-

Posts

296 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Slowhand

-

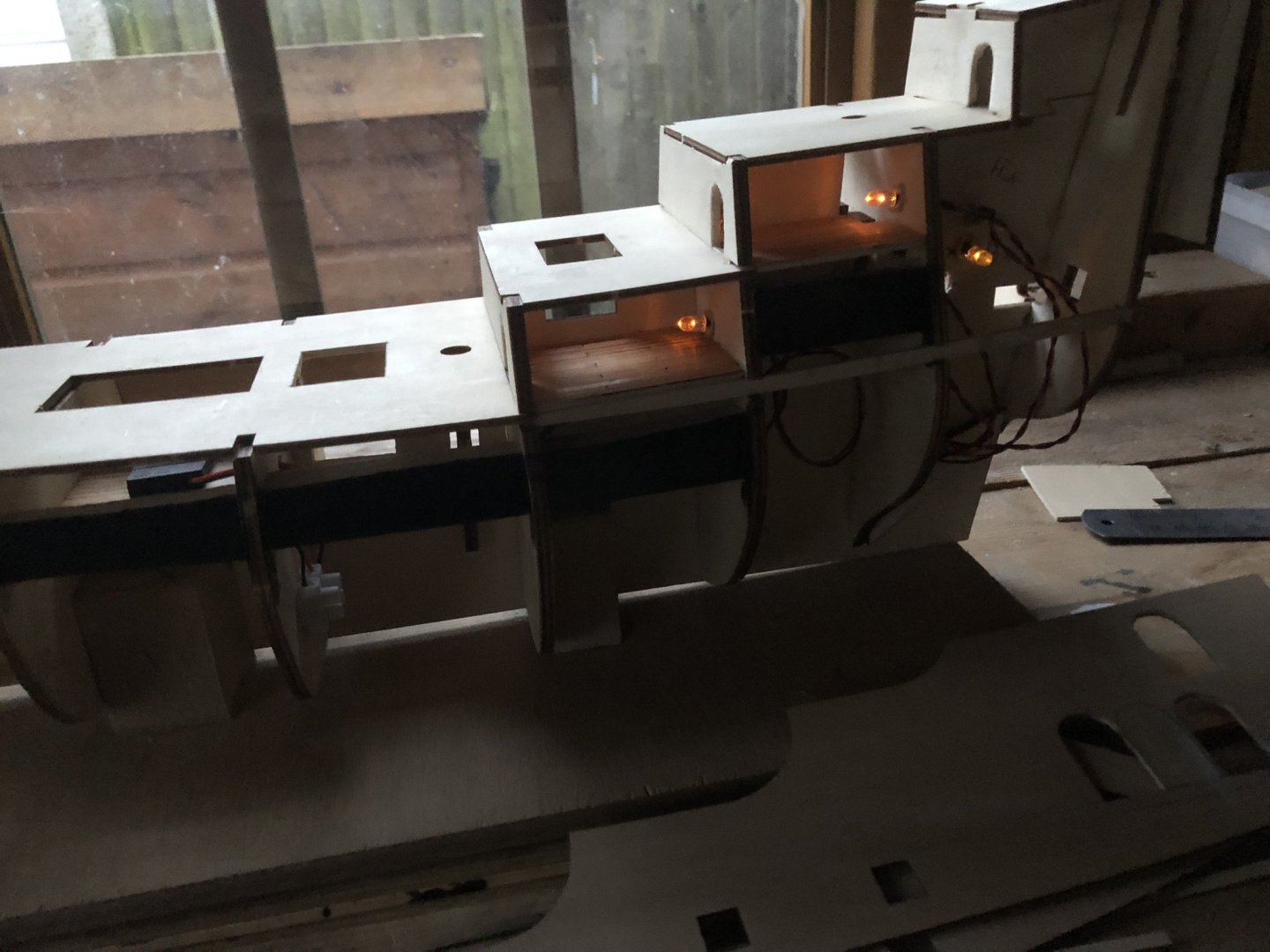

The fit with the false keel, bulkheads and decks was so snug, I didn’t need to build a slipway, just glued 4 blocks of wood on a plywood base to hold build upright. As for my San Martin of a few years ago added blocks between bulkheads to fit false cannons to poke through gun ports. LED lights added to stern areas to twinkle and shine in gloomy interior. OcCre always suggest planking decks before fitting. I decided not to as wanted a deck Color sympathetic to the hull so will plank hull and see how it looks. Definitely not using veneer sapelli planking for the hull.

-

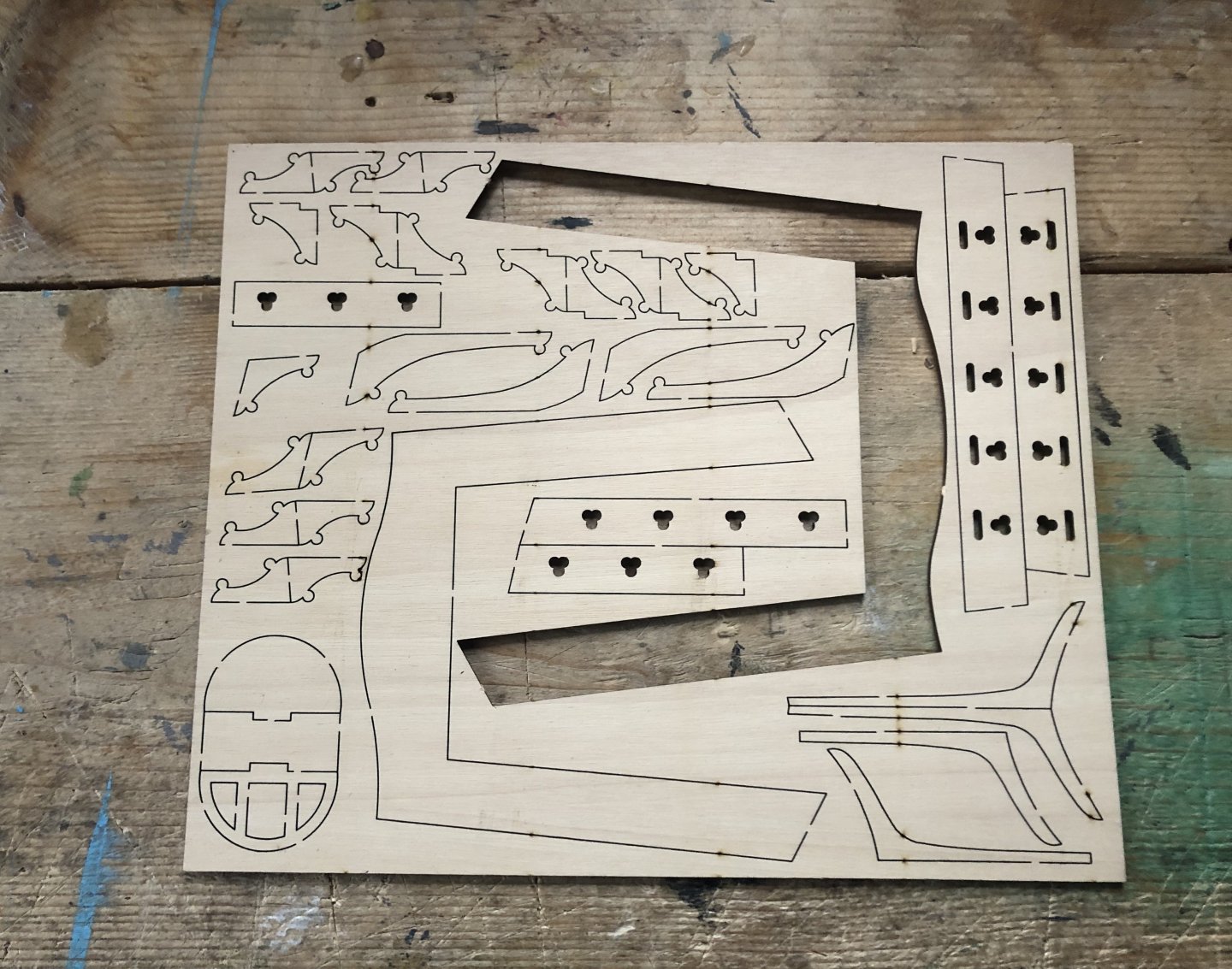

A typical OcCre kit, with nice materials, sharp cuts and the sails especially, much better since my last build. The false keel,bulk-heads and deck all fitted together nicely, tight on a dry build but with a bit of easing made a nice frame. Lots of metal fittings I hope to replace, as many as possible but we’ll see.

-

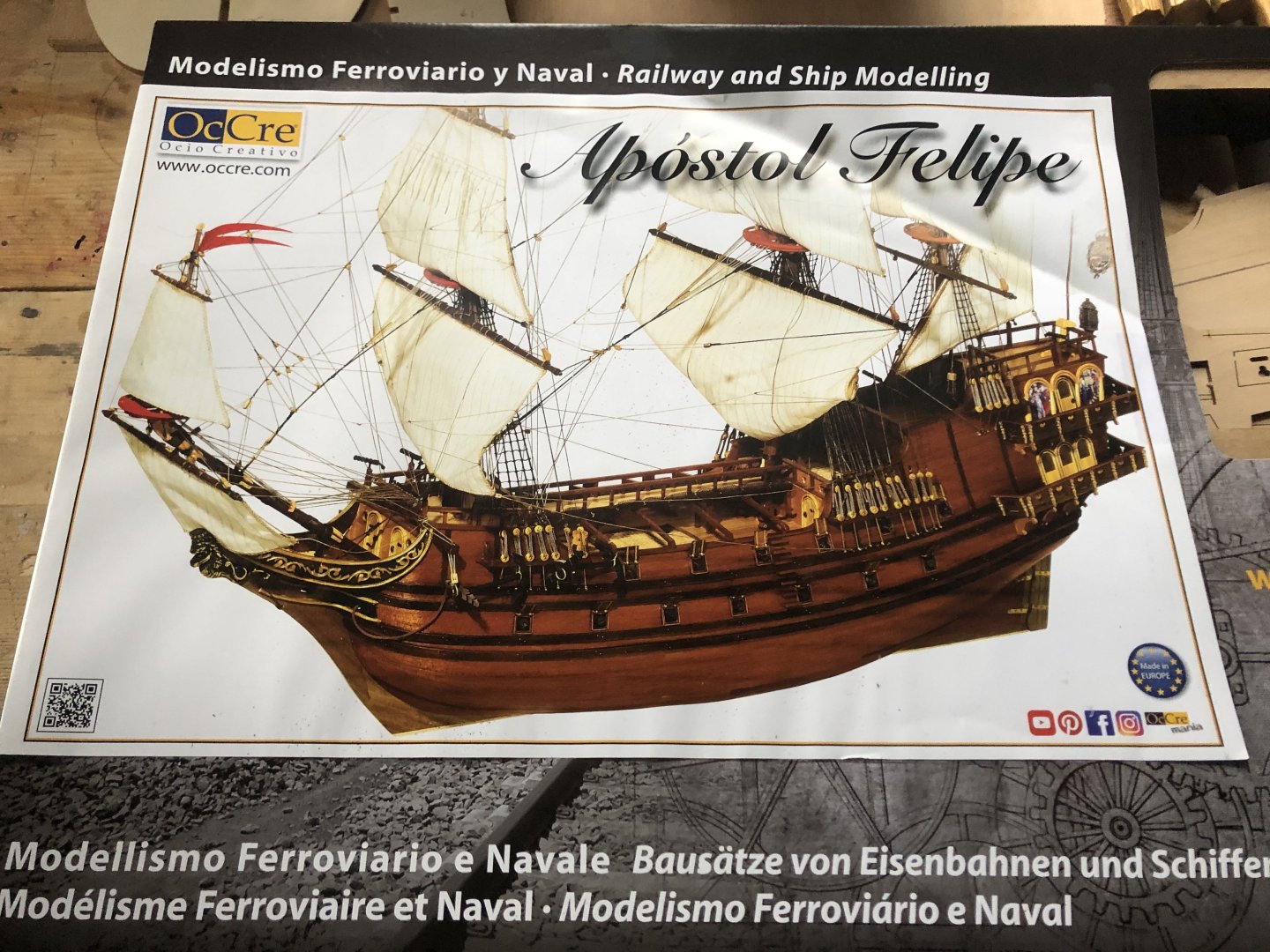

I love a Spanish Galleon and have been intending to build this kit for a while. I saw a build log by Costeo a while ago and it inspired me to build the ship. I don’t intend to modify it as much as he did. Two photos from his build below and a link to his build log too. Such a shame it was never completed.

-

Nice build, you can sail on a gaff rigged ship The Golden Vanity which is nearly identical to a Mumble-Bee. I did this year, a weekend sailing round the Isle of Wight anti-clockwise.

- 206 replies

-

- Vanguard Models

- Brixham trawler

-

(and 2 more)

Tagged with:

-

Mayflower by tj456 - 1/19 scale

Slowhand replied to tj456's topic in - Build logs for subjects built 1501 - 1750

Hi, TJ before you start on the starboard side and lose access to the port side do you think your thin ribs will be strong enough? -

A question for Tim, which I forgot to ask when thread was previously alive was when I tried doing similar with a Guillow's Hurricane I found getting a finish on the in-filled wood incredibly frustrating. Applied a filler and sanded and found the finish was mostly good except for a few areas where filler broke away. So filled these and sanded again then another rough area had appeared and so on. One step forward and one step back. Being in Uk, filler was not exactly the same as yours but tried at least two and same problems. Eventually accepted would not get a prefect finish.

-

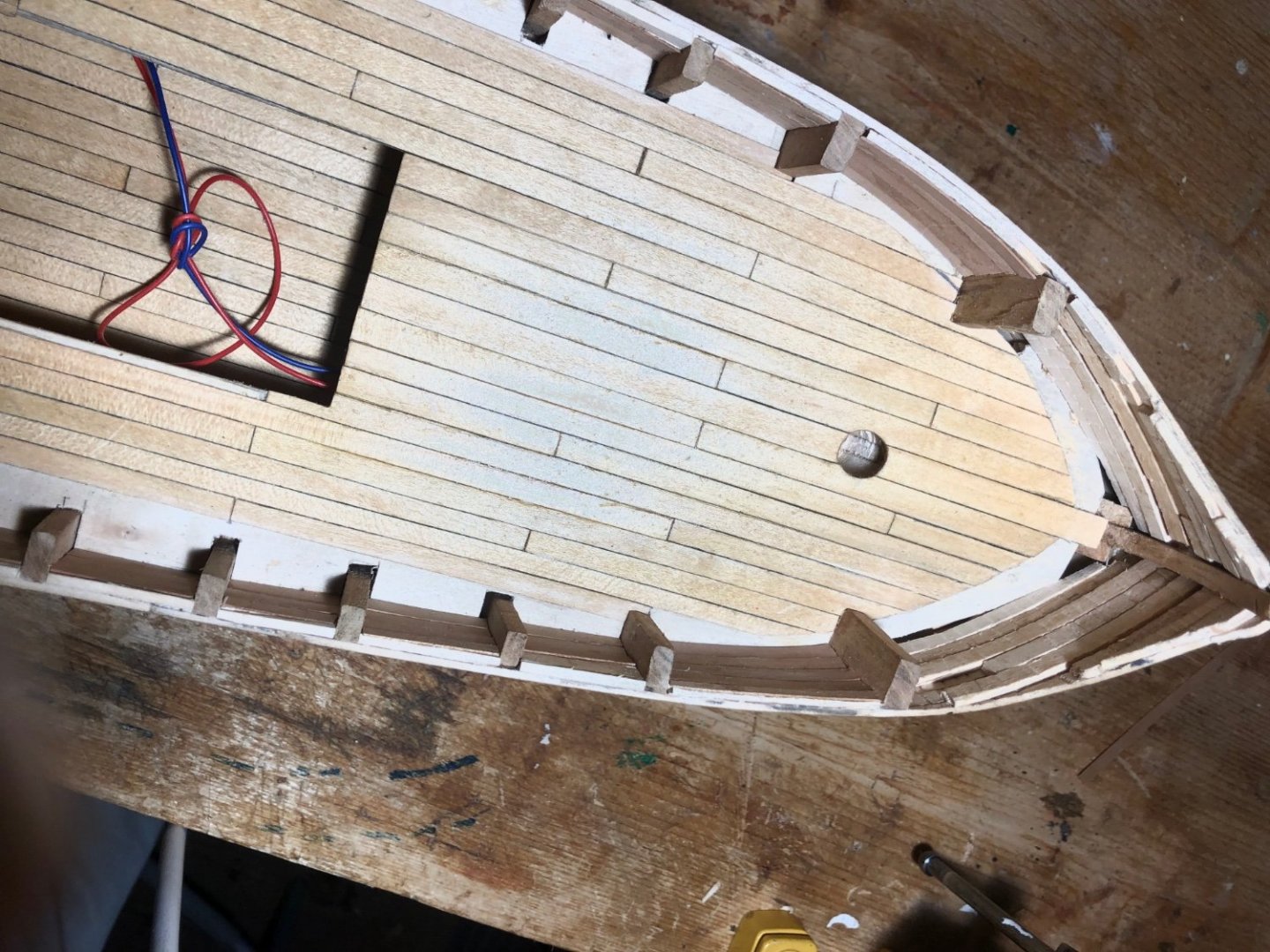

Well this took longer than expected but caught up with the port hull side planking. Cold weather slowing down drying of the wood glue and the length of the hull has meant progress much slower than hoped for. For the first time in a while happy where builds going. Eedge bended planks at bow that removed need to spile so thanks Chuck

-

Well it’s been a time since my last post, bit of problem getting sheet pear or cherry wood which I need to do final layer of planking at the bow and mid ships, hopefully edge bending will remove need to spile. Intended supplier no longer has any in stock. The bow almost like a Viking longship. Decided to put project to one side, but before doing so would plank the stern as neatly as possible to encourage me to pick it up again some stage in future. Planking in mahogany best compromise as uncertain supply in pear may do below below waterline in lime and cover with whitestuff as in orig model. Just received a Dumas Tiger Moth so that’s next.

-

Yes Doris, your work is quite amazing a true crafts person

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

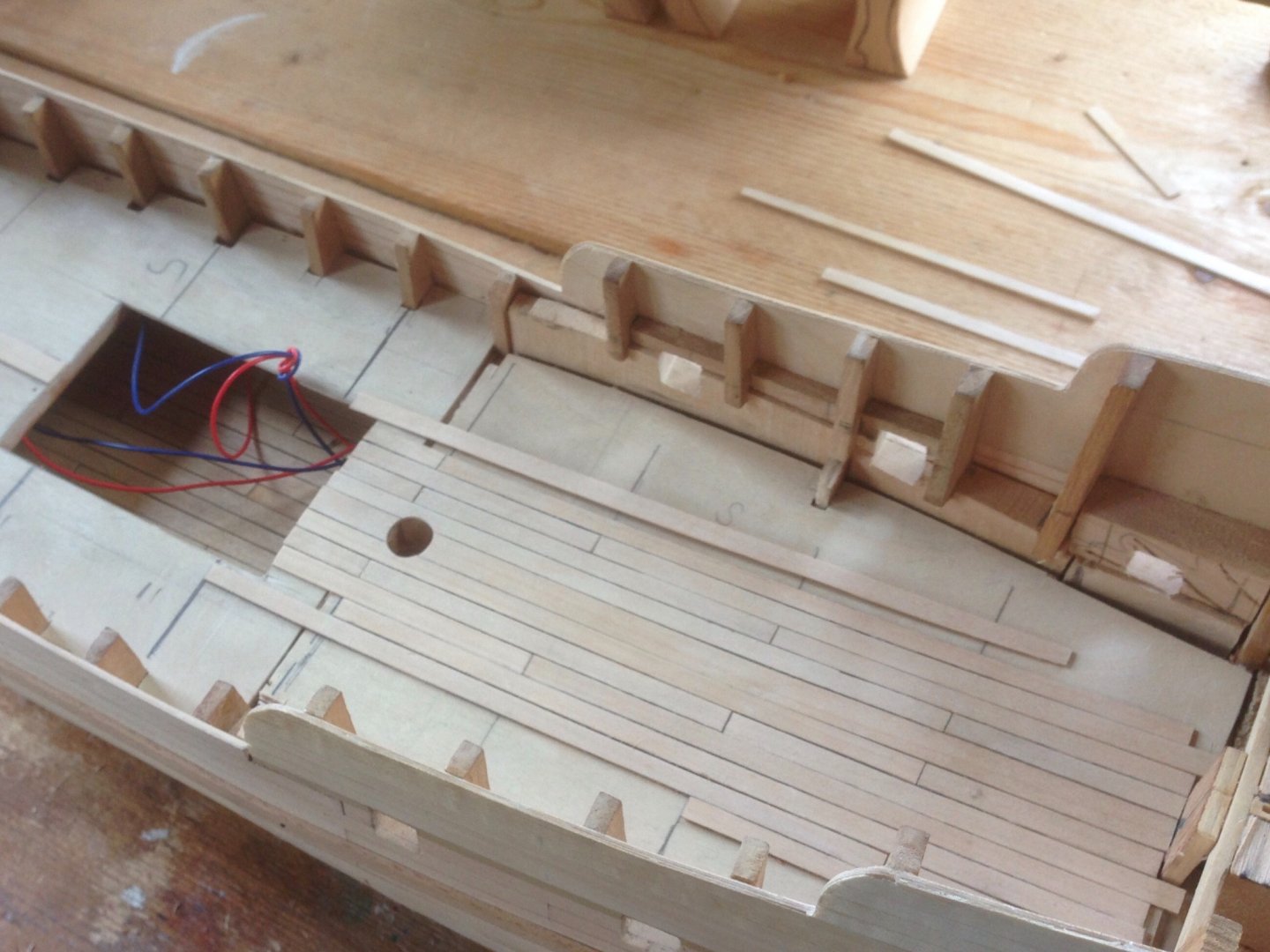

Well that’s the main deck planked apart from the edges waiting for a power? saw to do the curved pieces. Not sure why a couple of planks appear darker after applying Danish oil, never mind it’ll be covered by the quarter deck if another coat of oil doesn’t reduce contrast. Next up two additional gun ports towards the bow and holes for the oars

-

Ah interesting. I have always used white glue it appears to be the default in the UK. When I mix the wood dust with neat PVA it initially matches the wood then darkens significantly as it dries. The final finish Danish or wipe on poly makes no difference to the mismatch between the wood and the filler. Off to the shed to try a 1:1 mix plus water.

-

I know it’s a very well known technique to fill gaps, cracks with a filler which matches the wood, but when I mix PVA with a wood dust say lime , cherry or beech the mix always dries darker than the original wood dust. The only time the filler is a matching colour is when there’s hardly any PVA there and the mix is too crumbly to be much use. My friend in my wood working group has the same problem. Tried different UK manufacturer’s but to no avail. Any suggestions please?

-

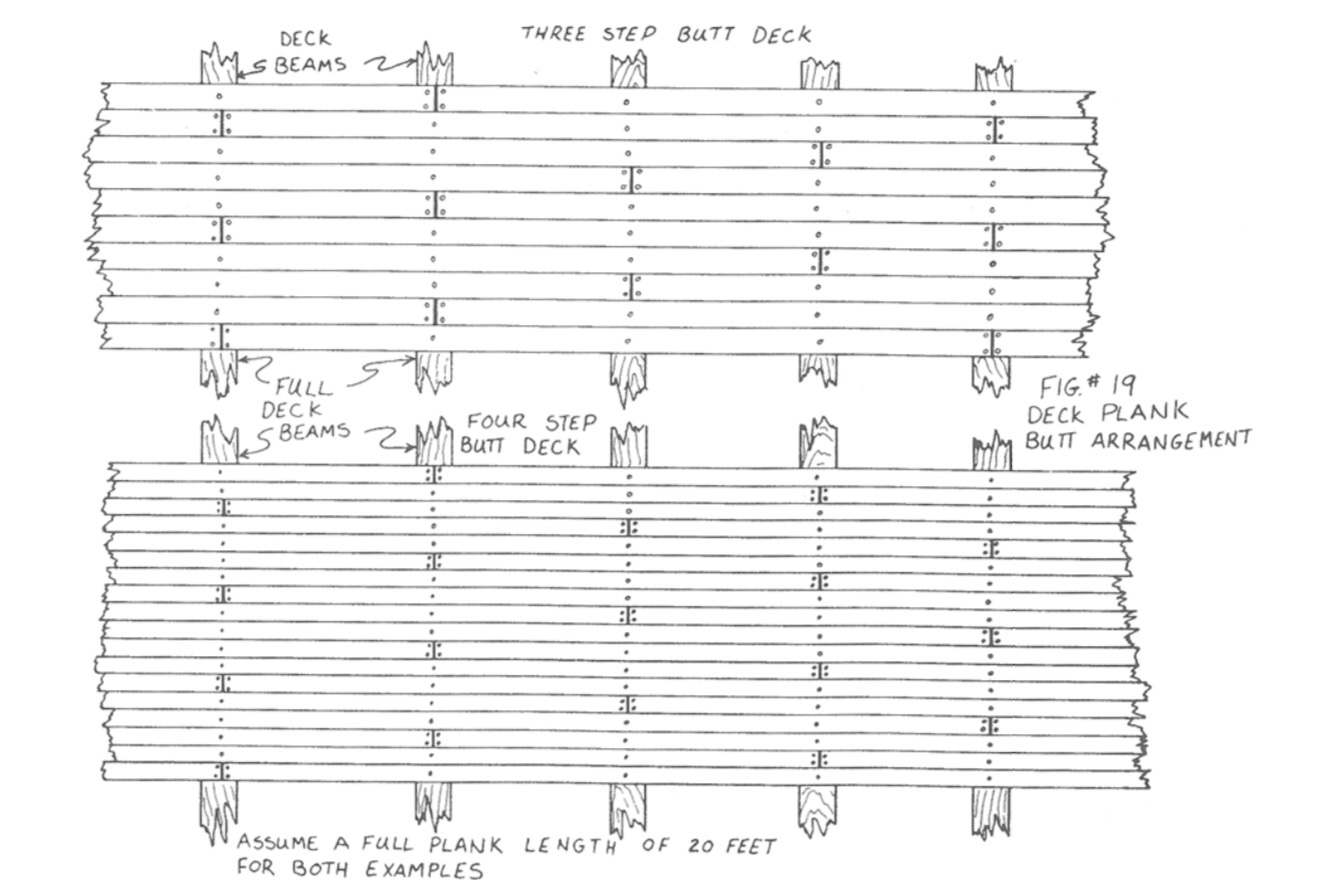

The OCD in me noticed a plank right in the middle was not quite right. None will be visible when the grating is in place but it was dead centre. A trick I learned earlier was it’s easy to remove a plank by slicing down the middle with a scapel and levering off the rest without damaging neighbours and putting in new plank. Might be of interest for newbies. Getting the 3 plank butt shift pattern so easy using the NRG guide.

-

Always felt, planking a deck is a bit like mowing a lawn, easy, but very satisfying. Nice work on your decks and for the rest of the build it’s really come to fruition after your earlier struggles.

- 332 replies

-

- fluit

- abel tasman

-

(and 1 more)

Tagged with:

-

MONTAÑES by Amalio

Slowhand replied to Amalio's topic in - Build logs for subjects built 1751 - 1800

Amilio, I think you’ve started showing off making these double spindles😜

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.