hdrinker

-

Posts

170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by hdrinker

-

-

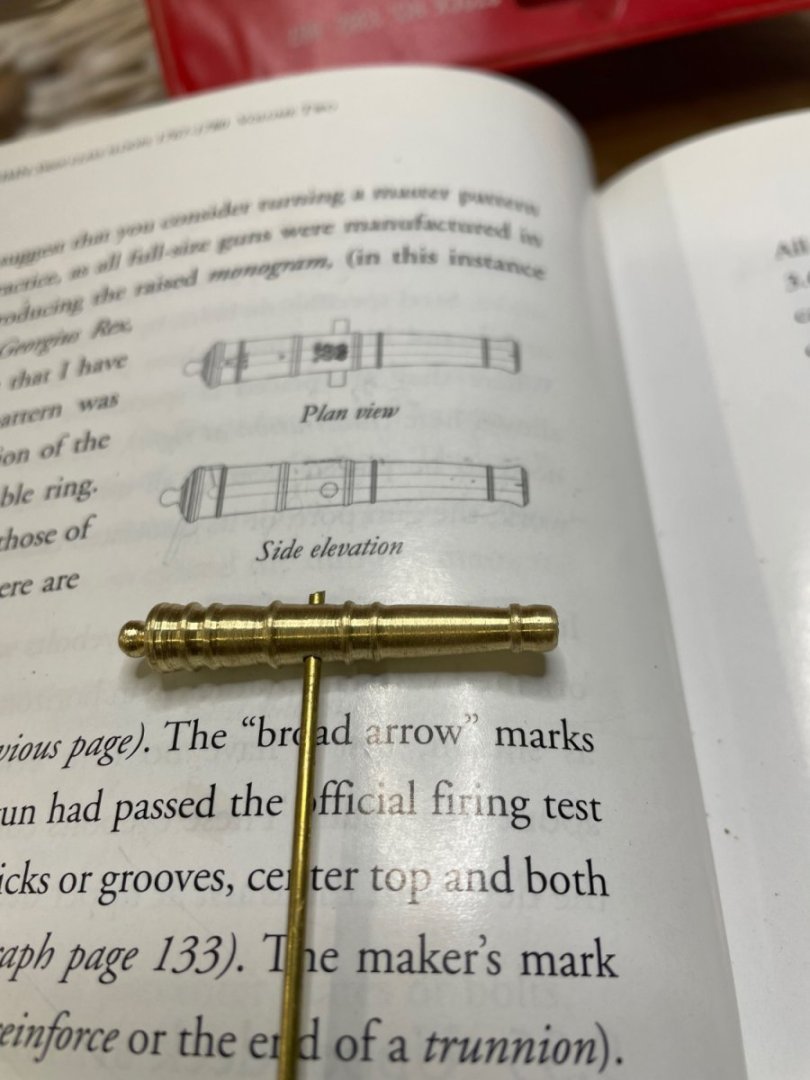

Have started the gun carriage tackle. Not including the hardware on the carriages themselves, there are a total 96 blocks, 96 eye hooks and 80 ring bolts. All to be blackened and lacquered. A daunting task of which making the metallic components alone occupied the day today and will do so for another several days for blackening, etc. Haven’t begun the blocks.

-

-

-

-

-

- Saburo, gjdale, scrubbyj427 and 8 others

-

11

11

-

- KARAVOKIRIS, GrandpaPhil, CiscoH and 4 others

-

7

7

-

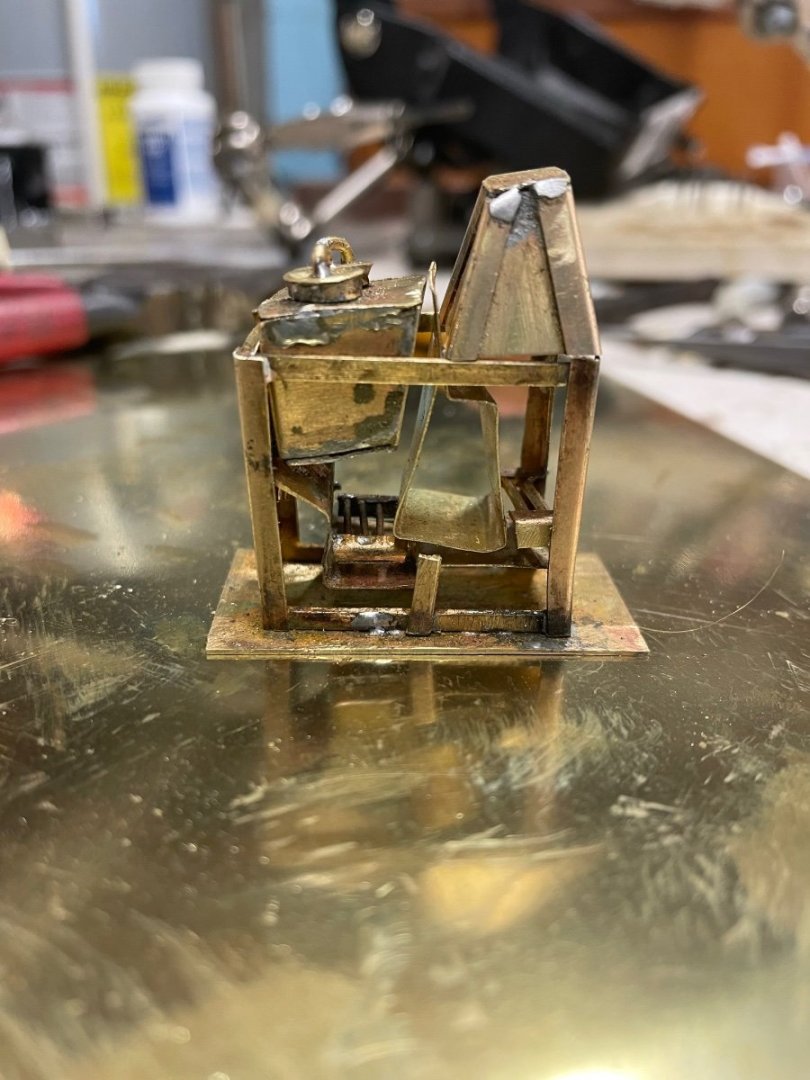

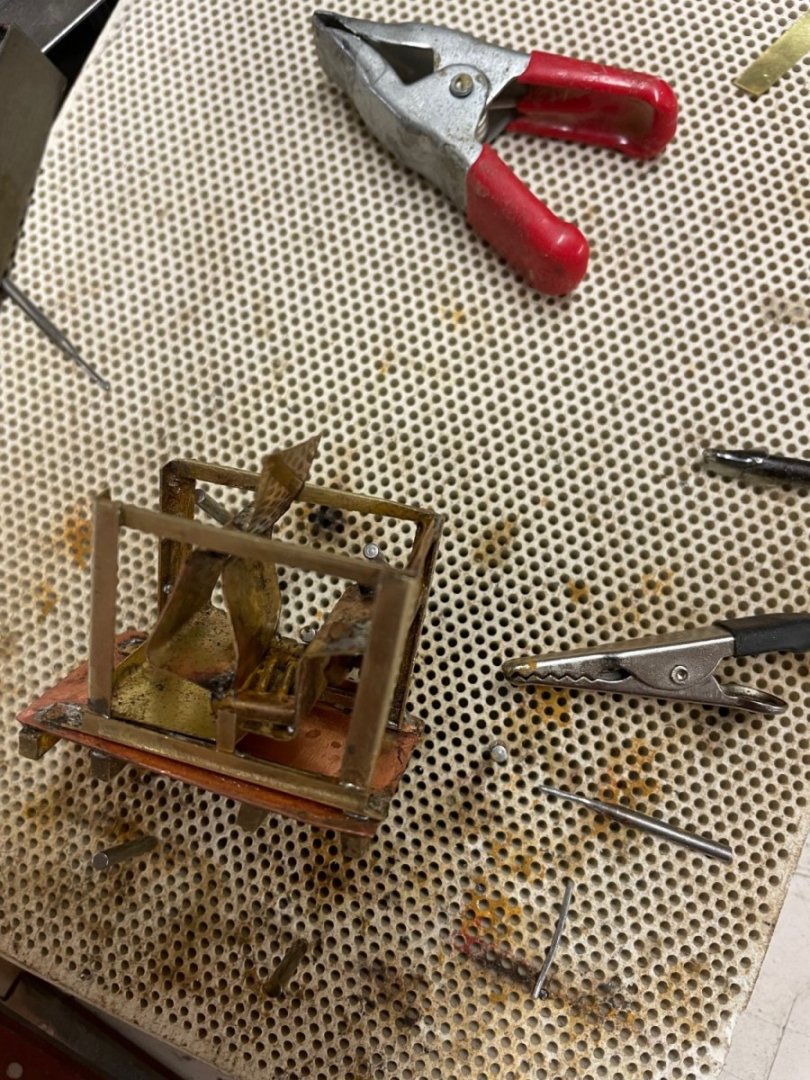

Thanks Kevin. As it turned out, I used a blackening solution which after several applications undid much of the fine detailed soldering. So several steps back, I persist. But I no longer shake in fear at the soldering process. I’m using resistance soldering almost exclusively and find that with a sharpened tip, the heat can be applied to a very small area without threatening adjacent joints. When there’s an issue, yellow ochre paste applied to the joint at risk works well .

-

Progress, although not of the standard set by Captain Giampierocicci!

- dvm27, giampieroricci and mtaylor

-

3

3

-

-

- KARAVOKIRIS, bruce d, allanyed and 5 others

-

8

8

-

-

-

-

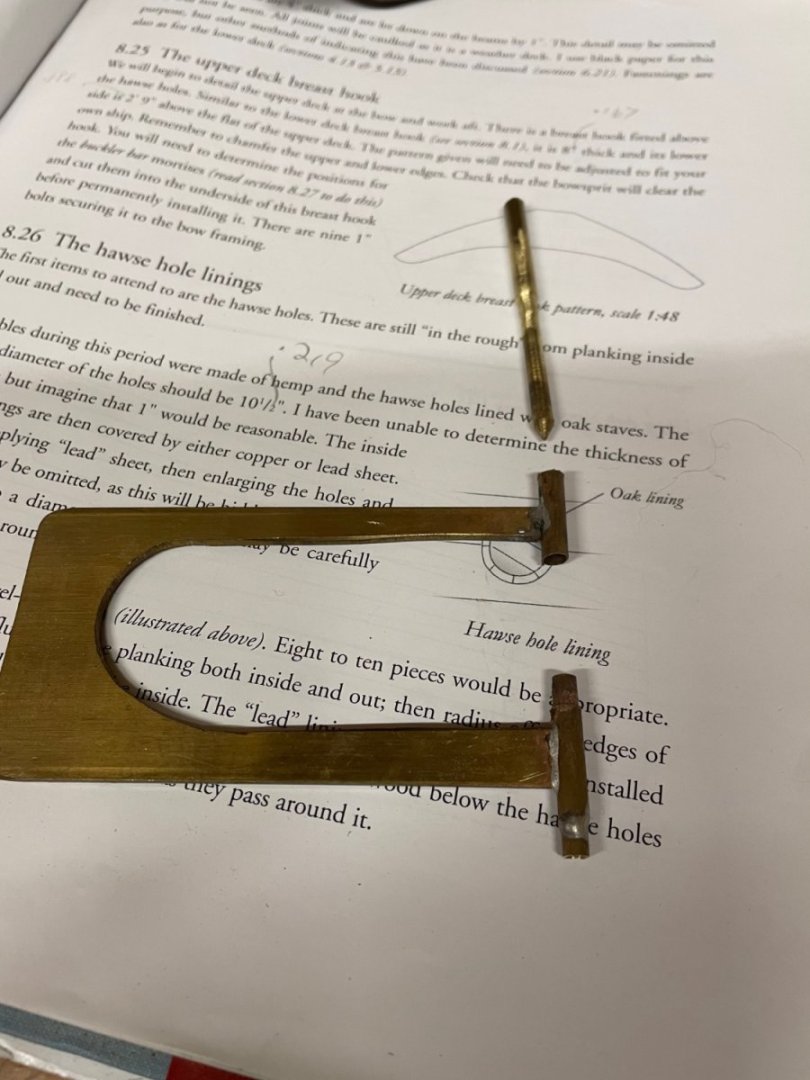

Such a fine craftsman you are. I was about to abandon my crude efforts on the stove, but your work has inspired me not to give up…. Yet. One difficulty I am encountering is soldering a third piece to an already soldered joint between two other pieces, as in connecting the cross piece between the two side frames. How do you keep the first one from melting?

Henry

-

- bruce d, GrandpaPhil, CiscoH and 2 others

-

5

5

-

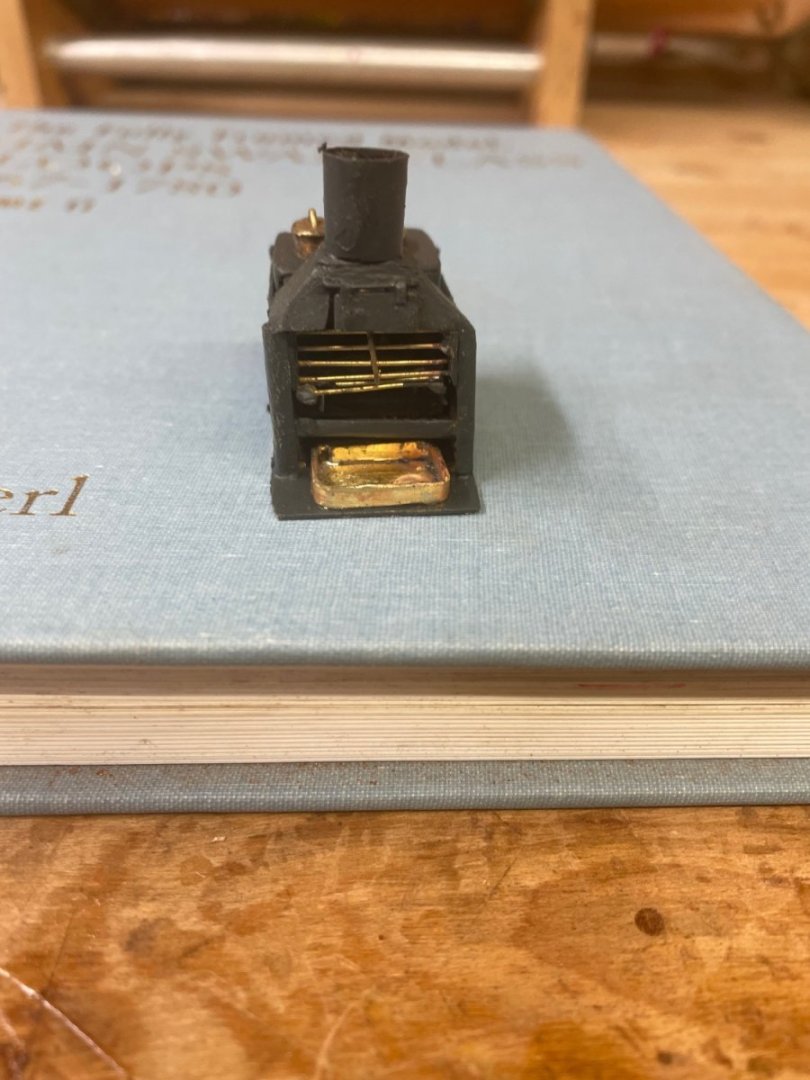

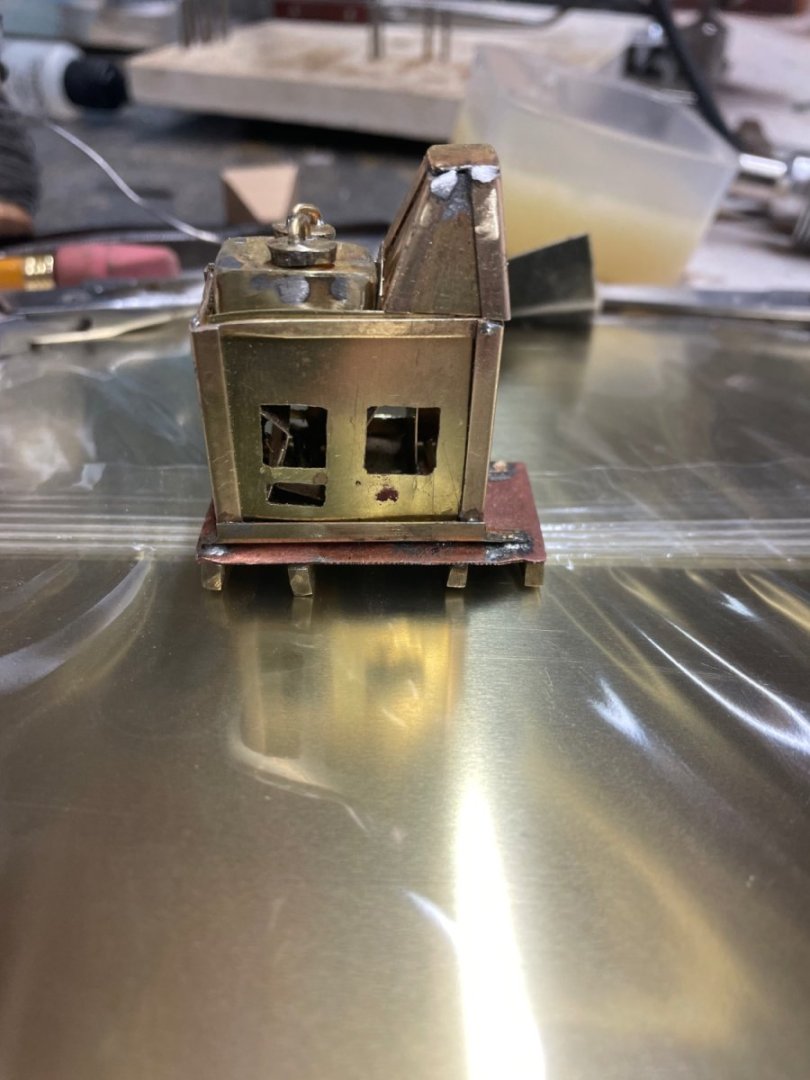

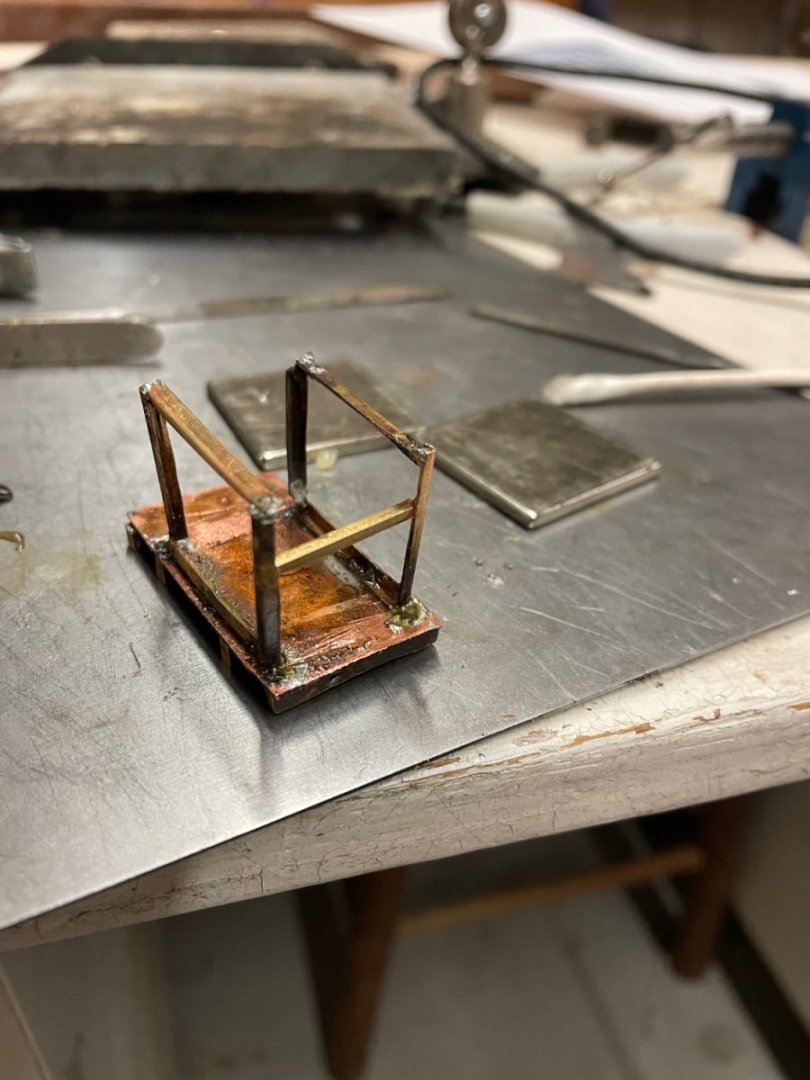

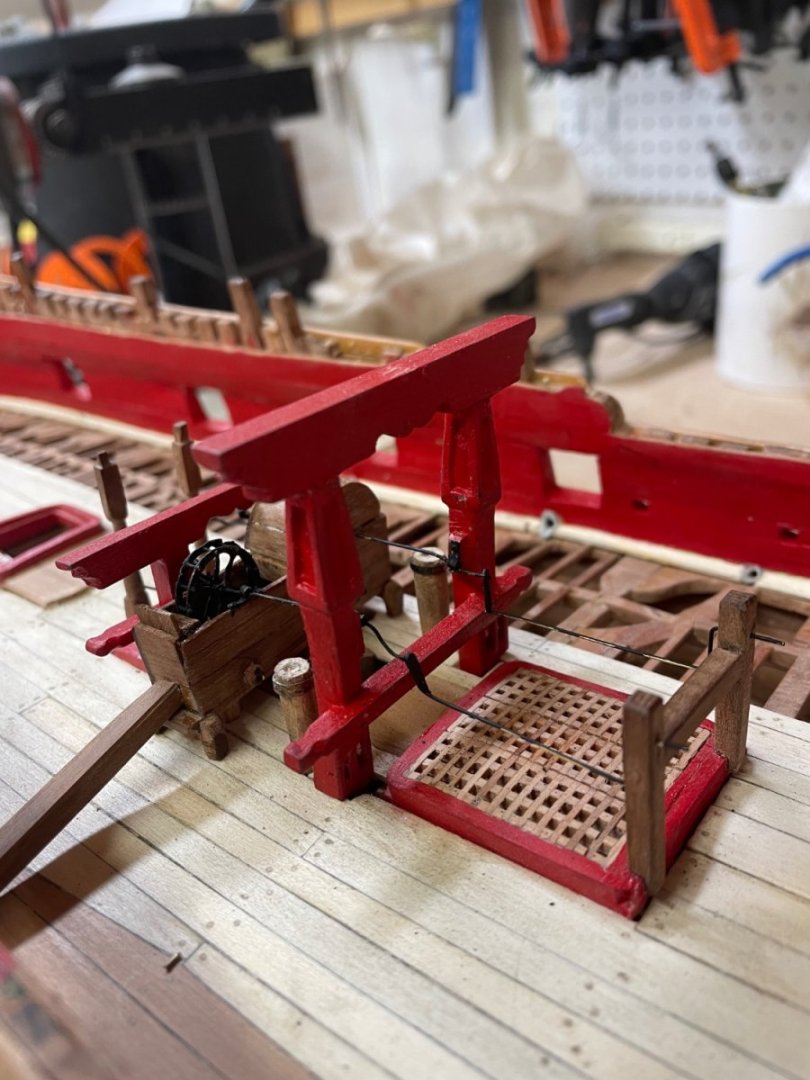

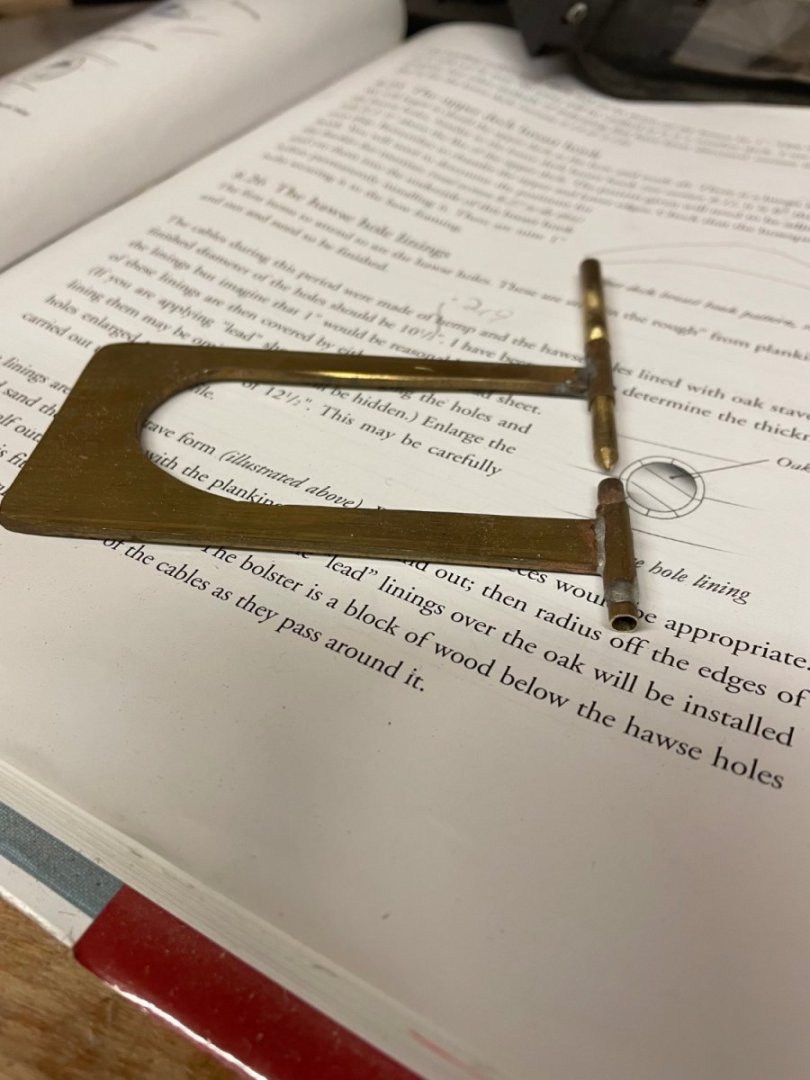

Well, the stove was delayed until I figured out what soldering method would work best for me. Decided to tackle the chain pumps first. Wow! It took days of frustration trying to get everything lined up so the driving rods would passs through all the various bearings, more - less straight. Turned out to be less than more. But it was an opportunity to try out soldering tiny parts. Resistance soldering proved my favorite. I think I’m ready to tackle the stove.

- GrandpaPhil, bruce d, gjdale and 7 others

-

10

10

-

I’ve struggled and am still struggling with silver solder. Can’t seem to get even “easy” to melt with my mini butane torch. I thought using silver solder at different hardness’ would allow the successive joining of very small parts adjacent to one another without melting what I had previously soldered. But I’ve completely failed at this effort. Any suggestions?

Henry

This is a great discussion! I’m away from my shop for a few weeks, but will take all this advice to heart when I get back and post my results. Thanks to everyone.

Henry

-

Starting the Brody Stove. Has anyone made the stove in metal? How does one solder tiny brass or copper pieces next to each other without melting what you just joined before? It can be impossible sometimes to apply a heat sink when the pieces are really close /together. Have tried silver solder but can’t get it to melt with my mini butane torch.

Henry -

I’ve struggled and am still struggling with silver solder. Can’t seem to get even “easy” to melt with my mini butane torch. I thought using silver solder at different hardness’ would allow the successive joining of very small parts adjacent to one another without melting what I had previously soldered. But I’ve completely failed at this effort. Any suggestions?

Henry

-

-

-

-

Pegasus by hdrinker - 1:48 - POF - Swan practicum

in - Build logs for subjects built 1751 - 1800

Posted

After guns and lids done. Preliminary quarter deck beam fitting.