-

Beautiful work, John. I bet a lot of your talking to the public is because they ask questions about the model. She's a real attention-getter. I find that a ship at the framing stage seems to get more attention than one that's been planked. People get fascinated by the sheer number of timbers needed beneath that outer skin. Steven

-

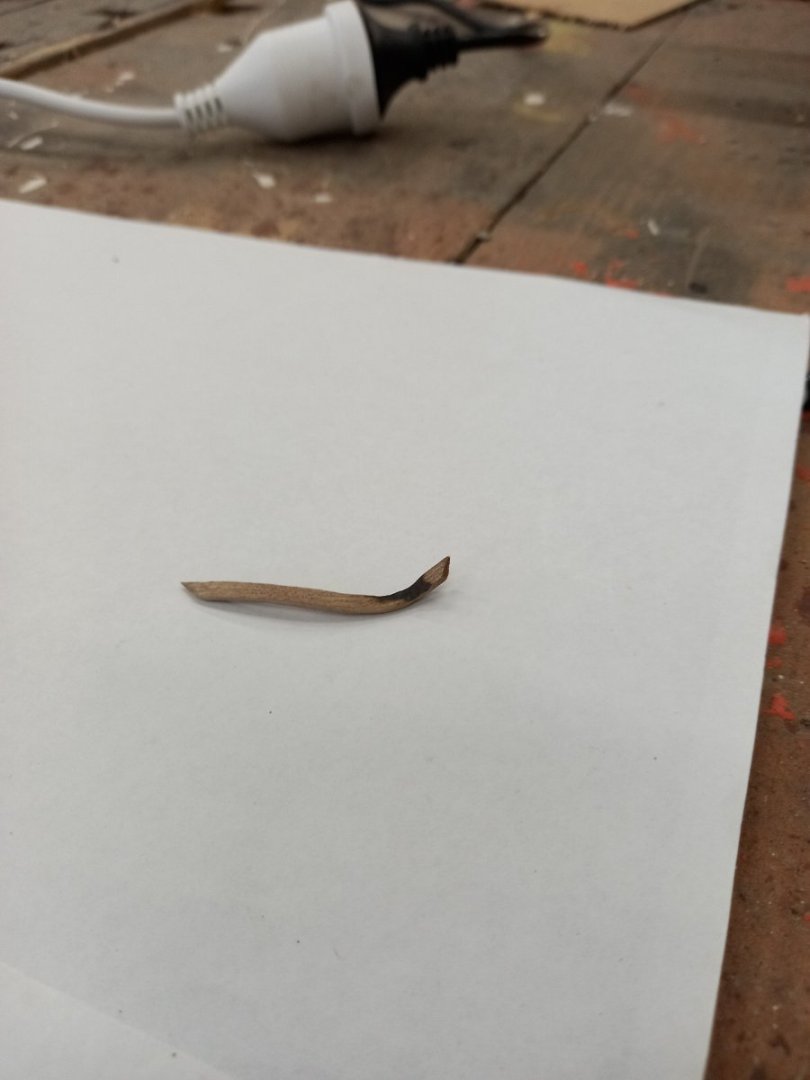

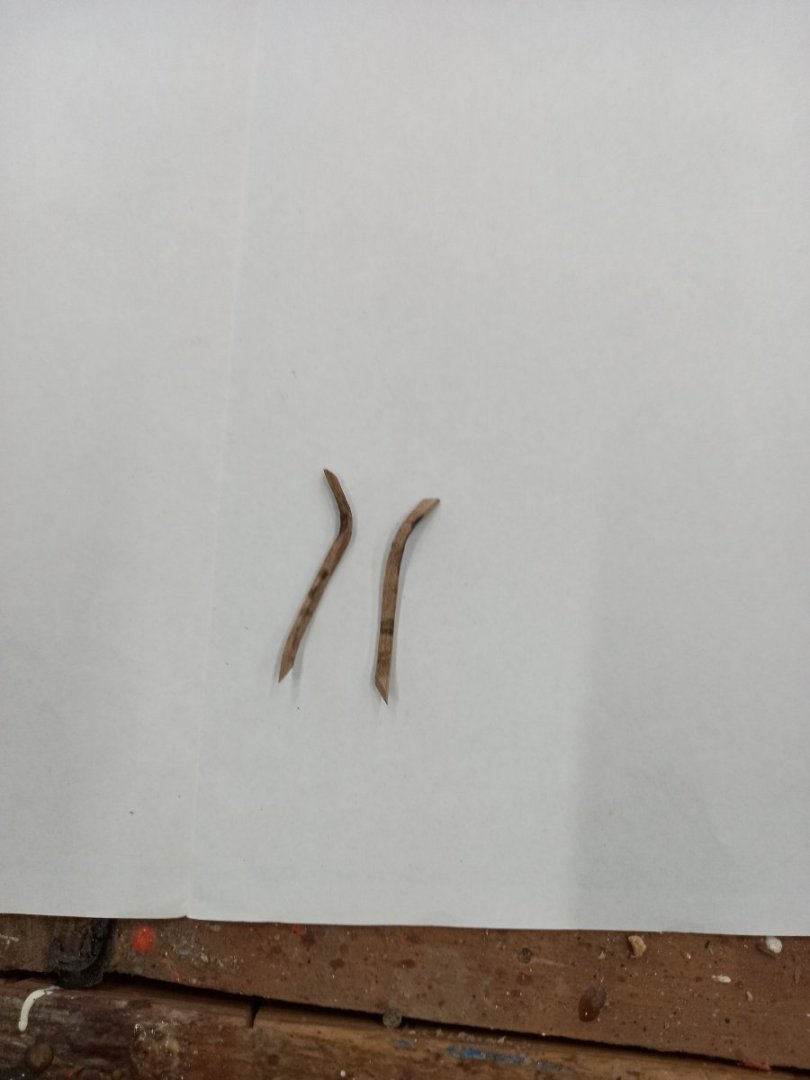

So here's the "bow brace" (see my previous post). Very complex 3-dimensional curve, bent using soaking in water plus my trusty soldering iron. A bit of charring, but as it's going to be painted black it really doesn't matter. I'm actually very happy with this - I've come a long way in heat bending since my first attempts on the dromon model about 7 years ago. The two sides are virtually identical mirror images of each other, and look a lot like the original mosaic. I have no idea if this is really what that thing looked like, but it seems to work for me. And here's the windlass with holes cut and ready to install. Steven

- 409 replies

-

Thank you, Glen. Yes, Louie's been around since the early 60's when he was in black and white on TV (and pretty primitive). He's got a place in Australian folklore and we're actually rather fond of him because of his rebellious attitude - he's what we in Oz call a larrikin ("Larrikin is an Australian English term meaning "a mischievous young person, an uncultivated, rowdy but good hearted person", or "a person who acts with apparent disregard for social or political conventions") which fits very well with the Australian psyche. But it's "rubbish tip" (i.e. garbage dump), not "rubbish tin" - a whole bigger area of rubbish to come from and much more shudder-inducing - which is what the advertisers had in mind . . . Steven

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

That's very impressive, Glen. She's really taking shape. I wish you the best of fortune in inserting her in the bottle without mishap. (BTW, I used weeds I found growing across the road from my home in one of my own models, as 'padding' or perhaps 'underlay', for the cargo in the hold (as it had been found in the remains of a 15th century cog). Your deckhouse looks very good. Steven

- 174 replies

-

- Waa Kaulua

- bottle

-

(and 1 more)

Tagged with:

-

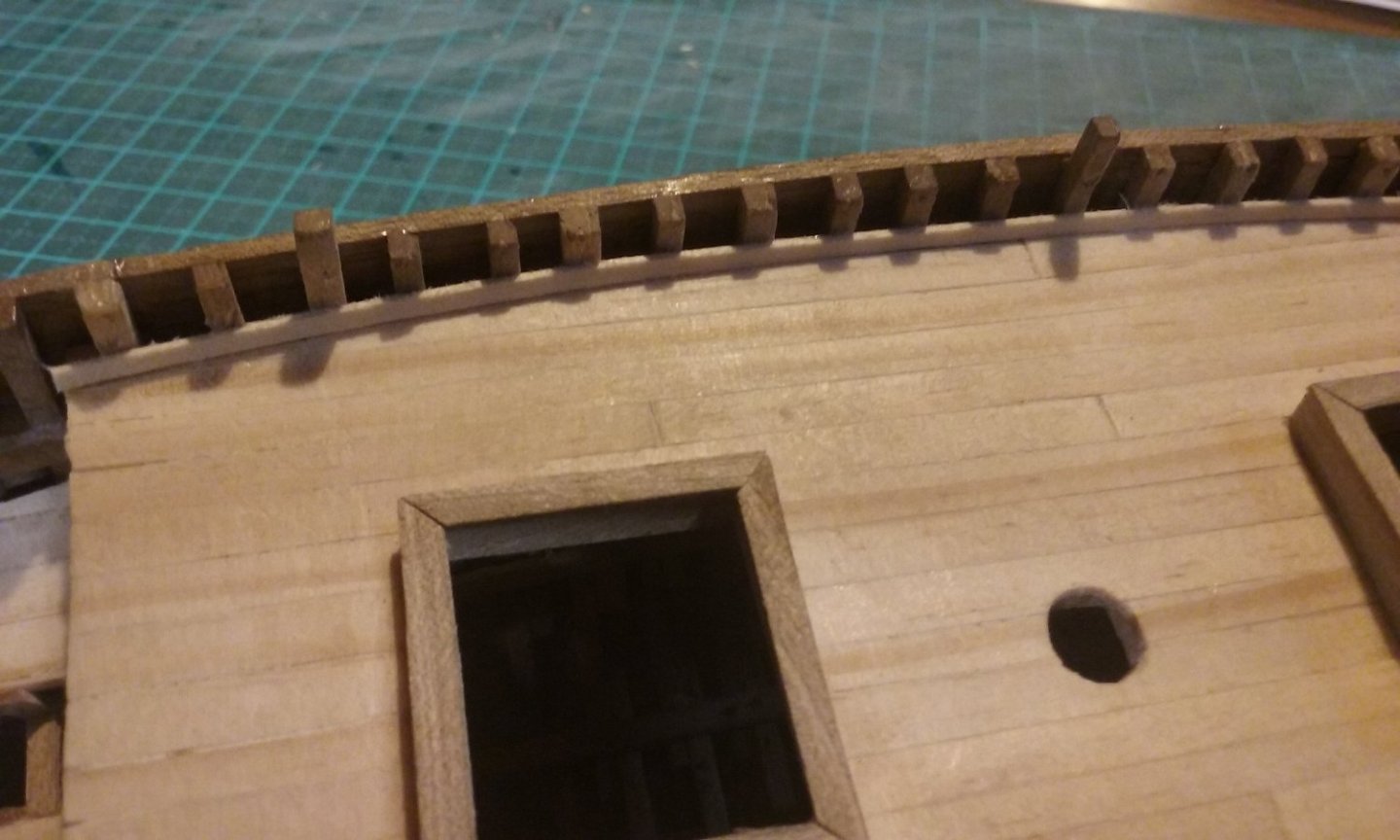

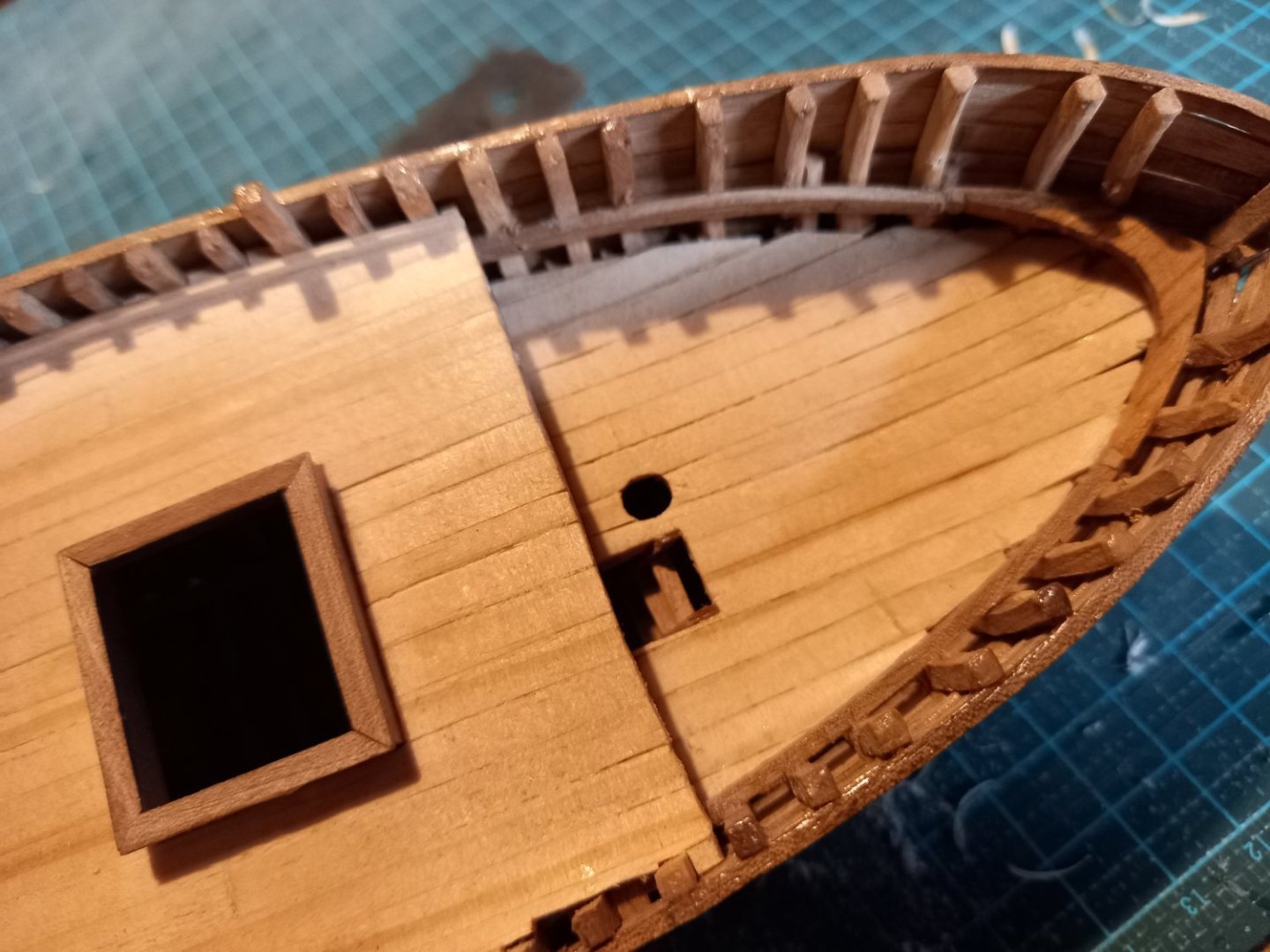

Hull sanded, gaps filled. She's looking very smooth and nice. I've been working on the curved 'brace'(?) at the stempost, as shown on this mosaic. Once that's on I can paint the hull (black, to imitate pitch). This thing presumably curves in three dimensions. My idea was to make 2-dimensional curve on a flat piece of wood following the shape in the mosaic, and curve in the 3rd dimension by heating and bending. Here is the evolution of my prototype - trial and error. I made two pieces, one for each side of the ship, glued together so they would be identical, and then separated. But I got a surprise - every time I tried a prototype out against the hull I discovered I had too much curve - until I realised this thing must have been made from a straight piece of wood and the curve developed from bending it. Waterways added. I'm thinking of adding scuppers. I have some very small diameter brass pipe which would probably do the job. I've been considering fitting out the owners' cabin below the poop deck with furniture - table, hanging cots, storage chest. Trouble is, unless you look directly down the stairwell from the poop deck you can't see anything anyway. That staircase down from the cabin is to the bilge or orlop. It's very nice, but it won't be visible when the poop deck is in place, so it'd be a bit pointless to add anything else - except out of masochism. And I've been working on the windlass. That's all for now. Steven

- 409 replies

-

Thanks everybody for the likes and comments (and 'Wows!') Guy wires added - and she's done - finished - complete. Steven

-

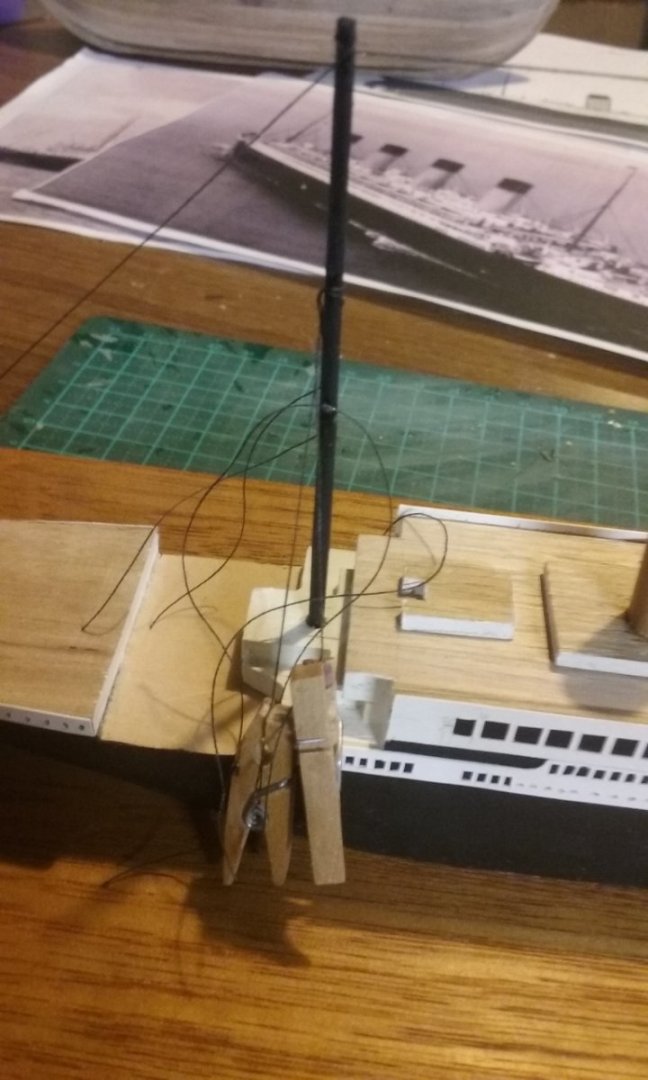

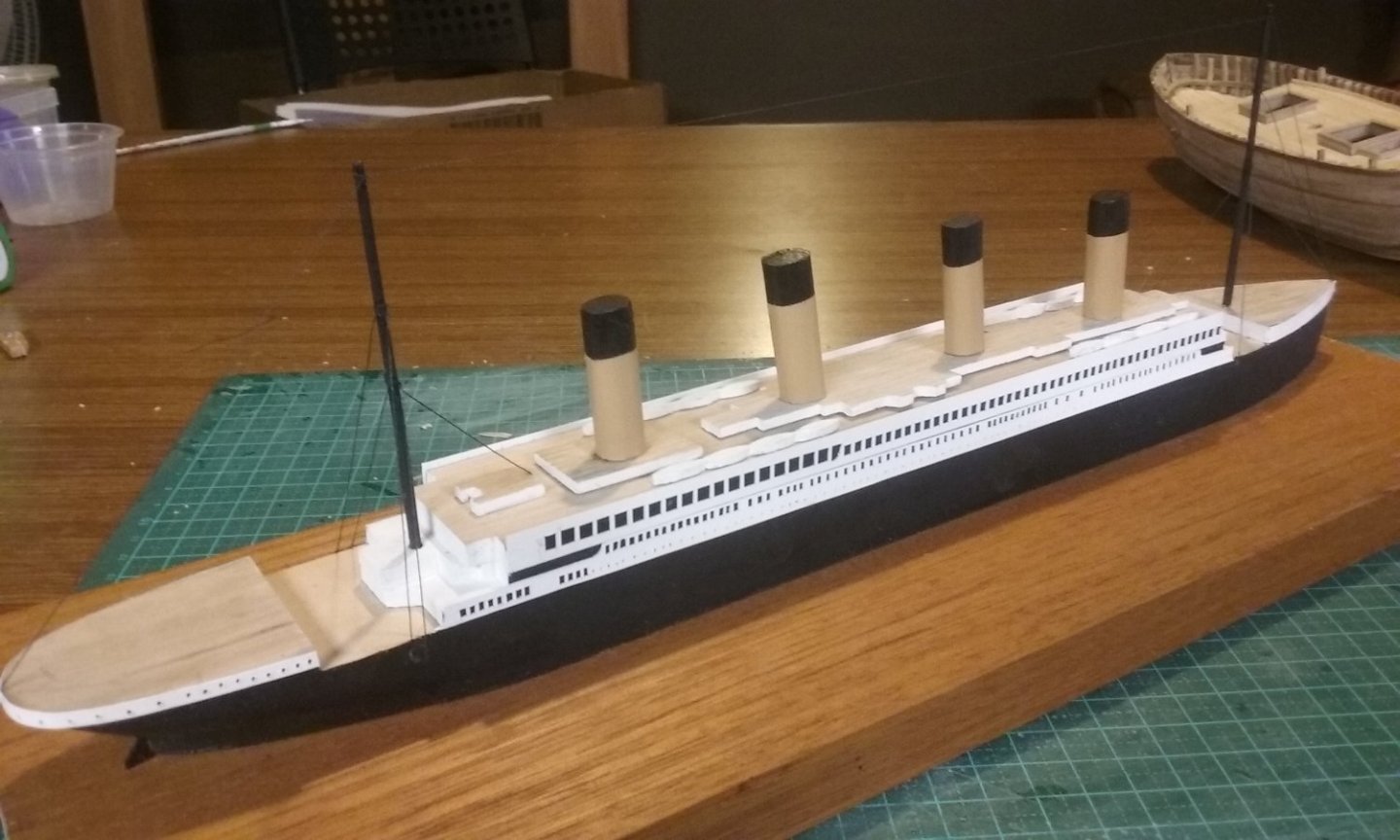

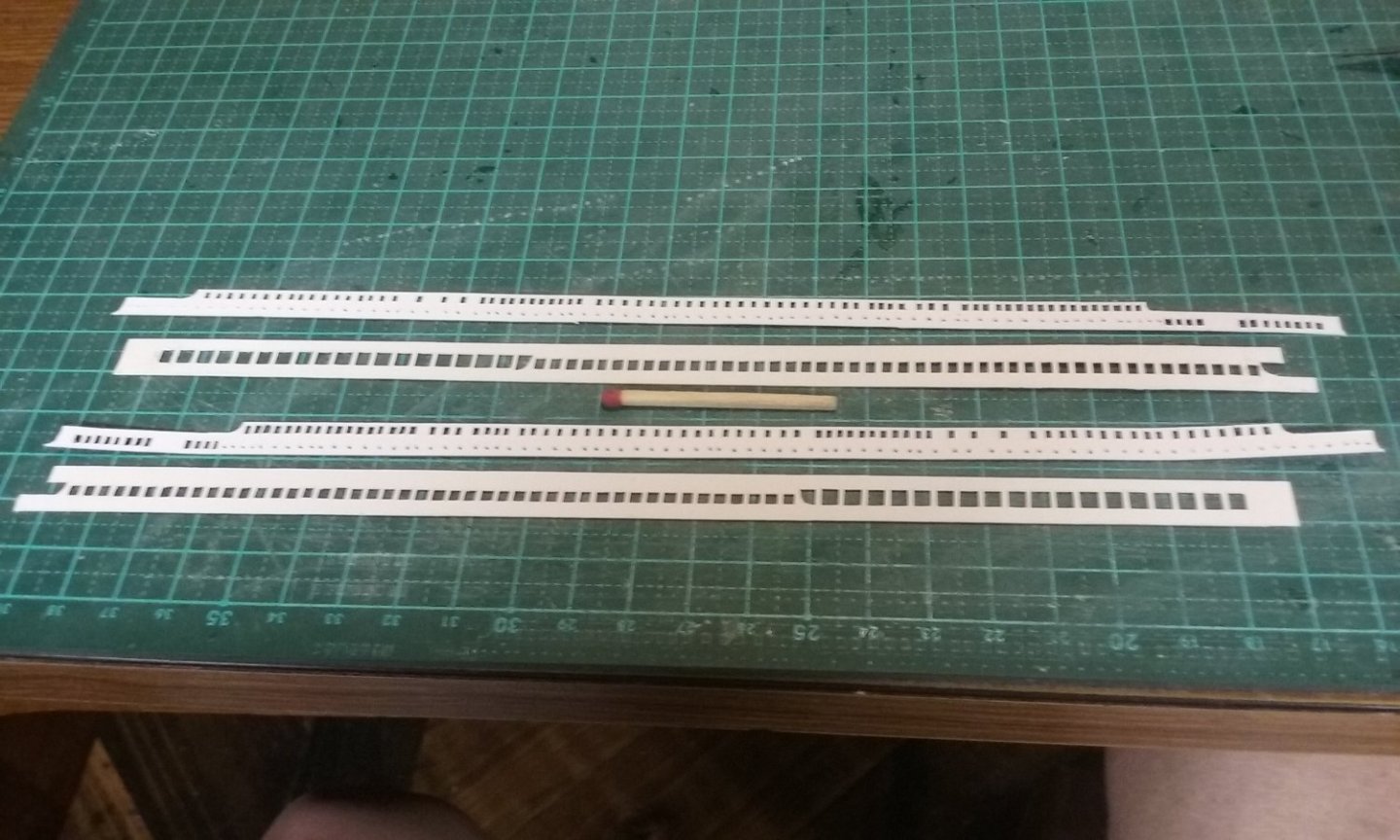

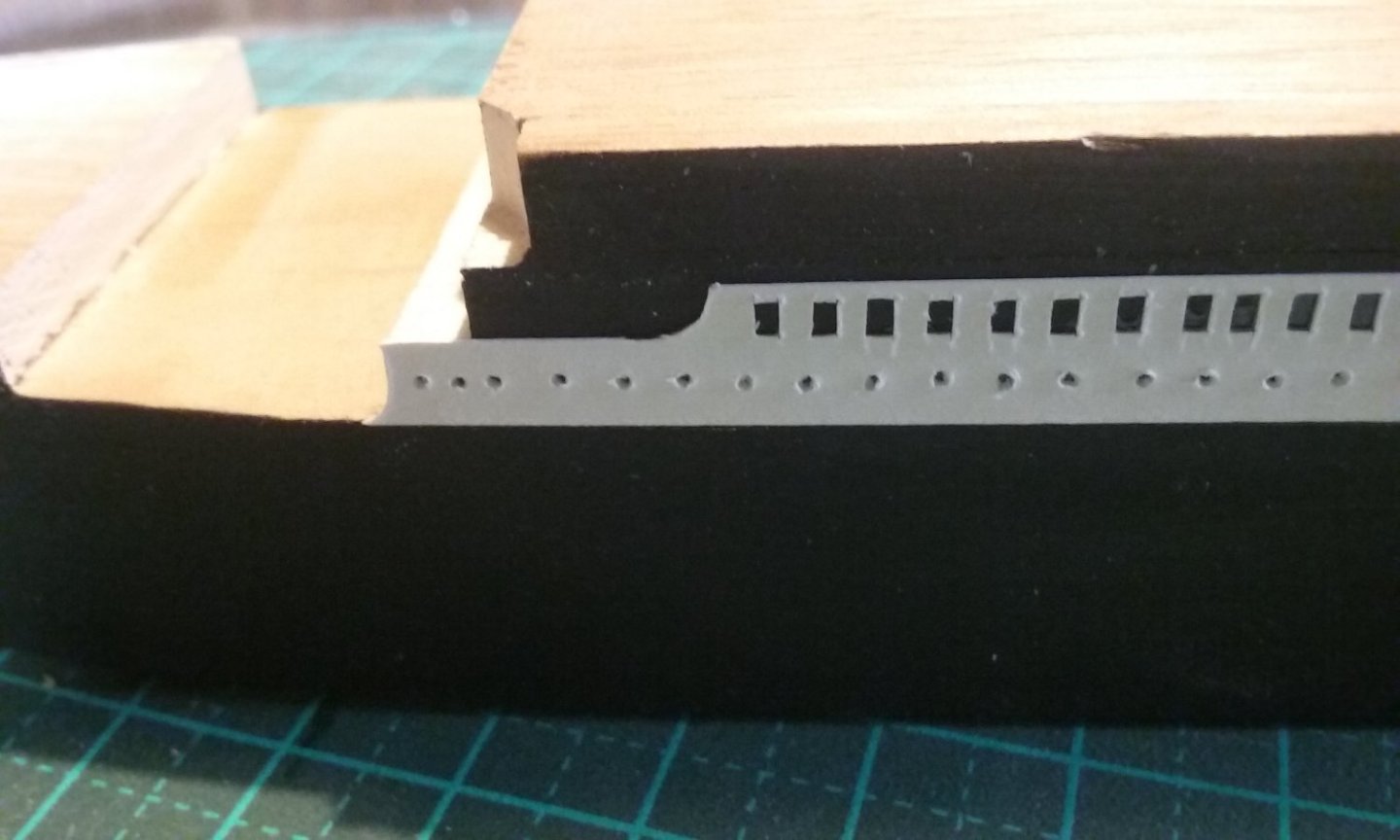

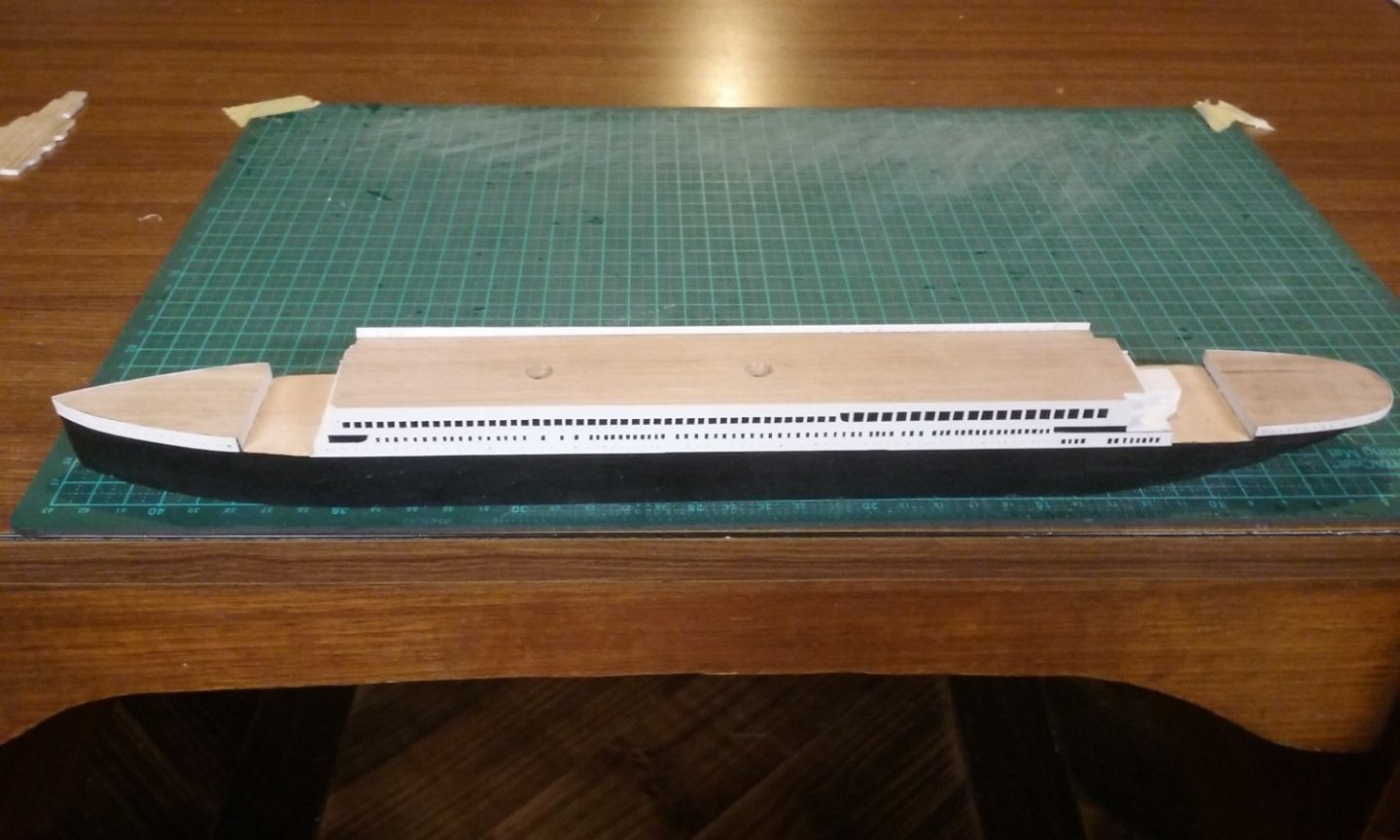

Well, now that it's (almost) finished I'm feeling rather better about the Titanic. I made strips out of card and cut the openings, portholes etc along the bulwarks and promenade decks into them. Not perfect, but hey, they're pretty small . . . Started gluing the strips along the sides: Actually starting to look quite good. Now for the superstructure for the boat deck, the funnels and masts. Tilted at 5 degrees from the vertical - fortunately my drill press has a swivelling bed. Just need to add some guy wires for the masts and she's done. Oh, and wax the raw edges of the base so it doesn't look so freshly cut. Turned out rather better than I'd feared. I think the client (and his girlfriend) will be happy with it. Steven

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.