-

Posts

1,829 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by tkay11

-

I really smiled at your dog with the snowballs in your video, Doris. It must give you great company and love when you feel alone. I have sent the video link to my Czech family in Prague so that they too can admire your prodigious and amazing output from their varied artistic and technical viewpoints. Tony

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

RB Productions, or Scalemates, have similar saws for sale, which I think are a bit cheaper. Their site also has lots of interesting modelling tools. I have used this type of saw for a five years now and it really is very useful. The saws and holders are at https://www.scalemates.com/kits/rb-productions-rb-t013-saw-blade-holder--675096 They also have an interesting nano saw set at https://www.scalemates.com/kits/rb-productions-rb-t038-nano-saw-set--675092 Their general site is at https://www.scalemates.com/brands/rb-productions--691 Tony

-

I'm with you concerning the lathe. I certainly love my Taig/Peatol lathe, which I bought together with a lot of extras off eBay. Great value, certainly much cheaper than Sherline or Proxxon, and with a really practical tailstock. The only thing I would like in addition is an electronic speed control, but I get by without it. Tony

- 123 replies

-

- Model Shipways

- Pinnace

-

(and 1 more)

Tagged with:

-

Thanks for the link to the Pandora book. I was looking at videos of how modern boatsmen set up this rig in France and Italy, and it certainly looked a lengthy process. So I totally agree that the rig you have done is not only sufficient, but also very practical. I was really just showing it because of my interest in the rig. Tony

- 70 replies

-

- 22ft Yawl

- Vanguard Models

-

(and 2 more)

Tagged with:

-

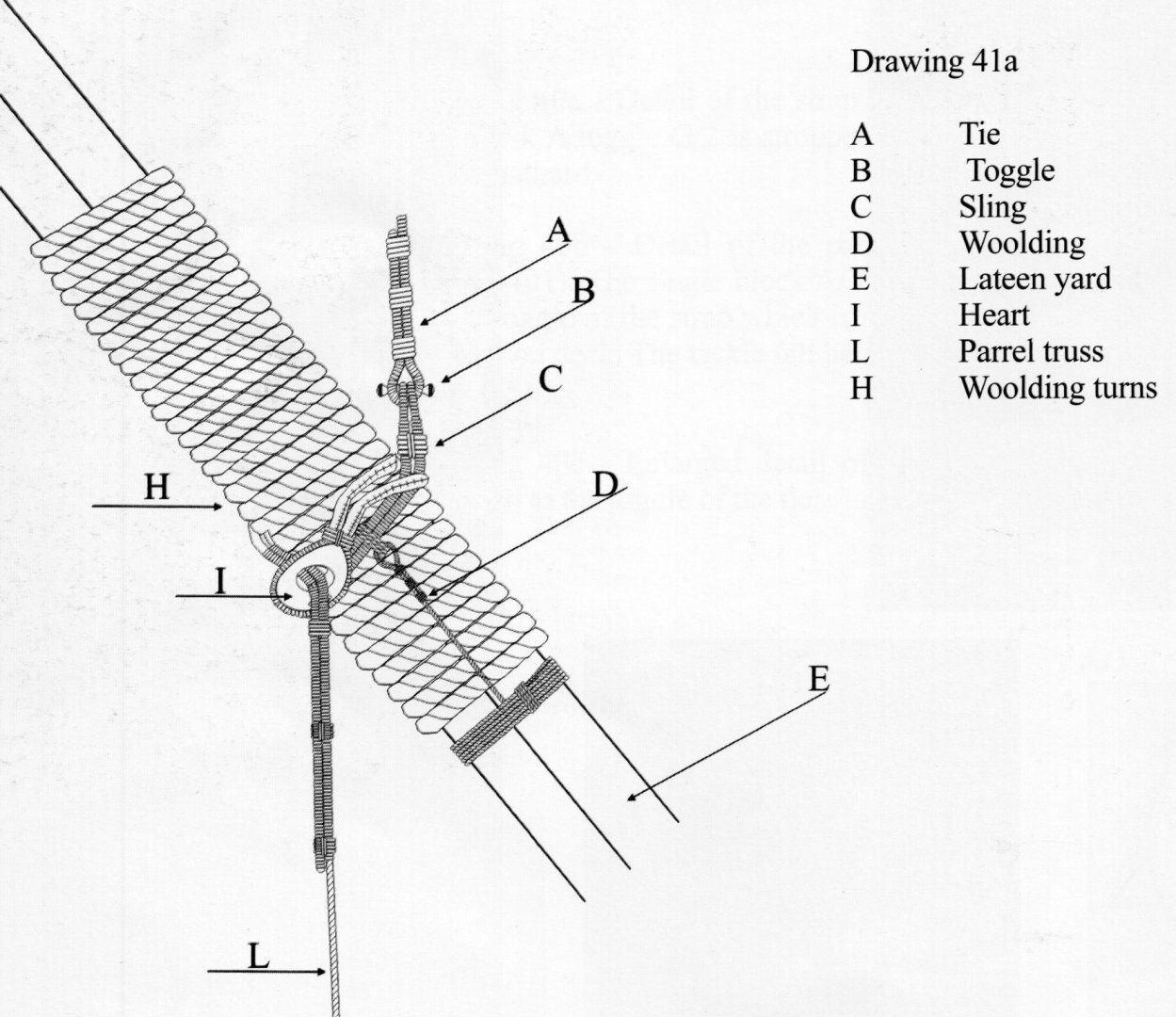

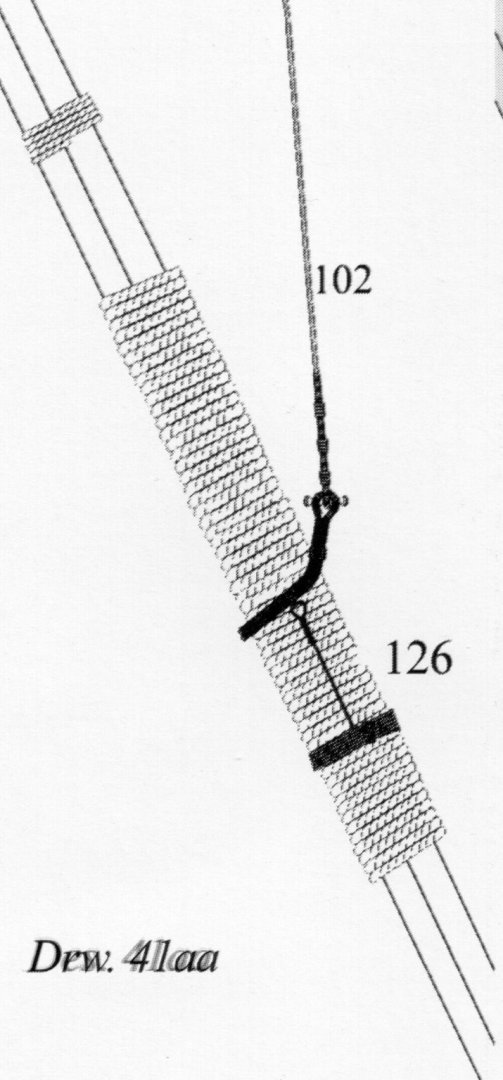

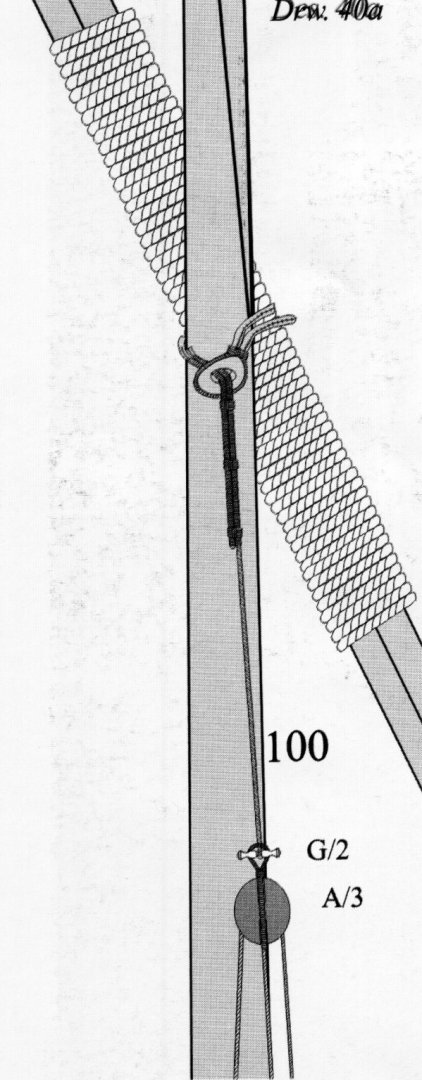

I'm not sure whether this is of interest, as it doesn't really apply here, but as I have been quite puzzled myself about lateen rigging it was good to find specific diagrams for the Allège d'Arles (1833) which illustrate how it was done on the Mediterranean coast, and is still followed on the French and Italian coasts for small boats: It's quite a neat way of doing it. Tony

- 70 replies

-

- 22ft Yawl

- Vanguard Models

-

(and 2 more)

Tagged with:

-

I like the idea of folding over the seams. Till now I’ve been making them as strips, following Antscherl’s method. Tony

- 70 replies

-

- 22ft Yawl

- Vanguard Models

-

(and 2 more)

Tagged with:

-

Miniature Drill Bit Chuck for Dremel Tool?

tkay11 replied to turangi's topic in Modeling tools and Workshop Equipment

I'd be a bit careful with that claim. I bought the chuck and found it very difficult indeed to put a 0.3mm drill bit in it and keep it dead straight. The best I could manage was 0.4 on my copy. I did buy a miniature jewellers' pin vice that I could insert in a collet in the Proxxon drill, and that proved much better. Better still are the very cheap Chinese Tungsten Steel Carbide drill bits which I buy in units of 10 for each size from 0.3 to 0.5 on eBay. Their shank fits Dremels and Proxxons just fine with the collets. They do vary slightly from one batch to another by about 0.01 mm, but I'm quite happy with that. Although these tend to snap when using a cheap drill stand which has some play or is not perfectly vertical (hence my buying in units of 10), I find them to do the job perfectly in the Proxxon mill or my modified Proxxon drill stand. They won't be up to the job when using a hand drill, though, so if that's your intended use you'll have to stick to HSS. Tony -

Is it not possible to print very small letters to dry transfer decal with just an inkjet printer? Tony

-

Roter Löwe 1597 by Ondras71

tkay11 replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Well done with the drill! You must have been holding your breath a bit! Tony -

How to stain or dye boxwood?

tkay11 replied to tkay11's topic in Painting, finishing and weathering products and techniques

Thanks, Derek. I too have a pile of old boxwood rulers I picked up from eBay before they became so expensive (more so than buying from suppliers per cubic meter) and before people started advertising non-boxwood rulers as boxwood (I was stung a couple of times before I noticed). I bought them specifically to build just those small parts and deck fittings that require detail, and planed the sides of their markings. I have already decided to do just what you suggest as I have dry shellac to hand. All the same, I'll also be trying the castello with an eye to the future. Tony -

How to stain or dye boxwood?

tkay11 replied to tkay11's topic in Painting, finishing and weathering products and techniques

Hmmm. More excellent food for thought. Thanks, everyone, for chipping in. After all the comments so far, I will experiment a bit, but may well in the end leave the boxwood as is, especially after seeing Roger's pic of the dyed boxwood. Interesting thought about briar, jaager, I'll have a poke around the web. Of course the lockdown here makes going out and about impossible for the moment. Don't worry about screaming: it's a natural response when something like that is so easily researched on the web. I didn't take offence, especially as you went on to provide very interesting observations as per usual. I took it as more of a groan. As for ageing, Gregory, I've seen the opposite happening to myself -- getting paler the longer the lockdown and these dark winter days. So maybe that proves the point that sunlight does indeed darken. Tony -

How to stain or dye boxwood?

tkay11 replied to tkay11's topic in Painting, finishing and weathering products and techniques

Thanks for the scream, jaager, and for the interesting thoughts about mixing dyes and about shellac. I hadn't thought of those, and I have a good stock of shellac which I make up myself with spirit. I did know about the difference between dyes and stains but my thoughts just made a slip while writing too quickly. So I hope you can forgive my senile moment. Thanks also for mentioning the beautiful old colour of the boxwood, Allan. I too love the colour and would prefer to use it as is. It's just with 2mm blocks and below I find it hard to use pear and the lighter colour of the boxwood looks a bit odd to me when I look at contemporary models. In fact I might continue without trying to alter the colour. I also have a stock of India ink for the wales, but that won't be for the boxwood. Roger: you put the thought of castello into my head. I have a large chunk of that, so I might try making small blocks with that. Gregory: thanks for the experience with Chuck's blocks, as that seems to be good evidence. Mike: thanks for the comparison between water- and spirit-based Liberon. I had tried the spirit-based on some lime and had the same experience. So I'll try water-based in future. Anyway, a very stimulating set of thoughts for me to use as I ponder! Tony -

How to stain or dye boxwood?

tkay11 replied to tkay11's topic in Painting, finishing and weathering products and techniques

Thanks, ah100m, good tip. I was using water-based stains of my own concoction before. Perhaps spirit-based has better infiltration. Tony -

I'm making blocks from boxwood (from an old ruler) and would like advice or comments on how to stain them. My attempts in the past have been rather woeful, with poor uptake of stain. I'm reluctant to paint, but want to replicate the dark brown colour of old blocks in the mid-19th Century. Anyone? Tony

-

That's a beautiful model. What did you use for the deck plans? Tony

- 26 replies

-

- gigino

- brigantine

-

(and 1 more)

Tagged with:

-

Sorry to hear about the problems with the models, Daniel, but it's great that you're back on the forum. I have no advice to give. The only glues I can think of that might work are contact adhesive or two-part 5-minute epoxy. Tony

- 56 replies

-

I can't remember whether this has been mentioned before, but there is a nice jig for making your own sharpening guide for very small chisels (1mm, 2mm etc.) which you can download at Patrick Sullivan's site. His video is on YouTube. It's done for round stock, but can easily be re-drawn for rectangular blades. Tony

-

If you build good supports, there's no need to glue. This would have an advantage should you have an accident or mishap and need to remove or repair the mast in future, and will help in squaring the mast once the rigging is in place. The other thing to note is that the rigging will hold the mast firmly in place once completed. Of course, a blob of epoxy will keep it very firmly in place if you're confident about its position. Tony

- 139 replies

-

- Lady Nelson

- Amati

-

(and 2 more)

Tagged with:

-

That's a wonderful drill press, Andrea. Very much my kind of thinking, as you have said. I really enjoy seeing what I can do with existing tools and modifications. It is a great part of the overall fun as well as another method of learning. And don't worry about your English. At first I thought you were a native English speaker -- you are very clear in your explanations. Tony

- 9 replies

-

- Schooner

- training vessel

-

(and 1 more)

Tagged with:

-

Thank you very much for the compliment, but I don't think that you should believe you will come out with much lower results. Your beautiful work already shows your pride of finish. I look forward to the tips you yourself provide, and from which I can learn as well. The build logs with the most detail about processes, problems and solutions are always the most interesting to me. They are much more interesting than the logs with just pretty pictures of a perfect product. Tony

- 9 replies

-

- Schooner

- training vessel

-

(and 1 more)

Tagged with:

-

Nice start, and I'm looking forward to following your build. Are you using the plans from AAMM in France? Tony

- 9 replies

-

- Schooner

- training vessel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.