-

Posts

9,703 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

HM Cutter Cheerful 1806 by Erik W - 1:48 scale

Chuck replied to Erik W's topic in - Build logs for subjects built 1801 - 1850

Excellent. -

Its rather simple. Build logs are for the purpose of documenting your progress as you work through a given project. As Chris explained. Yes this also logically would end with photos of the project completed. But it doesnt make sense to use a build log to post only photos of your completed model. If you dont show “build photos” it should not really be there. It isnt a BUILD log then. And separately The gallery is entirely separate and shouldnt be confused with the build log area in functionality. It is there for the sole purpose of adding albums of your completed models. Simple enough. They can be of a model you also used a build log to document during its construction. It is your choice. The reason we limit it to only photos of a completed model should be obvious. In the early days…Many folks were abusing having two areas to post construction images and placing them within their logs and also in a gallery album. Many in fact would always bump photos of other members models off the top of the forum (gallery banner) in order to always have their own models prominently displayed across the top of the forum every hour of every day. We have had Some very self serving members in the past. I am not kidding when I say we had two guys that wouldnt let another member have their gallery images posted for more than an hour before they would just bump them off with more nonsense build photos from about ten different angles of their own work. Hence the rule of only posting pictures of completed models. It is not a second opportunity to create two build logs on the same site. Both are absolutely optional. They serve different purposes. Create a build log if you like…and create an album for your completed projects if you like. Or both. In addition…the display of our gallery as it stands is limited to our forum software capabilities, unfortunately. So what you see now with images across the top of the forum are how it works. As well as other album viewing details. These can not be changed. It is better to have a gallery than not have one so …it is what it is. But build logs should contain construction photos…if not…use the gallery for you completed model photos please.

-

In about an hour or two it will reopen....

-

I disagree, Consistent and symmetrical deadeyes can make a world of difference whether rigged or not. These are 3D printed in the darker "swiss pear color" and lighter "boxwood color" are also available. It really shows when the deadeyes are grooved for the rigging between a pair of deadeyes so the ropes lay properly. With every little detail you can improve upon it will make the overall look of your model better. Switching out blocks and rope are an easy way to elevate a model although it does increase the cost. But a cheaper alternative would be to make your own if its at all possible.

-

USPS is now shipping to Canada again. So I have enabled Canada in my online store and have started accepting orders again. I have no idea how long it will take to get there but at least you can place orders again if you live in Canada. Chuck Also.....FYI....The last day for any orders before my move is January 17th. I will be closing the entire store down in order to pack up my shop for the move. We are physically moving the first week of February 10th and it might take a week after that to set up the shop again. So I expect to reopen the store as soon as I can after Feb. 10th. Thank you for your patience!!! I am so excited about enjoying the new view from my workshop.

-

HMS Winchelsea (1764) 32 gun frigate GROUP PROJECT INFO

Chuck replied to Chuck's topic in Group Projects on Model Ship World

Absolutely -

Beautiful model. Bitter sweet I imagine as I always feel that way after finishing a long project. You made a fantastic Winnie. Chuck

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I will consider that....I have a lot more unusual blocks to make first....shoe blocks and rack blocks and euphroe blocks for example. Also some cleats and other misc stuff. Chuck

-

Those new deadeyes look very good on the model. Well done. I am shipping your 4mm deadeyes out this morning!!! I cant remember if you you bought any of my resin blocks in the past but if you want to sample them also let me know. No 3d print layer lines and they are very smooth. Even down to the 2mm sizes. I am actually making a bunch more of them today....sister blocks and clue blocks.... as they are selling out quicker than I thought. Chuck

-

Yes it is that tall. Maybe they had a tall topgallant mast but look how short the topmast is. Its a weird rig and I didnt really use it. I mainly used the rig from the contemporary Surly model and the early cutter in the Science museum. But that is an earlier cutter but close enough for my tastes. Chuck

-

That model is actually mis identified. It is not actually the Cheerful or Surly. In fact, for most of its time is was just named as an unidentified cutter. It is most likely a much later cutter based on certain things. But there are too amny crazy differences between the original drafts and that model. I am talking about many many. Position of hawse holes, wales , channels , gun ports etc. in addition, the model was rigged and re rigged many times over the years. It is not original. Check out the position of the topmast on the wrong side of the main masts. So take that model rig with a huge grain of salt. I was told by the curators that the rig could be a construct from two different contemporary models which is what Henry Culver did quite a bit back in the day. Use the Surly model in the Canada collection instead.

-

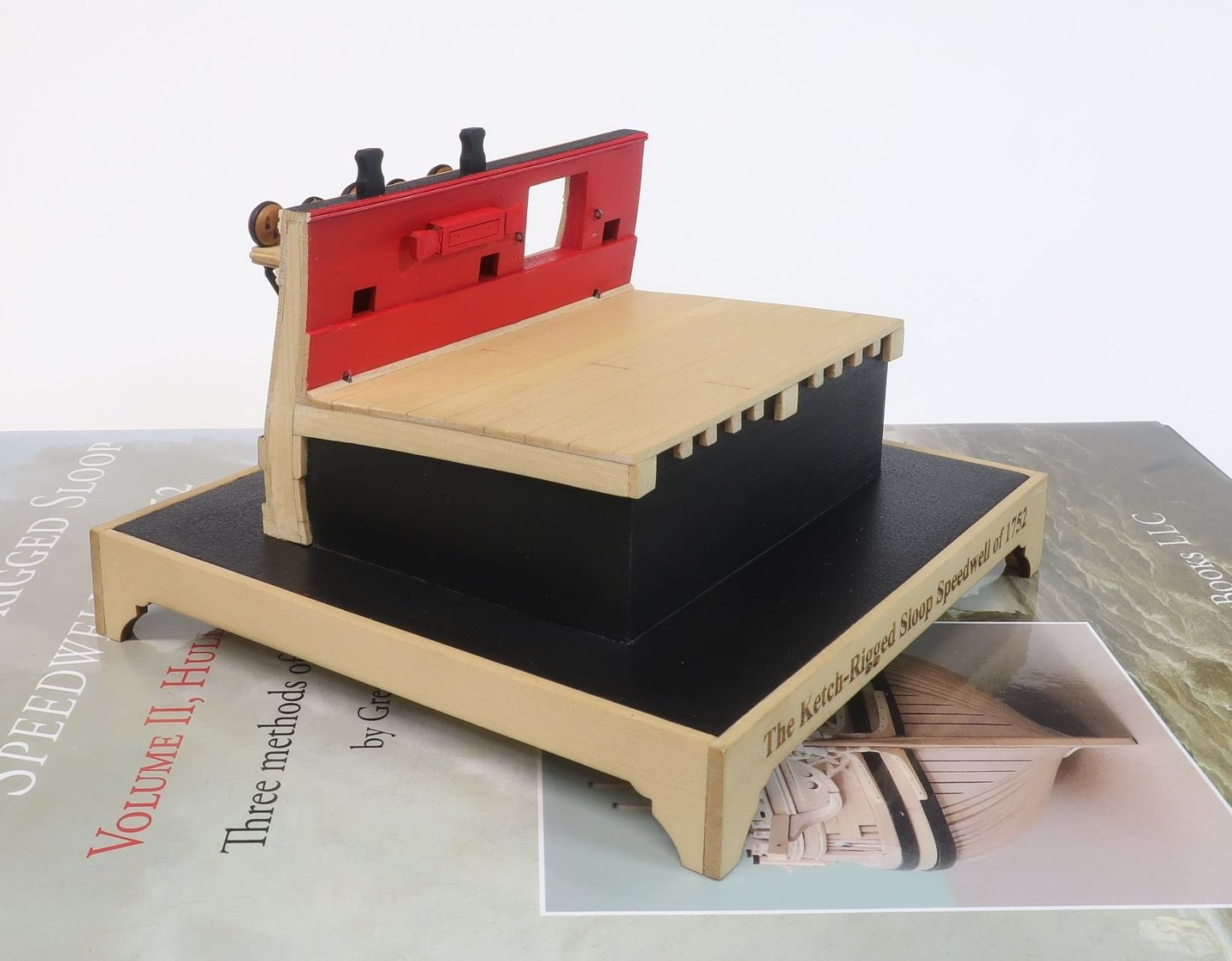

Its 3/8” scale just like the full hull model. Thanks guys for kind words. This project is essentially for my club and I will be making a limited run of about 25 kits. All of them will be given away. A dozen of them will be given away as door prizes at this years Joint Club's show in New London Ct. It will be part of the raffle at the April show. A dozen of them will be raffled along with a Preac Saw. Some of you might recall that I did a similar thing many years ago with a limited edition boxwood kit of a pinnace at a joint clubs show. This is essentially the same thing. Six more of remaining will be auctioned off here at Model Ship World. Chuck

-

Although time has been limited for me for working on the model, I have been making progress. I have finalized the way I will do the deadeye strops and chainplates. These are all laser cut and makes life a lot easier. Once designed the actual construction time was non-existent. It took seconds to add the strops. This was just a test run but an improved version of those I developed for the Winnie. They really do just slip right on. There will be two sizes of deadeyes and strops. The chainplates will all be the same more or less. They are laser cut and 1/16" wide and about the thickness of was brass straps would have been. You must do a little bit of work on the straps but not much. The hole for the little brass pin must be drilled through the bottom of the strap. I used a "67 drill bit. Its acrylic so this was so much easier than drilling through brass. At the top of the strap there is a little "hook" shaped on the end. This will fit into the bottom of the strop after the deadeye is placed on the channel. The width is 1/16" as I mentioned which is a tad wide for the hook to fit in the strop bottom. So this was filed narrower on both sides. This was done just at the "hooked" part of the strap which fits into the strop which you can see above. They are cut from black acrylic so no need to blacken but you may want to weather them a bit to "metalize" them in appearance. This is what they will ultimately look like on this sectional model which was really fun to make of the Speedwell. The deadeyes are my new resin 3D printed ones. These are the color of Swiss Pear. I will be using these on my model. You can see how nicely the straps and strops worked out. Also have a look at those molding strips on this sectional model. The fancy molding. This was a new test and also laser cut. I will be using them on the sectional model projects. The inboard side. The entire sectional test is completed. I just have to add and rig one cannon. That was the whole purpose of this mini-model. It is to be used to help teach building techniques for cannon carriages and the their rigging. My local club members in NJ will be using it as a quick and hopefully fun group build as a tech session taught by me. It should be fun. There will also be some gun crew figures added. This is a close up of the molding test. I know how some guys hate creating scrapers to make their own molding. This will save the guys a lot of time. I am thinking about offering these as stand along optional moldings for the big project as well. Or for any model really. There are three profiles. 1/16", 3/32" and 1/8" wide. All three are 1/32" thick. They are laser cut on Syrenite. They can be used as is but I do recommend sanding the top and bottom edges to soften them and round them off. Although the color as is looks great. I like to enhance it by wiping some Gel Stain on them and then wiping it off. It settles into the grooves and help highlight the profile. It deepened the color a bit as well. You know...just like I handle making the carved resin figurehead and stern figures look like boxwood. It takes about 2 minutes to do. Then wipe off the excess. The more coats the deeper the color depending on your preference. I think folks might like the option to buy these molding strips regardless of the project. So expect soon. But let me know if you are interested as I wont waste material and time if there is little interest. Volutes and scrolls should be easy to add to this line of products as well although every model uses a different size scroll-work. So maybe I have to thing about that. It can also be painted and as I said sanded easily.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.