-

Posts

9,724 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Chuck

-

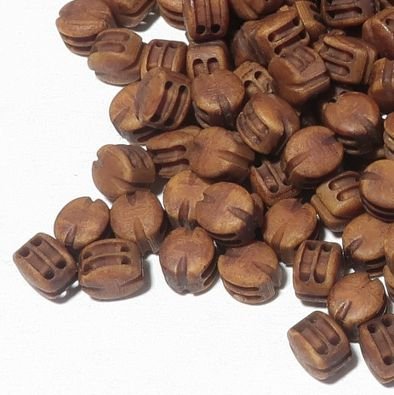

Well, LOL...you guys actually managed to do it. I thought it would have been impossible. You cleaned me out...literally every package of rope and every package of blocks...swiss pear that is. At 1:45 PM I had to call it, a $620 order for rope from a great customer in Germany. He cleaned the shelves empty of what was left. Approx. 3600 linear feet of rope. Unfortunately this means I have to close up the store to restock. Otherwise they literally sell out as quickly as I can make them. I need to build up some cushion in my inventory so I dont have a heart attack chasing orders while open. Its springtime...its beautiful outside. What are you guys doing cooped up in the shop buying so much ship model stuff? Get outside in the garden and enjoy the great weather, LOL. Seriously though, thank you so much....and sorry about the delay. I am working on it!! Lets see, I think I am working on 5mm pear deadeyes currently and .018 brown rope...a long way to go. I am not going anywhere and I am NOT going out of business, there is no pandemic...so I have no idea why or what seems to be happening. Its mind-boggling to say the least. Crazy

-

I honestly dont know. Because its on the buyers end I wont know until someone tells me. So if anyone out there has some knowledge. I think until May 4th anything under $800 is still good to go but after May 4th its anyones guess. I shipped a few to Canada yesterday and today so maybe will know shortly if those folks let me know. Chuck

-

I opened the online store yesterday and at the time was nearly fully stocked. But in two days I have seen a huge upswing in sales....huge. I am not sure why. Maybe the tariff situation but I really dont know. Maybe from folks seeing the rope and blocks at the show? Anyway, I just want to let folks know I am diligently making more blocks and rope...but its going to be a slog. I am down to nearly nothing left in stock right now. I will be working as fast as I can so thank you for your patience. The "swiss pear" colored 3d printed blocks in particular are literally flying off the shelf. The more folks see and use them, the more I sell. I have all my 3d printers working full tilt. Again thank you for your patience.

-

Placeholder for the kit instructions of the Speedwell Battle station. The kit will be given away at the Joint Clubs show this Saturday. But I will be heading up a group build at out local club in New Jersey. The goal for our small club was to create a teaching mini kit to help describe one method for doing three things. I will also be distributing a bunch of these small kits here on MSW. -Building a cannon carriage with a jig -Rigging a cannon with a simplified approach -Painting small figures for your ship models. The last tech group tech session will require a separate set of instructions for the group to be made later. Mono SpeedBattleStationInstructions.pdf Plan sheet joint clubs.pdf Material list list materials.pdf I have been asked by so many people to NOT make this a limited edition kit at all.... and because it would be a great opportunity for other local clubs to also use it as a group build. I havent decided yet. Same is true with doing a group project here at MSW because this is something that wont take several years to finish and it is a very quick project. Plus it has three main points of teaching that is commonly asked about by new and intermediate builders. Granted this is just one approach to doing them all. But it would be interesting to see some of the other approaches. The instructions attached contain a very detailed step by step for rigging the cannon because that was one of the main focuses for my club group build. The kit also contains a jig for making the gun carriage.

-

I think he means the ones that came with kit. They are not blocks but instead sound like bullseyes but made out of wood. Used for leading rigging through them and not actual blocks.

-

kit review Kit Review - HMS ENTERPRIZE (1774) by CAF MODELS

Chuck replied to kljang's topic in REVIEWS: Model kits

One is manufactured by a legit Chinese mfg (CAF). CAF does not pirate or copy designs for their kits. The other mfg distributed through DD in Canada is ModelShipDockyard. Also a Chinese company. MSD and DD sell and pirate intellectual property and often steal the work of other mfg’s for profit. They are on our banned list of mfg’s. So its an easy choice. Chuck -

Syren does in fact have cleats and other fittings...Many suppliers do. Chuck

- 34 replies

-

- muscongus bay lobster smack

- Model Shipways

-

(and 1 more)

Tagged with:

-

I wouldnt recommend doing that. Best to start with the wales as they establish the run of planking above and below them. If you start with the ports it is all to easy to establish the incorrect run of planks. Once the wales are established, Line off the hull below it....or plank the hull above it and between the ports. But lining off is the best practice regardless. See the many tutorials posted on this site. Chuck

-

Roter Löwe 1597 by Ondras71

Chuck replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Really nice and precise craftsmanship. Those blocks are fantastic.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.