-

Posts

9,718 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

Thanks…Im on a roll for a change. At the expense of my inventory but this is too much fun to stop now. Next up will be the breastrail at the fore side of the Poop deck. Last there will be the rudder head box. That will complete all the deck fittings. Sadly I wish there more…but then I can complete all the exterior work to finish off the hull.

-

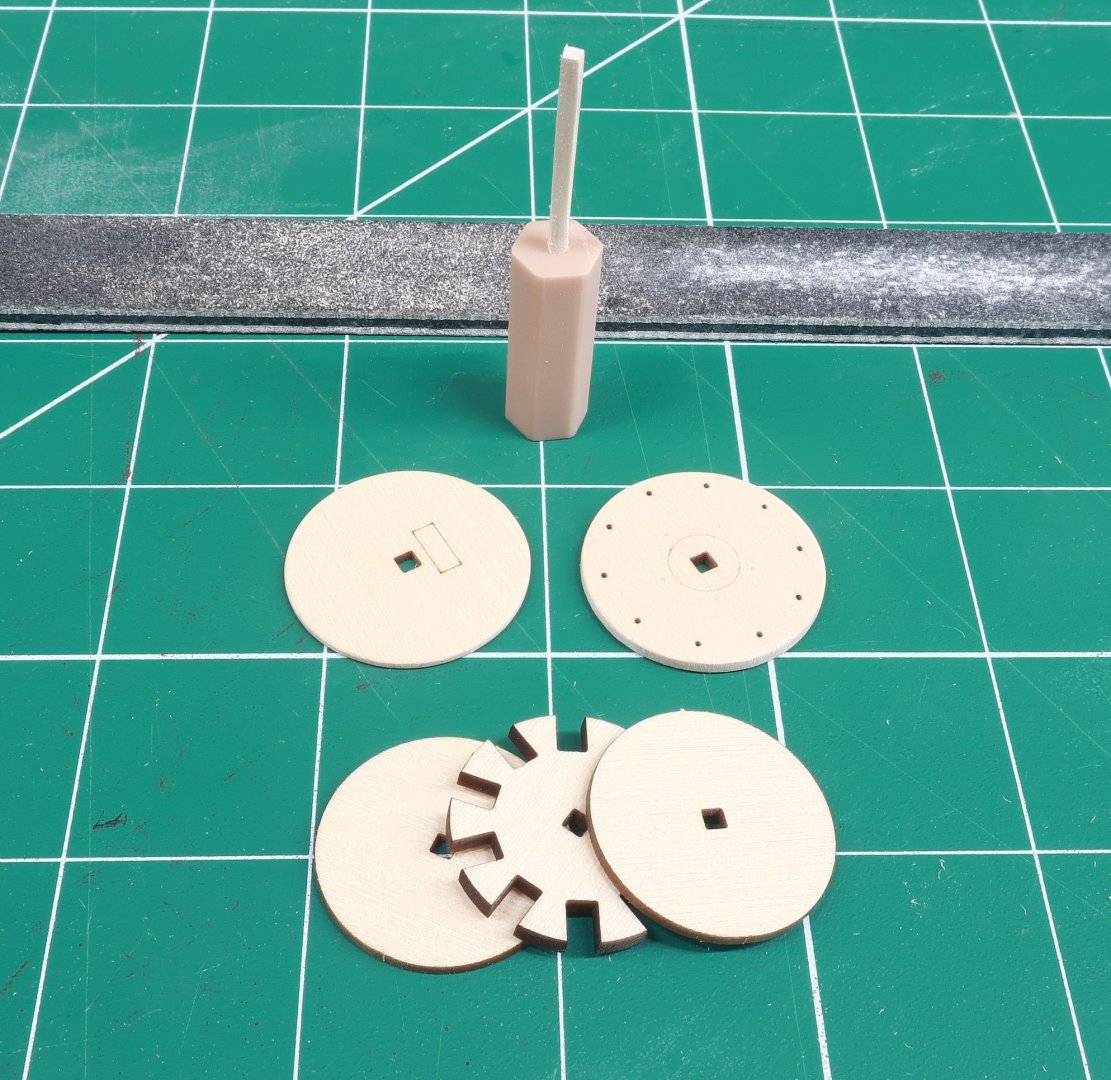

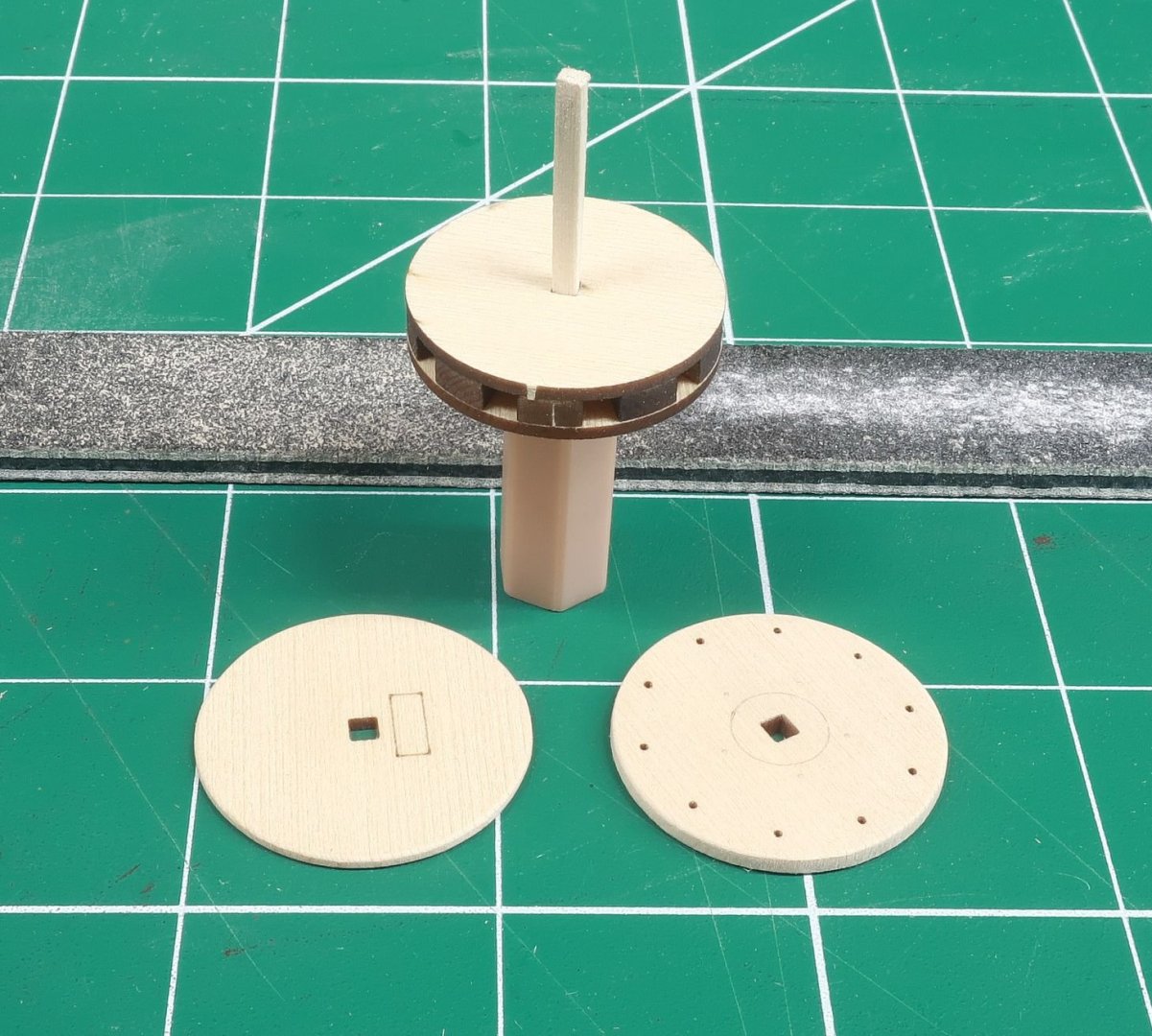

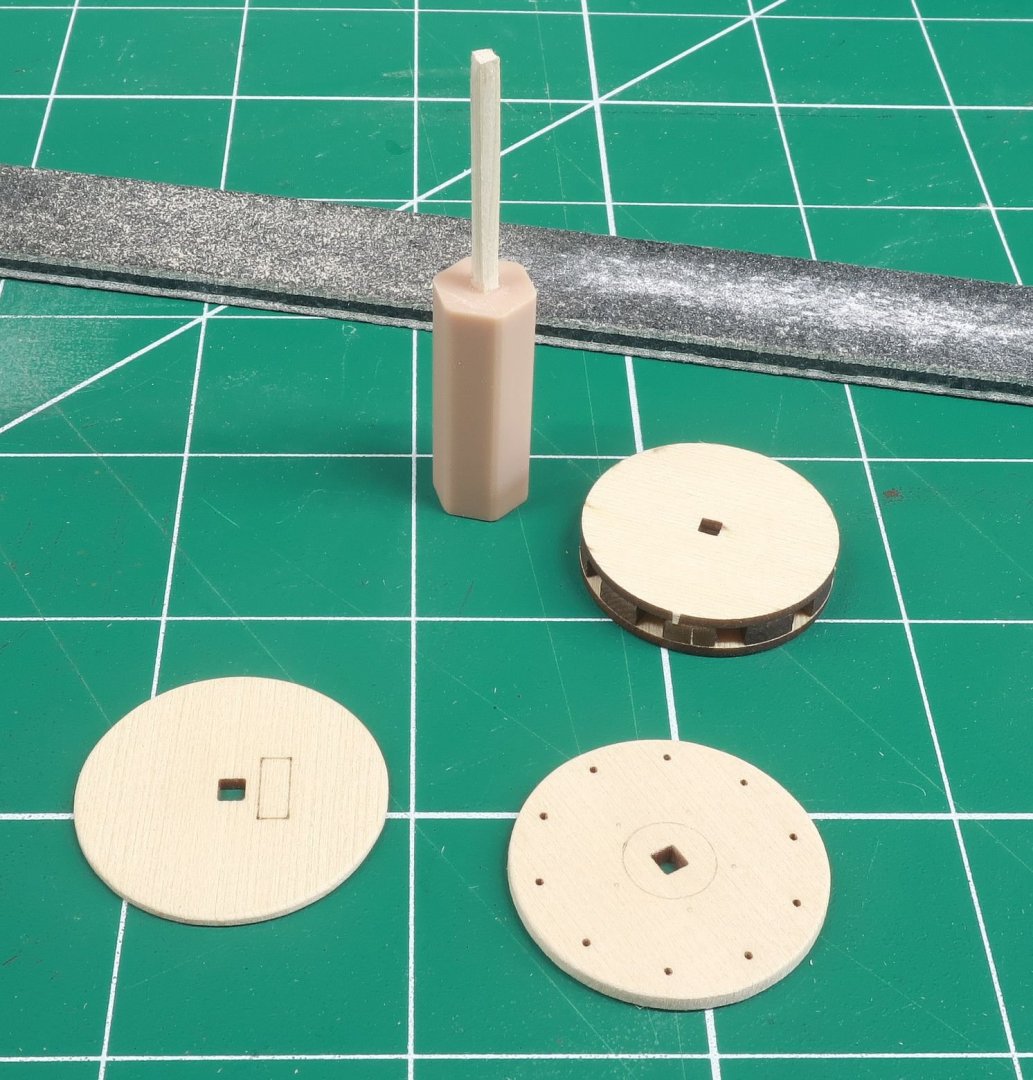

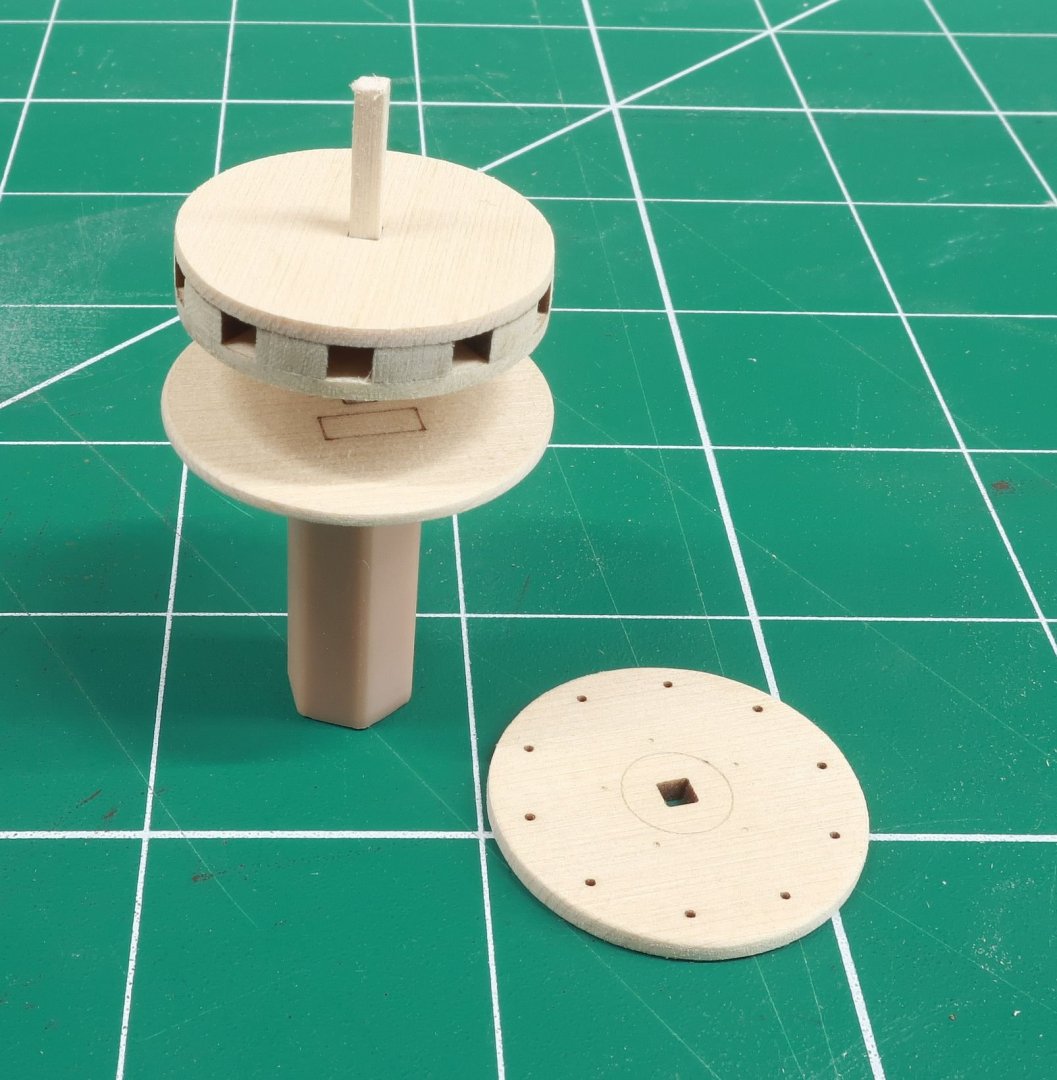

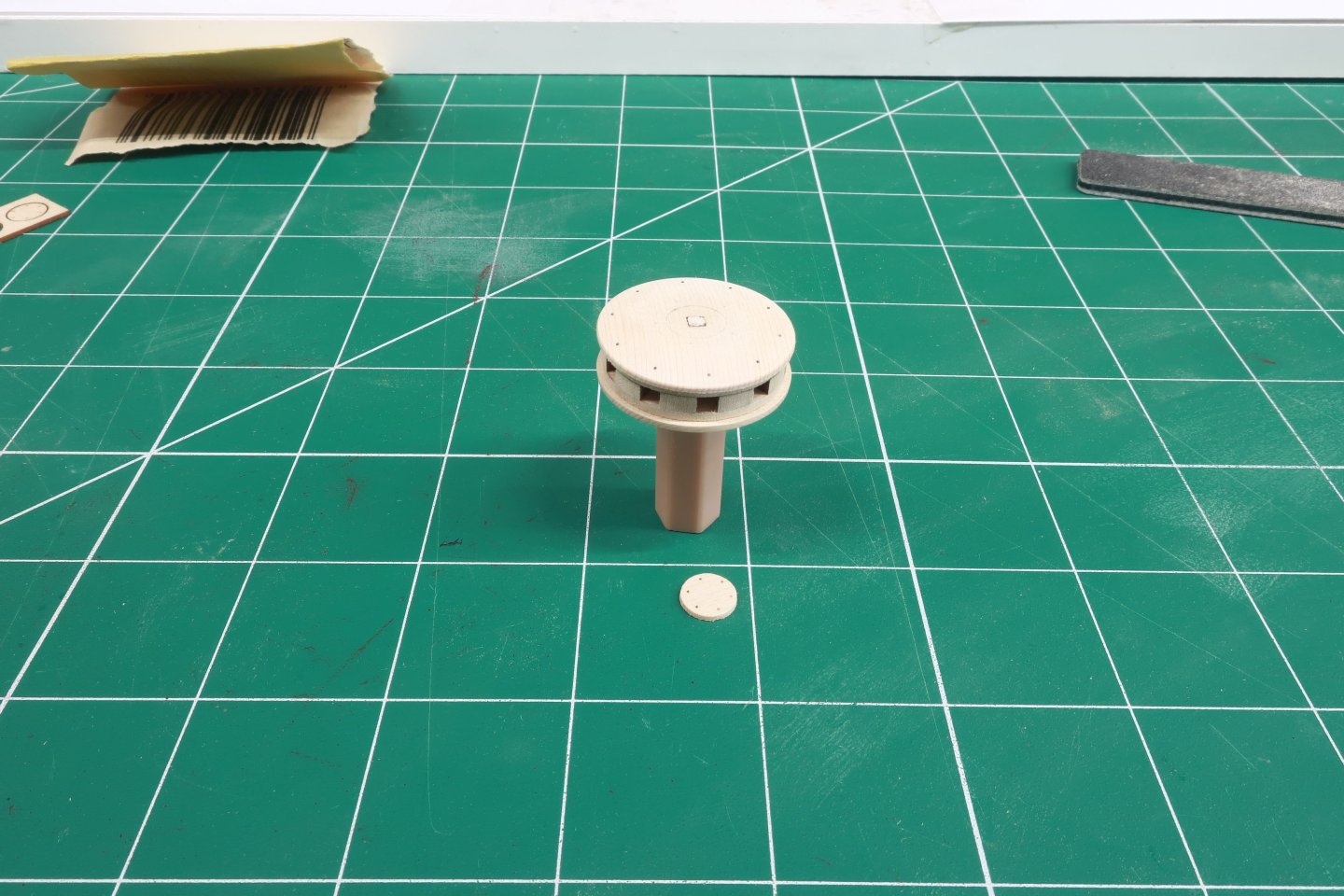

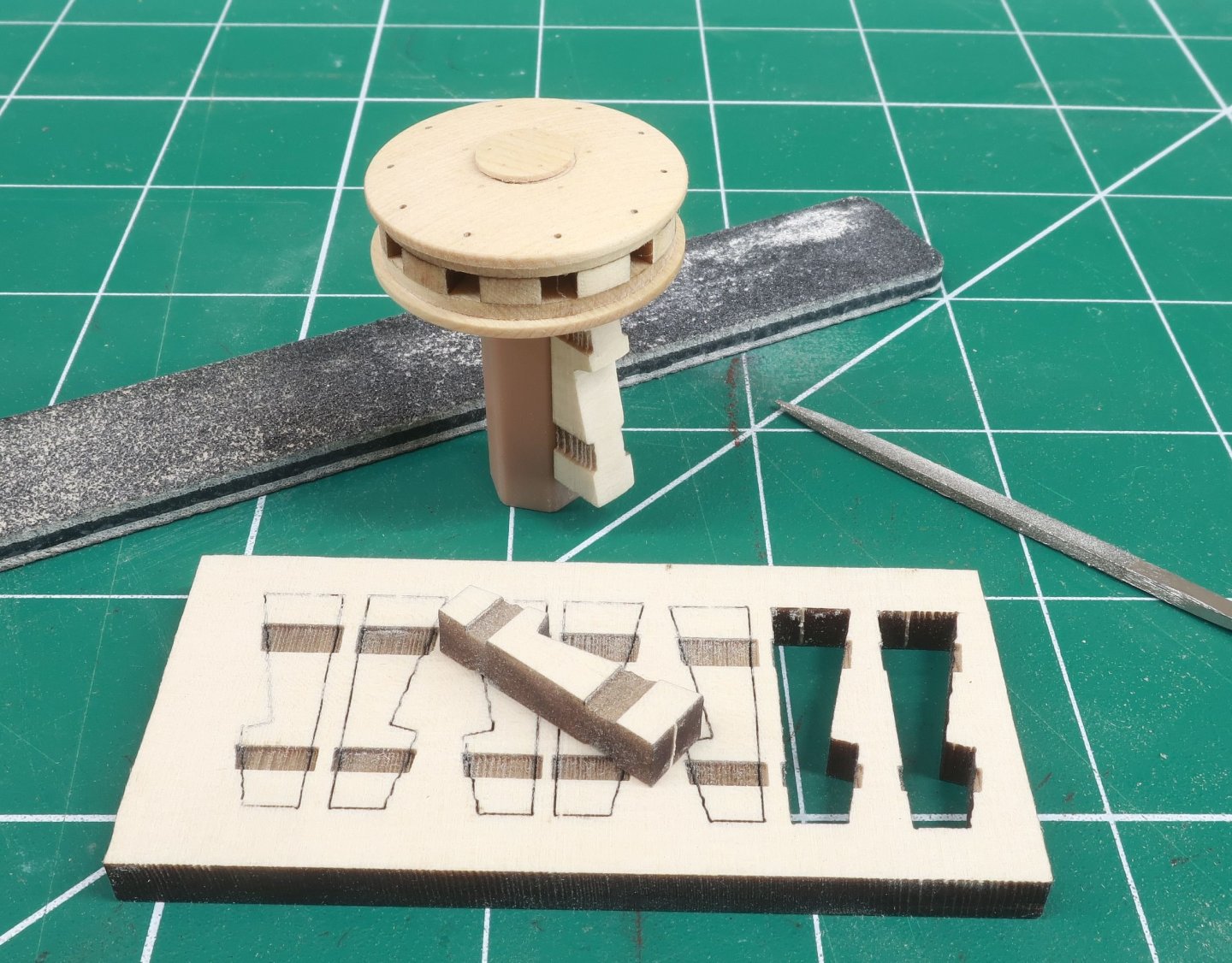

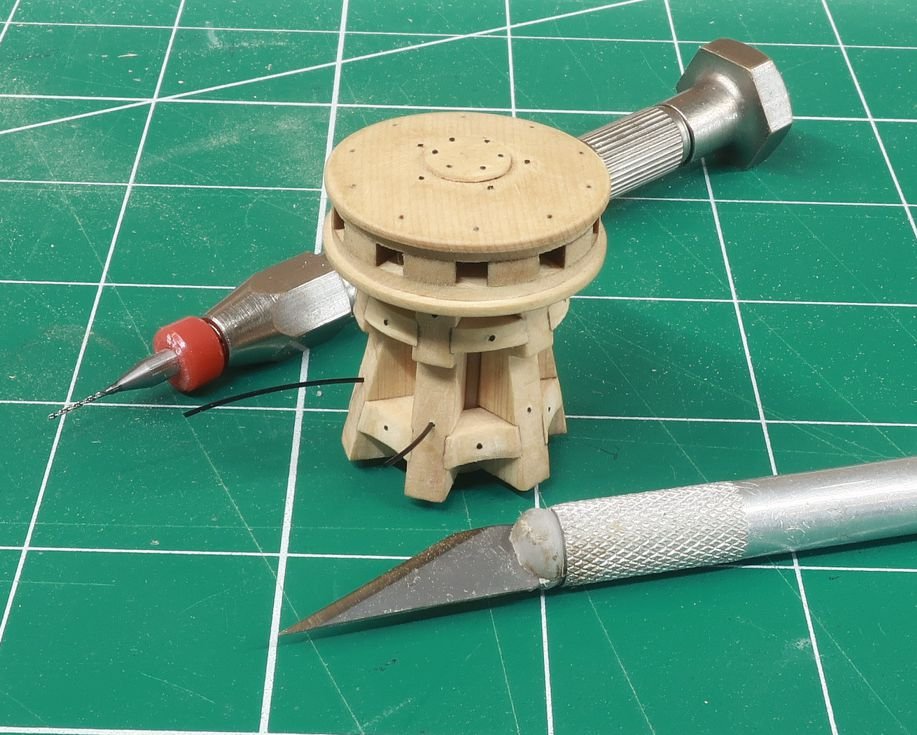

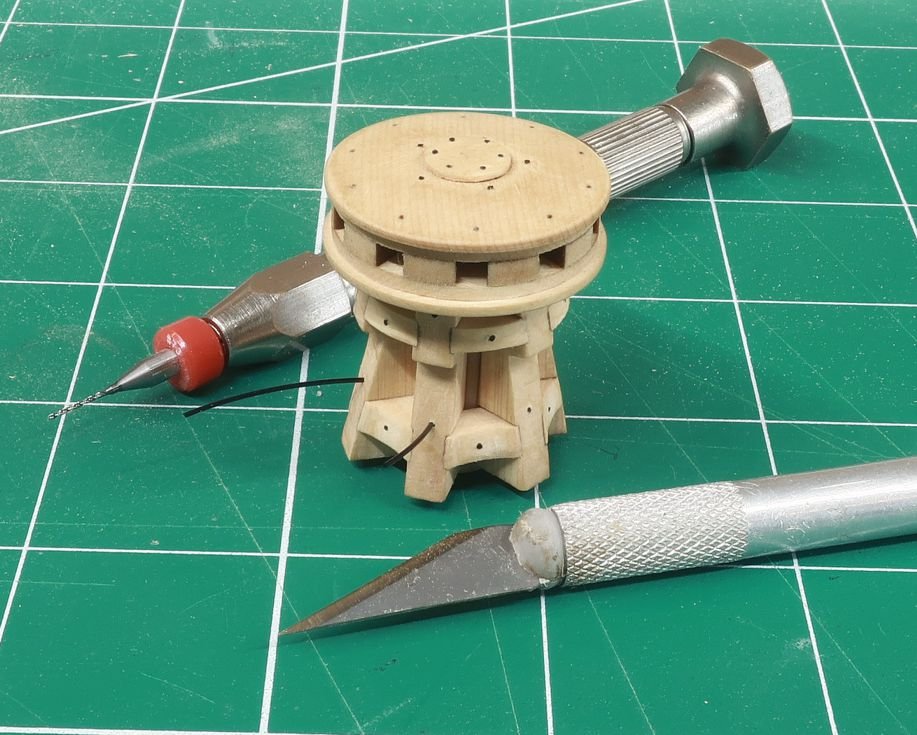

The step - by - step... The capstan is built almost exactly like the one for the Winnie. The main difference is the center drum. That added a bit of tedium to this task. With the 3D printer however it can be made in one piece and perfectly shaped. The benefit is that it saves so much time and it is so precise. It will also not be seen at all when the capstan is completed. You need to cut a 3/32" x 3/32" strip to use as the registration for the other layers. Its a little big initially by design. You need to sand it so the pieces are a nice press fit when you slide them on. But dont force the layers onto the strip because you could break the thinner layers. You can see some of the layers in the photo below. The two at the top have had the laser char cleaned from the sides. I used a sanding stick. Dont worry about the three at the bottom yet. Those are next...slide them onto the strip (or use an entirely different strip) gluing the three layers together. But dont glue it to the strip as you will want to remove it. See below To make it easier to remove the char from these assemblies, you can place them onto a 3/32" strip as long as its a tight fit...otherwise it will fly off. But then chock it in your hand drill and have at it. Use a fine grit sanding stick. Its soft wood so be careful. This is a later process when most of the drum is glued up in layers and being sanded. But I wanted to show you that you didnt have to sand them by hand. You need to do that to the three center layers with the square holes first. Then glue that on top of the slightly larger disc with the square etched onto it for reference. Then glue the top on and sand it as shown in the photo above with the drill. I also sanded a slight dome shape into the top side of the drum while on the drill. This makes the sides a bit thinner and gives the top a nice shape. But keep the center area flat for the last small top layer. I thinned the top this way until the side edge was 3/64" thick or close to it. I am not sure if you can see the top shaped like a dome or rounded off but now that last small disc can be added. But first go ahead and glue the drum assembly to the 3D printed center first. Then snip off any excess 3/32" strip sticking out above the center and sand it flush. Then glue the little disc on top and center it with the etched circle that should help you do just that. Then its time for the whelps. There are plenty of extra provided. But sand them free of laser char and glue them to each face of the 3D printed center. Make sure you but them flush against the bottom edge of the drum. Note the laser etched mortices on both side of each whelp. These are for the chocks. Take a look at them before you glue them in position and flatten them out if need be with a small file. Sometimes the etched surface isnt perfect and needs a little cleaning up. A few swipes with a file should do the trick. With the whelps all finished...start adding the chocks. These will take some time. The thicker chocks are the bottom row. You will most likely have to sand both sides of the pie pieces and test them in position. Make sure they fit tight in the mortices of the whelps. Dont rush this as a clean tight fit is what makes the capstan look so good. The sand the outside edge concave or convex with a curve depending on if it is the top or bottom row of chocks. The chocks are over-sized so you will be shaping and testing and repeating the process. Plan on spending an entire day building this capstan with care. Then add the simulated bolts with some 20lb blk fishing line. There are also bolts on the top of the drum. The holes along the outside of the drum are for the pins that hold the capstan bars. They are not for bolts and should remain as holes. All the other laser cut holes around the center of the drum were places there for your simulated bolts. So add those as well. Thats it...it will take some time to do a decent job. But remember that there are fewer deck fittings on this little sloop and therefor it is even more important to do a respectable job on them. They will all be front and center and a focus point when anyone views the model. You can pint it red or leave natural. The contemporary model is painted red. I havent decided yet. What do you guys think? There are also two pawls that were used to stop the capstan from turning. Only one side was engaged at a time. One goes to port and the other to starboard. See the plans. These were made from scrap 1/16" x 1/16" strips and glued into position.

-

Speaking of simulated bolts...someone was asking about them. Here is the capstan which I am literally finishing up this afternoon. So I figured its a good time to show the bolts in progress. It is all yellow cedar. It has many bolts which add so much to its look when finished. In this case I am using 20lb blk fishing line. I just cut some sort lengths and stick them into some pre drilled holes. Nothing difficult here. They need to be a press fit so no glue is needed. I am using a #73 bit for the holes. Then just slice them off so they are slightly proud of the surface. That is it. I will have a step - by - step for the capstan later today hopefully. The capstan is painted red on the contemporary model....sooo I have yet another decision. But it turned out well. Chuck

-

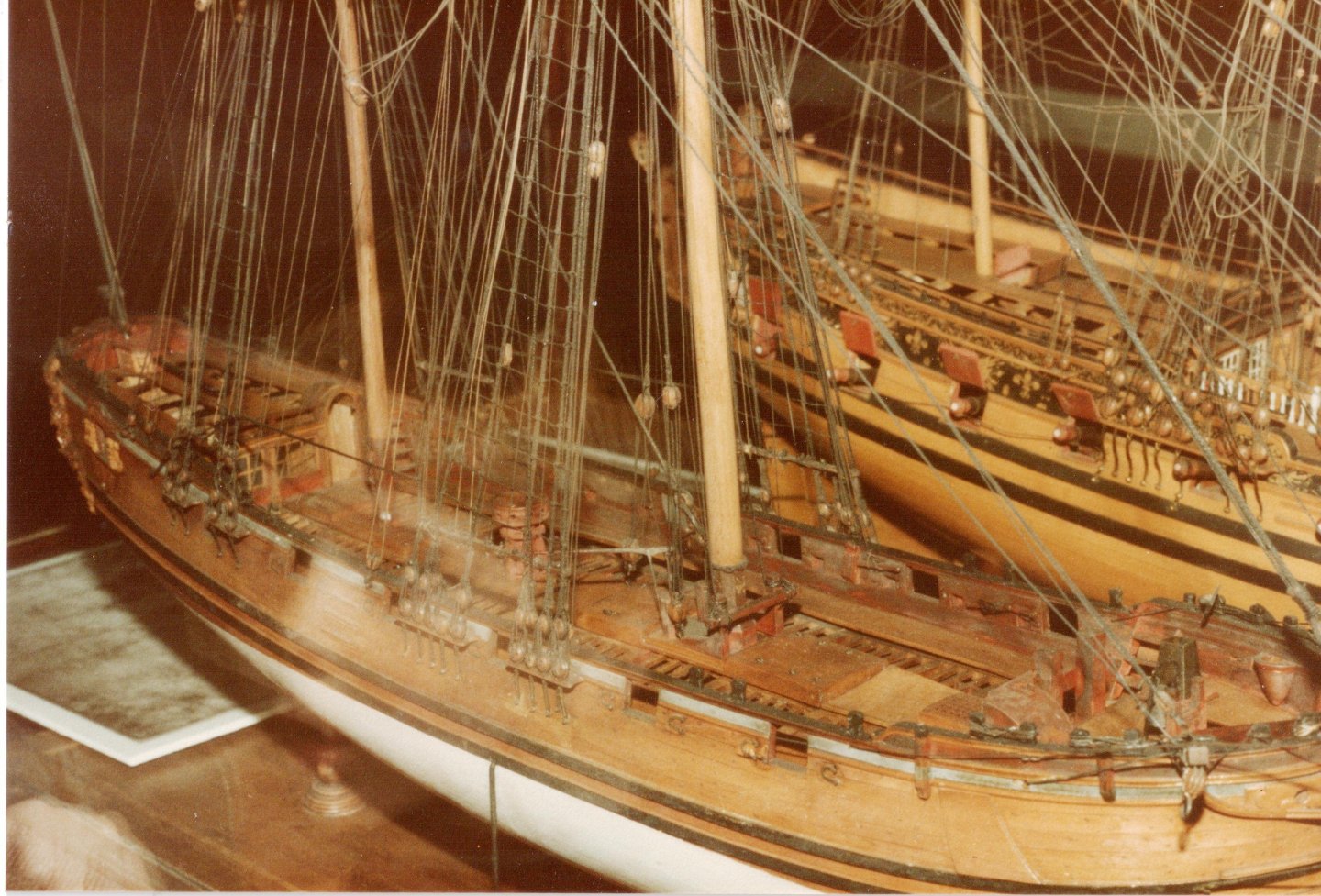

Moving right along... The elm pumps and mast coats were completed. The mast coats were straight forward. They were made by gluing three lasercut layers together. The same as on the Winnie and other projects. These are interesting however as the are octagonal. So are the masts partly up their length. The laser char was removed and the top edges were beveled or rounded off. Then they were glued together and painted as on the contemporary model. The pumps were a whole different story. On the contemporary model these pumps are quite elegant and light. They are shown with very thin parts and slightly different than others I have seen or built. There is a long slender metal post that supports the handle. The handle is also very thin and long. How these builders achieved this detail at 1/4" scale just amazes me. They are also painted red on the contemporary model. Just look at how thin and delicate the pumps are on the model below. Note the small carved panel detail on each face of the pump. I really wanted to see if I could replicate this same delicate look on my model at 3/8" scale. Although less worn and dusty, LOL. Anyhow...I decided to try my hand at 3D printing this. Not only to make construction easier but maybe I can incorporate some of those more delicate details this way. The photo below also shows the mast coats completed and painted. For the pumps I had to create a left and right matching pair. The body and its long slender metal post is all designed as one piece. My attempt at those very subtle carved panels can hopefully be seen in my poor photographs. You can leave the pumps natural and just paint the metalwork or go red as I have done. Its up to you and they are printed with a tan/boxwood color resin for this purpose. The handle is laser cut from actual boxwood since it will be left natural and ties in an actual wood element to help pull off the realistic look. I added a piece of 24 gauge black wire to the handle before gluing the handle onto the pump. There is a hole in the bottom of the pump hole for this but I did drill it out larger for the wire. I glued the handle in position trying to establish the same height and angle for them port and starboard. Here is what they look like on the model. There were holes in the deck where the pumps will go to help with placement so you can kind of match them to the pump tubes below deck. Its not very difficult to do. While not a perfect match to the contemporary model I think the slender and delicate look has been faithfully recreated. I also decide what the hay...and painted the bsprit step red as well as I complete more deck fittings. Oh and the mast coats are not glued in position yet. That will be left for later when we step the masts. One last fitting remains on the gun deck. That is the capstan and I will build that next. Then its onto the poop deck rail and details. Chuck

-

You cant fully judge with the hull upside down. It is more important to view the hull right side up as it will naturally be. You will be able see the run more accurately. If the run dips or if what appear to be dents which is an optical illusion caused by the run of the strakes or tape. Flip it over!!!

-

Its really easy...simply drill a small hole just big enough to accept whatever size fishing line you are using. Then insert the fishing line into the hole. It should be a press fit if you drilled the correct size hole. No glue is needed. Then take a sharp straight razor or even a #11 blade and slice it off. But dont make it flush to the wood. Slice it so it stands proud just a little bit. Here are some various examples on the coamings and on the keelson. I also use this method for treenailing but in that case I do slice it off flush with the planking. See below. You can select black fishing line or even a dark brown for treenails. The trick is just not going too large. I believe the treenails below are 10lb or 15lb....I have to look back. The bolts can be larger at 25lb...30lb...or even 40lb for larger keel bolts. For example look at all the bolts in the frames. They are I believe 30lb black fishing line.

-

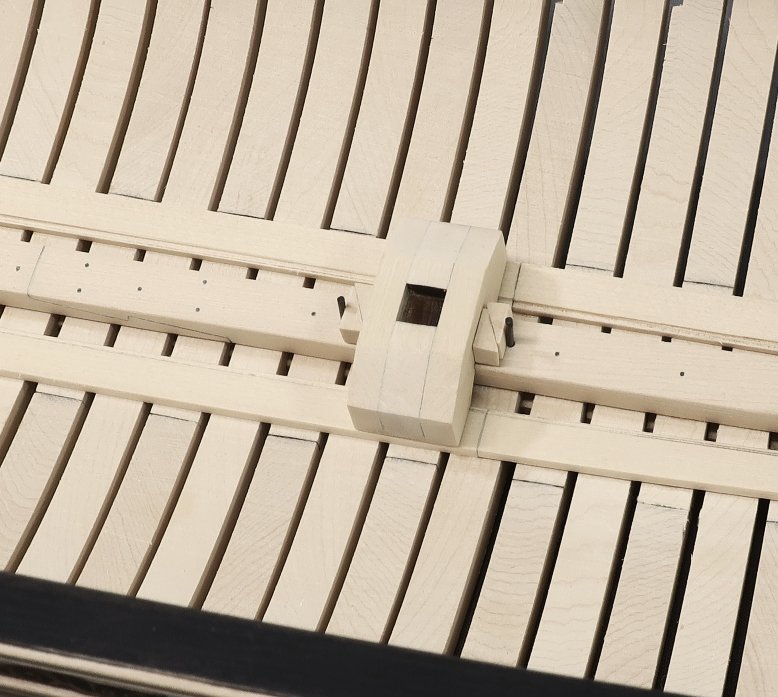

Thank You!! She is slowly filling out with details as I work my way aft with deck fittings. The main bitts are just forward of the main mast. This is shaped and assembled from more laser cut parts the same way as I have designed the others throughout the project. See below. With the main bitts the sides were glued together first as they come in two parts. This was before the char was removed. The char was removed and the top "timberheads" were carved and shaped as before. Then the cross beam was glued to them after it was cleaned and shaped. The ends need to be filed on the top and bottom to match the profile while being cleaned of char. I also beveled the extreme edges on each side. To finish it up I added simulated bolts with 30lb black fishing line according to the plans. I have placed the bitts on the model but not yet permanently. I will do that later. The bitts were painted bulwark red as on the contemporary model. As more fittings get completed I am still thinking about painting the belfry bowsprit step red as well. Time will tell...what do you guys think? Mast coats and elm tree pumps are next up.

-

Just an FYI Blocks and Rope are now fully stocked!!! Next up will be some testing on ship's wheels and other goodies. Things are starting to work out nicely in production. Happy modelling!!! Blocks are $5.75 per package as opposed to $9.50 per package from the other guys!!! Why pay 50% more when you can buy the original and best with no tariff or international shipping to the USA.

-

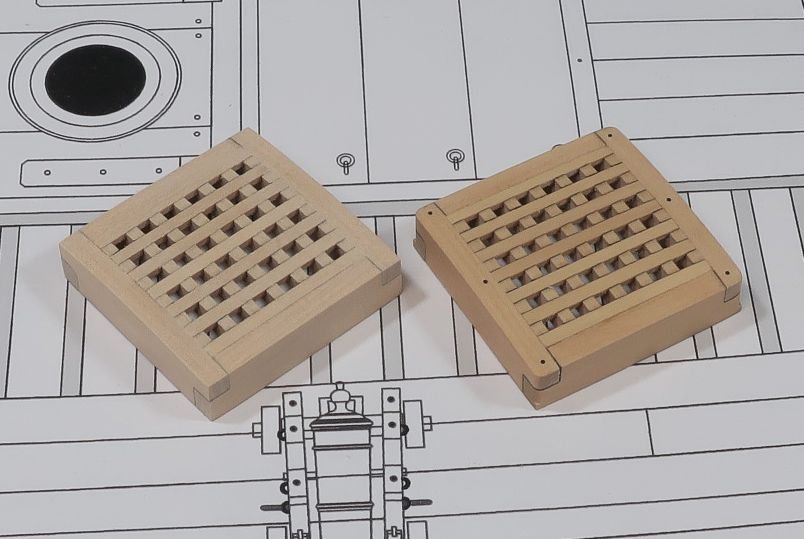

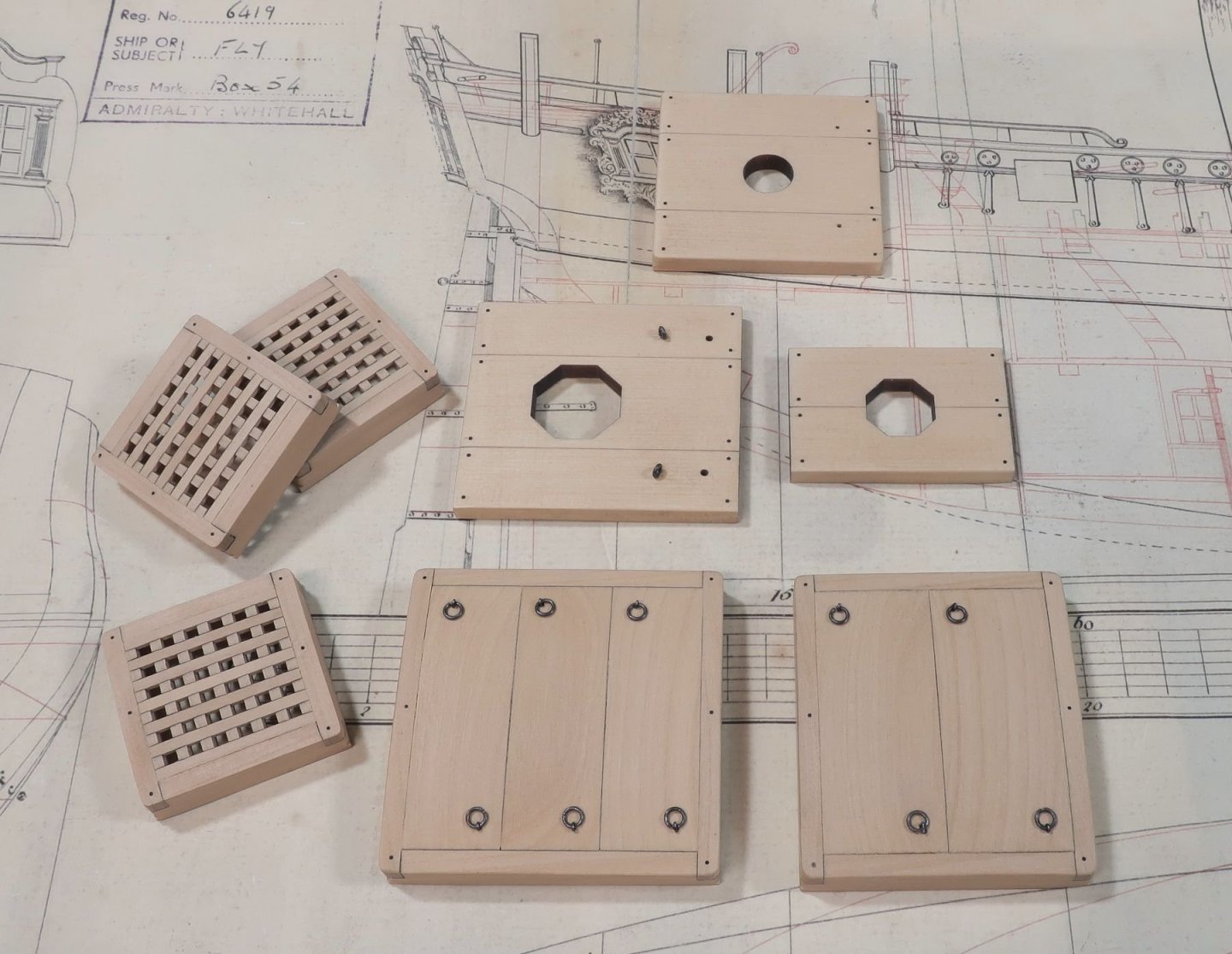

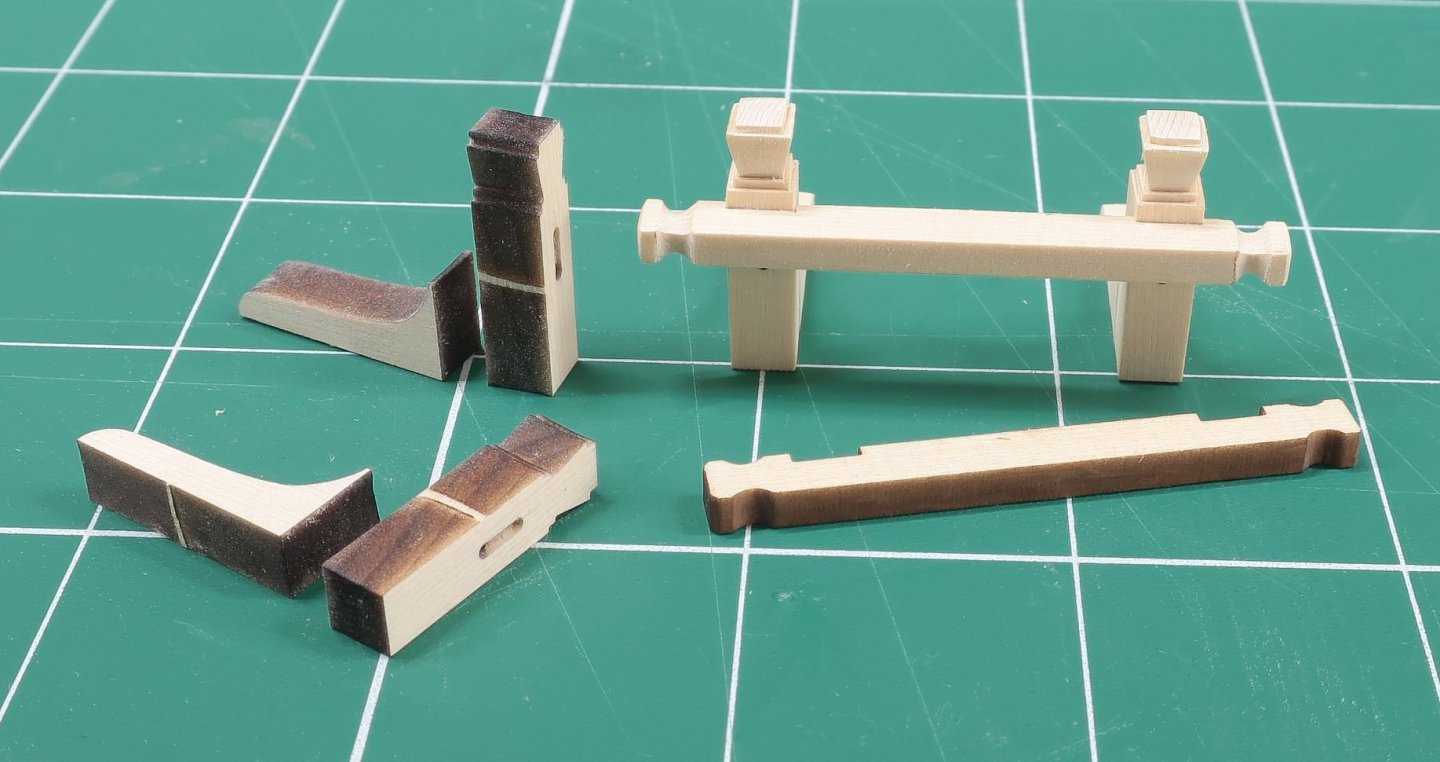

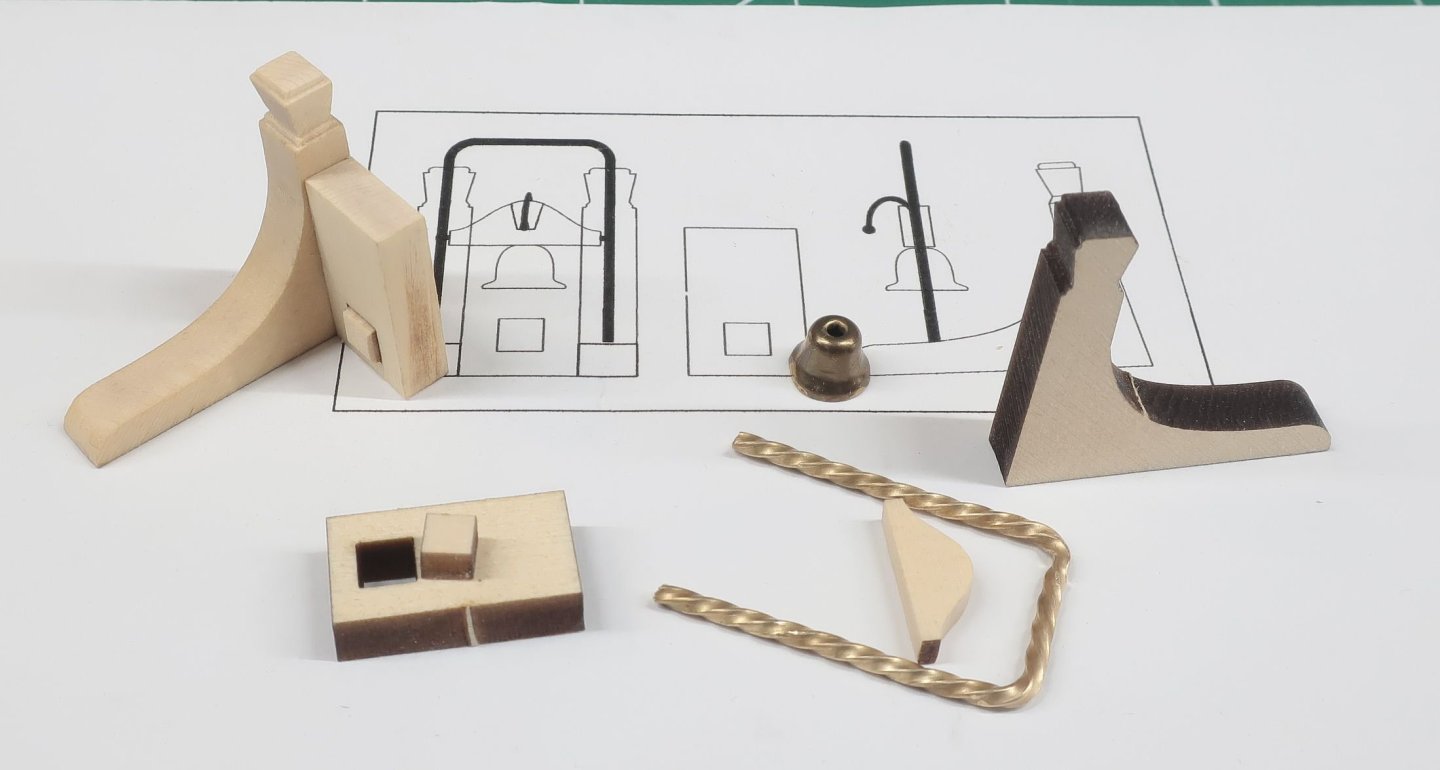

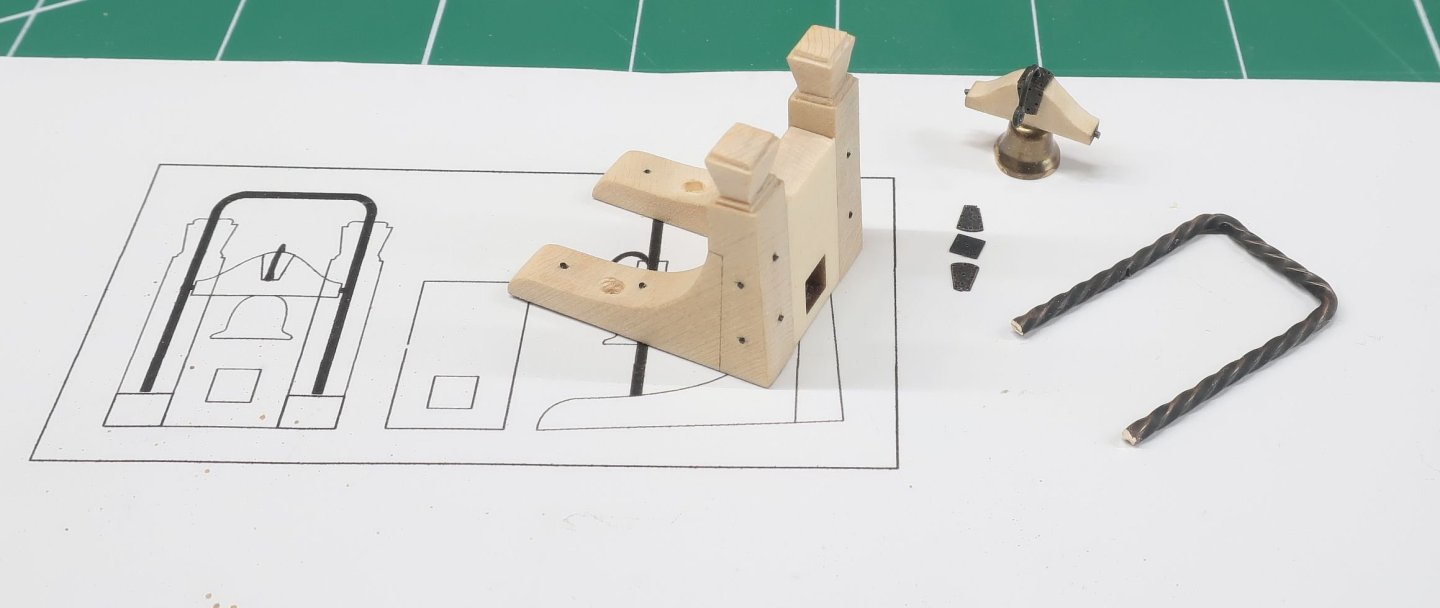

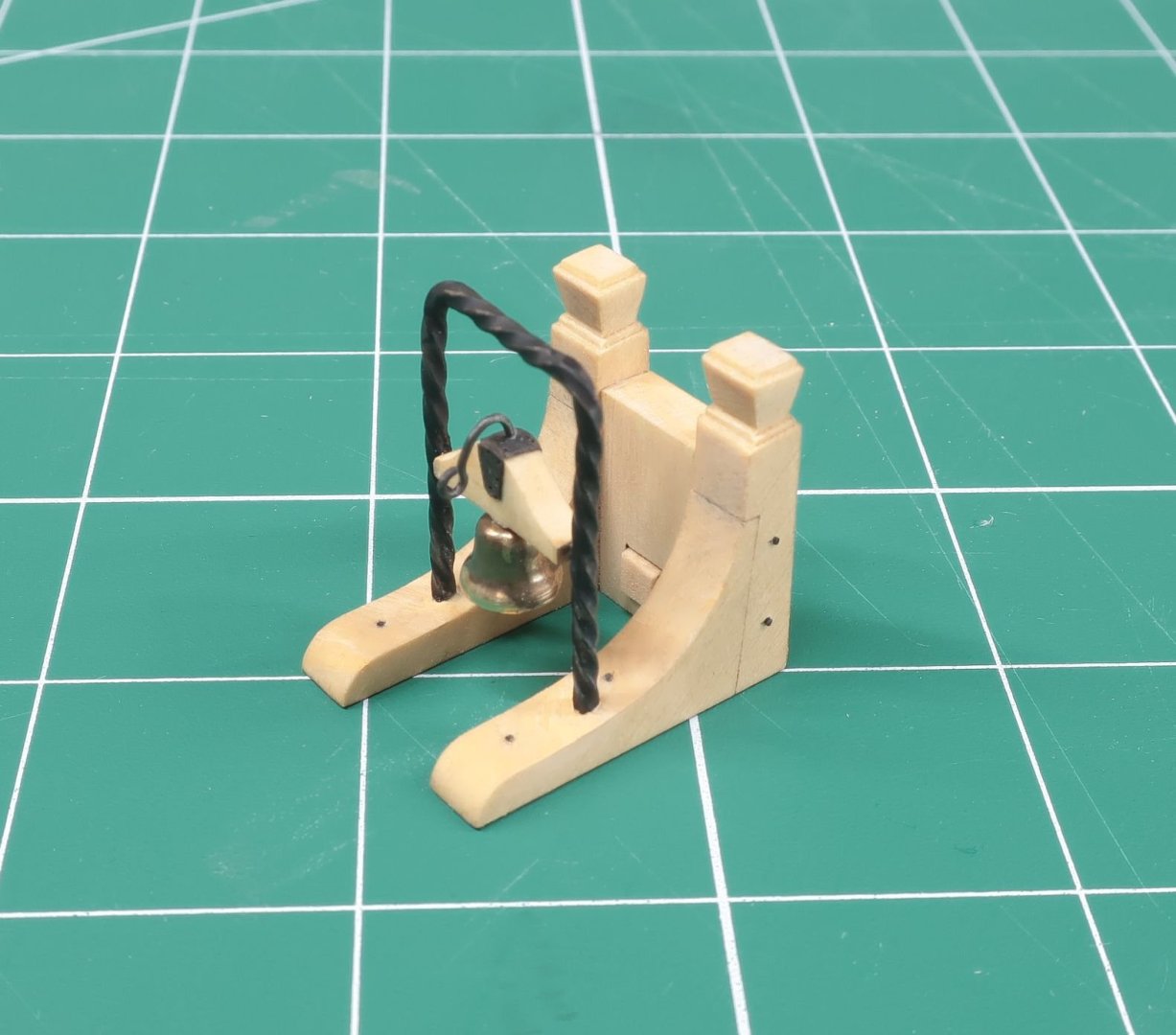

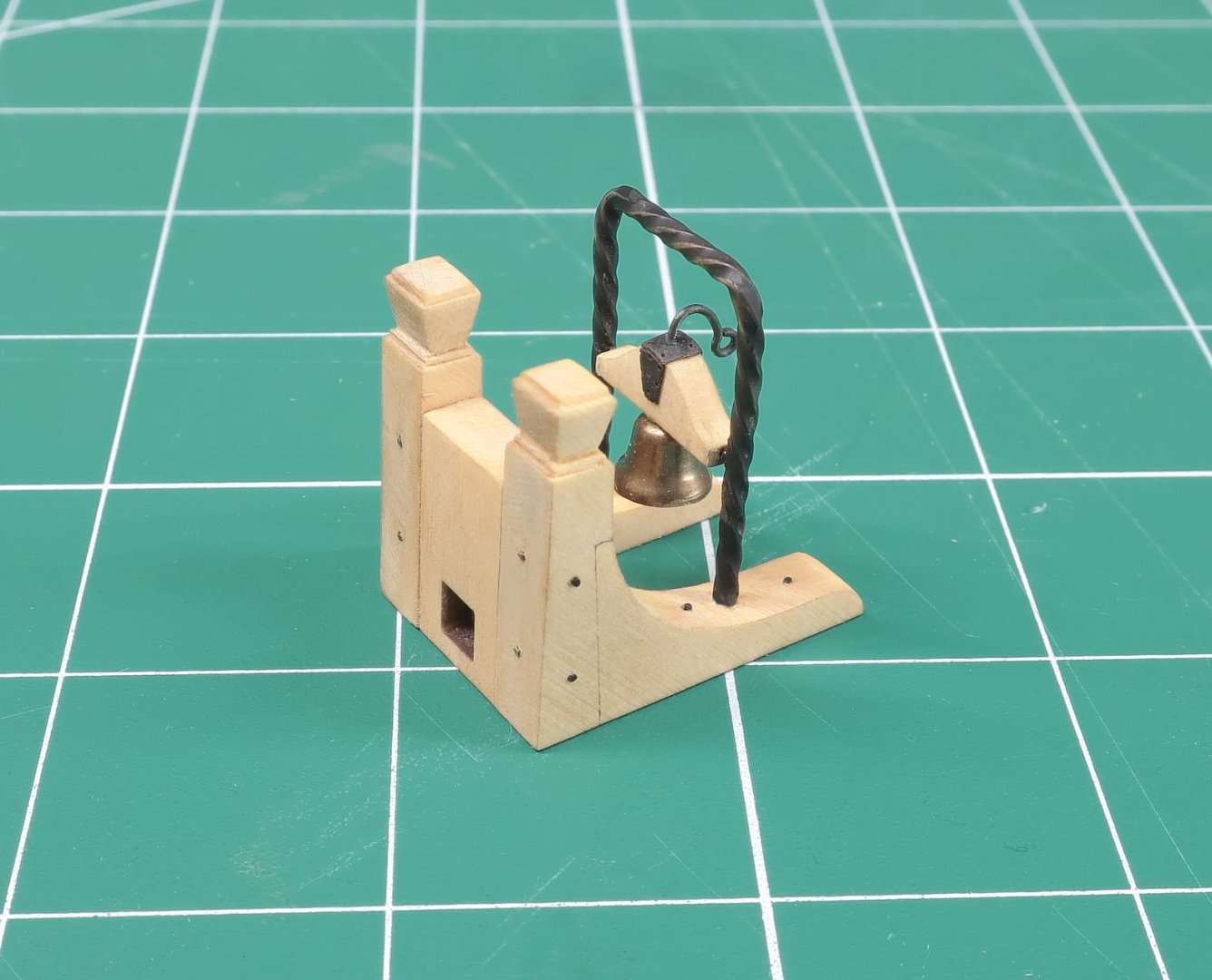

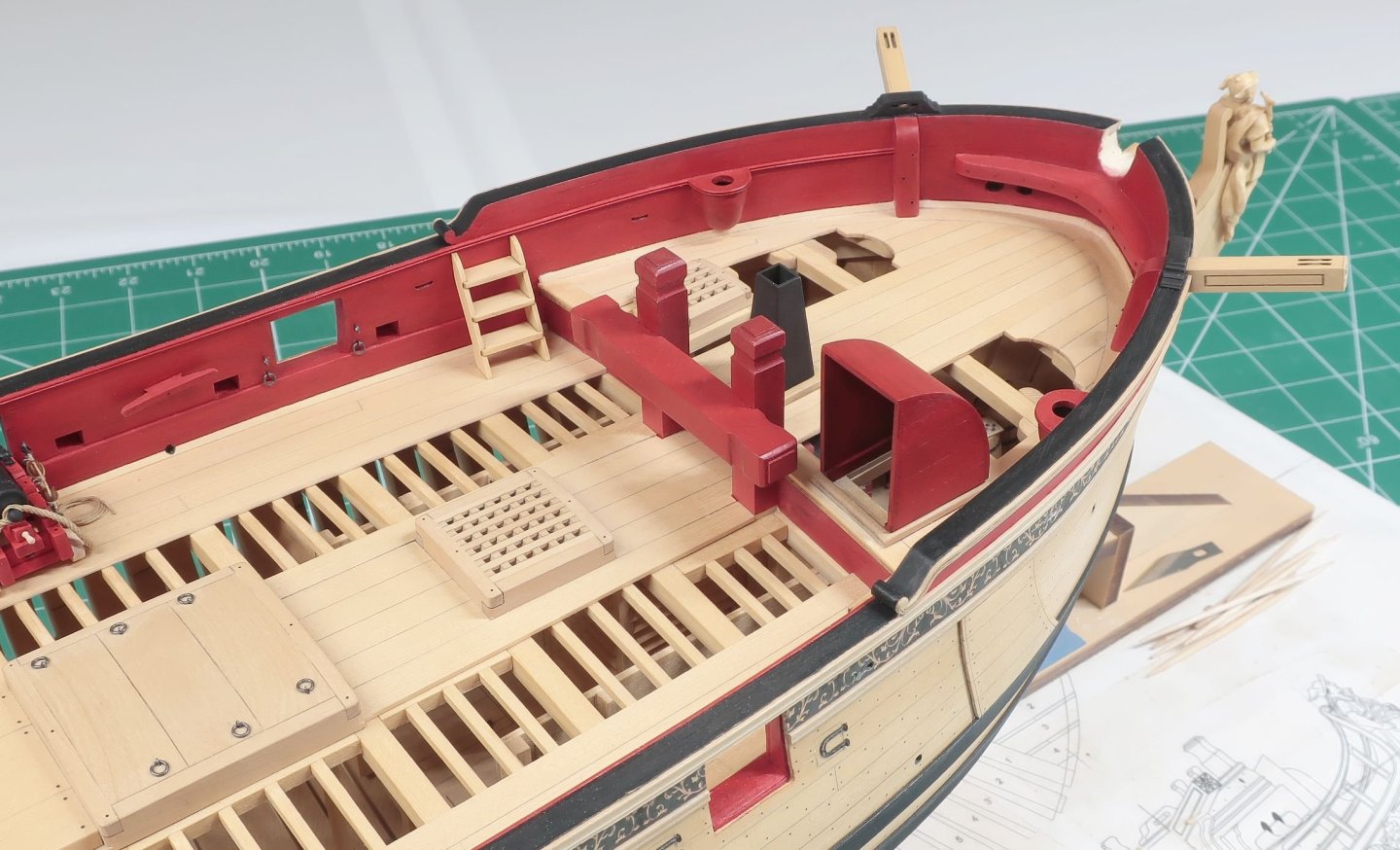

Lots of dust on the model...maybe today I will clean it all up. Anyway...the bowsprit step/Belfry was up next. At this point none of the fittings are glued on deck. I am not yet sure if I will paint it red or leave it natural. The contemporary model has it painted red but the paint is so worn and light on that model it all pretty much blends in to everything else. So I will wait until all of the fittings are made to determine whether I paint this. I know the heel of of bowsprit inboard will be painted red so I will wait to see if painting the bsprit step red would be too much. Here are most of the elements laser cut for the bstep/belfry. There is a bunch of faking it on this fitting but in the end you wont be able to tall. First I cleaned these Cedar pieces of laser char. Dont be shy here. It will all come off and look clean but takes time and care. I used some 220 grit and 320 grit sanding sticks and even a sharp #11 blade. You can see one side of the bstep all cleaned of char. The other has yet to be cleaned and shaped. You must finish the top and match the shaped timberhead. For this a sharp blade was used to make a series of "stop cuts" and then basically carve the two sides that needed shaping. This was after char clean up. The center where the bowsprit will be stepped was cleaned and assembled. Note the aft side of the step. I have inserted a small laser cut square to simulate the tenon of the bowsprit. Its just easier and cleaner this way. Leave it standing proud a bit. The forward side sill has a nice deep mortice for the actual tenon of the bowsprit. Then there were the belfry elements. This includes a length of twisted square wire. This will be proved. Yes this is commercially available. You must use the plan to shape it which is shown. Then blacken it. The other elements are also shown. Moving along...the step is now completed and drilled with simulated bolts. Once again these were black fishing line (30 lb). Note the laser etched seam which should go on the outside if each side piece...dont mix up the side pieces when assembling. I also drilled the holes for the wire belfry. That wire was blackened. The stock for the bell was completed at this time. Some laserboard elements simulate the ironwork. I glued the top on first and then the two faces. Some 24 gauge wire was inserted into the ends of the stock. But you can attach this to the wire frame anyway you wish. I knew it would be a challenge to drill through the frame for most so once again this is simplified. I just filed some slots on the inside of each frame of the twisted wire at the height needed. I used the plans to establish where. These tiny grooves were enough of a slot to slide and glue the belfry stock in position. Its pretty secure. Its not under any pressure so it should be safe and secure. Before doing so however, I added the handle to the top of the bell stock. I just bent it according to the plans. I used 22 gauge blk wire. You can add a tiny length of rope if want to. I have decided not to as they always seem to hang left or right or curl up and that annoys me. The bell was simply glued to the underside of the stock. Then it was glued within the frame as described. There is a little bit of cleaned up needed as my fingers must have been dirty. But this is the result. And finally shown on deck but not glued in position yet. The companionway hood is also not glued in position yet. No hurry with that. This completes the fcastle deck fittings. Now we start the gun deck fittings. Ignore the dust!!! Comments and questions are always welcome!!! Chuck

-

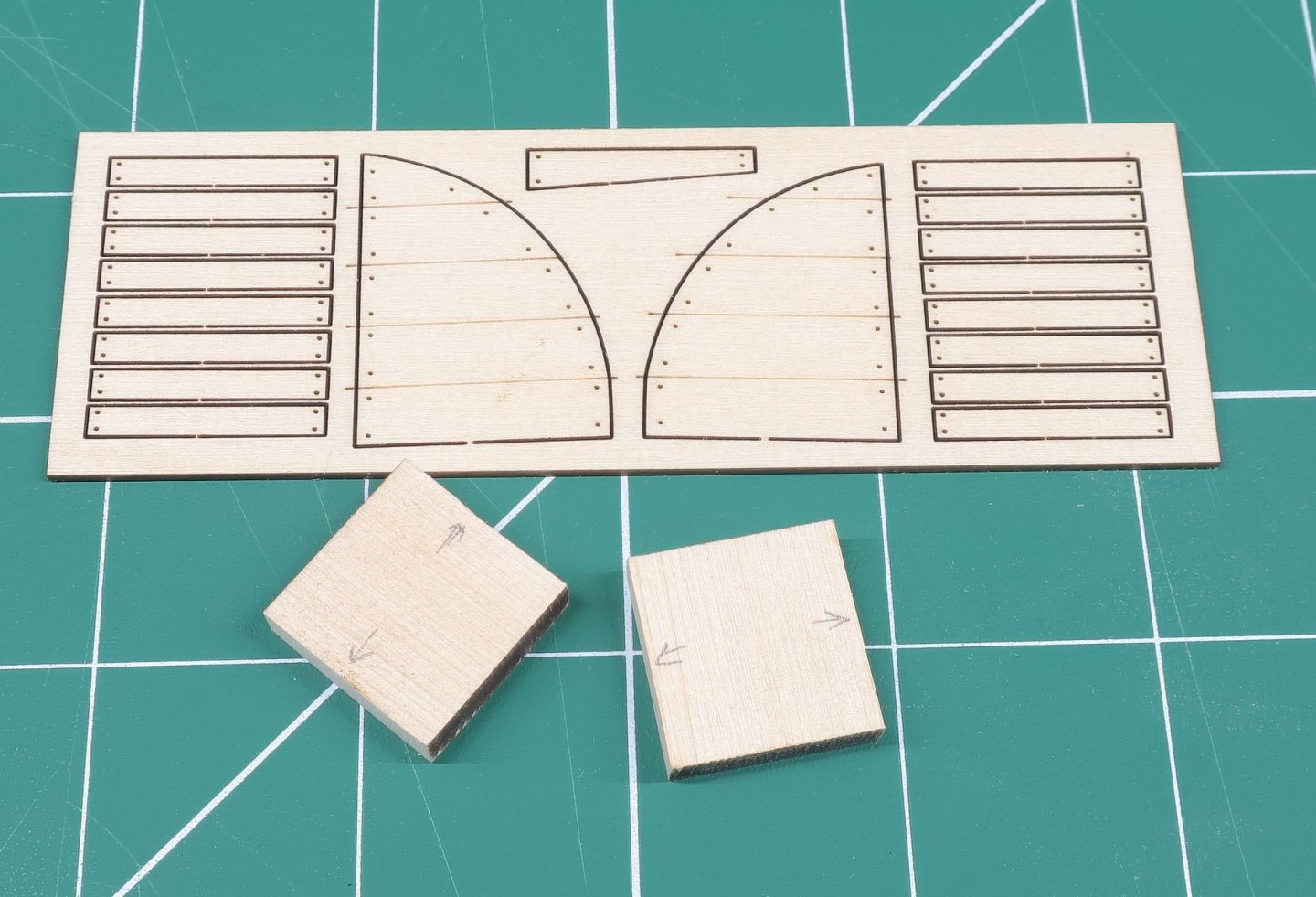

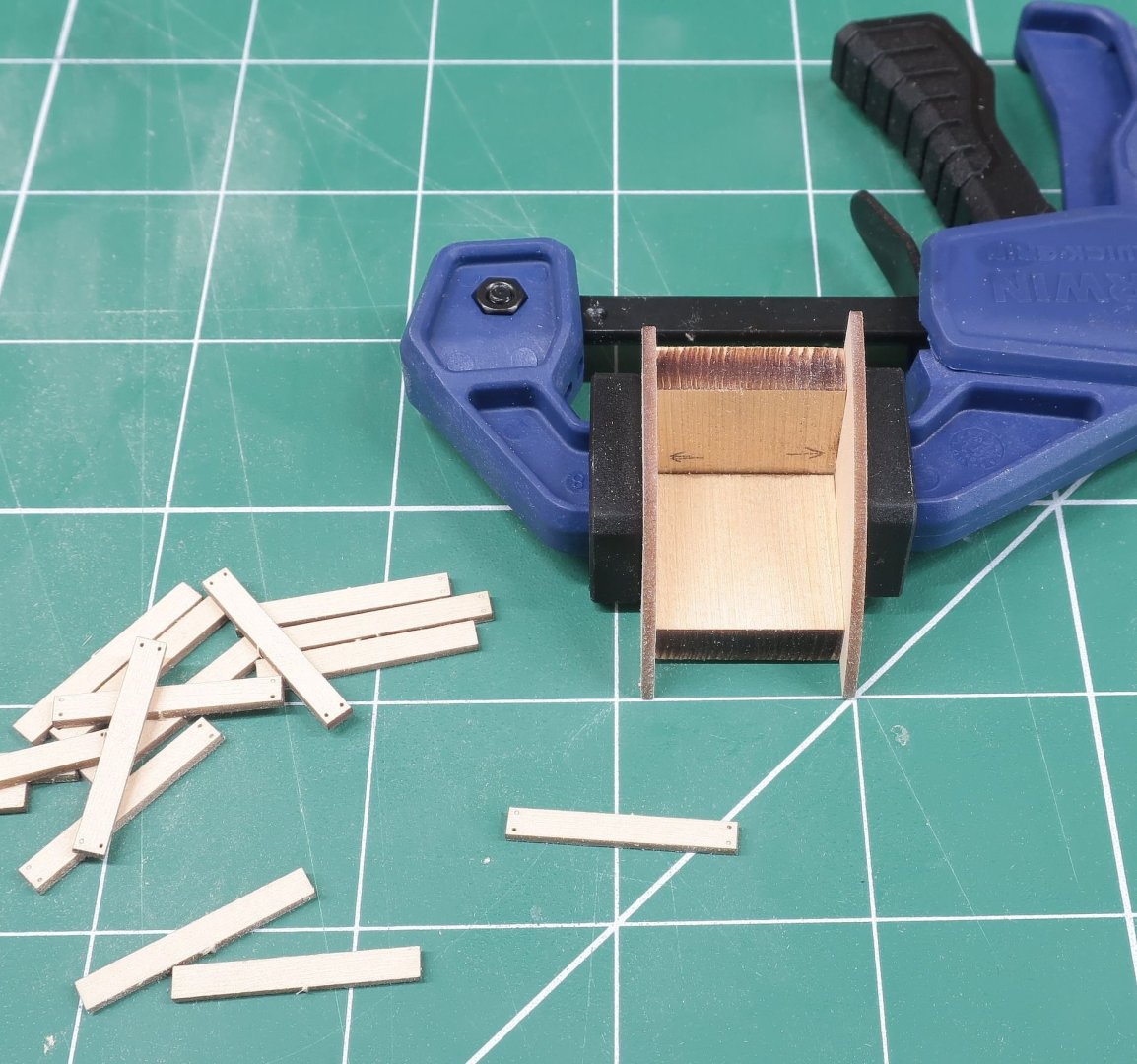

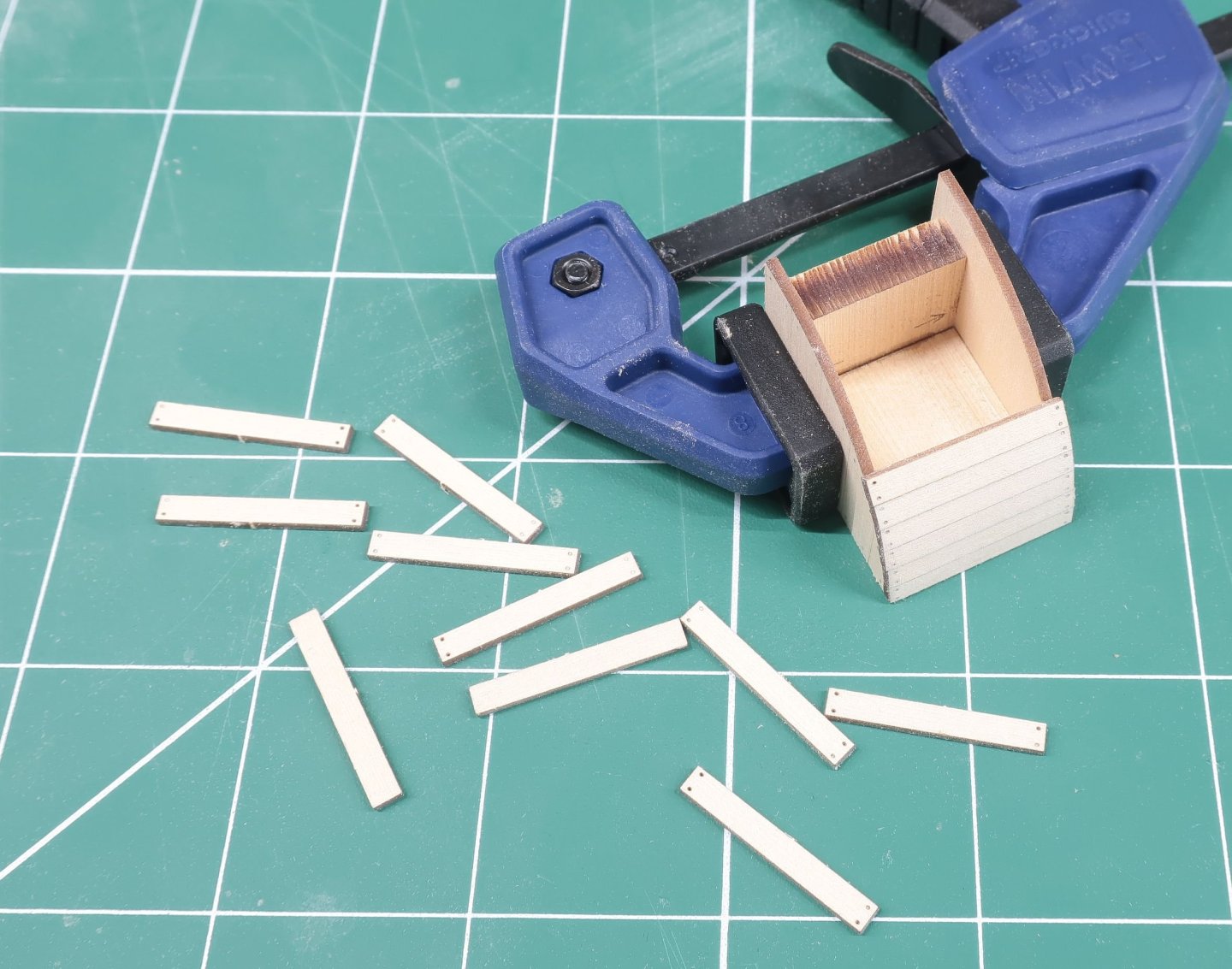

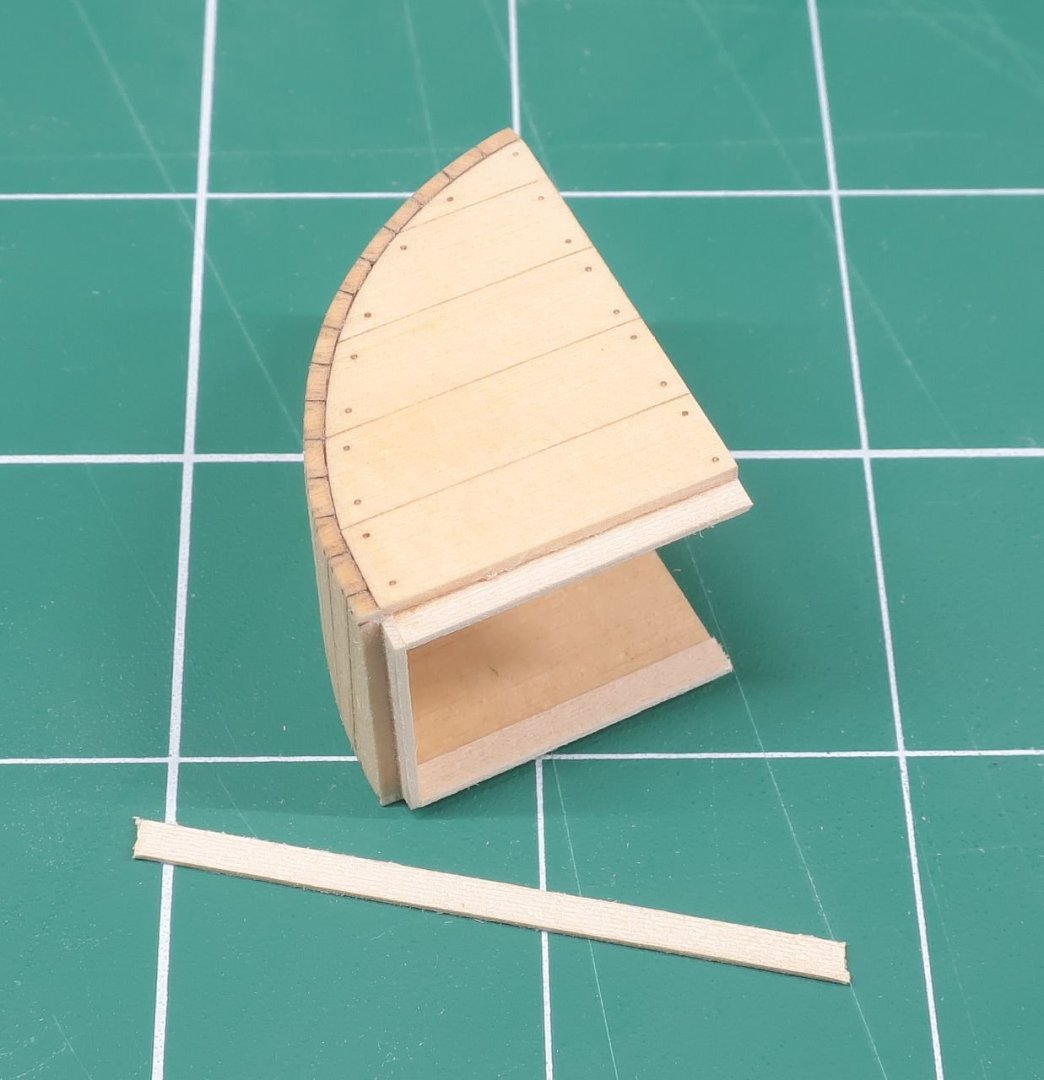

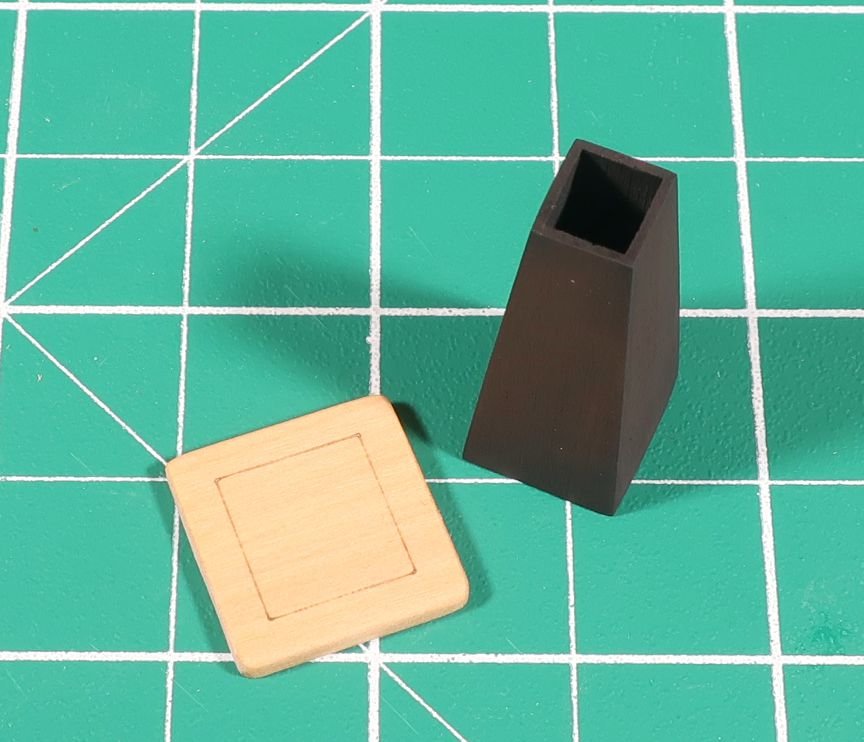

Making the hood for the fcastle companionway it is pretty straight forward but you have to be careful to align the sides properly before adding the top planks. It is all laser cut. Here are the pieces. The two thick squares are crucial to its fit when completed. They are laser cut slightly wider than the coaming. You need to sand the sides until the square is a nice press fit inside the coaming as shown below. Then you can glue the two squares together to form an "L". This "L" is the proper width if your squares were a nice fit in that coaming. Then clamp the two side panels to them so you can start gluing the thin cover boards to it that form the roof. The one thing you must be sure of when clamping the sides onto this fixture....dont glue it to the fixture!!! Its just used to properly align the two sides the correct distance apart. In addition, the two sides are no the same height. One side is longer than the other....the starboard side is longer. This is because of the deck round-up. So when clamping them to the fixture you must make sure the top edges are lined up and even. See it below in relation to the squares on the mat. The bottom edge shows each side being a different length. But the top must be squared up and even. Then start gluing the cover boards onto the sides. One at a time. But as you proceed, you must bevel the side as you are placing them on a rounded shape. But dont over-do the bevel. You dont need too much. When you are almost done with the boards, the last final board is laser cut wider and at an angle to compensate for the bottom of the hood being at an angle. When its all done you can sand the sides flush which were slightly longer than needed to clean it all up. Then its time to test its alignment on the model. It sits on top of the coaming...not within the coaming. Look at it from dead on and from the side. Make sure its straight and vertical and leaning to one side when viewed from the bow. Make sure it is not leaning when viewed from the side. You can sand the angle of the bottom of the hood to adjust any leaning. Once satisfied, move onto the next step. Now its time to cut small lengths from a 1/8 x 1/64" strip. This is glued half onto the inside of the hood with the other half forming a nice lip. This will be inserted into the coaming when done. It should fit perfectly if your two squares and fixture was the correct width. I am guessing that this hood was portable and removable. So you dont even have to glue it in position if you have a good fit. You can leave it natural or paint it bulwark red. Its your choice. I have painted it red to continue following the look and color scheme of the contemporary model. The seams and joints and nails do show through after painting it but its very subtle which I prefer. Mine is not glued in and it will prove useful as I may be removing it from time to time as it may get in the way of doing other work up there. Now onto the bowsprit step....and belfry.

-

Thanks guys…yes things are finally getting into a routine again. My sons wedding in a few weeks will be the last bit of excitement. That old pinball machine was left by the previous owners. It works but needs a bit of love repair. The lights arent working on the back part but other than that its all good. A nice distraction. And yes another pet project should I need one. I am Hoping the kids will take it off my hands so it becomes their project. Chuck

-

Work continues on the model. I am working on the hood for the fcastle hatch currently. But I realized I hadnt yet posted an image of my new workspace for building the actual models. This is probably the largest work bench I have ever had. Its actually a ping pong table. LOL BUT its a pleasure to have such a large uncluttered surface to build on top off. Speedwell at 3/8” scale is a very big model but it looks puny on my bench. Oh and these new and inexpensive LED lights from Amazon are a real treat. I have them on the forward side of the table and they can be manipulated in so many ways. Its also very bright (up to 6000 lumens) and can be adjusted in intensity and other colors etc. In addition I have about 30 green cutting mats many are large and many are small. I bought these for when my local club members come by for a workshop. So everyone gets a cutting mat. But in the meanwhile I can cover the whole front side of the space to keep everything safe and clean. So now I can start being productive on my models again….until I am compelled to beat my high score in pinball. Which isnt that high actually. Chuck

-

BTW...I don't intend to stop making chapter sets for the Winnie beyond chapter 2. So all is good. I would never stop making them if someone has begun the model or bought most of the chapters and just needs a few more to complete the project. So you are good to go should you not sell this or even for someone buying this. In fact all chapter sets in Cherry are currently in stock. Chuck

-

Very interesting stuff. Thanks for sharing.

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Thanks guys. Kent I hope you are on the mend. I really cant make any more battlestation kits because it was given away as a limited edition. All 25 went fast and are being built which is great but they were signed and numbered. I doubt the guy who got kit number 7 of 25 would be very happy with me if I suddenly made another 25 kits. But I could be wrong. chuck

-

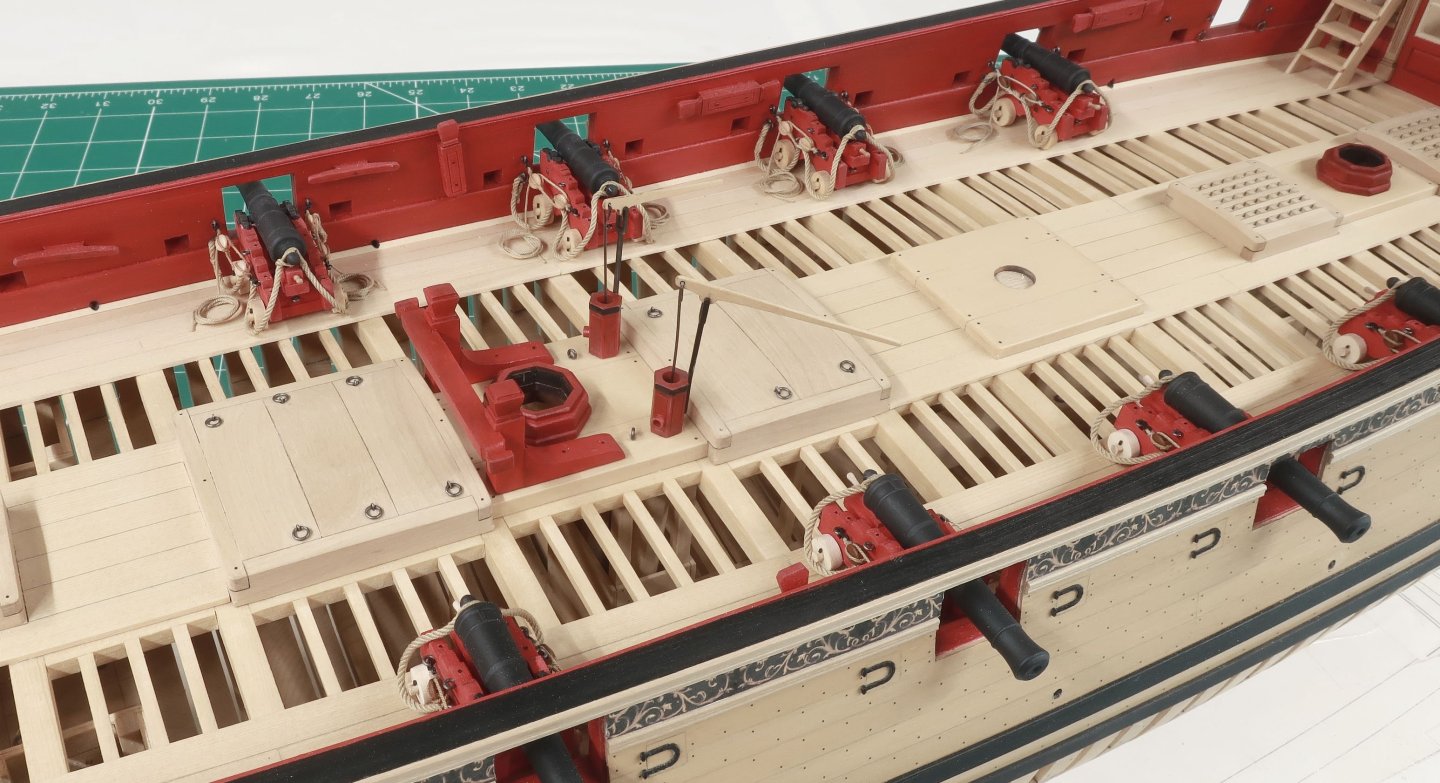

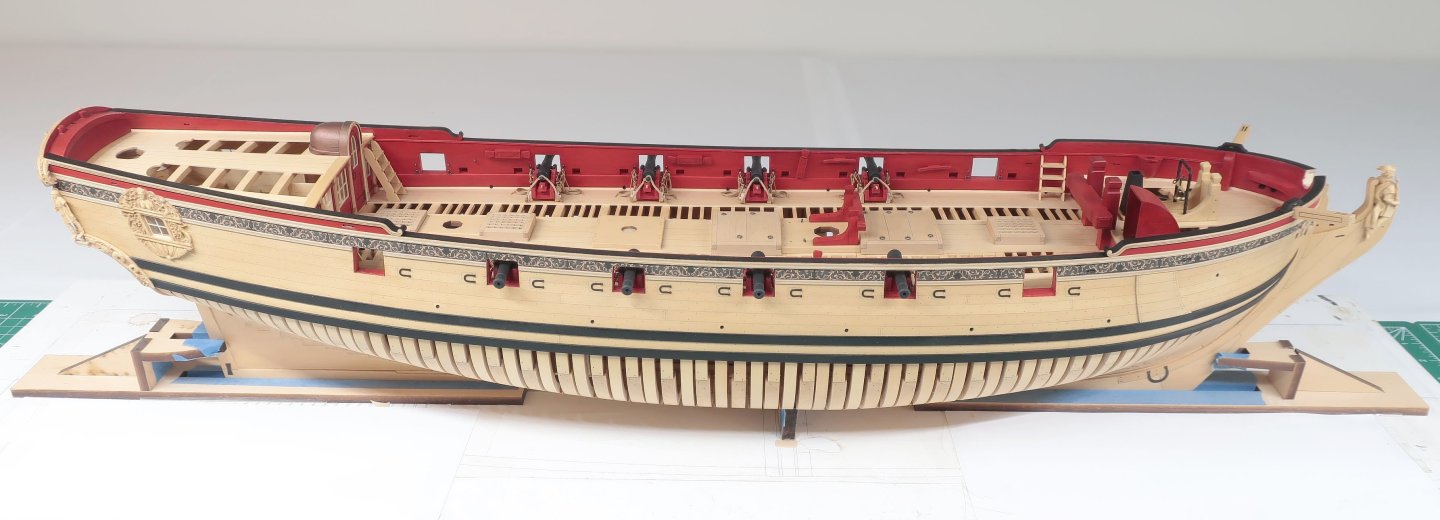

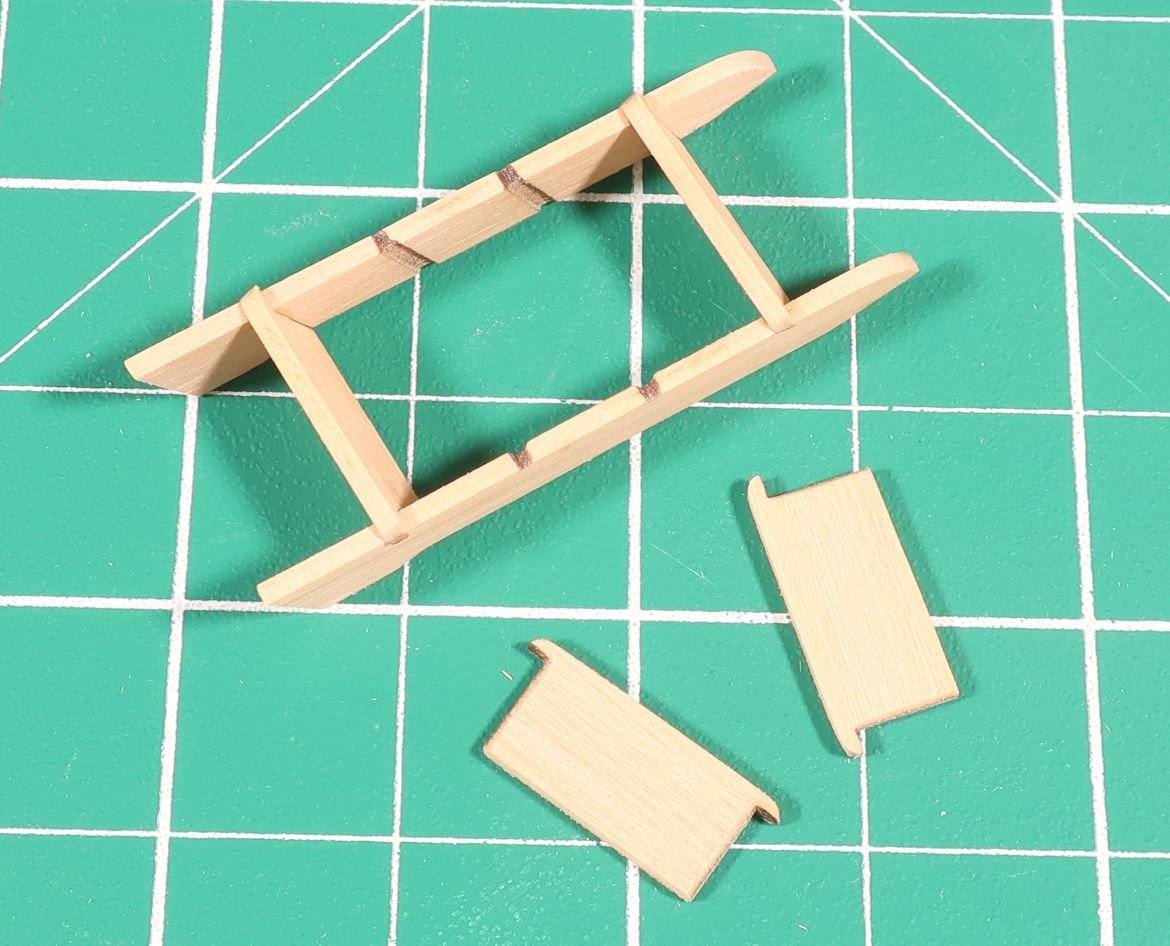

I am actually in a comfortable position with my inventory so I could start spending time working on the model again. I cant tell you how good that feels. I am not doing any heavy stuff yet...but its a start. I had time to finish rigging those last four cannon on the port side. That alone was a great thing to have completed. That actually finished up chapter 8. Its a good thing because chapter 9 is where the real fun begins. Its basically all about those fun little deck fittings. So I started slow.. There are four ladders to be built. Two leading to the poop, and two leading to the fcastle deck. These were made exactly like the others we have made for speedwell. Everything is laser cut. I just cleaned the char and assembled them. One note however...because of the deck roundup, the ladders leading to the poop deck need some tweaking after being built. The bottom of each side was left a tad longer so you can sand the inboard side shorter. You will need to do this so your ladder doesnt slant when you place it against the bulkhead. You want it vertical with the columns of the bulkhead behind them. So that inboard side will need its bottom edge shortened slightly. Its the little details. Here is the shorter ladder up to the fcastle deck...and you can see the guns that I finally finished rigging. Those are my Swiss Pear color 3D printed blocks used for the guns this time. I switched them out to try both colors. I think I will fully rig her with the Swiss Pear blocks now that I see them on the model. In addition, I also finished the stack for the fire hearth...I had built this a while back when I made the fire hearth but it must have gotten lost during the move. So I made a new one...I will also include those parts in chapter 9 in case anyone loses theirs as well. Nothing difficult here...fake it till you make it. We wont be using a real coaming here. Its just a laser cut boxwood square basically. Sand the char off and apply some WOP. Then center the hearth stack where the laser etched reference is and you are finished. I also knocked off the top edge all around this simulated coaming. No hard edges for me!! Here is what the stack looks like on the model. And here is an overall shot of the progress to date although I have some paint touch-up to do and some dust clean-up. But its really nice to making some progress again. Next up I will be finishing up the fcastle deck fittings.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.