-

Posts

612 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Remcohe

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Remcohe replied to albert's topic in - Build logs for subjects built 1751 - 1800

Congratulations Albert a milestone and so beautifully executed. Naiad is on my wishlist but the number of frames does make me doubt. Remco -

what is the ideal modelling table?

Remcohe replied to AON's topic in Modeling tools and Workshop Equipment

Be sure to add plenty drawers, big ones for drawings, shallow ones for tools. If space isn't an issue make more that you think you'll need and you'll probably end up with just enough And check the thread with all the members's workshops, you catch some ideas there too. Remco -

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Thanks all for your kind words. Sometimes you run into a part and had no clue that it would be that hard to make. The quarterdeck transom is such a part, looking rather unexciting. One redo and the better part of a couple of days work went into it. I had expected the counter timbers to be trickier but after watching Mark doing his Belona's counter with the help of a jig, I constructed a small jig that saved a lot of head aches. The mortises on the wing transom I had made light-years ago had to come off as the spacing was all wrong. Where would a shipwright be without his bottle of isopropyl Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

HMS Naiad 1797 by albert - FINISHED - 1/48

Remcohe replied to albert's topic in - Build logs for subjects built 1751 - 1800

Congratulations Albert, your efforts pay off, the hull looks beautiful. Remco -

When that day comes, may I recommend "Creating lifelike figures in polymer clay" by Katherine Dewey. This book really helped me to get the proportions of faces and figures right. I started making lifelike figures in no time after putting the described concepts in practice. Some tweaking is needed as we work on a much smaller scale, but the theory is still the same. Remco

- 1,449 replies

-

Mr Crispy.... Nice work Tony, I know how hard it is to sculpt figures. Remco

- 1,449 replies

-

Thanks for the kind words. Maury, I had to make the door a bit longer, but now you're mentioning it, I probably better put the extension above the door. It does look a bit strange now. I fear taking the door out will damage the pantry, let me think about that. Fleas Druxey? I thought I was a step ahead of you by adding the palliasses and now your starting about fleas. Boy where does this end..... Work moved to the outside of the hull. The knee of the head (made 1,5 years back) is now permanently fitted as I had to add the iron plates to the bottom of the hull. I glued them temporarily in place to draw the outlines and then used a chisel to remove the wood so it fits flush to the hull. I'll remove them to prevent any damage to the plates. This concludes TFFM Vol 1, a bit of a milestone, this took me 4,5 years to complete and still two volumes to go......... I hope everybody is patient enough to bear with me till the end (and throwing challenges at me will make the journey longer..) Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Added a bed and a closet for one of the cabins. The palliasse, a straw filled matras, was made from sculpey. I found a picture on the internet and made one like it. The pantry was made using the same technique as the sail room Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

I'm like 1 year of work behind Tony before I get to the hammock battens. No worries, I'll take it into consideration

- 1,449 replies

-

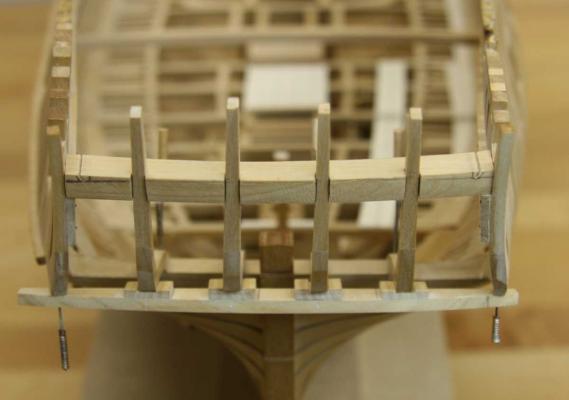

test fitting, test fitting and more test fitting. Most bulkheads are shaped in situ and than added to the overal fixture off the model.

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Nils, your work is truly stunning. Could you explain a little bit more on how you made the depth indicators. Did you use a color printer? And photo print paper is quite thick, did you remove some of the backing paper before glueing it to the hull? Thanks. Remco

- 222 replies

-

- gorch fock

- barque

-

(and 2 more)

Tagged with:

-

Thanks all for the kind comments. I did, at 1200 dpi it managed to keep the font readable. A couple of years back this wouldn't be possible on a home printer. So back to the more mundane cabin building. The doors have louvered openings, the rest is pretty straight forward but involved a lot of testfitting. alle the bulkheads are assembled off the model as this was easier to build. It's getting pretty crowded on the deck and there is more to come, a pantry, the bitt's and pump's Remco

- 1,215 replies

-

- sloop

- kingfisher

-

(and 1 more)

Tagged with:

-

Karl I'm curious what great parts you are going to make with this tool, looking forward to the pictures. Remco @Google translate, thanks for the laugh, 'cool tool' would be the appropriate translation for what Karl means

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

Nice little stove Bob. Can't help you on what type of base you would need. But should you decide to make a brick one, I expect them to be individually laid Remco

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.