Roger Pellett

NRG Member-

Posts

4,519 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Roger Pellett

-

Steven, This is much more than a replica. It is your interpretation of currently available information. Good work! Roger

- 740 replies

-

- Tudor

- restoration

-

(and 4 more)

Tagged with:

-

I agree with Mike. It’s best left alone.

- 16 replies

-

- hull repair

- Hudson Bay Company

-

(and 2 more)

Tagged with:

-

Dremel rotary tool?

Roger Pellett replied to Mark m's topic in Modeling tools and Workshop Equipment

I have been building ship models for over 50 years. In the early 1970’s I received a Sears Lil’ Crafty rotary tool as a Christmas Present. I still have it. IMHO, these rotary tools are too aggressive for quality ship model work. They can very quickly ruin work. I mostly use it with an abrasive cut off disc on metal parts. A while ago I bought a Proxxon rotary engraving tool. It runs from a separate 12v power supply. It is small enough to be held between the thumb and forefinger like a pencil. This tool is much more useful than the full sized rotary tool. It is particularly good for cleaning excess glue and solder from hard to reach joints. Roger -

At 1:350 scale, a 6 in wide deck plank would have a scale width of approximately .02in; about as thick as two sheets of ordinary computer paper. In reality, by the 1940’s deck planks could have been narrower than 6in. A skillful paint job would probably be more realistic. Roger

- 48 replies

-

- New Jersey

- Tamiya

-

(and 1 more)

Tagged with:

-

A 1 in plate at this scale would be only .005 in thick. Plating of this thickness would only be used in high stress areas like the sheer strake. Ordinarily hull plating would be considerably thinner. Roger

-

Before embarking on Gig 2.0 is there a way that you can temporarily hang the gig from its Davits? As part of the overall picture it might look better than as a stand alone model. Roger

-

How was a ship's launch boat prepped to sail?

Roger Pellett replied to Peanut6's topic in Masting, rigging and sails

In the US Civil War era Navy, seamanship books and the Navy’s Ordnance Instructions mention outfitting boats with gear before launching. US Navy specifications for this same era state that all thwarts in cutters and launches were to be removable with heavy clamps, a longitudinal structural member, providing the structural strength ordinarily provided by fixed thwarts. When installed the thwarts were secured by iron pins in holes into the clamps. Some of the boat gear; masts, booms, etc. was stowed in the wooden hammock “netting’s” atop the bulwarks. The point to all of this is that practices varied between different navies. Boats, at least in the US Navy, were considered to be not part of the ship but “Outfit” so detailed information can be very difficult to find. Roger -

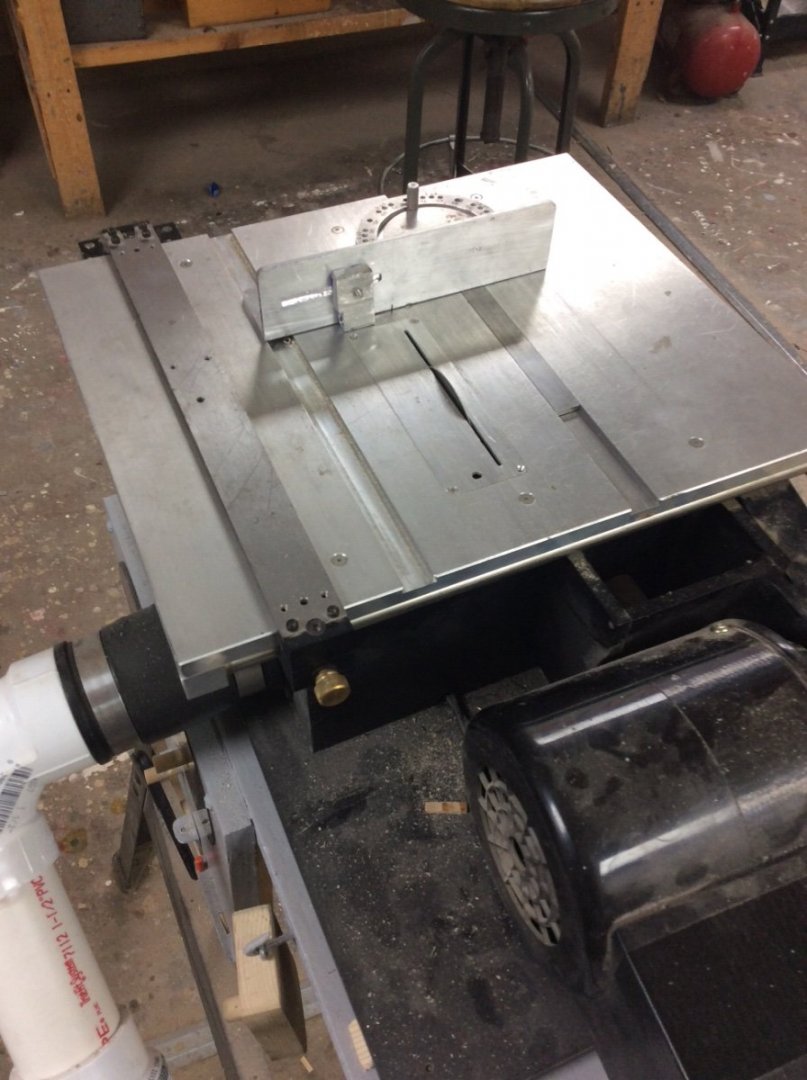

Byrnes Saw Mini Sled

Roger Pellett replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

Keith, I missed your questions yesterday. The sled is a special purpose tool intended to accurately cut thin brass sheet stock, thin plywood, etc with the thin dimension vertical and the width lying flat on the table. Other than a very slight nick on the corner of the angle there is no slot. Advancing the sled until the corner of the angle just kisses the blade completes the cut without launching the cut piece into outer space. The saw is then turned off to remove the cut piece. I will post a new picture of my improved stop later today. I too have a micrometer that I bought with the saw. Adding it to the sled is food for thought. Dave, blade specifics later today. Roger -

Byrnes Saw Mini Sled

Roger Pellett replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

Bob, I am trying to live with the “Buy it as you need it” philosophy for buying tools. 90% of the remaining work on my 1908 Lake Freighter model is metal; mostly brass, and at present brass sheet stock. My sled was built specifically for 90 degree cuts of small pieces of sheet brass. For this use, I actually prefer it to Jim’s larger table. Roger -

Byrnes Saw Mini Sled

Roger Pellett replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

Thanks Joe! -

Byrnes Saw Mini Sled

Roger Pellett replied to Roger Pellett's topic in Modeling tools and Workshop Equipment

Pat, Please do, that’s why I posted it. Today, I intend to improve the adjustable stop. The one that I show is hard to adjust accurately. I also found, the hard way!, that the sled will only maintain accuracy if the pin is left in the miter gauge. Roger -

How was a ship's launch boat prepped to sail?

Roger Pellett replied to Peanut6's topic in Masting, rigging and sails

He probably took them with him but would possibly not put them in place. -

The model that I am building requires a lot of metal work; brass bulwarks, deck plates, fittings, etc. I use my Byrnes saw as the primary tool for cutting brass sheet stock. With a fine toothed blade it produces accurate, distortion free cuts. I have reached the point where I am making bollards. The base of these is 1/32 in sheet stock (scale 3in). I require multiple rectangular pieces, 3/16in wide X 7/16in long. Ripping 2in long 3/16in strips was easy to do but cutting these into 7/16in pieces is more difficult. To do this and for cutting other small pieces I decided to make a sled for my saw, keeping the following in mind: I wanted to cut multiple pieces to the exact same length. I wanted to take advantage of the saw’s ability to produce truly square cuts. I Wanted to keep all 10 fingers! The body of the sled is a piece of 1-1/2 in aluminum angle. The Byrnes saw miter gauge was set at 90 degrees, and the angle was tightly butted against it and secured by a small machine screw threaded into the tapped hole of the miter gage slider. A slot was milled in the face of the angle and a #8-32 thumb screw goes thru the slot to secure the adjustable stop. An afternoon’s work using materials on hand. Roger

-

How was a ship's launch boat prepped to sail?

Roger Pellett replied to Peanut6's topic in Masting, rigging and sails

Before the 1700’s the longboat, the largest of the ship’s boats was usually towed. Numerous paintings exist of these very large boats towed by the mother ship with one or two boat keepers on board. The two or three smaller boats would be carried aboard. By the 1700’s longboats became smaller, so the entire boat outfit was kept on board in the waist amidships with some stacking of smaller boats atop larger ones. By 1800 warships were equipped with davits or boat cranes so two or three boats, usually cutters were hung over the side ready to be launched. At least one of these was designated as a “lifeboat,” the term applying to recovery of a man overboard, not to save the crew when abandoning ship. The rest of the boats were stowed in the waist. Most of the boat’s thwarts were removable, and period seamanship books often mention the need to install them when launching. Period seamanship books are emphatic that boat crews are to sit in the bottom of the boat when it is under sail. With this in mind, I suspect that Bligh would not have shipped the loose thwarts in Bounty’s crowded Launch. Sails would not be stored in boats when not used as the flax material would rot. Pictures exist of small boats with bowsprits anchored with the jib hoisted in stops. When getting underway, pulling on the sheets would break the stops, setting the sail. This would avoid putting a man on the bowsprit. It would also minimize the chance of the jib getting in the water under the bow of the boat. The mainsail, if loose footed was often furled in a long roll and hoisted part way up the mast to keep it dry. The easiest way to rig the mast in a small boat is to loosely fasten the shrouds, stick the butt end of the mast in the mast step and then to walk forward lifting the mast while a man in the bow pulls on the forestay. Roger -

replacement X-ACTO blade #30

Roger Pellett replied to Peanut6's topic in Modeling tools and Workshop Equipment

Back in the 1960’s the professional model builders in the model shop at the University of Michigan’s Naval Architecture Towing tank used these bronze spoke shaves for shaping the large wooden test models. As a student, I was on a team investigating design of a shallow draft tanker that could navigate the Suez Canal and we were building an 8ft long model to tow in the tank. I still have and use a set of these for shaping hulls. The occasionally come up on eBay. -

It appears that when built she had a bow rudder plus a bow thruster. Why both? Here on the Great Lakes our 1000ft ore carriers navigate our very small harbors with just bow thrusters and sometimes stern thrusters. They don’t require tugs. Roger

- 454 replies

-

- Union Steamship Company

- Stepcraft 840

-

(and 3 more)

Tagged with:

-

US and Australia might be apples vs oranges but here in the US we have a company named Harbor Freight that sells all sorts of low priced tools. They sell a two wheeled dolly of the type used by movers for about $45. Unlike some of their offerings these are of decent quality and would be perfect for moving your lead ballast. Roger

- 454 replies

-

- Union Steamship Company

- Stepcraft 840

-

(and 3 more)

Tagged with:

-

To build a great model, I believe that the builder needs to have an artistic vision of what the the finished model is going to look like before he/she starts. These can run the gamut from formal presentations with brass pedestals and a polished wood plinth to dioramas with the Ship in a natural setting. IMHO, billowing sails do not enhance the appearance of a ship model in a formal presentation. Furled sails are a better choice and “bare poles” are the best. On the other hand, there are some very attractive models with full sails shown in a diorama setting. Roger

-

HMCSS Victoria 1855 by BANYAN - 1:72

Roger Pellett replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Another couple of thoughts: If drilling is overheating the joint try packing the ID of the tube with wet tissue. This should greatly increase heat transfer from the joint as you are taking advantage of the latent heat of the water. The brass and bronze alloys “work harden.” In other words they harden when distorted while cold. If your drill bit is not immediately taking a bite from the surface being drilled, it is hardening the tiny spot that you are trying to drill. If the bit doesn’t immediately bite it is not sharp enough. Roger- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

HMCSS Victoria 1855 by BANYAN - 1:72

Roger Pellett replied to BANYAN's topic in - Build logs for subjects built 1851 - 1900

Pat, If drilling is causing the joint to fail, and the joint does not get hot enough to burn you when you touch it, then I would investigating the joint design. Soldering a flat plate to a cylinder might not provide enough surface area for a strong joint, as the cylinder curves away from the square edge of the plate. While it is counterintuitive a thinner plate might allow the solder to flow more freely into the crevice to provide a stronger joint. I use Bakers Fluid as a flux. It is a clear non-viscous fluid. Applied to the joint with a fine tipped brush it wicks into the joint and seems to help the solder flow better. It would also also help if you can introduce a mechanical key into the joint. Maybe a tiny peg that fits into a hole in the tube? Roger- 1,005 replies

-

- gun dispatch vessel

- victoria

-

(and 2 more)

Tagged with:

-

Basic rigging lines on shrimp boat

Roger Pellett replied to Fright's topic in Masting, rigging and sails

The only thing that I know about shrimp boats is that I like to eat what they catch! Having said that, I believe that some of the “working lines” would be wire rope too. This would include lines leading directly to the trawls from the winches. The wire rope supporting the mast, often referred to as Standing Rigging would probably be galvanized so more grey than black. There is an excellent series of posts on the forum of a New England fishing boat. The builder, “Fried Clams” does an excellent job of showing real working rigging. Look it up. Roger

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.