-

Posts

590 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by vossy

-

-

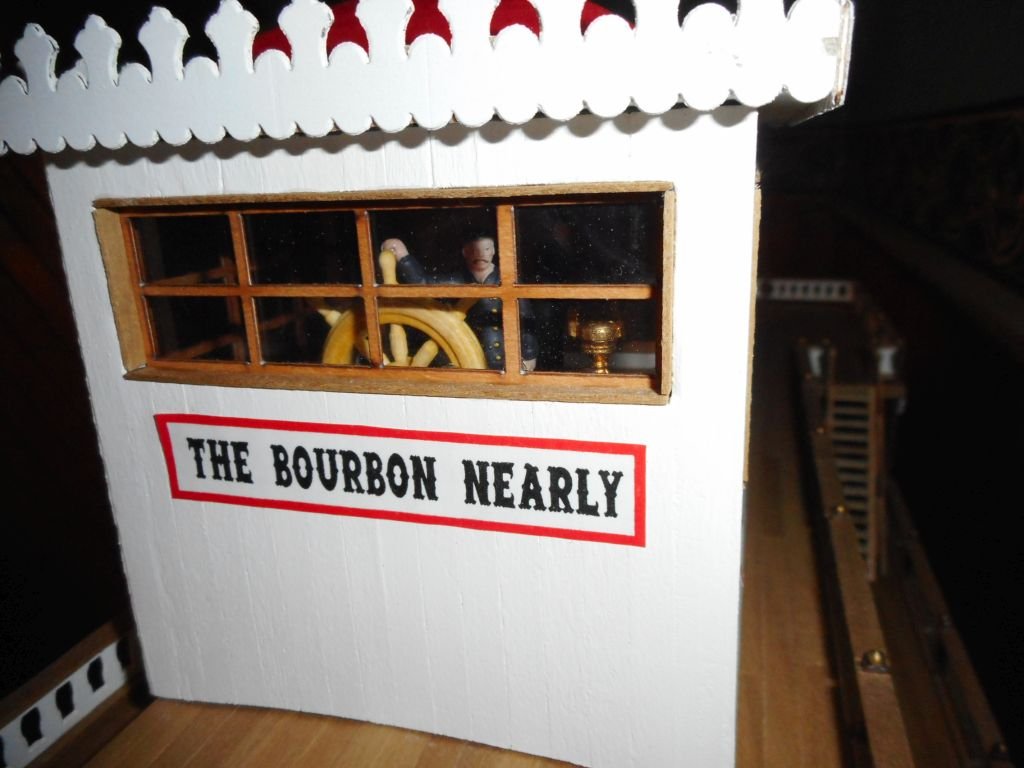

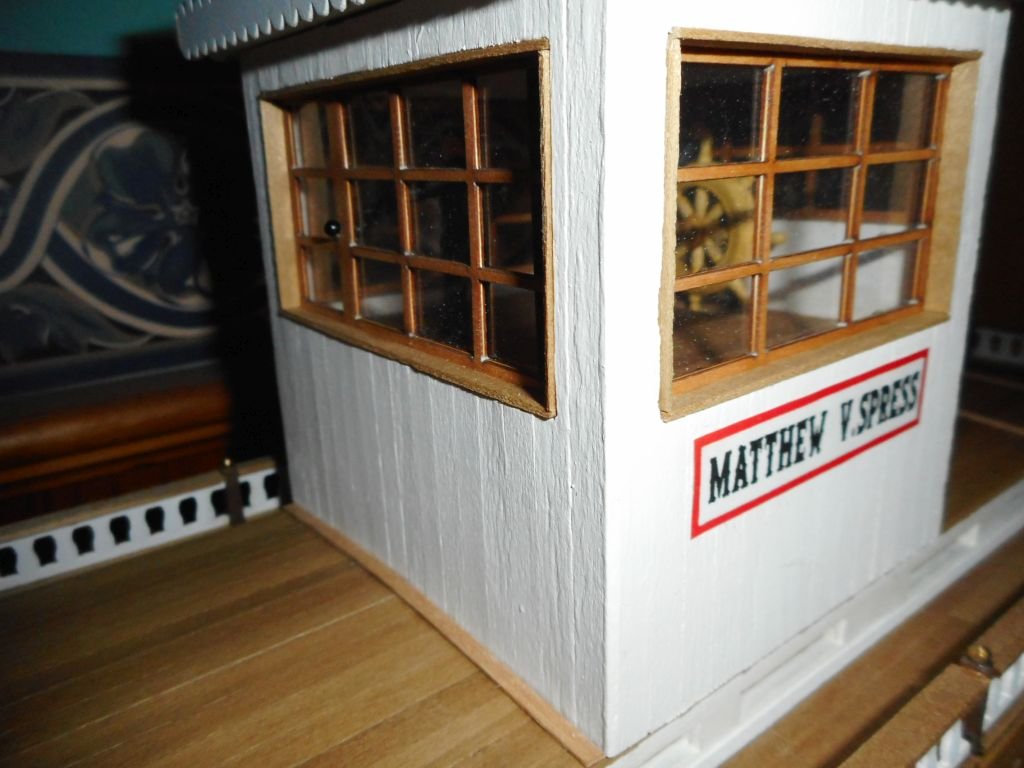

Bit of a long overdue update. Sorry about the poor photography and lighting.

Main smoke stacks nearly finished and ready to be installed. Have to touch up painting on bridge (well that's what i called it in the Navy). Now have about 30 passengers and crew that will be added later.

Cheers

Chris

-

Another beautiful build David. Congratulations.

Chris

- thibaultron, zappto and drobinson02199

-

3

3

-

Fantastic model of the most beautiful building on the planet! Everyone should aspire to visit the real thing at least once in their lives. Great job. Congratulations.

Cheers

Chris

- popeye the sailor, mtaylor, Canute and 2 others

-

5

5

-

Good job. I too am working on this model. One thing though; gloss paint shows more imperfections than flat/matt paint because it is shiny, and thus highlights any imperfections. This edict is true on both small model projects and large houses. Most houses, at least here in Australia, will be painted with a semi-gloss/low sheen exterior as opposed to a ultra shiny gloss level which will only highlight the imperfections.

Cheers

Chris

-

On 2/15/2019 at 11:37 AM, CDW said:

I believe this 1:250 ship model that's coming out soon has my name written all over it. Man, this thing is so darned tempting!

This looks like a fabulous new model. Do you have any idea of the dimensions? I am extremely tempted to get this one myself.

Cheers

Chris

- Piet, Canute and popeye the sailor

-

3

3

-

Hi Eric, all building has slowed to a trickle as I have just started a new job which requires a lot of technical training, so by the time I get home I am pretty much zonked out. I have another 2 weeks training left after which I go on shift. So probably in a few weeks I hope to be right back into it. I will more than likely finish the Mississippi first though. Up to the smoke stack stage with her so she shouldn't take too long once i'm back to it, then Chaperon will kick off fully. Thanks for the interest.

Cheers

Chris

-

Hey James, welcome. Number 1 thing I advise is build something you are interested in. No matter what your level of experience etc. we all run into problems at some point. By having a genuine interest in the subject of the build you will be far more likely to overcome the problems and complete the build. My very first wooden model ship was the Amati Santa Maria. Scale 1:50 (from memory), and recommended for intermediate modellers. The instructions were total garbage, as many European kits are, but because I was/am a Columbus fanatic I ploughed on through the problem area's and ended up with a very fine double plank on bulkhead model that I am very proud to say I built. So I reckon being invested in the subject of your build should constitute an extremely large percentage of the decision making process as to which kit to tackle first. And don't forget, no matter what problems you run into, you can bet your house that someone else here has experienced the exact same problem previously and can help you out with answers.

Cheers

Chris

-

Thanks Pat. We have a local hobby shop here which I reckon I have seen the rods in question.

Cheers

Chris

- Canute, mtaylor and thibaultron

-

3

3

-

The Mastini book is gold! If you can get it do so.

Cheers

Chris

- CaptainSteve, mtaylor, thibaultron and 1 other

-

4

4

-

Thanks for the response everyone. Unfortunately nothing I have tried works to my satisfaction. This brass wire is way too thick and non-pliable to stretch or roll etc. Once the temperature drops below 40c here, if it ever does, I think I will take Mark's tip and go to the local hobby shop to source some straight rods. My other thought was maybe a very thin chain through the stanchions instead? The constant heat here will doubtless give me plenty of time to mull over the choice.

Cheers

Chris

- mtaylor, Canute and thibaultron

-

3

3

-

Hi Anna, I would start by using 80 grit sandpaper to give the hull a good sand by hand. Don't use power sanders unless you are very skilled with them as they can, and will, remove more than you want to. Once the hull has been sanded you need to fill in any large gaps and attain the correct flowing hull shape for the final planking to cover. To do this you may need to fill and sand a few times to form the correct shape. During this process I would suggest you use 120 grit sandpaper. Everyone will have their own method of sanding, whether using blocks etc. I tend to just fold the paper and hand sand it. This way I can sort of feel the curve as well as see it. When you are happy with the hull shape, give it a final sand with 240 grit paper. Note how we have progressively gone from quite course to very fine paper. Finally, depending upon the type of filler you applied you may need/want to brush a clear coat on it so the subsequent glue on the covering planks has a good surface to bond to. I don't tend to do this as the filler I use doesn't require me too, but I know of some very good builders on this site that do. So as with many things in this hobby there are many ways to skin a cat. Or plank a boat.

Cheers

Chris

-

Thanks Ken, Steve. Here are a few pics to further show my problem. No way can I pull the wire straight using a vice and pliers, and the 2 metal ruler method does zip as well. Reckon I may need some sort of heat source perhaps?

So what I am trying to do is make the horizontal brass rails as shown in the last picture. What I currently have is this. I have tried pulling, clamping, rolling, stretching etc. to no avail. The wire remains warped and frankly unusable. The picture here is the offending item under a stock standard grey lead pencil for some sort of scale.

Nice straight rails.

- Canute, CaptainSteve, mtaylor and 1 other

-

4

4

-

Hi, I have a length of very thin brass wire I need to straighten out. It came in the kit in a round form and needs to be nice a straight when cut into lengths to use as railings. Problem is, when I unwind the wire it bends and kinks and hence looks terrible. Any tips on straightening bent or kinked fine brass wire?

Cheers

Chris

-

G'day Anna, elastic bands (rubber bands), make great temporary holding clamps. They conform to pretty much every shape and are cheap as chips. As Eric has said, once the wood has dried it will hold its shape enough to allow gluing. Again, I usually use elastic bands to further hold the piece whilst the glue sets. As for you bow section on your hull; it wont be too expensive to buy some more thin strips to put another layer of planking over what you have done. If you choose to do so, firstly sand and fill the entire hull to achieve a nice flowing curvature toward the bow and stern (front and back). Give it a nice sand, and you will find you now have a really nice surface to apply a final planking layer which will look first class. Also, try not to use nails unless you want them to be seen. On my current build you can see where I have deliberately put exposed nail heads on the blades of the paddle to simulate large bolts. I will do this to a few more larger structural pieces to further simulate what I think may have been seen on the real vessel.

Overall, your vessel is coming along very nicely and you should be very proud. I will continue to follow along with interest. Good luck.

Cheers

Chris

-

Upper Port side staircase. Not 100% happy with this, but it is what it is. I maybe able to deflect eyes from

it via cunning methods elsewhere. Anyway, the Port side is always my "test" side so I hope to do better

on the Starboard. All mistakes are my own and not the kits or manufacturer.

Cheers

Chris

- vossiewulf, Anna, drobinson02199 and 5 others

-

8

8

-

if you say, and are correct, I would say scratch built.

cheers

chris

- Canute, CaptainSteve and josh44

-

3

3

-

-

- Cathead, cog, popeye the sailor and 3 others

-

6

6

-

Stunning build David! You should be immensely proud. And boy I wish I worked as fast as you! Have a great trip, looking forward to your next project.

Cheers

Chris

-

-

Long time coming I know, but finally a bit of an update! Still finishing off the upper rails, but over the Christmas period I got myself some more willing passengers! Unfortunately these figures only come in packs of 6 and all packs contain the same figurines. So, as you can see from earlier posts I already have a few glued into position on the lower deck horse bay area. So what I will do now is paint the ladies dresses different colors (have already made a bit of a start on this), and I figure if I position them in different parts of the boat they will all look like different people. Some of the worker type people, I intend to cut and manipulate arms etc. and repaint to get a different looking figure. Anyway, here's some pics. Oh, and they are all just lined up here. No-one glued into position as I cant see any ending up here. Just a mass gathering to show the people.

Cheers

Chris

-

A lot of kits of such ships as the Golden Hind, Revenge, etc. have similar hull decorations. They tend to use thin printed card, which doesn't look 100% great, but its not too bad either. So perhaps you could print your own and see how that goes?

Cheers

Chris

-

-

PVC pipe is great for our hobby. I use a length about 1200mm long capped at one end with plumbers resin and glue. I fill it with water and soak planks prior to bending. The uncapped end has another non glued cap on it to stop the planks popping out before they are soaked. I have used this for about 12 years and it has never leaked.

Cheers

Chris

1929 Chris-Craft 38' Commuter by drobinson02199 - FINISHED - Dumas - Scale 1:12

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Just super David. Congratulations yet again!

Chris