-

Posts

3,993 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by dgbot

-

Impressive joinery. One small mistake and you have to start all over again. Bravo on your patience and steady hand. David B

-

What do you use your mill for ?

dgbot replied to captainbob's topic in Modeling tools and Workshop Equipment

Having a small mill can be nice. But if you do not have the training it can be a very expensive drill press. If you know what you are doing it can do many things. David B -

Wood filler vs. spackle

dgbot replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

I also use Elmer's I find that it is the easiest filler to use.. David B -

A couple of years ago I bought this kit at a good price. I am looking at it again and I wonder of anyone has built it. David B

-

Model Shipways and Blue Jacket have the best instruction manuals as far as I am concerned David B

-

Plank Beveling and stealers

dgbot replied to bigpav's topic in Building, Framing, Planking and plating a ships hull and deck

There are several tutorials about planking. Several of them can be found here. A single planked model means you have to take a little more care when laying your planks. Try to plan ahead and double check your runs. This will involve bending and shaping them to fit the hull . David B -

Looking good Bob. David B

- 277 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

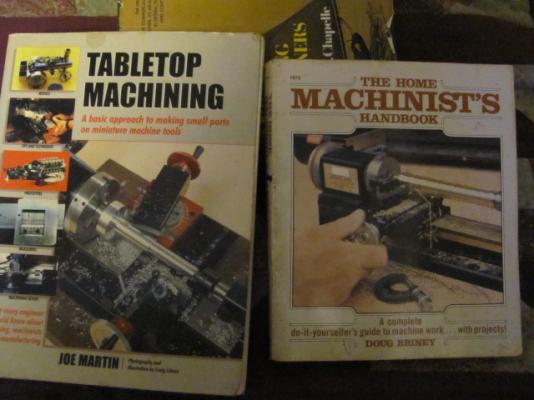

Two books come to mind that should help you. Tabletop Machining by Joe Martin and The Home Machinist's Handbook David B

-

Microlux Tilt Arbor Saw Problems

dgbot replied to capnharv2's topic in Modeling tools and Workshop Equipment

Does the Proxon run at a higher RPM to compensate for power? If so this mght be the problem. The jim Byrnes saw is a powerful beast. David B -

Great paint job. Did you use a brush or did you spray it on? David B

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

miniature saw blades - moved by moderator

dgbot replied to Jsiegel17's topic in Modeling tools and Workshop Equipment

You can buy these blades from Thurston Saws, Or try MSC International. or Enco. David B -

I have to agree with all of the rest. Great job. Kudos! David B

- 52 replies

-

- steelgolem

- missouri

-

(and 1 more)

Tagged with:

-

Great work Toni. what kind of finish are you going to use when you get to it? David B

- 1,449 replies

-

Great work on your A frame. And I like the look of your dredge guards. A great way of thinking outside the box. David B

- 135 replies

-

- willie l bennett

- model shipways

-

(and 1 more)

Tagged with:

-

One of the things about this boat is all of the various models there were. You are going to have a lot of fun detailing and outfitting it. Keep up the good work. David B

-

As Wefalk said you need a dead flat surface for honing an engraver. I made mine from HSS tool steel and drill rod. After grinding them to the disired shape I made a fixture and used that to hone them. I turned down some dowels and used them for the handles. They are very easy to produce. and fun to use. David B

-

For metal turning of brass I have made my own out of tool steel and put them in a handle. They do come in handy every now and then. David B

-

CA vs. Wood glue

dgbot replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

I use both. metal to wood for CA and pva glue for everything else. PVA in my opion works better for wood. You might have to clamp the part but the end result is better and stronger. A CA joint has little shear strength and can be difficult to clean up if you use to much. David B -

Replacing Ply Bulwarks

dgbot replied to jbford's topic in Building, Framing, Planking and plating a ships hull and deck

Not at all. Over the years I have replace the ply bulwarks many times. As for a solid sheet or a built up it will depend on your patience and the model you are working on. David B -

Silver Soldering Tools

dgbot replied to bundybear1981's topic in Metal Work, Soldering and Metal Fittings

I use a Smith's Little torch and am glad for the investment. As a result I can do small joints as well as large ones. The secret is using the right size of flame for the job. This will be learned through trial and error. David B

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.