-

Posts

2,005 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

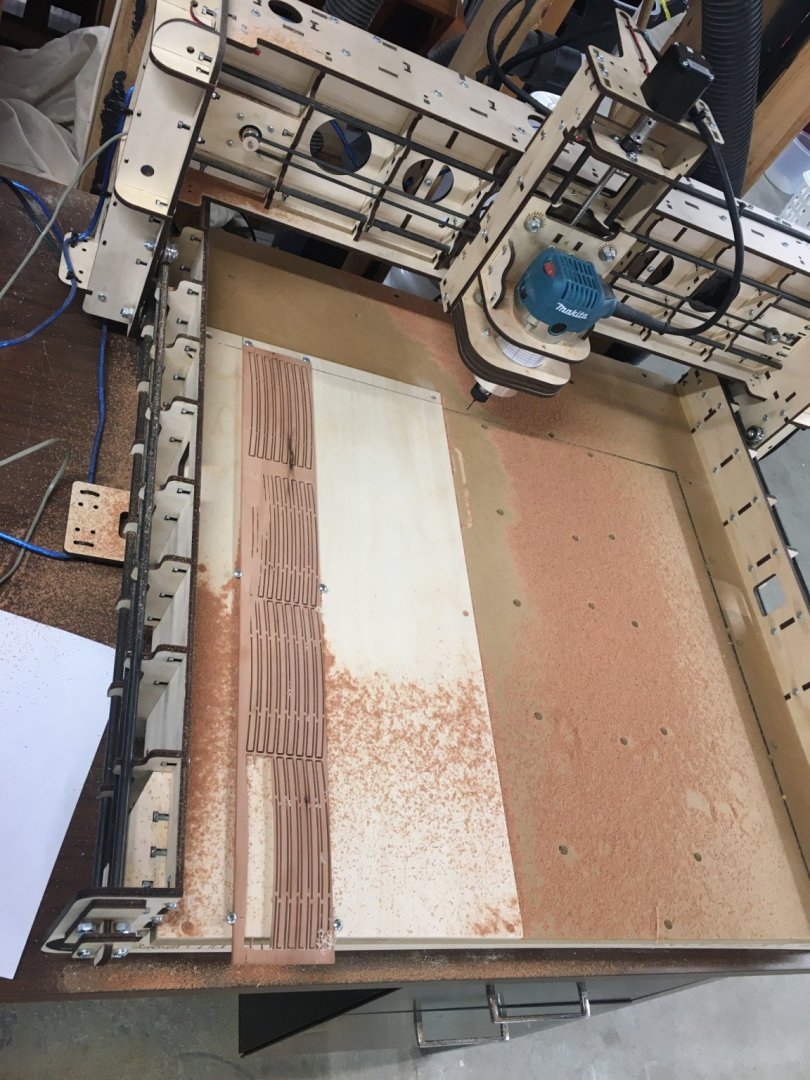

Thanks J - it’s a BobsCNC EVO4 and yes you have to assemble it which takes a few days to do it right.

- 889 replies

-

I’m still working on the upper deck framing but I need to start thinking about the forecastle and Quarter deck beams and hooks, so using a new tool in the workshop that I have been learning, I cut all the beams out of some pear stock.

- 889 replies

-

Import into a CAD program using "insert raster image", trace the lines, splines etc, then delete the image and check if everything looks good before saving as a .dxf file which a CAM software can then open.

-

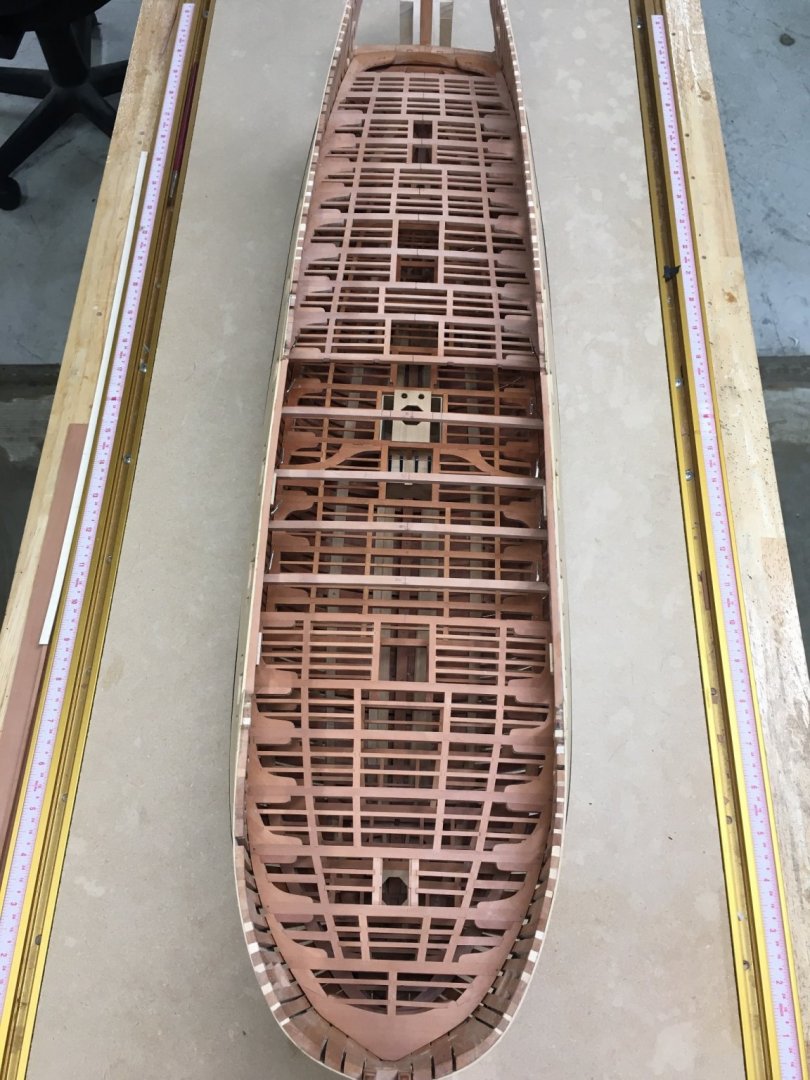

Thanks All, It always surprises me how that light pink of the good quality Swiss pear I got from Jeff darkens to that beautiful deep reddish hue after a few months, superb quality wood! I wish Jeff or someone of his caliber was still around, we shall miss him for a long time in this hobby! ben

- 889 replies

-

Thanks Everyone, Work on the upper deck aft framing is almost complete and I just have to tie it in with the Wing Transom now. Then there are the five trickier mid sections to complete the upper deck.

- 889 replies

-

Very Very Nice Michael, turned out beautifully. You have the same cases that I used then? Look forward to see what you come up with next. ben

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I'm in no rush to finish either build and I have limited modelling time, but I find taking a break from one build for a while and working on the other keeps me interested in both, a scratch fully framed model is a long term project especially if you want good results - there are no shortcuts. Keep up the good work. ben

- 475 replies

-

That cross chock sure is a fun piece to make I remember. Looks to me that you have made a fine start. ben

- 475 replies

-

The ribbands would be temp while the hull was constructed, normally 4x4" full size timbers and they would run along the line of the floor/futtock joints ( where each of the frames was chock jointed to the next piece ).

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

The stern frames are called "transoms" Is it the pictures or does the cherry really have that much color variation??

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

- 889 replies

-

Thanks Everyone for the likes and comments, it’s always appreciated. ben

- 889 replies

-

Forward upper deck framing almost complete, need to add the riding bitts and the final ledge piece. ben

- 889 replies

-

Very nice, 16 days to get to where you are is soo fast, took me a couple of years to do that on my scratch swan class sloop! These new kit designs from the likes of CAF, Syren and Vanguard are going to transform this hobby.

- 322 replies

-

- enterprise

- caf

-

(and 1 more)

Tagged with:

-

- 889 replies

-

Michael - Mainly just a couple of different size diamond files - nothing too special or secret - just a lot of time, If i screw up (which happens a lot) I have to remake a beam set which sucks but thats the way it is.

- 889 replies

-

Upper deck framing well underway, always a constant battle against cumulative error but that’s why I am constantly checking against my framing plan to minimize its affects, you can maybe just see the overlay that I print out on transparency film to help me do this. ben

- 889 replies

-

- 889 replies

-

Hi Toni, So I had to make changes to include:- Dual fore/aft beam arms instead of the single fore one shown in TFFM as opposed to Pegasus's NMM plans Larger fore hatch due to my mistake following TFFM instead of NMM deck plans, movement of all ledges etc.... because of this. adjustments to all beam widths and knee positions to suit my hull inside shape adjustments to shape of wing transom knees to suit my hull ben

- 889 replies

-

I finally finished up modifying the upper deck plans to suit my hull, now I can actually start building it.

- 889 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.