-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

Really nice Sir . I like the details on the axles and the wheels. You've done a great job, better than I did and I'm pleased to say so Remco

-

Absolutely marvelous Greg! What did you use to 'fixate' the Fiebings dye, I noticed mine is water soluble even to the touch of a damp finger. Remco

-

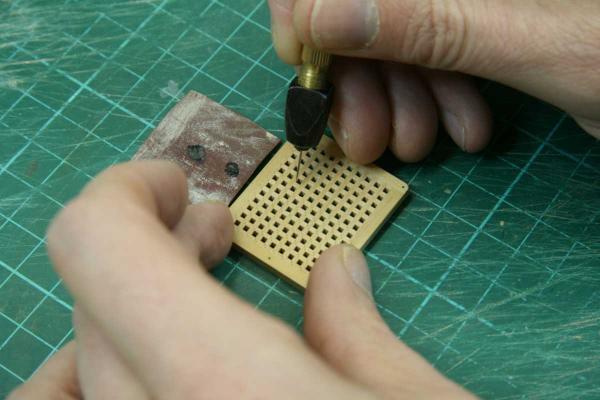

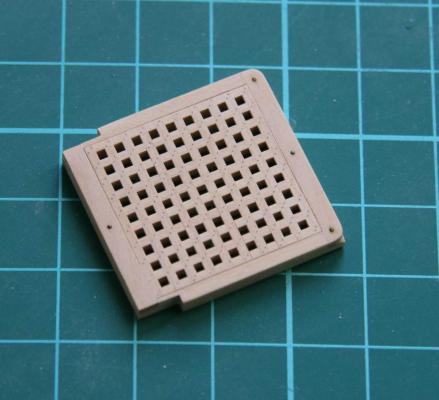

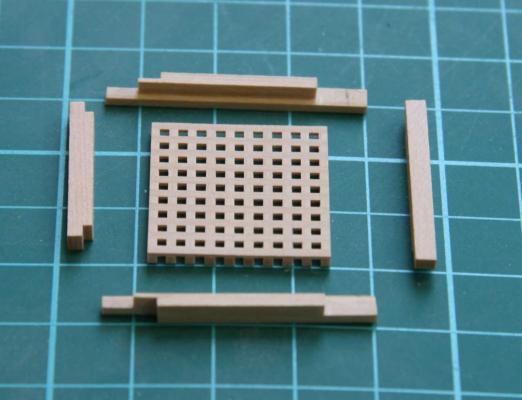

Go for it guy's make lots and lots of pins They are key to position parts temporarily, I don't exaggerate but I think any particular beam in this build is taken in and out at least 100 times to position parts, mark mortices etc etc. So today I did a little detailing of the gratings. I simulated the pins that were used by making small holes with a needle and then taking the same needle tip loaded with graphite to enhance the holes. This really takes your mind off-line after a busy day For comparison, the 'big' bolts on the corners are 0,4 mm Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

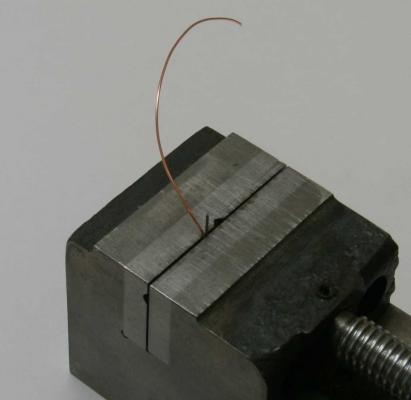

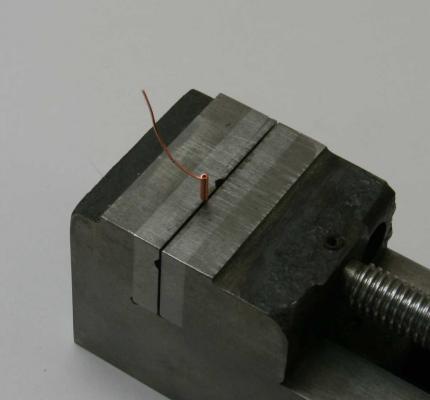

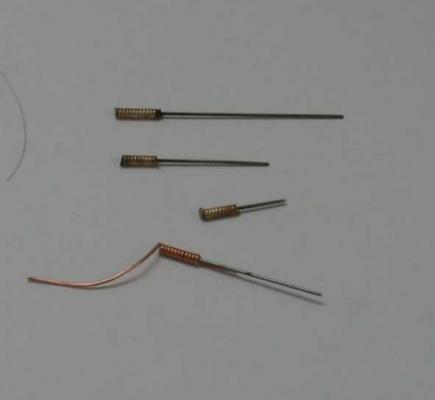

Thanks guys for your very kind compliments. Sure Maury, the pictures speak for them selfs. I use spring steel wire 0,5 mm cut to different lengths and the tip slightly grinded in to a point like a needle. After the copper wire is coiled it's silver soldered to the pin. I use a potato to act as a heat sink, you definitely don't want to anneal the steel, this happened to my first batch of pins and the steel becomes soft. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks guys. Greg the pins are easy to make, I think they rank amongst the top 10 most used tools in my build. Ben, with my scroll saw they were relative easy to make and there were no remakes :-) I couldn't find an appropriated sized piece of brass for the iron knee so I made it from boxwood and tinted it black with Fiebing's leather paint I'm also doing lot's of mortice cutting for the remaining carlings and ledges. A little off topic, but it was time to make a better storage for my chisels. They used to wander over my bench with the tip protected by a little piece of isolation foam. This was a nice little project, keeps them safe and organized Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Where Do You Keep Your Working Plans

Remcohe replied to BubbleHead's topic in Modeling tools and Workshop Equipment

-

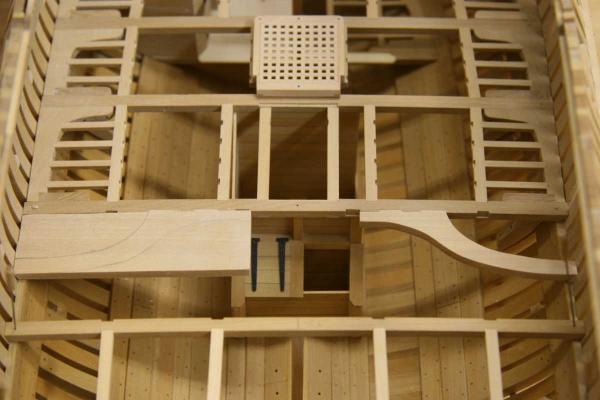

Thanks Piet. Jan what can I say, the MSW Oracle didn't answer and I went forward taking a 50% bet I got it right Meanwhile, more knee's opposing knee's gratings and so on. Everything is loosely fitted before marking the mortices for the ledges. Doing tasks in batches certainly speeds things up. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

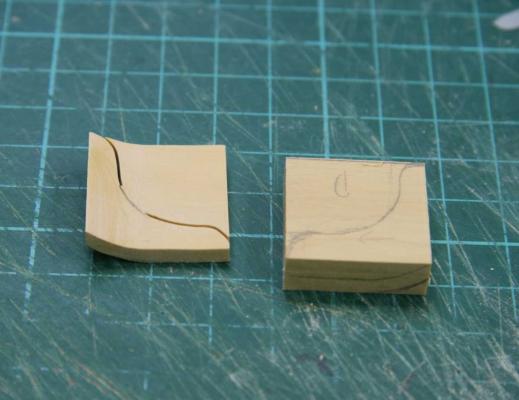

Thanks Duffer. Your right Joe..... So I continued and didn't change the mortices. Getting the round up of the deck into this special beam took some patience... Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks Mark I have a question, without really thinking about it I cut the mortices for the tabs of the beam arm half blind, but when is was shaping the tabs of the beam arm I started thinking if this is correct. The tabs could also be the full with of the receiving beam. TFFM discribes the beam arm is bolted to the opposing beam so the half blind mortices would give extra strength but the whole fitting is different than the carling and ledges so maybe unnecessary complicated. Its just to know how it was on a real ship because once fitted the different is not noticeable unless one could crawl under the lower deck :-) I haven't cut the thickness of the tabs yet so I can go either way. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

You make it look so simple, but this must be difficult parts to make and fit so neat to the beams Remco

- 1,449 replies

-

Sweet! So now you're planning on how you're going to make the locking mechanism for the loading door? Remco

-

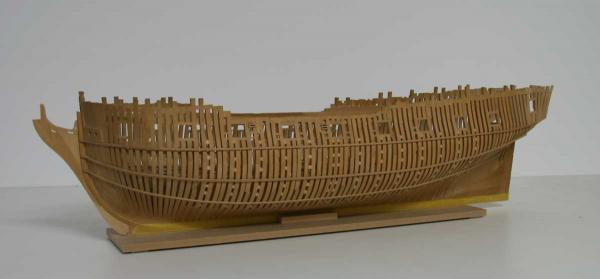

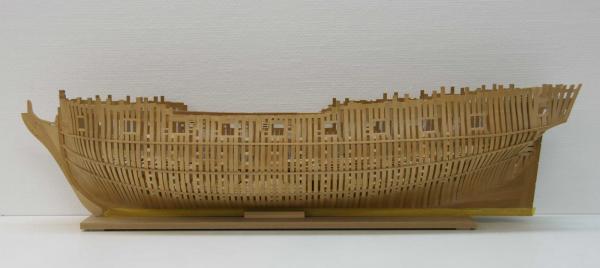

Beautiful, it's almost a sin to lay planks over the finely detailled beam construction. Remco

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

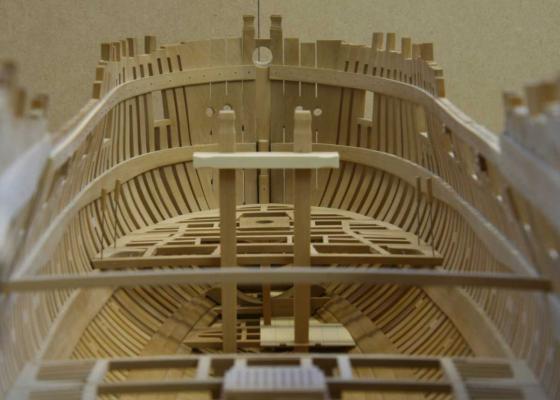

Martin, on the left is a workbench I only use for building full size parts like jigs and furniture. I had some alignment issues with the carlings so I decided to cut all the mortices for the remaining beams and marked them all using a batten. Important lesson to remember for the upper deck.... Pillars are installed temporarily and still need to be chamfered. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Nice close ups. All the details really come out well after the coat of primer, the metal sheets look is particularly realistic. Maybe here thanks for reminding Andy, don't we all hope to see some rivets Remco

-

Piet all the work you put into the hull paid off. She look tremendous! Permission granted to be really proud of yourself ;-) Remco

-

Ed no magical powers, I did use a building board to erect the frames and to make measurements inside the hull. But whenever possible I take the model from the board and work seated. Ok, maybe the space are I do most of my work is tidy the rest of my shop isn't. Especially for you Joe I immediately took a picture as the shop is right now. A bit distorted as I made a panorama picture to capture the whole shop. One might wonder why no storage on the walls, I had that in my previous shop and it takes away an enormous amount of light. One cannot have enough light :-) It looks small in the picture but the room is spacious enough measuring 4.40 x 2.70 m. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

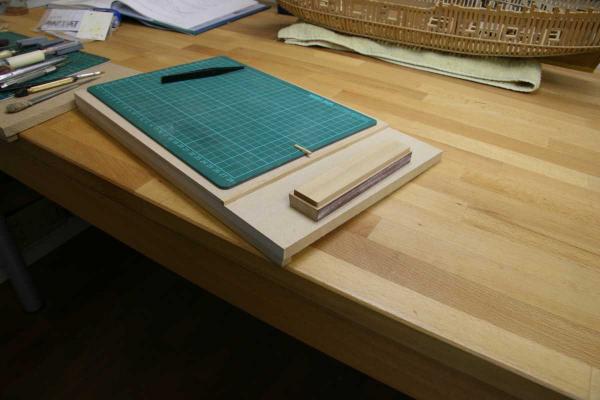

Thanks for the appreciation. Greg's right, starting with a cross section (and a cross section is already a big project!) is good advise. Today something different. For some time I've been using a small board as a movable workstation, so I can move is out of the way if I need to install something in the hull. As you can see I don't use a building board to hold the hull as I work mostly seated. The board is also used for my sanding block and today I added a small edge to is so it works as a shooting bord now. I had to adapt the sanding block so it will ride along the edge. A good sanding station helps to make perfect joints ( and sharp chisels....). Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

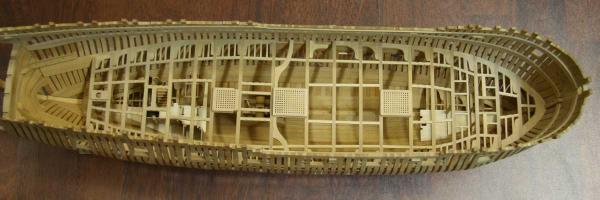

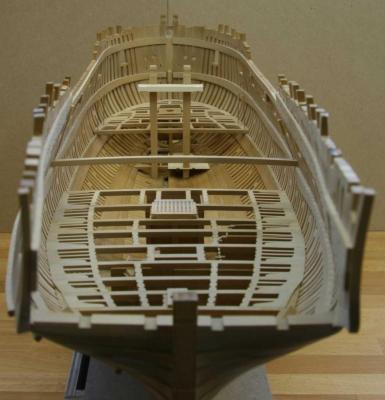

My two cents in the "should I buy the kit" discusion With the knowledge I have now of the 'kit' I would not buy it again. Apart from the hefty price tag it's more of a scratch build starter package than a kit. And although all the parts are precut, Mr Hunt had no good control of his CNC router leaving ugly dents in every part. Cleaning up is tedious and will harm the overall shape of the parts. I stopped using them a long time ago.... Building the kit is just as complex as making it from scratch, so if I could go back in time I would: Get the Swan plans from admiraltymodels.com Get the Swan framing package from hobbymillusa.com Get TFFM Vol I, II and III from seawatchbooks.com, well I got them as you need the books even if you have the 'kit' as the practicum won't take you all the way. (ps just a happy customer from the above company's nothing more) Buy yourself a good scroll saw and table saw, you can easily squeeze this into the budget of the kit price you've just saved from spending. And it's a good investment for future projects. Take a plunge into the wonderful world of scratch building, it's not as difficult as I had imagined especially with all the help and knowledge here on MSW you can tap in to. And one other thing, if you mess up a kit part like the hawse timbers ( it took me more than one attempt ) you're in trouble. But if you make your own parts you just cut a new set and try again..... Now lets get back on topic Thank you Martin for your kind words. Current state of the lower deck. Progress is slow bud steady. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Wonderful Karl. The pictures taken at deck level look like there taken on a on full scale model..... Remco

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

John, I followed your build silently. She turned out beautifully, congratulations on finishing such a fine model Remco

-

Piet, have you considered turning the torpedo tubes from a nice piece of hardwood? Remco

-

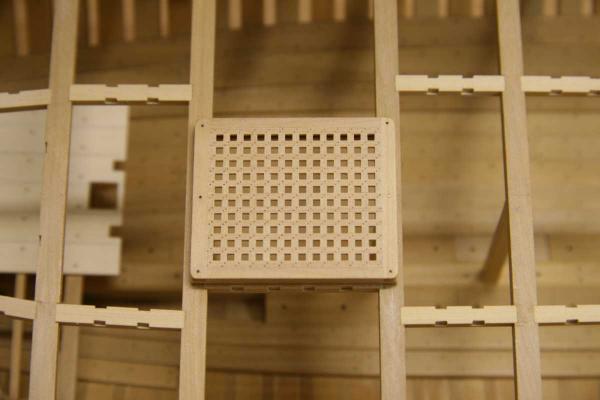

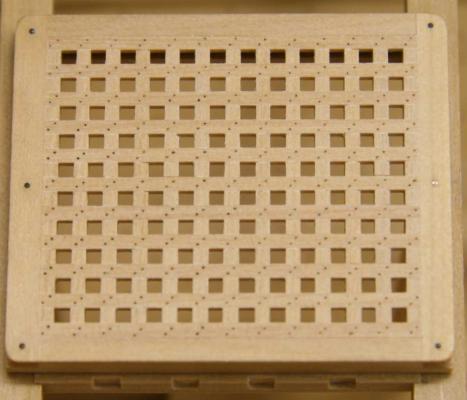

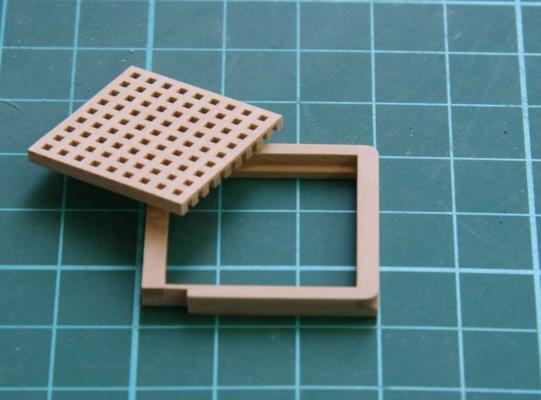

Thanks. I temporary turned my attention to make the aft hatch and grating. Making gratings was one of the things I've been looking forward to making. I finally got around to set up my table saw to make the notched battens, it was actually less difficult than I had imagined. In the end I didn't use the special sled I had made, but just a regular cross sled with a small batten off set from the blade to make repeated cuts. I had to adapt the coamings to let the bitt pins pass. A big batch of notched battens were made so I only need to do this once and have good supply to make all the gratings. The nails are simulated with a graphite tipped needle, just like I did on the mast tops. Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.